Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Food Science & Technology

Oxidation is an undesirable series of chemical reactions in oil that completely degrade its quality. Oxidation affects the quality of the oil during its production and its subsequent storage, and it is a strictly post-harvest level quality assessment. It describes the handling of olive oil and how it was produced (cold/hot extraction) and stored. It is known that, when an oil is exposed to oxygen, heat, and light, it becomes oxidized.

- olive oil oxidation

- analytical methods

- chemometrics

1. Introduction

Olive oil is an edible vegetable oil solely deriving from the fruits of the olive tree (Olea europaea L.). It is produced by only mechanical or other physical means. It is mainly cultivated around the Mediterranean Basin, although in the past 50 years other regions have been added (California, New Zealand and Argentina). Its annual production reaches 3 million tonnes with a projection to increase approximately 3% year on year in the coming decade [1].

Global olive oil imports, exports as well as consumption have been growing consistently in recent years, thanks to olive oil’s remarkable organoleptic and nutritional properties, and the growing demand for premium healthy oils. Extra-virgin olive oil (EVOO) is one of the fundamental elements in the Mediterranean diet. At the same time, a very large agricultural industry is behind olive oil production, employing millions of people in producing countries [2].

Olive oil is one of the most regulated food commodities in the world, despite being a target of adulteration at different stages of its production and mainly of its supply chain. The oil is often substituted by fraudsters with lesser value oils and its identity is compromised [3]. This not only affects its aroma and taste but also erodes consumer confidence in the product and the perceived health benefits that come with it. Nowadays, both standard and modern analytical methods are applied to identify fraud [4]. Cultivar; environmental conditions such as geographical origin and geoclimatic characteristics; agronomic practice such as orchard management, irrigation and fertilization; harvesting time; olive maturation; storage of harvested olives and technological processes are parameters that have the most significant influence on olive oil quality, with the cultivar being of utmost importance since the olive cultivar and its characteristics are directly related to olive oil quality [5][6][7][8].

Standard analytical methods are incorporated in the legislation framework for olive oil trade. On a global level, the olive oil trading standards were developed by Codex Alimentarius CODEX STAN 33–1981 [9]. The Codex standards have been adopted by major organizations and countries worldwide, the International Olive Council, International Standard Organization (ISO) and in part by the European Union (EU). All those are frequently updated with new regulations that are trying to protect the integrity by describing methods that assess the authenticity, quality and purity of olive oil [10]. Although there are differences in the standards, a harmonization process is ongoing.

The virgin olive oil (VOO) category defines pure olive oil of high quality. Here, the oil is obtained from the fruit of the olive tree solely by mechanical or other physical means under conditions that do not alter the product’s integrity, while washing, decantation, centrifugation and filtration are the only treatments it undergoes. Within this category, there is EVOO and VOO, which are defined by different percentages of free acidity (0.8% or more up to 3.3%), and within the EU, specific organoleptic characteristics that correspond to those predetermined for each category (Regulation (EEC) 2568/91). Other categories are “refined olive oil”, “olive oil” that is a mixture of EVOO and refined olive oil, and olive pomace oil resulting from the extraction of olive pomace using solvents [11].

The acidity of the VOO is affected both by the quality of the produced olive fruit and by the cultivation practice, while it is undoubtedly the most important quality criterion. There are also a number of other chemical indices related to quality established for the VOO category. However, the organoleptic characteristics are broader because they include broader quality and authenticity parameters. The differentiation between categories is in the number of defects that can be detected by the sensory features obtained by a panel during the organoleptic trial with the higher categories accepting less defects than the lower ones [12]. One of these quality-related defects that can be detected, both chemically and sensorially, is the oxidation status of olive oil, commonly referred as rancidity. Oxidation affects the quality of the oil during its production and its subsequent storage, and it is a strictly post-harvest level quality assessment. It describes the handling of olive oil and how it was produced (cold/hot extraction) and stored. It is known that, when an oil is exposed to oxygen, heat, and light, it becomes oxidized. Oxygen and heat, and to a lesser extent, light, can significantly influence oxidation at the early stage of production, in the malaxation stage, up until its bottling and storage. In storage, the effect of light can be seen more influentially as almost all bottles in which olive oil is sold at present are opaque [13].

Oxidation is an undesirable series of chemical reactions in oil that completely degrade its quality. To understand oxidation, one should by familiar with the chemical compounds of olive oil. Oleic acid is the major fatty acid in olive oil [14], whereas other fatty acids found in the total fatty acids composition of olive oils are palmitic acid, palmitoleic acid, stearic acid, linoleic acid, α-linolenic acid and other minor acids. Diacylglycerols, monoacylglycerols and four classes of sterols, namely, common sterols (4-Desmethylsterols), 4α-Methylsterols, triterpene alcohols (4, 4-Dimethylsterols) and triterpene dialcohols, complete the group of olive oil lipids. All the major lipids EVOO components are listed in Table 1 [15].

Table 1. Major lipids EVOO components (adapted from [15]).

The fatty acid profile also plays an important role in the quality and characterization of olive oil as its composition reflects the nutritional properties of olive oil [5]. EVOO is mainly composed of triglycerides, with a high content of monounsaturated fatty acid (MUFA) and relatively low polyunsaturated fatty acid (PUFA) amounts [16]. The fatty acid composition of olive oils is variable, depending on the geographical region and botanical origin [17].

During the photo-oxidation of oil olive, the highly unstable and reactive singlet oxygen reacts with the unsaturated fatty acids, leading to the formation of the undesirable hydroperoxides [18]. Olive oil consists of a mixture of several esterifying triacylglycerols (TAG), representing 98% of its composition. The triacylglycerols consist of primarily monounsaturated fatty acids (FAs) (oleic acid or C18:1, present at 55–70% of total FAs) and a much higher content of polyunsaturated FAs (linoleic acid or C18:2, 5–15%). The unsaponified matter (1–2%) contains squalene, pigments, tocopherols, sterols, waxes and, perhaps more importantly, the polar fraction [19]. There are at least thirty-six structurally distinct olive oil phenolics that have been identified [20], including phenolic acids, phenolic alcohols, hydroxy-isocromans flavonoids, lignans and secoiridoids. Phenolic acids can be divided into three subgroups: benzoic acid derivatives, cinnamic acid derivatives and other phenolic acids and derivatives. Phenolic alcohols include hydroxytyrosol, tyrosol, p-Hydroxyphenyl ethanol (3,4-Dihydroxyphenyl), ethanol-glucoside, 2-(3-4 Dihydroxy phenyl) ethyl acetate and 2-(4-hydroxyphenyl) ethyl acetate. Hydroxy-isocromans are 3,4-dihydro-1Hbenzo[c]pyran derivatives, mainly occurring in nature as part of a complex-fused ring system. Flavonoids can be further divided into two subgroups: flavones and flavanols, including hydroxy-isocromans (+)-Pinoresinol 1-phenyl-6,7-dihydroxy-isochroman and 1-(3-methoxy-4-hydroxy)phenyl6,7-dihydroxy-isochroman. Lignans, based on the condensation of aromatic aldehydes, include (+)-1-Acetoxypinoresinol, (+)-1-Hydroxypinoresinol and (+)-Pinoresinol [20]. Secoiridoids are olive oil-specific phenolic compounds originating from oleuropein and ligstroside, i.e., the oleuropein aglicone mono-aldehyde (3,4-DHPEA-EA), the ligstroside aglicone mono-aldehyde (p-HPEA-EA), the dialdehydic form of elenolic acid linked to Hy (3,4-DHPEA-EDA or oleacin) and the dialdehydic form of elenolic acid linked to Ty (p-HPEA-EDA, or oleocanthal) [21][22][23]. Phenolic compounds from VOO have been shown to have potent antioxidant activity that can directly scavenge some radical species and minimize the amount reactive oxygen species (ROS) generated by fatty acid peroxidation [24].

The sum of phenolic acids (such as caffeic acid or syringic acid) and simple phenols (such as tyrosol and hydroxytyrosol) constitute the polar fraction. These simple forms, however, are in smaller quantities. Secoiridoid derivatives of the glycosides oleuropein and ligstrodide, lignans and other complex flavonoids are the main polar constituents [25]. To note, oxidation is an inevitable natural process. Some oils, such as olive oil and especially, EVOO are better in delaying it than others with longer induction periods due to their composition [26]. In principle, oxidation can be influenced by the fatty acid (FA) composition since there is a difference between monounsaturated and polyunsaturated FAs in their oxidation rate. However, among different olive oils, no significant differences are expected due to their fatty acid profiles, since they are almost identical. However, oxidation can be influenced by the unsaponified matter or the minor constituents, such as tocopherols, phytosterols, vitamin E and especially the polar fraction, which vary substantially from oil to oil. It has been shown that the oxidative stability of olive oil is significantly dependent on polar phenols. Between olive oil production and consumption, the possible loss of polar phenols can lead to the degradation of its quality [27]. Storage, in particular, reduces both polar phenols and tocopherols, rendering the olive oil susceptible to oxidation.

Oxidation status or rancidity can be detected by both the organoleptic test and a chemical test, although, as discussed later, the chemical test (peroxide value, PV) can also measure the presence of allylic hydroperoxides, which appear first during the oxidation process, whereas the sensory panel and other methods can potentially detect secondary products (aldehydes and ketones) of musty and rancid flavor, which are formed during the oxidation process [28][29].

The ever-increasing demand for extra virgin olive oil (EVOO), characterized for its unique organoleptic properties and health benefits, has led to various fraudulent practices to maximize profits, including dilution with lower-value edible oils. The deliberate mislabeling of lower commercial-grade olive oils or even mislabeling by a false declaration are some of the activities of adulteration. The poor nutritional quality, rapid oxidation as well as possible unhealthy substances formed during processing are issues concerning adulterated oils [6][16]. Food fraud mitigation strategies are mainly targeted to detect adulteration rapidly, accurately and easily in relation to lower grades of olive oil (refined, soft deodorized or pomace olive oil) or other lower-cost vegetable oils (e.g., hazelnut, sunflower, soybean, cotton, corn, walnut, canola oil and many others) [30].

2. Detection of Olive Oil Oxidation Status during Storage

It is also important to briefly highlight some oxidation mechanisms of olive oil during storage in relation to the factors already mentioned (i.e., light exposure, heat temperatures, air and packaging material). The formation of unstable hydroperoxides through tri-acylglycerol fatty acid reactions with molecular oxygen, and stimulated by free fatty acids, mono and diacylglycerols and thermally oxidized compounds seems to be crucial during oil storage at high temperatures. Then, unstable hydroperoxide degradation drives the generation of volatile and non-volatile substances that change oil quality. In addition, the presence of metals in the oil act as catalysts and they affect the above-mentioned reactions when the oil is exposed to light and high temperatures. Additionally, in dark conditions, autoxidation may start and in the presence of light, photo-oxidation may follow and, due to enzymes, enzymatic oxidation may take place. Since the autooxidation of olive oil occurs even in the absence of light and photooxidation takes place through the action of natural photosensitizers such as chlorophyll and occurs when olive oil is exposed to light, it is more than clear that the storage and packaging conditions of olive oil are of primary importance [31].

The phenolic content in oil is a factor that triggers the change in quality because they take part in oxidative and hydrolytic mechanisms. Phenolic compounds can importantly protect glycerides from oxidation and preventing oxidation via reactions such as radical scavenging, hydrogen atom transfer and metal chelating [7][8][22].

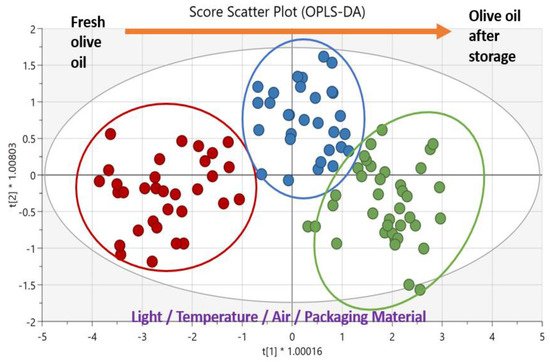

All the studies presented in this review concur that chemometrics help the evaluation of results positively. In this type of studies, which focus on the changes in olive oil during storage, several measurements from different analytical techniques were collected; thus, it is crucial to treat the measurements with chemometrics. Chemometric analysis provided two very important benefits, which are the following: i) the determination of the significant parameter responsible for the changes during storage, and ii) the good presentation of the results by using scatter plots after the clustering or discrimination of the samples, as shown in Figure 1 (in which the OPLS-DA method was applied). Undoubtedly, in approximately the last two decades, chemometrics and artificial intelligence have become well-established in the food sector, and in the future, technological development will also make them more important and necessary in this field.

Figure 1. Score scatter plot obtained after chemometric analysis based on the OPLS-DA method. The presentation of fresh olive oil vs. olive oil after storage, classified in 3 groups, and the parameters that affect quality.

This entry is adapted from the peer-reviewed paper 10.3390/biom12091180

References

- International Olive Oil Council. Available online: https://www.internationaloliveoil.org/ (accessed on 9 July 2022).

- D’Adamo, I.; Falcone, P.M.; Gastaldi, M.; Morone, P. A social analysis of the olive oil sector: The role of family business. Re-Sources 2019, 8, 151.

- Meenu, M.; Cai, Q.; Xu, B. A critical review on analytical techniques to detect adulteration of extra virgin olive oil. Trends Food Sci. Technol. 2019, 91, 391–408.

- Aparicio, R.; Conte, L.S.; Ad Fiebig, H.J. Olive Oil Authentication. In Handbook of Olive Oil; Aparicio, R., Harwood, J., Eds.; Springer: Boston, MA, USA, 2013; pp. 431–478.

- Skiada, V.; Agriopoulou, S.; Tsarouhas, P.; Katsaris, P.; Stamatelopoulou, E.; Varzakas, T. Evaluation and Origin Discrimina-tion of Two Monocultivar Extra Virgin Olive Oils, Cultivated in the Coastline Part of North-Western Greece. Appl. Sci. 2020, 10, 6733.

- Tarapoulouzi, M.; Skiada, V.; Agriopoulou, S.; Psomiadis, D.; Rébufa, C.; Roussos, S.; Theocharis, C.R.; Katsaris, P.; Varzakas, T. Chemometric Discrimination of the Geographical Origin of Three Greek Cultivars of Olive Oils by Stable Isotope Ratio Analysis. Foods 2021, 10, 336.

- El Yamani, M.; Boussakouran, A.; Rharrabti, Y. Effect of storage time and conditions on the quality characteristics of ‘Mo-roccan Picholine’ olive oil. Biocatal. Agric. Biotechnol. 2022, 39, 102244.

- Mousavi, S.; Mariotti, R.; Stanzione, V.; Pandolfi, S.; Mastio, V.; Baldoni, L.; Cultrera, N.G.M. Evolution of Extra Virgin Olive Oil Quality under Different Storage Conditions. Foods 2021, 10, 1945.

- Codex Alimentarius Commission. Standard for Olive Oils and Olive Pomace Oils; CXS 33-1981; FAO: Rome, Italia, 1981.

- Conte, L.; Bendini, A.; Valli, E.; Lucci, P.; Moret, S.; Maquet, A.; Lacoste, F.; Brereton, P.; García-González, D.L.; Moreda, W.; et al. Olive oil quality and authenticity: A review of current EU legislation, standards, relevant methods of analyses, their drawbacks and recommendations for the future. Trends Food Sci. Technol. 2020, 105, 483–493.

- Boskou, D.; Tsimidou, M.; Blekas, G. Polar phenolic compounds. In Olive Oil; AOCS Press: Thessaloniki, Greece, 2006; pp. 73–92.

- García-González, D.L.; Tena, N.; Aparicio, R. Characterization of olive paste volatiles to predict the sensory quality of virgin olive oil. Eur. J. Lipid Sci. Technol. 2007, 109, 663–672.

- Frankel, E.N. Recent advances in lipid oxidation. J. Sci. Food. Agric. 1991, 54, 495.

- Hernández, M.L.; Velázquez-Palmero, D.; Sicardo, M.D.; Fernández, J.E.; Diaz-Espejo, A.; Martínez-Rivas, J.M. Effect of a regulated deficit irrigation strategy in a hedgerow ‘Arbequina’ olive orchard on the mesocarp fatty acid composition and desatuase gene expression with respect to olive oil quality. Agric. Water Manag. 2018, 204, 100–106.

- Jimenez-Lopez, C.; Carpena, M.; Lourenço-Lopes, C.; Gallardo-Gomez, M.; Lorenzo, J.M.; Barba, F.J.; Prieto, M.A.; Simal-Gandara, J. Bioactive Compounds and Quality of Extra Virgin Olive Oil. Foods 2020, 9, 1014.

- Lozano-Castellón, J.; López-Yerena, A.; Domínguez-López, I.; Siscart-Serra, A.; Fraga, N.; Sámano, S.; López-Sabater, C.; Lamuela-Raventós, R.M.; Vallverdú-Queralt, A.; Pérez, M. Extra virgin olive oil: A comprehensive review of efforts to ensure its authenticity, traceability, and safety. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2639–2664.

- Ben Hmida, R.; Gargouri, B.; Chtourou, F.; Sevim, D.; Bouaziz, M. Fatty acid and triacyglycerid as markers of virgin olive oil from mediterranean region: Traceability and chemometric authentication. Eur. Food Res. Technol. 2022, 248, 1–16.

- Psomiadou, E.; Tsimidou, M. Stability of virgin olive oil. 2. Photo-oxidation studies. J. Agric. Food Chem. 2002, 50, 722–727.

- Tsimidou, M.Z.; Georgiou, A.; Koidis, A.; Boskou, D. Loss of stability of “veiled” (cloudy) virgin olive oils in storage. Food Chem. 2005, 93, 377–383.

- Cicerale, S.; Conlan, X.A.; Sinclair, A.J.; Keast, R.S. Chemistry and health of olive oil phenolics. Crit. Rev. Food Sci. Nutr. 2008, 49, 218–236.

- Ambra, R.; Lucchetti, S.; Pastore, G. A Review of the Effects of Olive Oil-Cooking on Phenolic Compounds. Molecules 2022, 27, 661.

- Di Stefano, V.; Melilli, M.G. Effect of storage on quality parameters and phenolic content of Italian extra-virgin olive oils. Nat. Prod. Res. 2020, 34, 78–86.

- Bitsani, E.; Agriopoulou, S.; Athanasopoulou, C. The Cultural, Nutritional and the Socio-Economic Value of Greek Messinian Olive Oil. In Strategic Innovative Marketing and Tourism. Springer Proceedings in Business and Economics; Kavoura, A., Kefallonitis, E., Giovanis, A., Eds.; Springer: Boston, MA, USA, 2019; pp. 307–315.

- Jukic Špika, M.; Liber, Z.; Montemurro, C.; Miazzi, M.M.; Ljubenkov, I.; Soldo, B.; Žanetic, M.; Vitanovic, E.; Politeo, O.; Škevin, D. Quantitatively Unraveling Hierarchy of Factors Impacting Virgin Olive Oil Phenolic Profile and Oxi-dative Stability. Antioxidants 2022, 11, 594.

- Karkoula, E.; Skantzari, A.; Melliou, E.; Magiatis, P. Direct measurement of oleocanthal and oleacein levels in olive oil by quantitative 1H NMR. Establishment of a new index for the characterization of extra virgin olive oils. J. Agric. Food Chem. 2012, 60, 11696–11703.

- Parthasarathy, S.; Soundararajan, P.; Krishnan, N.; Karuppiah, K.M.; Devadasan, V.; Prabhu, D.; Rajamanikandan, S.; Velusamy, P.; Gopinath, S.C.; Raman, P. Detection of adulterants from common edible oils by GC–MS. Biomass Convers. Biorefin. 2022, 1–21.

- García Martín, J.F. Potential of Near-Infrared Spectroscopy for the Determination of Olive Oil Quality. Sensors 2022, 22, 2831.

- Vichi, S.; Pizzale, L.; Conte, L.S.; Buxaderas, S.; López-Tamames, E. Solid-phase microextraction in the analysis of virgin olive oil volatile fraction: Modifications induced by oxidation and suitable markers of oxidative status. J. Agric. Food Chem. 2003, 51, 6564–6571.

- Morales, M.T.; Rios, J.J.; Aparicio, R. Changes in the volatile composition of virgin olive oil during oxidation: Flavors and off-flavors. J. Agric. Food Chem. 1997, 45, 2666–2673.

- Pasias, I.N.; Raptopoulou, K.G.; Proestos, C. Analytical Chemistry and Foodomics: Determination of Authenticity and Adulteration of Extra Virgin Oil as Case Study. In Comprehensive Foodomics, 1st ed.; Cifuentes, A., Ed.; Elsevier: Athens, Greece, 2020; pp. 494–500.

- Sanmartin, C.; Venturi, F.; Sgherri, C.; Nari, A.; Macaluso, M.; Flamini, G.; Quartacci, M.F.; Taglieri, I.; Andrich, G.; Zinnai, A. The effects of packaging and storage temperature on the shelf-life of extra virgin olive oil. Heliyon 2018, 4, e0088.

This entry is offline, you can click here to edit this entry!