Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Olive oil production in Mediterranean countries represents a crucial market, especially for Spain, Italy, and Greece. Waste generated from olive oil production processes can be divided into solid waste and olive mill wastewaters (OMWW).

- olive oil production

- olive mill

- wastewater remediation

- polyphenols

1. Introduction

Olive oil production is a fundamental sector for several European (EU) States, especially Spain, Italy, and Greece. In particular, Spain has the largest area of olive cultivation (estimated at ca. 2.47 million ha), followed by Italy (ca. 1.16) and Greece (about 0.81 million ha) [1][2]. However, olive oil production is responsible for several environmental concerns (soil contamination, underground seepage, water-body pollution, and odor emissions) due to poor waste management practices [3]. In this scenario, concerning olive mill wastewaters (OMWW), special attention must be paid to their high phenolic content, which is responsible for their antibacterial effect, phytotoxic effect, and dark colour.

Recently, phenols, fatty acids, and volatile acids have been recognized as potentially hazardous for environmental health: the former have pronounced antimicrobial and phytotoxic properties, whereas the latter show toxicity due to their long alkyl chain.

All these components make OMWW toxic to anaerobic bacteria, thus inhibiting conventional secondary and anaerobic treatments in municipal water plants. Furthermore, the high BOD (biological oxygen demand) and COD (chemical oxygen demand) levels, which cannot be reduced by anaerobic digestion, represent a further threat to receivers [2][4]. Moreover, land spreading and treatment in evaporation ponds could lead to problems related to groundwater pollution. The use of olive oil waste in agriculture may also affect the acidity, salinity, N immobilization, microbial response, leaching of nutrients, and concentration of lipids, organic acids, and phenolic compounds [5].

Alternative approaches based on physical treatments, such as dilution, evaporation, centrifugation, or sedimentation guarantee a high level of OMWW purification. However, they are expensive and energy-consuming, thus leading to an exponential increase in the processing cost. The olive oil industry, in its current status, composed of small and dispersed factories, cannot bear such high costs [6][7][8][9][10][11][12][13].

In recent years, advanced oxidation processes (AOPs), including photolysis, photo-oxidation, Fenton, and photo-Fenton reaction, have emerged as promising alternatives for simplicity and high organic removal efficiencies [14][15][16][17][18][19][20]. In particular, heterogeneous photocatalysis seems to be a successful technology in water decontamination due to its non-toxicity, low cost, and mineralization efficacy. However, due to the OMWW matrices’ complexity, it is not easy to develop and successively optimize efficient photocatalytic systems that are so far characterized by common limitations (i.e., difficult recovery, poor stability, low reusability, fast deactivation).

2. An Insight into the EU Legislation

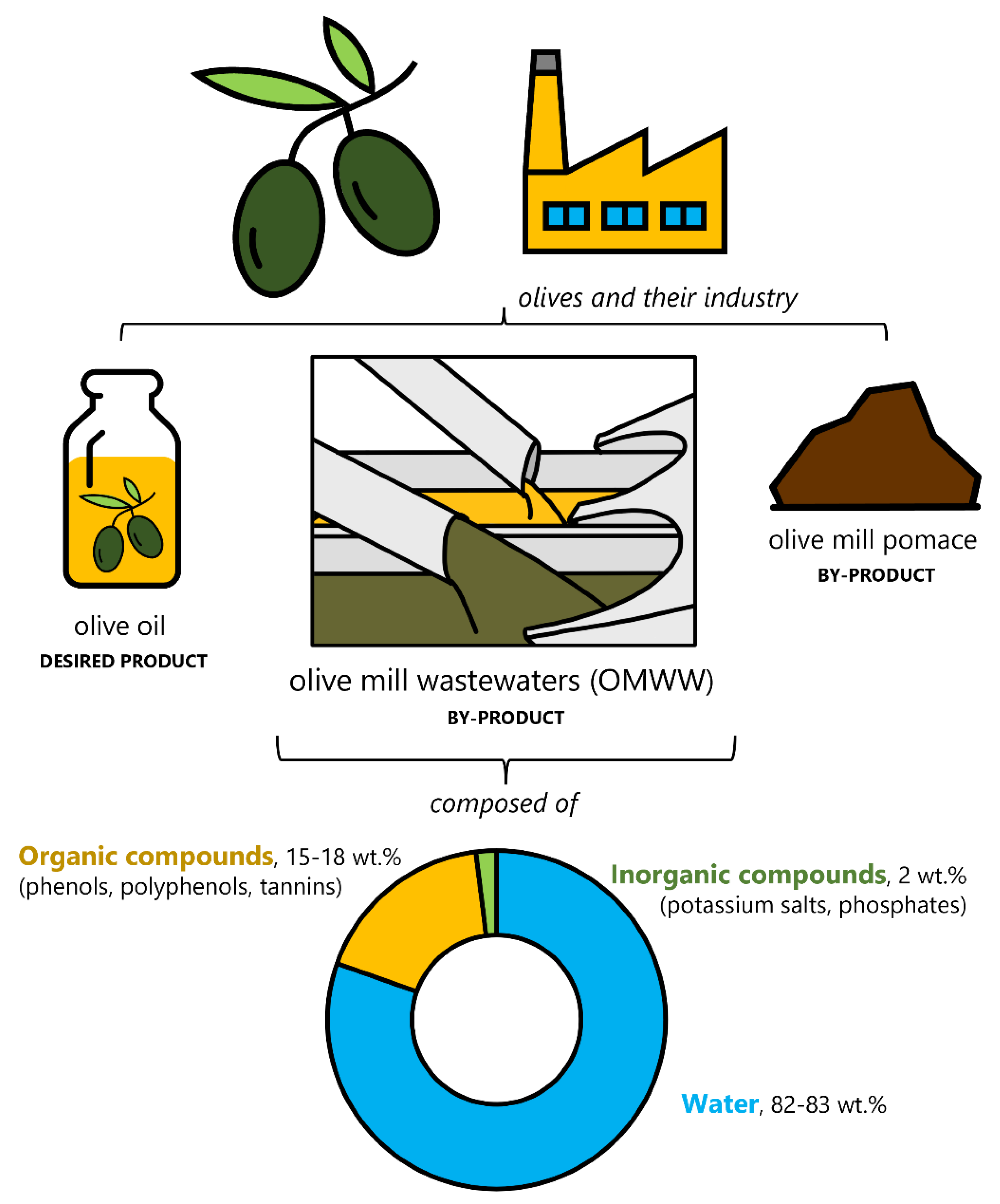

Olive oil is the desired product of the olives industry. Unfortunately, olive mill pomace and wastewater represent undesired by-products, requiring proper disposal treatments because of their complex composition (Figure 1).

Figure 1. Scheme of products and by-products from the olive oil industry.

The present work aims at discussing only the production and treatment of OMWW. OMWW composition is influenced by different factors, i.e., extraction methods, olives’ type and origin, climate conditions, and cultivation/processing practices [21]. In general, it can be mainly summarized as follows (Figure 1): ca. 80–83 wt.% consists of water, ca. 15–18 wt.% relates to organic compounds (mainly polyphenols, phenols, and tannins), and the remaining 2 wt.% contains inorganic matter (i.e., potassium salts and phosphates). Specifically, phenols levels in OMWW range from 1 to 8 g·L−1, whereas micronutrients and mineral nutrients mainly consist of K2O, and P2O5, which can be found in considerable amounts (2.4–10.8 or 0.3–1.5 g·L−1 intervals, respectively) [2]. Thus, it is critical to design efficient treatment methods, aligned to precise legislative constraints, whose general panorama is described below.

Concerning the processing of olive residues, the reform of standard agricultural policy related to olive oil does not provide specific provisions for their management [1]. It should be noted that a significant part of EU legislation acts according to Directives. These latter are legislative acts, setting objectives that all EU countries must reach and translate into their national legislation. This means that the member Countries have to adopt and impose complementary measures that should be compliant with the EU directives.

Following this scenario, an example is setting the emission limits and environmental quality standards. Of course, every Country can adopt laws and regulations that can be very different compared to others. Still, in the end, international norms are necessary for a common strategy to manage olive waste. In general, EU legislation governs each member state’s framework of national legislation. Several EU laws regulate waste management, and the Waste Framework Directive, WFD (2008/98/EC), acts as core legislation, including hazardous waste and oil rules [22]. In addition, Landfill Directive 99/31/EC regulates landfill disposal [23]. In this case, the waste producer, such as the olive mill operator, is responsible for managing wastes up to their recovery and disposal [24].

Here, the crucial point is to classify wastewaters as waste or by-products. If they are considered by-products, their further use as fertilizers with few restrictions is strongly recommended [25]. In this context, the EC Directive 2008/98 (point 22) clarifies the necessity to discriminate well between “waste” and “by-product”, but unfortunately, considerable confusion is still present [22]. So, in many cases, law courts have to solve specific issues. To summarize, no EU legislation related to the management of OMWW exists today, and each EU country sets precise standard parameters.

3. Emerging Innovative Approaches for Olive Oil Production

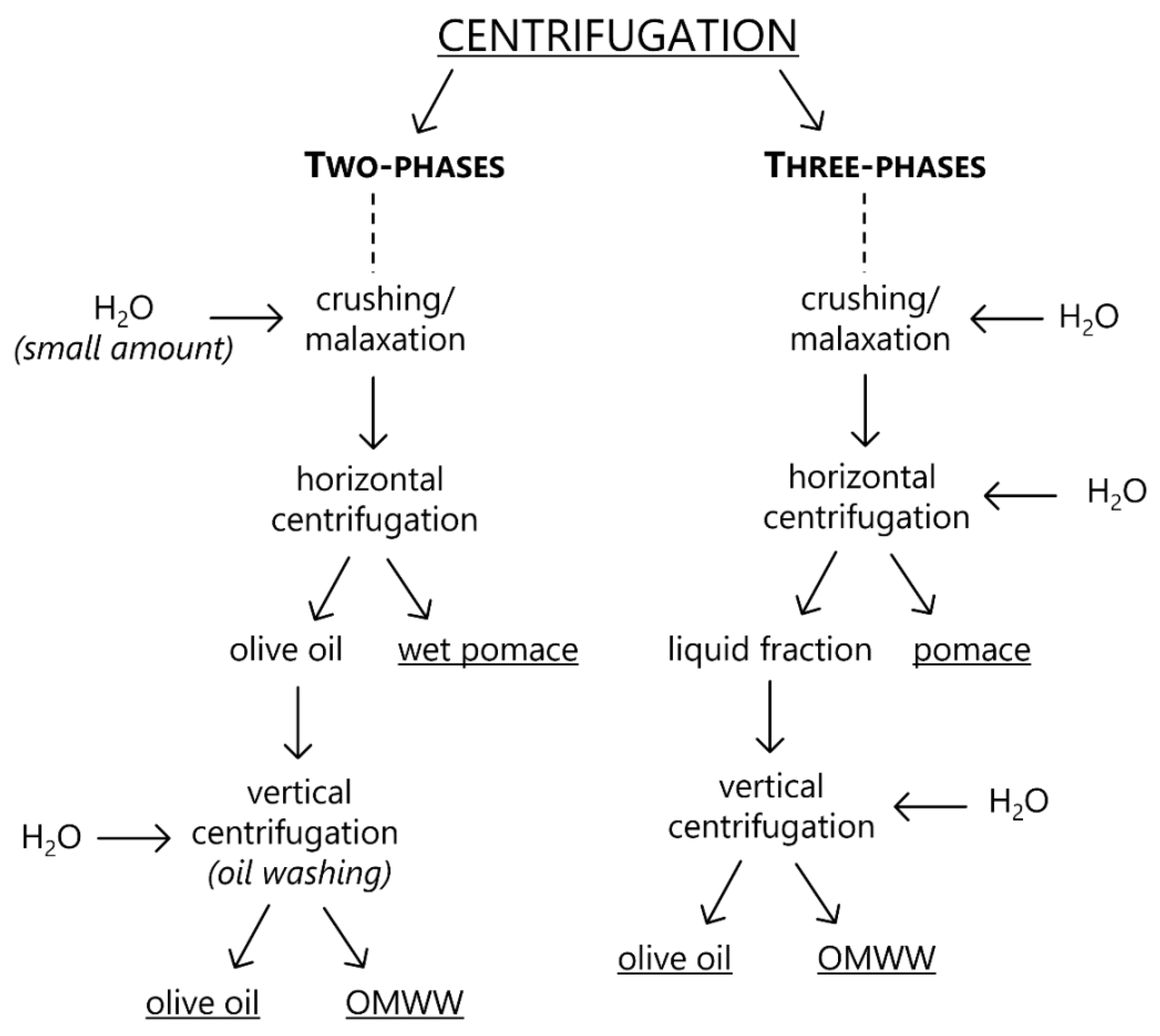

Conventional techniques in olive oil extraction have not significantly changed in the last 25 years. Three main steps can be identified (Figure 2): crushing and malaxation, which mainly affect the oil quality and yield, and centrifugation [26][27].

Figure 2. Scheme of olive oil production.

At first, stems, twigs, and leaves are separated from olive fruits [28]. These latter are then washed in a proper plant to remove dust, dirt, etc. In some plants, the washing water is recycled for the process after solid sedimentation or filtration, whereas in other cases, olives are directly processed without the washing step [29]. The next step involves malaxation: olives are ground up, mixed with/without their stones, and put in tanks, where the paste is divided into vegetation waters, pomace, and oil. Pomace, a brown-colored residue, is obtained by centrifugation and sedimentation after pressing olives [30][31]. Pomace mainly consists of skin pulp and pit fragments. Its separation is carried out using a horizontal decanter centrifuge and an olive oil press. The centrifuge step can be performed in two- or three-phases (Figure 3).

Figure 3. Scheme of two-phases and three-phases centrifugation strategies.

In the former case, wet pomace (also known as two-phase olive mill waste, TPOMW) and olive oil are obtained by horizontal centrifugation. Then, the obtained oil is centrifuged with water, producing olive oil and a small stream of OMWW [32][33]. In the latter, the olive paste is divided into pomace and a liquid fraction (olive oil plus OMWW), which is centrifuged with water to obtain high-quality olive oil and OMWW [32][33].

However, given the ever more urgent market demand, interesting novel methods characterized by minimal processing are currently the object of study. These approaches aim to obtain a final product with the same nutritional qualities in less time. In this context, numerous solutions, including the use of microwave, high-pressure processing, pulsed light, radio frequency, Ohmic heating, ultrasound, and pulsed electric field (PEF), have been investigated thanks to their advantages (enhanced extraction efficiency in reduced time with increased yield, and low energy consumption) [26][34][35][36][37].

Among them, ultrasound emerged as a powerful technology widely used in several extraction processes [37][38] and food processing methods (i.e., emulsification, filtration, crystallization, enzymes’ and microorganisms’ inactivation, thawing) [39][40]. Ultrasound can be applied to the olive paste to induce oil release from vacuoles in lower malaxation time. It has been demonstrated that high oil quality and yield are obtained [36][41][42][43][44][45].

Pulsed electric field (PEF) technology, used mainly in food science since 1960, consists of exposing food products (solid or liquid) to an electric field, inducing pore formation in cell membranes [46]. Recently, it has demonstrated its efficiency in reversible or irreversible permeabilization of cell membranes in different plants without causing significant temperature increase [34]. The possibility of maintaining low operating temperatures during the oil extraction process represents a valuable goal, as it allows the preservation of the product’s organoleptic and nutritional characteristics.

An alternative to the two previous processes is microwave-assisted extraction (MAE), which represents a more efficient and successful strategy than the conventional ones because microwaves provide rapid heating and biological cell structure destruction. As a result, it leads to high-quality products with shallow energy requirements, inducing reduced environmental impact and financial costs [47].

Recently, emphasis has been placed on obtaining an increased Extra Virgin Olive Oil (EVOO) quality, preserving its sensory characteristic and favorable health properties. The quality of the EVOO strongly depends on the presence of phenolic and volatile compounds [43][44]. So, the development of emerging technologies to increase the oil yield while protecting and improving the bioactive oil compounds and quality is of fundamental importance.

This entry is adapted from the peer-reviewed paper 10.3390/catal12080923

References

- Ducom, G.; Gautier, M.; Pietraccini, M.; Tagutchou, J.P.; Lebouil, D.; Gourdon, M. Comparative analyses of three olive mill solid residues from different countries and processes for energy recovery by gasification. Renew. Energy 2020, 145, 180–189.

- Inglezakis, V.J.; Moreno, J.L.; Doula, M. Olive oil waste management EU Legislation: Current situation and policy recommendations. Int. J. Chem. Environ. Eng. Syst. 2012, 3, 65–77.

- Mercé Sole, M.; Pons, L.; Conde, M.; Gaidau, C.; Baccardit, A. Characterization of Wet Olive Pomace Waste as Bio Based Resource for Leather Tanning. Materials 2021, 14, 5790.

- Kapellakis, I.E.; Tsagarakis, K.P.; Crowther, J.C. Olive oil history, production and by-product management. Rev. Environ. Sci. Bio/Technol. 2008, 7, 1–26.

- Azaizeh, H.; Abu Tayeh, H.N.; Gerchman, Y. Chapter 2: Valorisation of olive oil indus-try solid waste and production of ethanol and high value-added biomolecules. In Biovalorisation of Wastes to Renewable Chemicals and Biofuels; Elsevier: Amsterdam, The Netherlands, 2019; pp. 27–40. ISBN 9780128179512.

- Paredes, C.; Cegarra, J.; Roig, A.; Sanchez-Monedero, M.A.; Bernal, M.P. Characterisation of olive mill wastewater (alpechin) and its sludge for agricultural purposes. Bioresour. Technol. 1999, 67, 111–115.

- Paraskeva, P.; Diamadopoulos, E. Technologies for olive mill wastewater (OMW) treatment: A review. J. Chem. Technol. Biotechnol. 2006, 81, 1475–1485.

- Potoglou, D.; Kouzeli-Katsiri, A.; Haralambopoulos, D. Solar distillation of olive mill wastewater. Renew. Energy 2004, 29, 569–579.

- Niaounakis, M.; Halvadakis, C.P. Olive-Mill Waste Management—Literature Review and Patent Survey; Typothito-George Dardanos: Athens, Greece, 2004.

- Caputo, A.C.; Scacchia, F.; Pelagagge, P.M. Disposal of byproducts in olive oil industry: Waste-to-energy solutions. Appl. Therm. Eng. 2003, 23, 197–214.

- Al-Malah, K.; Azzam, M.O.J.; Abulail, N.I. Olive mills effluent (OME) wastewater post-treatment using activated clay. Sep. Purif. Technol. 2000, 20, 225–234.

- Azzam, M.O.J.; Al-Malah, K.I.; Abu-Lail, N.I. Dynamic posttreatment response of olive mill effluent wastewater using activated carbon. J. Environ. Sci. Health A 2004, 39, 269–280.

- Arvaniti, E.C.; Zagklis, D.P.; Papadakis, V.G.; Paraskeva, C.A. High-added value materials production from OMW: A technical and economical optimization. Int. J. Chem. Eng. 2012, 2012, 607219.

- Djellabi, R.; Giannantonio, R.; Falletta, E.; Bianchi, C.L. SWOT analysis of photocatalytic materials towards large scale environmental remediation. Curr. Opin. Chem. Eng. 2021, 33, 100696.

- Galloni, M.G.; Cerrato, G.; Giordana, A.; Falletta, E.; Bianchi, C.L. Sustainable Solar Light Photodegradation of Diclofenac by Nano- and Micro-Sized SrTiO3. Catalysts 2022, 12, 804.

- Lucas, M.S.; Peres, J.A. Removal of COD from olive mill wastewater by Fenton’s reagent: Kinetic study. J. Hazard. Mater. 2009, 168, 1253–1259.

- Stoller, M.; Bravi, M. Critical flux analyses on differently pretreated olive vegetation wastewater streams: Some case studies. Desalination 2010, 250, 578–582.

- Papaphilippou, P.C.; Yiannapas, C.; Politi, M.; Daskalaki, V.M.; Michael, C.; Kalogerakis, N.; Mantzavinos, D.; Fatta-Kassinos, D. Sequential coagulation–flocculation, solvent extraction and photo-Fenton oxidation for the valorization and treatment of olive mill effluent. Chem. Eng. J. 2013, 224, 82–88.

- Aziz, K.H.H.; Omer, K.M.; Mahyar, A.; Miessner, H.; Mueller, S.; Moeller, D. Applica-tion of Photocatalytic Falling Film Reactor to Elucidate the Degradation Pathways of Pharmaceutical Diclofenac and Ibuprofen in Aqueous Solutions. Coatings 2019, 9, 465.

- Aziz, K.H.H. Application of different advanced oxidation processes for the removal of chloroacetic acids using a planar falling film reactor. Chemosphere 2019, 228, 377–383.

- Podgornik, M.; Bucar-Miklavcic, M.; Levart, A.; Salobir, J.; Rezar, V.; Butinar, B. Chemical Characteristics of Two-Phase Olive-Mill Waste and Evaluation of Their Direct Soil Application in Humid Mediterranean Regions. Agronomy 2022, 12, 1621.

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed on 15 July 2022).

- Council Directive 1999/31/EC on the Landfill of Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:01999L0031-20180704&from=FI (accessed on 10 July 2022).

- Taccogna, G. The Legal Regime of Olive Pomace Deriving from Olive Oil Extraction at Olive Mills, Waste, By-Products and Biomass; On behalf of ARE S.p.A. Agenzia regionale per l’energia della Liguria, member of the community project: “MORE: Market of Olive Residues for Energy”; Department of Public and Procedural Law, University of Genoa: Genoa, Italy, 2010.

- EC-DG. Survey of Wastes Spread on Land, Final Report, European Commission, Directorate-General for Environment. 2001. Available online: https://ec.europa.eu/environment/pdf/waste/compost/econanalysis_finalreport.pdf (accessed on 30 June 2022).

- Aydar, A.Y.; Bagdatlioglu, N.; Köseoglu, O. Effect of ultrasound on olive oil extraction and optimization of ultrasound-assisted extraction of extra virgin olive oil by response surface methodology (RSM). Grasas Aceites 2017, 68, e189.

- Arvanitoyannis, I.S.; Kassaveti, A.; Stefanatos, S. Olive Oil Waste Treatment: A Comparative and Critical Presentation of Methods, Advantages & Disadvantages. Crit. Rev. Food Sci. Nutr. 2007, 47, 187–229.

- Facts and Definitions: The Olive Oil Source. Available online: http://www.oliveoilsource.com/millandpressfacts.htm (accessed on 25 June 2022).

- Olive Oil Waste Treatment. Available online: http://www.ucm.es/info/improliv/allgem.htm (accessed on 25 June 2022).

- Dakhli, R.D. Agronomic Application of Olive Mill Waste Water: Short-Term Effect on Soil Chemical Properties and Barley Performance Under Semiarid Mediterranean Conditions. EQA-Int. J. Environ. Qual. 2018, 27, 1–17.

- Fedeli, E.; Camurati, F. Valorisation des margines et des grignons´epuises par recuperation de quelques composants. In Proceedings of the Seminaire International sur la Valorisation des Sous-Produits de L’olivier PNUD/FAO/COI, Monastir, Tunisia, 15–17 December 1981.

- Rocha, C.; Soria, M.A.; Madeira, L.M. Olive Mill Wastewater Valorization through Steam Reforming Using Multifunctional Reactors: Challenges of the Process Intensification. Energies 2022, 15, 920.

- Production of Olive Oil. Available online: http://www.oliveoilsource.com/millandpressfacts3.htm (accessed on 26 June 2022).

- Abenoza, M.; Benito, M.; Saldaña, G.; Alvarez, I.; Raso, J.; Sanchez-Gimeno, A.C. Effects of pulsed electric field on yield extrac-tion and quality of olive oil. Food Bioprocess Technol. 2013, 6, 1367–1373.

- Puértolas, E.; Martínez de Marañón, I. Olive oil pilot-production assisted by pulsed electric field: Impact on extraction yield, chemical parameters and sensory properties. Food Chem. 2015, 167, 497–502.

- Clodoveo, M.L.; Durante, V.; La Notte, D. Working towards the development of innovative ultrasound equipment for the extraction of virgin olive oil. Ultrason. Sonochem. 2013, 20, 1261–1270.

- Aydar, A.Y. Utilization of Response Surface Methodology in Optimization of Extraction of Plant Materials; Intech Open: London, UK, 2018; pp. 157–169.

- Meroni, D.; Djellabi, R.; Ashokkumar, M.; Bianchi, C.L.; Boffito, D.C. Sonoprocessing: From Concepts to Large-Scale Reactors. Chem. Rev. 2022, 122, 3219–3258.

- Bermúdez-Aguirre, D.; Mobbs, T.; Barbosa-cánovas, G.V. Ultrasound Technologies for Food and Bioprocessing; Epub ahead of print; Springer: Berlin/Heidelberg, Germany, 2011.

- Chemat, F.; Zill-E-Huma, R.; Khan, M.K. Applications of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 2011, 18, 813–835.

- Veneziani, G.; Sordini, B.; Taticchi, A.; Esposto, S.; Selvaggini, R.; Urbani, S.; Di Maio, I.; Servili, M. Improvement of Olive Oil Mechanical Extraction: New Technologies, Process Efficiency, and Extra Virgin Olive Oil Quality. In Products from Olive Tree Dimitrios Boskou and Maria Lisa Clodoveo; Intech Open: London, UK, 2016; Available online: https://www.intechopen.com/books/products-from-olive-tree/improvement-of-olive-oil-mechanicalextraction-new-technologies-processefficiency-and-extra-virgin (accessed on 20 June 2022).

- Clodoveo, M.L. An overview of emerging techniques in virgin olive oil extraction process: Strategies in the development of innovative plants. J. Agric. Eng. 2013, 44, 49–59.

- Clodoveo, M.L. New advances in the development of innovative virgin olive oil extraction plants: Looking back to see the future. Food Res. Int. 2013, 54, 726–729.

- Clodoveo, M.L.; Hachicha Hbaieb, R. Beyond the traditional virgin olive oil extraction systems: Searching innovative and sustainable plant engineering solutions. Food Res. Int. 2013, 54, 1926–1933.

- Clodoveo, M.L.; Camposeo, S.; Amirante, R.; Dugo, G.; Cicero, N.; Boskou, D. Research and Innovative Ap-proaches to Obtain Virgin Olive Oils with a Higher Level of Bioactive Constituents. Olive Olive Oil Bioact. Const. 2015, 7, 179–215.

- Sun, D.W. Emerging Technologies for Food Processing, 2nd ed.; Elsevier Inc.: Dublin, Ireland, 2014.

- Çavdar, H.K.; Yanık, D.K.; Gök, U.; Gogus, F. Optimisation of microwave-assisted extraction of pomegranate (Punica granatum L.) seed oil and evaluation of Its physicochemical and bioactive properties. Food Technol. Biotechnol. 2017, 55, 86–94.

This entry is offline, you can click here to edit this entry!