Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Organic waste management is a major global challenge. It accounts for a significant portion of waste that ends up in landfills, where it gradually decomposes and emits methane, a harmful greenhouse gas. Composting is the most preferred method for managing organic waste, as it applies to the masses, may not require significant areas, and of course, is capable of reducing the rate of the production of waste, while at the same time, producing valuable by-products, in the form of compost with potentially reducing the amount of greenhouse gas emissions, if done properly.

- organic waste

- landfills

- aerobic composting

- composting technology

1. Manual Technology

In manual composting, the process is operated by hands and through mechanical means without automation. Five common types of manual composting methods: windrow, passively aerated windrow, bin, in-vessel, and vermicomposting methods, are described.

1.1. Windrow Composting

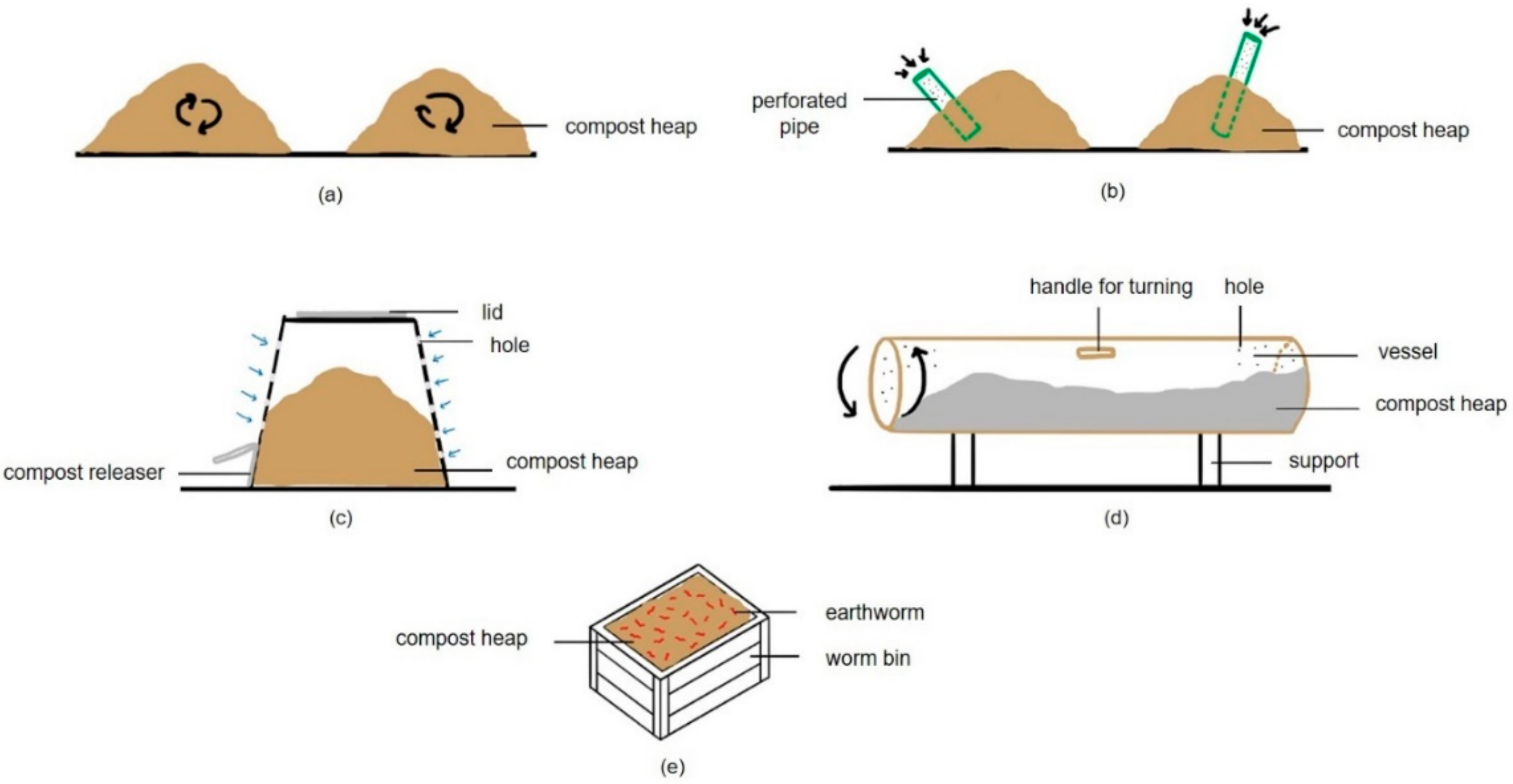

Windrow is the general term for the use of an elongated pile of stacked raw organic materials for composting, as shown in Figure 1a, and represents the most basic composting method. The method is suitable for treating large volumes of organic waste and producing large volumes of compost [1]. However, due to its simplicity, it is one of the most commonly adopted manual composting methods, especially for domestic composting.

Figure 1. (a) Windrow composting; (b) passively aerated windrow composting; (c) bin composting; (d) in-vessel composting; (e) vermicomposting.

Due to the sometimes-large windrow compost heaps, air-filled porosity needs to be maintained throughout the compost heaps, and aeration becomes a very important issue [2]. Commonly, the compost heaps are mixed with structure-giving materials, such as twigs, cardboard, or hard vegetables, to allow air to pass throughout the compost heaps effectively and oxygen, which is consumed by the microorganisms, to be replenished [3]. Particles in the compost heaps may also be reduced, either manually or automatically using a grinding machine, to increase surface area and hence, allow faster decomposition. In any case, the compost heaps need to be manually or mechanically turned [4] to re-establish porosity over time and re-introduce air and oxygen back into the compost heap. Additionally, turning also allows the rotation of compost materials, such that the exterior of the heap can be rotated to the interior of the heap and allow the microorganisms to inter-changeably decompose different parts of the heap.

The obvious benefits of windrow composting are that it requires low funding and maintenance [5]. However, it needs an amount of space to accommodate the compost heaps, which need to be spaced out from one another, for an effective composting process. Composting using the windrow method also consumes a relatively longer amount of time to produce good compost and requires manual labor for reducing the particle size to the appropriate size and turning.

1.2. Passively Aerated Windrow Composting

As shown in Figure 1b, passively aerated windrow composting is an improvement over simple windrow composting by introducing perforated pipes to allow convection airflow throughout the organic compost heaps, particularly at the center of the heaps [6]. Different pipe configurations can be adopted to bring oxygen to the microorganisms, with the use of the pipe eliminating the need for frequent turning. However, it is important to introduce the right air-filled porosity before putting the organic waste in the compost heap by appropriately reducing the compost particles as well as thorough pre-mixing. Insulation of the compost heap with finished compost may also be done to ensure thermophilic temperatures reach the outer layer of the compost heap.

The main benefit of this technology is that it does not require any turning [7], which subsequently allows the compost heap to retain its heat effectively while still being able to supply the much-needed oxygen to the microorganisms via the passive aeration system. Consequently, the method may result in a slightly shorter composting period than conventional windrow composting. However, the absence of turning during the composting process necessitates more thorough preparations of the organic waste before putting it in the compost heaps.

1.3. Bin Composting

This technology is mainly practiced at a domestic household level with limited space, as depicted in Figure 1c. It can treat only a limited amount of waste and only produce compost for self-consumption. Organic wastes are commonly inserted from the top of a specially designed container with a perforated wall to allow convectional air flow to the compost heap. The organic composting material degrades and becomes compacted slowly as it gets down into the container, with the final ready compost collected from the bottom of the container. Some containers may also include a stirring mechanism to allow a convenient method of mixing the compost heap, and as such, improve the air-filled porosity of the heap. The use of the self-contained system with perforated walls allows heat retention while enabling air to be circulated throughout the compost heap. For more extensive composting operations, bin composters can also be used on a large scale by combining the passively aerated method with bin composting [8]. The technology requires medium funding and a minimal amount of maintenance. Additionally, it requires less space than windrow composters as the waste is piled up vertically in the bin. No turning is also required, with the exception of stirring, which may need to be performed occasionally [9]. However, the composting process may take longer than windrow composting as the waste is contained inside a bin, and no turning is performed.

1.4. In-Vessel Composting

In-vessel composting is a method that encloses the composting materials within a container or a vessel [10], as shown in Figure 1d. Installations vary from very high-tech options, with different parameters monitored to very low-tech alternatives. In all configurations, airflow and temperature can be more easily controlled using this technology via the air portals from the holes around and on the sides of the vessel, allowing some air to pass through, which speeds up the composting process. Turning takes place manually, and it needs to be turned more frequently during the first two weeks of the composting process to help with the aeration process as well as to control both temperature and moisture. Large batches of organic waste can be added and composted using this technology, with the main benefit of requiring less space than the previous technologies. The organic waste is reduced in volume, and usually, after three weeks to months, the compost is further treated in an open space for the curing stage. Additionally, less labor is required as the mixing or turning occurs within the vessel. However, it is capital-intensive and requires high maintenance, necessitating regular checks inside the vessel to ensure a favorable composting environment [11] and manual mechanical rotation.

1.5. Vermicomposting

Vermicomposting, as depicted in Figure 1e, is a type of composting in which microorganisms and certain macroorganisms, such as earthworm species, are utilized at room temperature to improve the organic waste decomposition process and to provide a better final compost [12]. The method is different from conventional aerobic composting, with specially chosen red worms, commonly Eisenia Foetida, added to the compost heap. These worms have high appetites and breeding abilities, can digest the organic waste materials and pass them through their digestive tract to produce vermicompost in the form of granules [13]. Essentially, vermicompost is the worms’ feces, also known as castings, which are rich in nutrients. Their castings are packed with microbes, which help continue the decomposition process to produce the final compost. However, they need a comfortable space to live and work. Some bedding materials, either shredded paper or cardboard, have to be prepared inside a worm bin for the worms to live and work. They also need some moisture and organic waste. The timeline for the whole process varies depending on the quantity of worms, the temperature, and how much waste is added to the bin. Furthermore, worm reproduction can occur [14], which eventually floods up the worm bin with worms after some time, and this may require transfers to an additional worm bin to maintain effectiveness. Vermicomposting can decrease the pathogens in the process, albeit not as effectively as traditional composting, as pathogens are generally eliminated quicker in hot conditions. However, the worms cannot survive very hot temperatures, allowing some pathogens and weeds to survive. This method requires relatively low costs, maintenance, and space [15]. The worms used have the ability to consume the organic matter quickly, resulting in a faster composting process with additional help from the microbes in their castings, and the method requires very little labor.

2. Automatic Composting Technology

There are various reasons for the relatively low adoption level of composting, including a lack of awareness, the relatively long time required for composting to complete, and lack of knowledge of the biological composting process. Manual composting methods require some time to produce good compost, in addition to monitoring and effort, which can be a hassle for busy working people. Additionally, some composting methods also require plenty of space [16], and hence, may not be suitable for those who live in urbanized areas. An automatic composter aims to solve some of these problems.

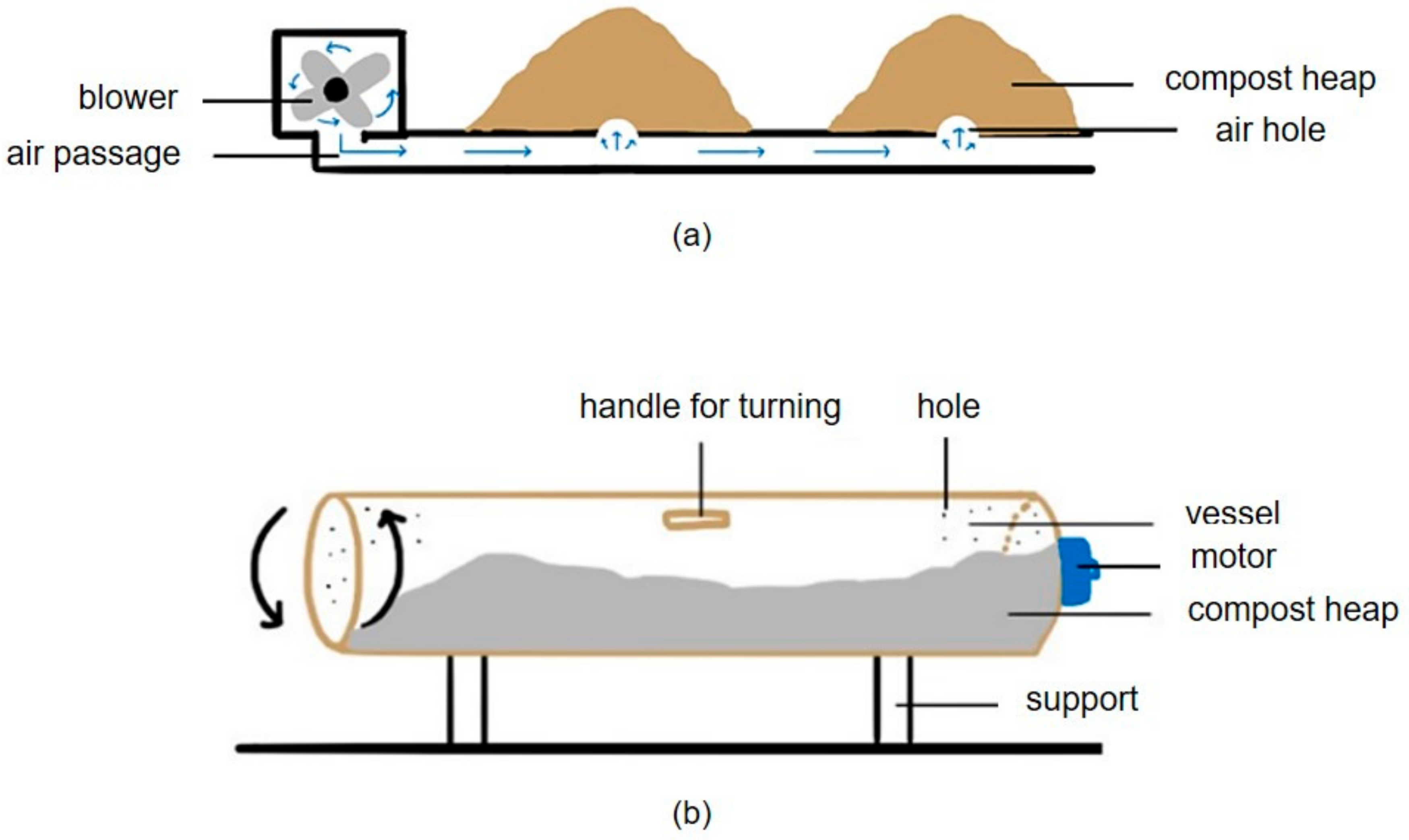

2.1. Forced Aerated Windrow Composting

In a forced aerated windrow setting, blowers are installed at the end of perforated pipes to force airflows to the compost heaps, as shown in Figure 2a [17]. The blowers inject air into the compost heaps, especially during the active stage, to supply the much-needed oxygen for the microorganisms, and hence, allow decomposition of organic waste materials. Airflow can be adjusted by changing the frequency and duration of the blower. The compost heaps are also commonly insulated to prevent heat loss and allow thermophilic temperature throughout the compost heaps, including the outer layers. Due to the efficient retention of heat and the ability to supply oxygen without turning, the composting process is commonly shorter. Little labor is required as compost heaps need not be turned [18]. However, the method requires high investment, given the need for blowers and aeration channels for airflow. Maintenance is also high and requires high space requirements.

Figure 2. (a) Forced aerated windrow composting; (b) automatic turning in-vessel composting.

2.2. Automatic Turning In-Vessel Composting

The technology illustrated in Figure 2b is similar to the manual in-vessel composting; however, the technology may vary in designs, size, and equipment. One of the automatic in-vessel composting processes is the motorized turning in-vessel composter. The automatic turning in-vessel composting uses a powered motor to rotate the vessels for aerating the compost heaps and can be scheduled to rotate at desired times and frequency [19]. Some in-vessel composting processes also utilize a motor for rotating the vessel, and are equipped with temperature and humidity sensors to automatically monitor important parameters; replacing most of the manpower required in manual in-vessel composting. As a high torque motor is needed to rotate the heavy waste-filled vessels, the method requires very high investment and maintenance to ensure every piece of equipment works well to carry out the work. However, the in-vessel composting method is considered space-efficient and requires a low amount of labor.

2.3. Electrical Home Composter

An electric composter is an indoor compost bin that uses aeration, heat, and pulverization to minimize the volume, emissions, and odor of food waste. A common home composter may be small enough to fit on a counter, but for other types, large amounts of garbage also do exist and can be used in both indoor or outdoor applications. A home electrical composter, also known as a food recycler, uses three-phase cycles to break down food waste [20], with most composters taking an average of 24 h to a few days to break down waste into simpler compositions.

An electrical home composter attempts to provide the optimum composting environment occurring during selected phases of the natural composting process. Mesophilic and thermophilic phases are shortened in most electrical home composters through the applications of heat, such that excess moisture in the organic materials can be rapidly reduced. Organic materials are commonly automatically ground to increase their surface area to speed up the composting process before the materials are mixed with soils or additives to populate the microorganisms. After going through the accelerated mesophilic and thermophilic phases, the end products are eventually cooled down to room temperature to give entirely dry and sterile products, instead of the common texture of mature compost. This is because the end product from the home composter has only undergone partial phases of the composting process: the mesophilic and thermophilic phases, but has not undergone the maturation phase. These end products may be further cured outside of the system to ensure the resultant compost is adequately matured.

Electrical home composters may differ in terms of the adopted processes, quality of end product, and duration to completion. Nevertheless, the majority of the electrical home composters are based on three-phase cycles, which include drying, grinding, and cooling phases [21]. Some electrical home composters may also produce non-dehydrated and non-dry compost. This is possible due to the implementation of an additional phase, called the curing phase. In this phase, the organic materials that have been broken down into smaller substances are stabilized, applied with some heat, aerated, and turned until the compost is partially-cured (albeit not fully cured and stabilized) and able to be used as a garden compost as a final product. Due to the extra phase, these types of composters may take up to two weeks to complete the whole process.

There are quite a number of electrical home composters available in the market, with some of the products shown in Table 1 below.

Table 1. List of some available electrical home composters in the market.

| Product Name | Product Image | Features | Price in USD | References |

|---|---|---|---|---|

| Vitamix FoodCycler FC-50 |  |

Size: 12.6” × 11” × 14.2” Weight: 27 lbs Capacity: 2.5-L bucket Power consumption: 0.8 kWh/cycle Processing time: dehydrated, ground, and cooled material in 4–8 h. Phase cycle: drying, grinding, and cooling only |

$400 | [22] |

| BeyondGREEN Composter |  |

Size: 20” × 12” 20” Weight: 22 lbs Capacity: 5 lbs per day Processing time: Compostable material in 5 days and high-nitrogen compost in 2 weeks. Phase cycle: drying, grinding, cooling, and curing |

$380 | [23] |

| Oklin GG-02 Composter |  |

Size: 30” × 18” × 18” Weight: 60 lbs Capacity: 8 lbs Power consumption: 60–90 kWh/month Processing time: usable soil amendment in 24 h. Phase cycle: drying, grinding, and cooling |

$1200 | [24] |

| Lomi Composter |  |

Size: 16” × 12” × 13” Capacity: 7 lbs Power consumption: 1 kW/h Processing time: dry material in 20 h Phase cycle: drying, grinding, and cooling only |

$499 | [25] |

| KALEA Composter |  |

Size: 9” × 25” × 20” Capacity: 7 lbs Power consumption: 200 kW/year Processing time: 48 h into nourishing compost Phase cycle: drying, grinding, cooling, and curing |

$800 | [26] |

| NatureMill ULTRA Composter |

|

Size: 20.3” × 20” × 12.6” Weight: 25.4 lbs Capacity: 120 lbs/month Power consumption: 5 kWh/month Processing time: compost in 2 weeks Phase cycle: drying, grinding, cooling, and curing |

$500 | [27] |

Electrical home composters are commonly embedded with different sensors for monitoring and control purposes. Temperature and moisture sensors are the most common sensors integrated onto an electrical composting system [28] to aid in the monitoring of thermal conditions inside the electrical composter and to ensure effective decomposition of the organic matter, preventing too wet or too dry contents, as well as to regulate the temperature from exceeding 70 °C, which can kill the microbes. An air pump is commonly used as an actuator to regulate temperature, such that the temperature within the system does not rise beyond a certain value, which may kill the microorganisms. Grinders are commonly used to shred organic materials to increase the surface area for the microorganisms to act on. These systems can be commonly operated with just a click of a button to activate the process, equipment, and sensors, from start to end product completion.

Most food recyclers use ventilation and heat to quickly break down food waste, much like a pile of regular compost. However, most of the end-product is completely dry, sterile, and immature [29], and hence, it cannot be considered proper compost. A home composter is primarily designed as an alternative for conventional composting; by reducing the hassle of managing compost heap and, as such, is suitable for people who want an odorless composting process with limited space to carry out conventional composting methods. This composter is designed to be used by anyone and may facilitate the reduction of food waste or organic waste from home. Despite its fast process, the initial investment of the machine itself can be high and requires high maintenance. However, its low space requirement and very low labor requirement make it an attractive alternative to conventional composting.

2.4. Comparative Summaries of the Manual and Automatic Composting Methods

Table 2 shows the comparative summary of manual and automatic composting methods. The literature indicates that many benefits may be obtained by adopting an automatic composting process; faster, easier, and more convenient composting, which may encourage composting at the source. Subsequently, this may reduce the need to transport the bulk of the waste to landfills and its associated problems. However, despite a large number of scientific pieces of research on the topic, none have specifically addressed the technological advancements in composting from the patent perspective. This is despite patents representing valuable information on the technology and may indicate directions of the composting technology. As such, there is a clear need to perform a systematic patent review on the technological advancements in the field.

Table 2. Comparative summary between some of the manual and automatic composting methods.

| Manual composting | |||||

| Method of composting | Cost | Maintenance | Space requirement | Composting duration | Labor requirement |

| Windrow | Very low | Very low | Very high | Moderate | Very high |

| Passively Aerated Windrow | Low | Low | Very high | Moderate | Low |

| In-Vessel | Very high | Very high | Moderate | Fast | Low |

| Bin | Moderate | Low | Moderate | Slow | Low |

| Vermicomposting | Very low | Low | Low | Fast | Very low |

| Automatic composting | |||||

| Method of composting | Cost | Maintenance | Space requirement | Composting duration | Labor requirement |

| Forced Aerated Windrow | High | High | High | Fast | Low |

| Automatic Turning In-Vessel | Very high | Very high | Moderate | Fast | Very low |

| Electric | High | High | Low | Very fast | Very low |

This entry is adapted from the peer-reviewed paper 10.3390/inventions7020038

References

- Jalalipour, H.; Jaafarzadeh, N.; Morscheck, G.; Narra, S.; Nelles, M. Potential of producing compost from source-separated municipal organic waste (A case study in Shiraz, Iran). Sustainability 2020, 12, 9704.

- Arslan, E.I.; Ünlü, A.; Topal, M. Determination of the Effect of Aeration Rate on Composting of Vegetable-Fruit Wastes. Clean—Soil Air Water 2011, 39, 1014–1021.

- Di, Y.; Liu, J.; Liu, J.; Liu, S.; Yan, L. Characteristic analysis for odor gas emitted from food waste anaerobic fermentation in the pretreatment workshop. J. Air Waste Manag. Assoc. 2013, 63, 1173–1181.

- St Martin, C.C.G.; Dorinvil, W.; Brathwaite, R.A.I.; Ramsubhag, A. Effects and relationships of compost type, aeration and brewing time on compost tea properties, efficacy against Pythium ultimum, phytotoxicity and potential as a nutrient amendment for seedling production. Biol. Agric. Hortic. 2012, 28, 185–205.

- Vigneswaran, S.; Kandasamy, J.; Johir, M.A.H. Sustainable Operation of Composting in Solid Waste Management. Procedia Environ. Sci. 2016, 35, 408–415.

- Veeken, A.; Wilde, V.; Hamelers, B. Microbiology Passively Aerated Composting of Straw-Rich Organic Pig Manure. Compost Sci. Util. 2002, 10, 2.

- Lim, L.Y.; Bong, C.P.C.; Lee, C.T.; Klemeš, J.J.; Sarmidi, M.R.; Lim, J.S. Review on the current composting practices and the potential of improvement using two-stage composting. Chem. Eng. Trans. 2017, 61, 1051–1056.

- Karnchanawong, S.; Suriyanon, N. Household organic waste composting using bins with different types of passive aeration. Resour. Conserv. Recycl. 2011, 55, 548–553.

- Arrigoni, J.P.; Paladino, G.; Garibaldi, L.A.; Laos, F. Inside the small-scale composting of kitchen and garden wastes: Thermal performance and stratification effect in vertical compost bins. Waste Manag. 2018, 76, 284–293.

- Manyapu, V.; Shukla, S.; Kumar, S.; Rajendra, K. In-vessel composting: A rapid technology for conversion of biowaste into compost. Open Access Int. J. Sci. Eng. 2017, 2, 58–63.

- El Zein, A. Moisture Content and Thermal Balance During Composting of Fish, Banana Mulch & Municipal Solid Wastes. Eur. Sci. J. 2015, 11, 169–187.

- Ganti, S. Vermicomposting. Int. J. Waste Resour. 2018, 8, 8–11.

- Kaur, T. Vermicomposting: An Effective Option for Recycling Organic Wastes. In Organic Agriculture; IntechOpen: Hampshire, UK, 2020; pp. 1–17.

- Munroe, G.; Scott, J.; Burlington, C.; Scotia, N.; Holsteins, K.; Pre, G. Manual of On-Farm Vermicomposting and Vermiculture Organic Agriculture Centre of Canada Acknowledgements EcoAction Program of Environment Canada and New Ground Vermicomposting, Halifax, Nova Scotia; Organic Agriculture Centre of Canada: Truro, NS, Canada, 2007; p. 56. Available online: https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/E-Learning/Moocs/Solid_Waste/W4/Manual_On_Farm_Vermicomposting_Vermiculture.pdf (accessed on 16 August 2021).

- Lalander, C.H.; Komakech, A.J.; Vinnerås, B. Vermicomposting as manure management strategy for urban small-holder animal farms—Kampala case study. Waste Manag. 2015, 39, 96–103.

- Cuyahoga County. Composting Guide; Solid Waste Management District: Garfield Heights, OH, USA, 2011; pp. 1–8.

- Larney, F.J.; Olson, A.F. Windrow temperatures and chemical properties during active and passive aeration composting of beef cattle feedlot manure. Can. J. Soil Sci. 2006, 86, 783–797.

- Zealand, C.N. Introduction to Composting Science and Management for Industry Training; UNSW: Sydney, Australia, 2007.

- Mishra, S.; Mishra, S.K.; Mishra, S.K.; Yadav, K.D. Energy Assessment of rotary drum and aerated in-vessel for composting of garden waste. Res. Sq. 2021, 1–16.

- Fakharulrazi, A.N.; Yakub, F. Designing an Automated Composter for Food Waste Management with the Implementation of Internet of Things. J. Sustain. Nat. Resour. 2020, 1, 9–14.

- Miller, S. Electric Composters: What Are They and How Do They Work? 2019. Available online: https://www.foodcycler.com/post/electric-composters-what-are-they-and-how-do-they-work (accessed on 24 August 2021).

- Vitamix. Vitamix® FoodCycler® FC-50. 2020. Available online: https://www.vitamix.com/us/en_us/shop/foodcycler-fc-50#specs (accessed on 7 September 2021).

- BeyondGREEN. beyondGREEN All-Electric Pet Waste and Organic Waste Composter. 2021. Available online: https://byndgrn.com/products/pet-waste-composter (accessed on 30 June 2021).

- Oklin. GG-02 Manual Handbook. 2017. Available online: https://www.papstar-storyteller.de/fileadmin/user_upload/GG02_-_User_Manual_Engl_.pdf (accessed on 20 September 2021).

- Gadget, M. Lomi Composter Review: Turn Food Waste to Compost with One Button. 2021. Available online: https://mrgadget.com.au/lomi-review-turn-waste-to-compost/ (accessed on 30 August 2021).

- Kalea. KALEA Biological Process. 2020. Available online: https://www.mykalea.de/faq (accessed on 16 September 2021).

- Machines, P.P. NatureMill Ultra Kitchen Composter. 2013. Available online: https://www.peoplepoweredmachines.com/naturemill/naturemill-ultra.htm (accessed on 29 July 2021).

- Elalami, M.; Baskoun, Y.; Zahra Beraich, F.; Arouch, M.; Taouzari, M.; Qanadli, S.D. Design and Test of the Smart Composter Controlled by Sensors. In Proceedings of the 2019 7th International Renewable and Sustainable Energy Conference, IRSEC 2019, Agadir, Morocco, 27–30 November 2019.

- Kucbel, M.; Raclavská, H.; Růžičková, J.; Švédová, B.; Sassmanová, V.; Drozdová, J.; Raclavský, K.; Juchelková, D. Properties of composts from household food waste produced in automatic composters. J. Environ. Manag. 2019, 236, 657–666.

This entry is offline, you can click here to edit this entry!