Smart textiles have attracted huge attention due to their potential applications for ease of

life. Recently, smart textiles have been produced by means of incorporation of electronic components

onto/into conductive metallic yarns. The development, characterizations, and electro-mechanical

testing of surface mounted electronic device (SMD) integrated E-yarns is still limited. There is a

vulnerability to short circuits as non-filament conductive yarns have protruding fibers. It is important

to determine the best construction method and study the factors that influence the textile properties

of the base yarn. This paper investigated the effects of different external factors, namely, strain,

solder pad size, temperature, abrasion, and washing on the electrical resistance of SMD integrated

silver-coated Vectran (SCV) yarn. For this, a Vectran E-yarn was fabricated by integrating the SMD

resistor into a SCV yarn by applying a vapor phase reflow soldering method. The results showed

that the conductive gauge length, strain, overlap solder pad size, temperature, abrasion, and washing

had a significant effect on the electrical resistance property of the SCV E-yarn

- Electronic yarn, soldering, reflow, SMD, smar textile, wearable electronics, itegration

1. Introduction

Smart textiles are textiles that contain advanced technologies enabling them to sense and give a response or react to the conditions of the environment [1]. They are textiles enabling different functions and features that can improve textile material's performance and the wearer's experience [2]. Most smart textiles are manufactured by using the integration of electronic components or conductive fibers onto textile substrates [3]. The development of electronic and photonic components for integration in fabrics will increase the application potential of electronic textiles [4]. Electronic textile or E-textile is one of

the under-development technologies with a wide potential impact on wearable, flexible, conformable, lightweight, and electronic devices integrated on textile clothing [5]. They

can also be used in large-area electronic systems embedded in technical textile [6,7], for the

healthcare sector [8,9], for on-body communication [10], and for entertainment and fashion, sports activity tracking, space suits, and security monitoring applications [11,12].

Most electronic textiles available today are made by attaching either permanent or removable electronic functionality [13–15]. The combination of microelectronics into textile

substrate can be carried out integrating to a yarn by various means [16], e.g., through weaving [17], through sewing and embroidering [18,19], using hybrid soldering techniques [20], using sewing integration [21], applying electrically conductive inks [22], through 2D-screen

printing [23], and through 3D-printing [24].Mechanical connectors such as snap buttons, crimp connections, crimp flat-pack,

socket buttons, bolt connection, ribbon cable connectors, and hook and loop have beenused for connecting electronics devices onto the surface of the textile fabric [14]. However,those forms of interconnection still suffer from incompatibilities including soft, flexible,pliable textile fabrics and rigid electronic components. This also has a significant impact onthe final design and properties of the textile fabric. Therefore, the integration of electronics

devices could be done without compromising the final design and characteristics of thetextile substrate.Surface mount device (SMD) components are now so small that they can be embedded in yarns with hardly a change in diameter. Goros and Weg [25] developed ahighly elastic tubular ring protective sleeve from small portable electronic devices. Inaddition, Horvath et al. [26] fabricated a pressure sensor barometer on a custom doublesided flexible and stretchable printed circuit board by using SMD and casting the assemblyin urethane rubber to obtain a sensing sleeve for use as a cardiac compression device.

Hardy et al. [27–29] presented integration methods of seven-strand copper electronic yarnembedded with semiconductor dies or micro electromechanical systems (MEMS).

The electrical characteristics of conductive yarns are an important design factor

that is influenced by the physical, electro-mechanical, and chemical properties of the

material [30,31]. Electrically conductive textile material manufactured from a conductive

yarn requires a perfect characterization for the design and manufacturing of safe and

consistently reliable products. Different researchers have studied the effects of physical and environmental factors

on the electrical conductivity of conductive yarn. For instance, the influence of Washington the electrical resistance of conductive yarns [32] and the electrical resistance of textile transmission lines after pre-treatment processes have been recently discussed. Mola [33],Liu et al. [34], and Sahin et al. [35] have studied the effect of laundry on the electrical conductivity of stitched surface mount e-textiles and fabrics for e-textile applications. The

analytical results found that the electrical conductivity of the base fabrics significantly affected the mechanical stress of laundry conditions. In addition, textile wet chemical processes caused a significant impact on the electrical resistance of conductive textile materials that were used as conductive track and transmission lines for the application of e-textile.

However, as mentioned above, the majority of these E-yarns were manufactured by using enameled copper conductive strands and these typically have highly rigid and coarse metallic yarn interconnections, which were the direct reason for their low durability in repeated deformation and unacceptable harsh handling of the resultant fabrics for clothing.

Moreover, to the best of the authors’ knowledge, there are no studies that examine both the effect of the physical-mechanical (gauge length, extension, and abrasion) and environmental factors (thermal, moisture, and chemical) on the electrical conductivity of both conductive

and E-yarns.

2. Materials and Methods

2.1. Materials

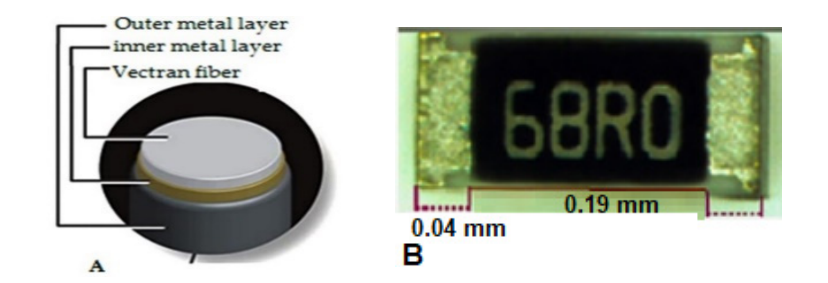

In this study, 15 Tex multifilament SCV (Liberator® 40) conductive yarn purchased from Syscom (1305 Kinnear Rd., Columbus, OH, USA) was used for the experiment [38]. According to the supplier information, the coated yarn was manufactured by coatingthe high-performance liquid-crystal polymer (polyester-polyacrylate fiber) with two thin

layers of silver, created by Kuraray Ltd., Japan, and marketed as silver-coated Vectran, Liberator. The properties of the Vectran conductive thread are shown in Table 1, and it scross-section is illustrated in Figure 1A. In addition, a Cermet resistor 68 W with 1% tolerance, 0.27 mm length with 0.04 mm solderable metallic terminal pads (Samsung ElectroMechanics RC2012F1820CS SMD 0805 resistor) was chosen as the electrical component to integrate with the yarn (Figure 1B). As solder paste, a carbon conductive paste was used(i.e., 847 solder series part number 473-1230-ND) from MG chemicals.

Figure 1. Silver coated Vectran (Liberator

®

40) (A), 68 W Cermet resistor SMD (B).

2.2. Methods

The methodological approach for this research comprised two phases. Initially, the development of SMD resistance embedded electronic yarn was performed. Thereafter, the

effects of factors on the electrical resistance of the E-yarn were studied based on the given experimental setup according to the international standard guidelines.

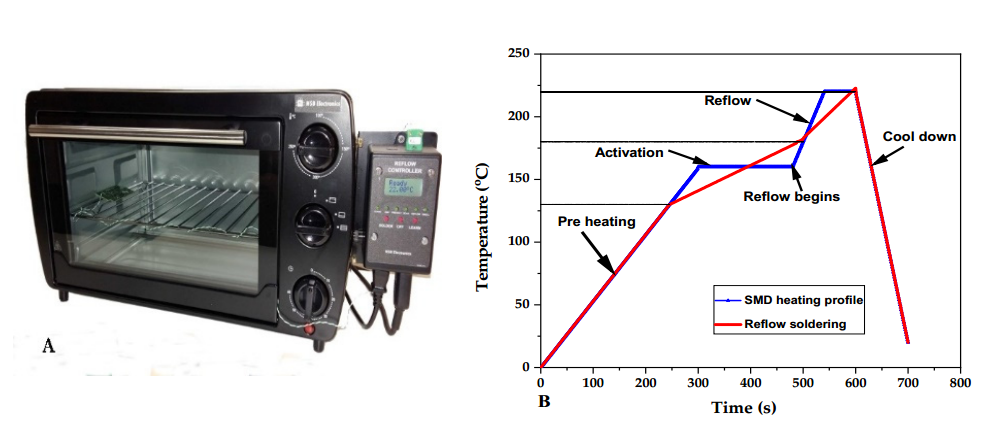

Development Process of Electronic yarn

The integration of the SMD resistor into SCV conductive yarn was performed using aBeta V3 PRO reflow temperature-controlled programmable machine (manufactured from Bay 98, Shannon Free Zone, Shannon, Co. Clare, Ireland). For connecting the SMD to the conductive yarn, a vapor phase reflow soldering method was used. This is a non-contact heating mechanism and constant heat circulation inside the area of application can be easily performed. The creation of a robust and efficient bond between the solder pads of the SMD resistor and SCV conductive yarn to form an interconnection is one of the key steps of the

integration process.

Figure 2.Developments of electronic yarn

Main steps followed during the electronic construction

1.Conductive yarn placement:

2.Solder paste printing:

3.Solder paste printing:

Figure 3.Bench top of the reflow oven (A), temperature profile of the reflow oven (B)

Figure 4. Electronic yarn

After constriction of the SMD resistor integration into electronic yarn, the physical and electromechanical characterization was done.

3. Results and Discussion

3.1. Electrical Conductivity

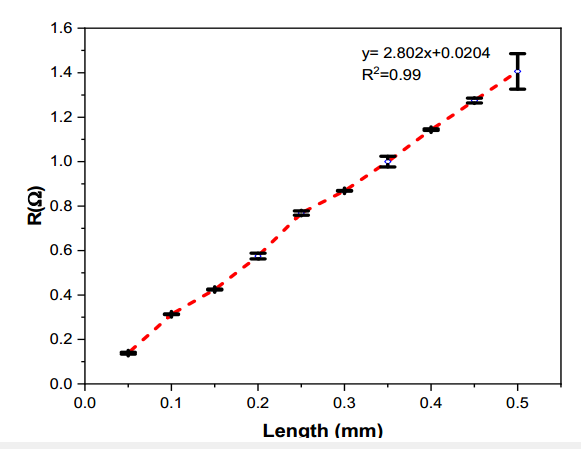

Figure 5. Dependence of electrical resistivity

The dependence of yarn resistance (R) on yarn gauge length for individual samples are shown in Figure 5. It proves that the electrical resistance increased with increasing

clamping gauge length as claimed in Ref. [41]. A nearly linear trend is visible, indicating the SCV conductive yarn has an appropriate uniform makeup with nearly constant resistance per unit length of 2.802 W/m.

3.2. Electrical Resistance under Strain and after Strain

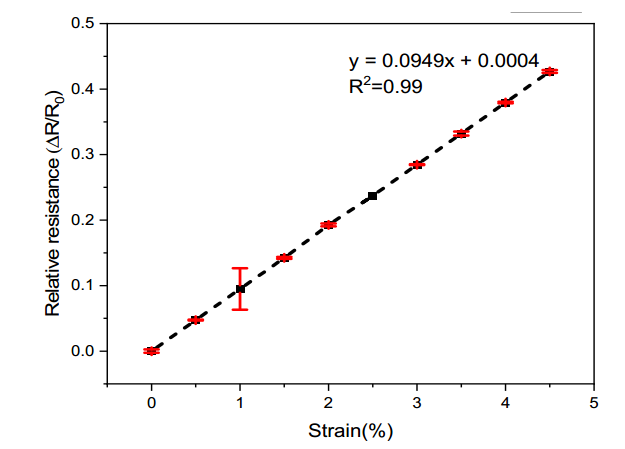

The electrical resistance of the SCV E-yarn after cyclic straining is displayed in Figure 6, which shows RCR at different levels of strain after stretch and relaxation of the SCV yarn. The fractional increment in resistance DR/R0 varied almost linearly with the applied strain (positive gauge factor).

Figure 6. Effects of strain on electrical resistance.

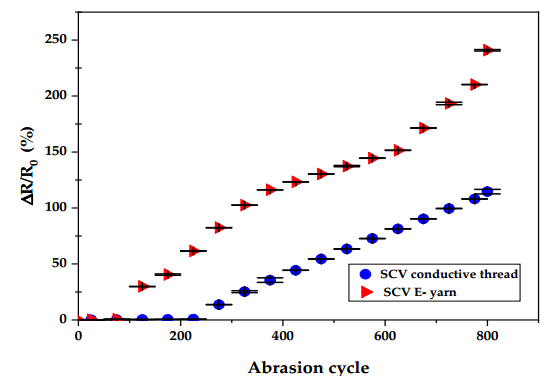

3.3. Effects of abrasion

Figure 7. effects of abrasion

Abrasion influences the electrical resistance of SCV conductive yarn and SCVE-yarn. The difference in electrical resistance before and after the yarn exposed to abrasion was highly significant (p < 0.001) as shown in Table 3. This is due to the formation of scratches and cracks in the outer metallic layer of the SCV conductive yarn. In addition, the mechanical stress during the abrasion may cause deformation of the conductive yarn surface, perhaps

causing a combined effect of creating projecting fibers (formation of protruding fiber) and breakage at the SCV filament fiber strands. .

The electrical resistance of the conductive yarn slowly increased at a magnitude of only0.71% before the 225-abrasion cycle. However, the resistance of the E-yarn was increased by 61.5% at 225- abrasion cycle. In addition, after the 800-abrasion cycle, the effects of mechanical abrasion were increased by a magnitude of 114.6% and 240.9% of the SCV conductive yarn and E-yarn respectively. The gradual increase in electrical resistance values shows that electrical resistance values often increase, meaning that the conductivity of the conductive yarns generally decreases after mechanical wear. This might be because of the

mechanical tensions that occurred during abrasion procedures. Furthermore, the SCV E-yarn started to deteriorate faster than the original SCV yarn due to extra damage that occurred at the solder pads. Therefore, the E-yarn could be covered by using a protective, insulating material such as encapsulation with thermoplastic polyurethane (TPU) or silicon encapsulation. These will protect the surface of the E-yarn from external harsh environments and the durability and performance will also increase.

3.4. Effects of Temperature

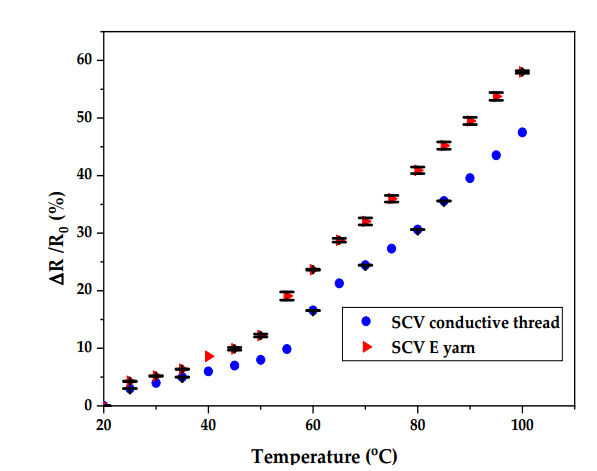

The effect of temperature variation on the electrical resistance of the SCV yarn and the E-yarn were investigated and the outcomes are shown in Figure 12. The change of electrical resistance with temperature was presented and detected at two different phases i.e., the temperatures below 50°C , and temperatures between 50°C to 100°C . In the first phase, at the beginning of the heating, the resistance of the conductive yarn was approximately constant, with the curve showing only a slight increase up to 50°C. After passing this critical temperature, the electrical resistance increased more quickly relative to beforehand.

Figure 8.Effects of temperature

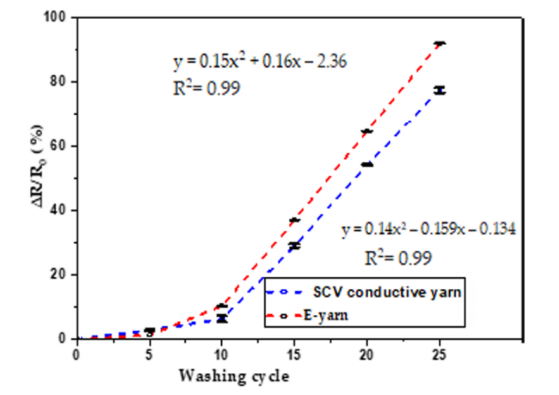

3.5. Effects of Washing

The effects of washing on electrical resistance percentage of SCV conductive yarn and SCV E-yarn are shown in Figure 13.

From Figure 9, it can be seen that starting from 0 to 10 washing cycle, the variation tendency of the washing cycle on electrical resistance of both the SCV conductive yarn and E-yarn was small. There was a small increase in electrical resistance for both samples after each washing cycle and their resistance increased by a magnitude of 6% for SCV conductive yarn and 10% for E-yarn before 10 wash cycles. The statistical result at alpha = 0.05 showed that electrical resistance increased slightly with each washing cycle and it was statically significant (p < 0.001). After 15 washing cycles, at alpha = 0.05, the statistical analysis confirmed that the dependent resistance on the washing cycle determined by ANOVA was highly significant (i.e., p < 0.001). Furthermore, washing might result in surface fractures on the SCV-conductive yarns as well as deformation along the SMD transmission lines. As a result of this, there would be an increase in electrical resistance or conductor line discontinuities.

After each washing cycle, the electrical resistance of all samples was increased [45].

Figure 9. Effects of washing

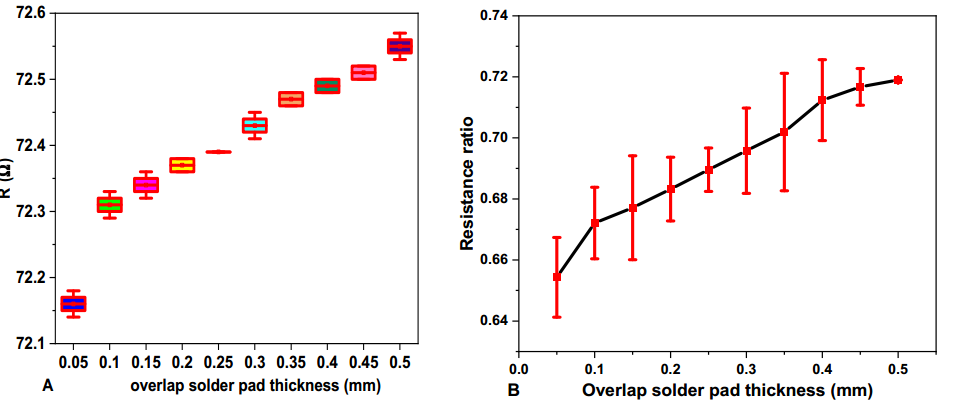

3.6. Effect of Solder Pad Overlap Thickness on Total Electrical Resistance of E-Yarn

The total electrical resistance of the E- yarn isa direct function of the resistance of left SCV-conductive yarn, left connector solder-pad resistance, and resistance of the SMD

resistor, right connector solder pad, and right SCV-conductive yarn. Therefore, the verage total resistance of E-yarn is 72.16 Ωper 0.31 m length. The resistance ratio RRwith one mm solder pad (connector) overlap length is66.58%. The effect of solder pad overlap size on the total resistance of the E-yarn and the resistance ratio are shown in Figure 10.

Figure 10.Effects of solder pad connector overlap thickness on the total resistance of E-yarn (A) and its resistance ratio (B).

4. Conclusions

In this research work, the method used for the integration of SMD into the SCV conductive yarn was vapor phase soldering methods for the application of smart textiles.

The integration of SMD resistors into the SCV conductive yarn was performed without damaging them. This integration method replaced other mechanical connectors such as snap buttons, crimp connections, crimp flat-pack, socket buttons, bolt connections, ribbon cable connectors, hook and loop, and conductive adhesives. The effect of yarn gauge length, cyclic strain, abrasion, temperature, washing, and solder-pad length on the electrical

resistance of SCV-conductive yarn and SMD resistor-embedded SCV E-yarn based on international testing standards were analyzed.

The application relevance and the advantage of resisting physical and external environmental factors was the reason for this research investigation. The integration of the SMD resistor into textile-conductive yarn helps to develop for the manufacturing of sensors, actuators, conductive tracks, and the fully functional wearable electronic textile.

It is evident that as the testing gauge length increased, the electrical resistance of conductive yarn increased. The resistance of conductive yarn also increased with strain

due to the elastic deformation SCV-conductive yarn, which led to an increase in length and increase in density of the conductive yarn. The analytical findings showed that at = 0.05, level, the effects of strain on the resistance of SCV conductive yarn and E-yarn were highly significant.

The effects of external factors such as mechanical abrasion, temperature, and washing environments on the electrical conductivity of E-yarn were also presented and the analytical outcomes indicated that the electrical resistance of both SCV-conductive yarn and E-yarn increased significantly with the increase in abrasion cycle, temperature, and washing cycle. Furthermore, the experimental results showed that the manufactured E-yarns were functional after 800 mechanical abrasion cycles and 25 washing cycles. In order to escape these challenges and to increase the durability and reliability of the SCV E-yarn, the overall structure could covered within TPU film or using silicon

encapsulation or by bridging by nonconductive adhesives and the coated silver conductive particle could firmly adhere to the yarn surface. All these protections should be efficient against mechanical stresses during mechanical abrasion, temperature, laundering, and mechanical strain, which had the biggest impact on the conductivity. In addition, the solder pad overlap thickness was directly influenced the electrical resistance of the SCV E-yarn.

References

1. Van Langenhove, L.; Hertleer, C. Smart clothing: A new life. Int. J. Cloth. Sci. Technol. 2004, 16, 63–72. [CrossRef]

2. Schwarz, A.; Van Langenhove, L.; Guermonprez, P.; Deguillemont, D. A roadmap on smart textiles. Text. Prog. 2010, 42, 99–180.

[CrossRef]

3. Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [CrossRef]

4. Tao, X. Wearable Electronics and Photonics; Woodhead Publishing Limited: Sawston, UK, 2005.

5. Rajan, K.; Garofalo, E.; Chiolerio, A. Wearable intrinsically soft, stretchable, flexible devices for memories and computing. Sensors

2018, 18, 367. [CrossRef] [PubMed]

6. Li, Q.; Wu, J.-T.; Liu, Y.; Qi, X.-M.; Jin, H.-G.; Yang, C.; Liu, J.; Li, G.-L.; He, Q.-G. Recent advances in black phosphorus-based

electrochemical sensors: A review. Anal. Chim. Acta 2021, 1170, 338480. [CrossRef]

7. Patel, P.C.; Vasavada, D.A.; Mankodi, H.R. Applications of electrically conductive yarns in technical textiles. In Proceedings of

the 2012 IEEE International Conference on Power System Technology (POWERCON), Auckland, New Zealand, 30 October–2

November 2012. [CrossRef]

8. Al-Azwani, I.K.; Aziz, H.A. Integration of Wearable Technologies into Patient’s Electronic Medical Records. Qual. Prim. Care 2016,

24, 151–155.

9. Gao, Y.; Li, H.; Luo, Y. An empirical study of wearable technology acceptance in healthcare. Ind. Manag. Data Syst. 2015, 115,

1704–1723. [CrossRef]

10. Bonato, P. Wearable sensors and systems. IEEE Eng. Med. Biol. Mag. 2010, 29, 25–36. [CrossRef]

11. Tappert, C.C.; Ruocco, A.S.; Langdorf, K.A.; Mabry, F.J.; Heineman, K.J.; Brick, T.A.; Cross, D.M.; Pellissier, S.V.; Kaste, R.C.

Military Applications of Wearable Computers and Augmented Reality. In Fundamentals of Wearable Computers and Augmented

Reality, 1st ed.; CRC Press: Boca Raton, FL, USA, 2001.

12. Shi, J.; Liu, S.; Zhang, L.; Yang, B.; Shu, L.; Yang, Y.; Ren, M.; Wang, Y.; Chen, J.; Chen, W.; et al. Smart Textile-Integrated

Microelectronic Systems for Wearable Applications. Adv. Mater. 2020, 32, e1901958. [CrossRef]

13. Lehn, D.I.; Neely, C.W.; Schoonover, K.; Martin, T.L.; Jones, M.T. Ettachments for e-Textiles. In Proceedings of the 7th IEEE

International Symposium, White Plains, NY, USA, 21–23 October 2003.

14. Simegnaw, A.A.; Malengier, B.; Rotich, G.; Tadesse, M.G.; Van Langenhove, L. Review on the integration of microelectronics for

e-textile. Materials 2021, 14, 5113. [CrossRef]

15. De Mulatier, S.; Nasreldin, M.; Delattre, R.; Ramuz, M.; Djenizian, T. Electronic Circuits Integration in Textiles for Data Processing

in Wearable Technologies. Adv. Mater. Technol. 2018, 3, 1700320. [CrossRef]

16. Nashed, M.; Hardy, D.A.; Hughes-riley, T. A Novel Method for Embedding Semiconductor Dies within Textile Yarn to Create

Electronic Textiles. Fibers 2019, 7, 12. [CrossR]

17. Bonderover, E.; Wagner, S. A woven inverter circuit for e-textile applications. IEEE Electron Device Lett. 2004, 25, 295–297.

[CrossRef]

18. Wang, Z.; Zhang, L.; Bayram, Y.; Volakis, J.L. Embroidered conductive fibers on polymer composite for conformal antennas. IEEE

Trans. Antennas Propag. 2012, 60, 4141–4147.

19. Linz, T.; Kallmayer, C.; Aschenbrenner, R.; Reichl, H. Embroidering electrical interconnects with conductive yarn for the

integration of flexible electronic modules into fabric. Proc.-Int. Symp. Wearable Comput. 2005, 2005, 86–89.

20. Darwish, S.M.; Al-Habdan, S.; Al-Tamimi, A. Knowledge-base for electronics soldering. J. Mater. Process. Technol. 2000, 97, 1–9.

[CrossRef]

21. Šahta, I.; Vališevskis, A.; Baltin ,

a, I.; Ozola, S. Development of Textile Based Sewn Switches for Smart Textile. Adv. Mater. Res.

2015, 1117, 235–238. [CrossRef]

22. Sancaktar, E.; Bai, L. Electrically Conductive Epoxy Adhesives. Polymers 2011, 3, 427–466. [CrossRef]

23. Paul, G.; Torah, R.; Beeby, S.; Tudor, J. The development of screen printed conductive networks on textiles for biopotential

monitoring applications. Sens. Actuators A Phys. 2014, 206, 35–41.

24. Wasserfall, F.; Ahlers, D.; Hendrich, N.; Zhang, J. 3D-Printable Electronics-Integration of SMD Placement and Wiring into the

Slicing Process for FDM Fabrication. In Proceedings of the 27th Annual International Solid Freeform Fabrication, Austion, TX,

USA, 8–10 August 2016; pp. 1826–1837.

25. Goros, J. Protective Sleve for Small Portable Elevtronic Devices. U.S. Patent 7555325B2, 30 June 2009.

26. Horvath, M.A.; Roche, E.T.; Vogt, D.M.; Mooney, D.J. Soft pressure sensing sleeve for direct cardiac compression device. In

Proceedings of the ASME 2015 International Design Engineering Technical Conferences & Computers and Information in

Engineering Conference (IDETC/CIE 2015), Boston, MA, USA, 2–5 August 2015; pp. 1–9.

27. Hardy, D.A.; Anastasopoulos, I.; Nashed, M.-N.; Oliveira, C.; Hughes-Riley, T.; Komolafe, A.; Tudor, J.; Torah, R.; Beeby, S.; Dias,

T. Automated insertion of package dies onto wire and into a textile yarn sheath. Microsyst. Technol. 2019, 2019, 1–9. [CrossRef]

28. Hardy, D.A.; Rahemtulla, Z.; Satharasinghe, A.; Shahidi, A.; Oliveira, C.; Anastasopoulos, I.; Nashed, M.N.; Kgatuke, M.;

Komolafe, A.; Torah, R.; et al. Wash testing of electronic yarn. Materials 2020, 13, 1228. [CrossRef] [PubMed]

29. Hardy, D.; Moneta, A.; Sakalyte, V.; Connolly, L.; Shahidi, A.; Hughes-Riley, T. Engineering a costume for performance using

illuminated LED-yarns. Fibers 2018, 6, 35. [CrossRef]

30. Li, L.; Li, G.; Cao, Y.; Duan, Y.Y. A novel highly durable carbon/silver/silver chloride composite electrode for high-definition

transcranial direct current stimulation. Nanomaterials 2021, 11, 1962. [CrossRef] [PubMed]

31. Hearle, J.W.S.; Morton, W.E. Physical Properties of Textile Fibres. J. Text. Inst. Proc. 1962, 53, P449–P464.

32. Varnaite, S.; Katunskis, J. Influence of washing on the electric charge decay of fabrics with conductive yarns. Fibres Text. East. Eur.

2009, 76, 69–75.

33. Patwary, S.U.; Lehew, M.L.A.; Connell, H.; Connell, H. Launderability of Stitched Surface-Mount E-Textiles. In International Textile

and Apparel Association; Iowa State University Digital Press: Ames, IA, USA, 2018; pp. 1–3.

34. Liu, W.; Shangguan, D.; Lee, J.C.B. Evaluation of Launderability of Electrically Conductive Fabrics for E-Textile Applications.

IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 763–769. [CrossRef]

35. Sahin, U.K. Effects of Home Laundering on Electrical Resistance of Signal Transmission Lines on Colored E-Textiles. J. Energy

Power Eng. 2017, 11, 336–344.

36. Bogan, K.; Seyam, A.F.M.; Slade, J. Evaluation of the electrical integrity of E-textiles subjected to abrasion. J. Text. Appar. Technol.

Manag. 2019, 11, 1–13.

37. Ding, J.T.F.; Tao, X.; Au, W.M.; Li, L. Temperature effect on the conductivity of knitted fabrics embedded with conducting yarns.

Text. Res. J. 2014, 84, 1849–1857. [CrossRef]

38. Properties of Liberator Conductive fiber. Available online: http://www.metalcladfibers.com/liberator (accessed on

15 December 2019).

39. ISO. ISO 2062:2009; Textiles Yarns from Packages. Determination of Single-End Breaking Force and Elongation at Break

Using Constant Rate of Extension (CRE) Tester. Available online: https://www.iso.org/standard/45642.html (accessed on

29 December 2021).

40. Monograph, A. Standardization of Home Laundry Test Conditions. In AATCC Technical Manual; AATCC: Research Triangle Park,

NC, USA, 2006; Volume 81, pp. 408–409.

41. Republic, C. A Study of Electrical Conductivity of Hybrid Yarns Containing Metal Fibers. J. Mater. Sci. Eng. 2012, 2, 197–202.

42. Knezi´c, Ž.; Penava, Ž.; Penava, D.Š.; Rogale, D. The Impact of Elongation on Change in Electrical Resistance of Electrically

Conductive Yarns Woven into Fabric. Materials 2021, 14, 3390. [CrossRef]

43. Tadesse, M.G.; Mengistie, D.A.; Chen, Y.; Wang, L.; Loghin, C.; Nierstrasz, V. Electrically conductive highly elastic

polyamide/lycra fabric treated with PEDOT:PSS and polyurethane. J. Mater. Sci. 2019, 54, 9591–9602. [CrossRef]

44. Hearle, J.W.S. The electrical resistance of textile materials: I. The influence of moisture content. J. Text. Inst. Trans. 1953, 44,

117–143. [CrossRef]

45. Tadesse, M.G.; Loghin, M.C.; Chen, Y.; Wang, L.; Catalin, D.; Nierstrasz, V. Effect of liquid immersion of PEDOT: PSS-coated

polyester fabric on surface resistance and wettability. Smart Mater. Struct. 2017, 26, 065016. [CrossR]

46. Stavrakis, A.K.; Simi´c, M.; Stojanovi´c, G.M. Electrical characterization of conductive threads for textile electronics. Electronics

2021, 10, 967. [CrossRef]

47. DiGiose, N. Power Management for Wearables: Make Friends with Your Battery; 2017; pp. 1–8. Available online:

https://www.powerelectronicsnews.com/power-management-for-wearables-make-friends-with-your-battery/ (accessed on

20 November 2021).

48. Bae, H.C.; Lee, H.; Choi, K.S.; Eom, Y.S. Fine-Pitch solder on pad process for microbump interconnection. ETRI J. 2013, 35,

1152–1155. [CrossRef].