Ethylene-propylene-diene rubbers (EPDM) are one of the most important polyolefin materials widely commercialized and used in various industries in recent years. The production of EPDM is based solely on catalytic coordination polymerization processes. The development of new catalysts and processes for the synthesis of EPDM has expanded the range of products and their manufacturing in terms of energy efficiency, processability, and environmental safety.

- single-site catalyst

- ethylene

- propylene

- diene

- EPDM

- rubber

1. Introduction

| EPDM Manufacturer |

Polymer Grade | Ethylene Content, wt% | Diene (ENB) Content, wt% | Mooney Viscosity ML1+4(125 °C) 1 |

Polymer Structures | Ref. |

|---|---|---|---|---|---|---|

| ARLANXEO | Keltan® | 44–71 | 0–11.0 | 22–92 | LCB 2, ND 3, MD 4, BD 5 |

[8] |

| DOW Elastomers | NordelTM | 50–85 | 0–8.5 | 18–85 | ND, MD, BD | [9] |

| ExxonMobil | VistalonTM | 54–77 | 0–10.0 | 16–82 | LCB, ND, MD, BD |

[10] |

| Mitsui Chemical | Mitsui EPTTM | 41–72 | 0–14.0 | 40–78 | LCB, ND, MD, BD |

[11] |

| KumhoPolychem | KEP® | 55–71 | 0–10.0 | 23–95 | No data | [12] |

1 Mooney viscosity is the routine industry standard correlated with molecular weight of EPDM. High Mooney viscosities are preferred. Abbreviation according to ASTM D1646 is ML 1+4 (125 °C), where M—Mooney units, L—large rotor, 1—the sample preheat time (min), 4—the sample test time (min) at 125 °C. 2 Long Chain Branching. 3 Narrow molecular weight distribution.4 Medium molecular weight distribution. 5 Broad molecular weight distribution.

2. Single-site catalysts

2.1 Metallocene Catalysts

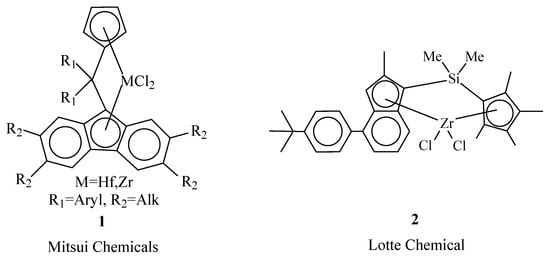

Promising for producing EPDM are two types of complexes: metallocenes of Cs symmetry [4-8] and zirconocenes of C1 symmetry [9]. The capabilities of Cs symmetry catalysts in the synthesis of EPDM can be demonstrated by the patent data of Mitsui Chemicals [16,17,18,19,20]. They claim a new effective class of hafnocene and zirconocene complexes of type 1 (Figure 1) containing different substituents in both the bridging group and the peripheral positions of the Flu ligand. When activated with CPh3B(C6F5)4 (4 and 10 equiv.), the complexes effectively provide ternary copolymerization of E/P/ENB at 80–120 °C. Hafnocenes 1 ensure the incorporation of ENB at a level of 7–11 wt% and form elastomers with high molecular weights (Mw = 1000–2000 kDa) [16,17,18]. The compounds with R1 = 4-MePh, 4-MeOPh, 4-Me2NPh and R2 = Me show the highest activity up to a 10,000–20,000 kg copolymer/(molHf h atm)). Zirconocenes 1 show high efficiency in the synthesis of well-vulcanizing VNB terpolymers with a low degree of branching [19]. Such copolymers cannot be obtained by using conventional vanadium and other metallocene systems. The content of VNB in this EPDM reaches 10 wt%. The molecular weights range from 50 to 600 kDa.

2.2. “Constrained” Geometry Complexes

Special attention in the synthesis of EPDM is paid to bridged monocyclopentadienyl complexes, the so-called “constrained” geometry complexes (CGCs). CGCs contain h5-Cp-ligand linked by a bridging group with a donor ligand (Don). The bridging group reduces the Cp–M–Don angle by approximately 20–30°as compared to Cp–M–Cp, which ensures high availability of a transition metal in the active site and, thus, a high degree of comonomer incorporation [21-23]. The donor is linked to the transition metal by a s-bond and ensures high stability of catalysts of this type at elevated temperatures (up to 160–180 °C).Variations in any part of the CGC ligands as well as the type of transition metal affect catalytic properties of the complexes, such as activity, the ability to insert comonomer(s), and molecular weight characteristics of the resulting polymers.

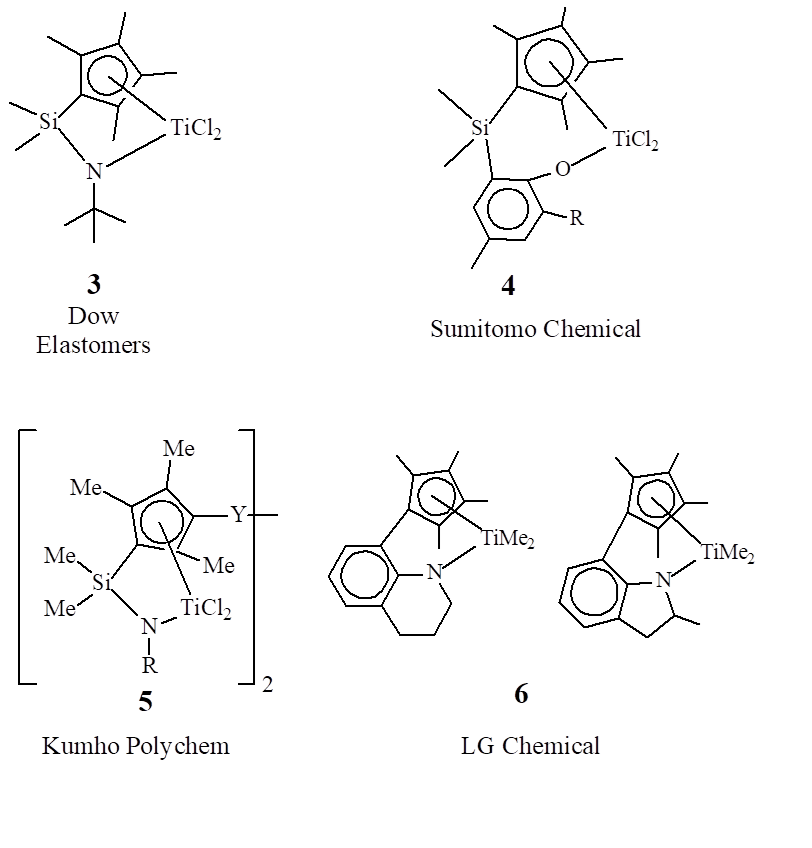

CGCs 3(Figure 2) were commercialized by DOW in the mid of the 1990s for homogeneous polymerization processes used for production of linear low-density polyethylene [23-26]. Complexes of this type are also effective for the synthesis of EPDM [25,26], which allowed DOW to launch a wide range of elastomers (NordelTM IP). CGCs provide production of EPDM with a wide range of Mw (up to 500 kDa), composition (up to 50 wt% ofpropylene and 7.5 wt% ofENB), and the Mooney viscosity (ML1+4(125°C)=18–85).

Figure 2. Chemical structures of CGCs 3-6.

In recent years, one can note increasing interest to catalysts of this type from several leading EPDM manufacturers. From the late 1990s to the present, active developments in the field of CGC molecular design have been carried out at Sumitomo Chemical, KumhoPolychem, and LG Chem, which have made it possible to significantly expand the range of promising catalysts for the synthesis of EPDM [27-34].

2.3 Half-Sandwich Titanium Complexes

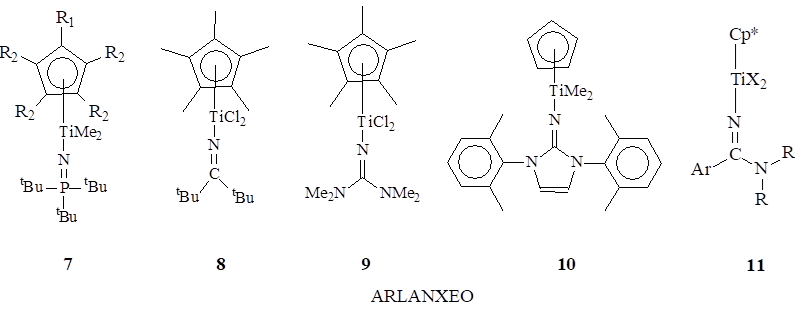

Another promising class of catalysts for the synthesis of EPDM are half-sandwich titanocenes 7–11(Figure 3) containing N-donor ligands [35-52]. Catalysts are included in the new technology was called Keltan Advanced Catalyst Elastomer (Keltan ACE™)

Keltan ACETM catalysts are characterized by high catalytic activity (up to 1200 tons copolymer/(molTi h)) in ternary copolymerization of olefins and dienes and make it possible to obtain copolymers with a high content of dienes (up to 15 wt% of ENB, 5 wt% ofVNB and 20 wt% ofDCPD). Most of these catalysts are stable in copolymerization processes at temperatures up to 120°C and form copolymers with high Mw values up to 2000 kDa. A variety of developed complexes of this type makes it possible to obtain EPDM with a wide range of properties [40-52].

On the basis of Keltan ACE™ technology, large-scale production of EPDM has been organized at the plants in Geleen, Netherlands, and Changzhou, China, each with listed annual capacity of 160000 tons, along with 40000 tons per year in Triunfo, Brazil [39,54,55].

Figure3. Chemical structures of half-sandwich titanium complexes 7-11.

2.4 Post-MetalloceneChelate Catalysts

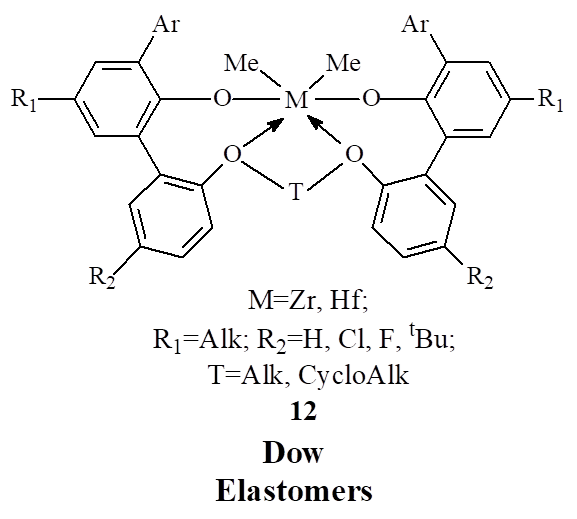

The most promising catalysts of this class for the synthesis of EPDM are aryloxyether12 complexes of hafnium and zirconium (Figure 4). The compounds were discovered using the approaches of Combinatorial Chemistry and High-Throughput Screening [56-60] and have been actively developed by Dow Elastomers for the last 15 years [25,61-75].

Figure 4. Chemical structures of aryloxyether12 complexes.

Aryloxyethercomplexes 12 have the most unique catalytic characteristics and by sum of properties surpass many known classes of catalysts for the production of EPDM [25,61–68]. The advantages of the catalysts are the ability to be effectively activated by low molar amounts of the activator (AlMAO/M=10-200, Bborate/M up to 5 mol/mol), and high activity in copolymerization processes in high-temperature solution polymerization conditions (120-180°C). The advantage of a high-temperature process carried out in the solution polymerization (the polymer is soluble in the reaction medium) is the formation of amorphous copolymers with broad molecular weight distribution. A feature of these systems is also their ability to form copolymers with high molecular weights (Mw=100-1000 kDa) and low content of gel fraction [25]. Such catalysts were used to obtainrubbers with a high content of propylene (up to 50 wt%) and dienecomonomers of various types (ENB, VNB, DCPD, etc., up to 16 wt%). Aryloxyether complexes are the basis of highly efficient Advanced Molecular Catalyst technology (AMC) developed in 2015 for obtaining new NordelTM rubber grades with improved properties [25]. Based on this technology, a plant with annual capacity of 200 thousand tons of EPDM was launched in Plakimin (USA) in 2018 [69].

- Conclusions

In conclusion, it should be noted that despite the fact that EPDM have being produced by the industry for more than 50 years, there is a high potentialin both improving the technologies for the synthesis of EPDM and expanding the range of their grades. This potential is ensured by the development of new-generation catalytic systems based on Group IVB complexes, which are alternatives to low-activity, unstable, and toxic vanadium catalysts. In particular, this is evidenced by high research activity over the past 10–15 years of the world’s leading manufacturers of EPDM in the development of new systems and their active commercialization. The main advantage of modern systems compared to vanadium ones is their environmental safety, higher activity, and thermal stability, with the possibility of producing EPDM with different contents of comonomers and microstructures, including highly branched and bimodal terpolymers. The use of these catalytic systems has already made it possible to bring to market new grades of EPDM with a wide range of properties (for example, Keltan® (ARLANXEO), NordelTM IP (Dow Elastomers), VistalonTM (Exxon), Mitsui EPTTM (Mitsui), etc.).

The huge potential for tuning the structures of catalytic systems allows us to count on the further creation of new efficient systems for the synthesis of EPDM and, accordingly, the production of elastomers with a high content of diene(s) and the creation of new polymer microstructureswith an even wider range of properties.

Funding:This research was funded by the Ministry of Science and Higher Education of the Russian Federation (State Task, No. registration AAAA-A19-119041090087-4).

This entry is adapted from the peer-reviewed paper 10.3390/catal12070704