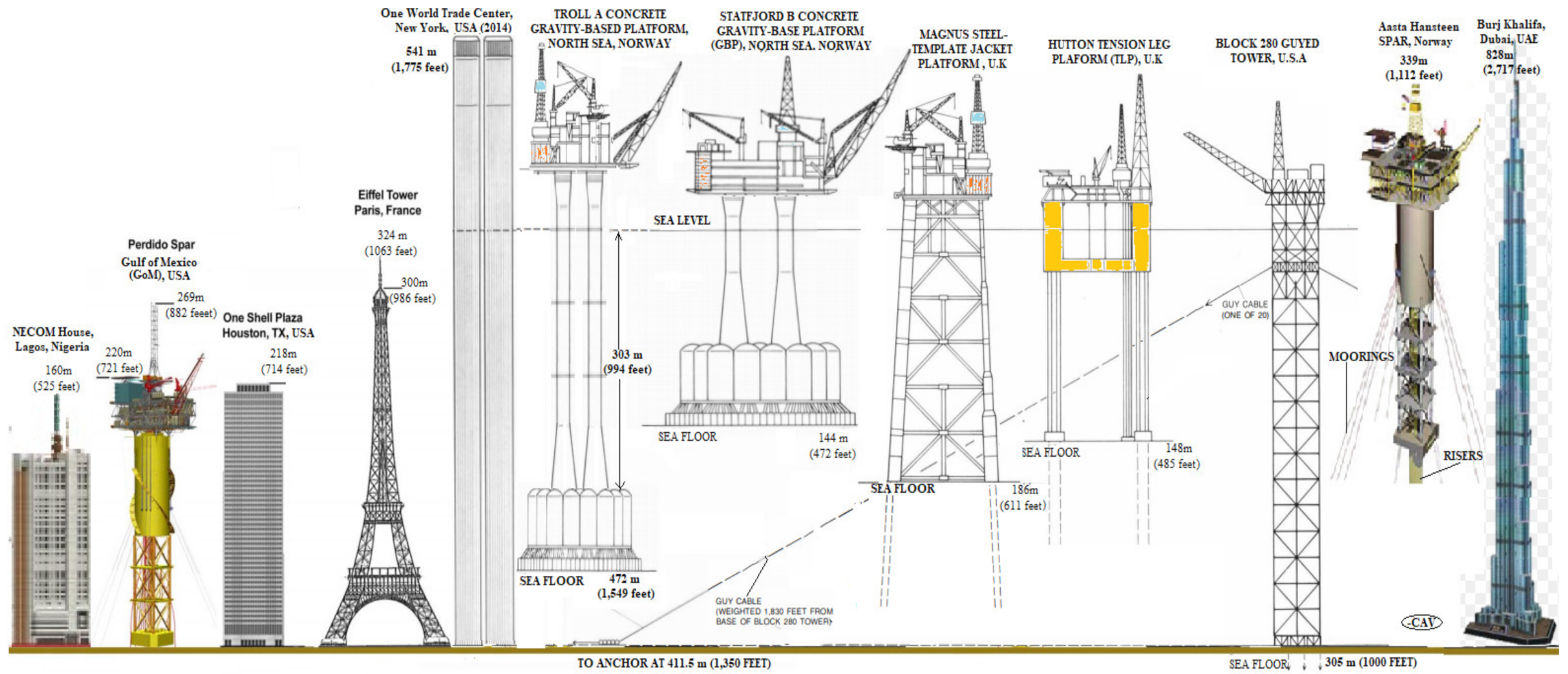

Diverse forms of offshore oil and gas structures are utilized for a wide range of purposes and in varying water depths. They are designed for unique environments and water depths around the world. The applications of these offshore structures require different activities for proper equipment selection, design of platform types, and drilling/production methods. There are advances made in ocean engineering which include a variety of innovative offshore structure designs, ranging from fixed platforms to floating platforms. Some of these structures include the deep-water semisubmersible platforms, jack-up rigs, floating offshore wind turbines (FOWTs), FPS (floating production systems) units.

- offshore structure

- offshore platform

- fixed platform

- floating platform

- oil and gas platform

- production platform

- drilling platform rig

- coastal structure

- marine structure

- offshore facilities and subsea systems

- review

- offshore

1. Introduction

2. Overview of Platform Installations

| Platform | Sidetrack Subsea Well | Sidetrack Dry Trees Well | Amount | Subsea Field |

|---|---|---|---|---|

| FPSO | 1 (2) | 2 (0) | 1 | 1 (1) |

| Mobile offshore production units (MOPU) | 6 (13) | -- -- | 1 | -- (2) |

| Semisubmersible | 32 (28) | 22 (16) | 9 | 6 (18) |

| Mini TLP | 17 (17) | 11 (16) | 5 | 1 (6) |

| Tension Leg Platform (TLP) | 51 (60) | 123 (150) | 10 | 8 (14) |

| Single Point Anchor Reservoir (SPAR) | 34 (43) | 133 (129) | 16 | 13 (18) |

| Fixed Platform (FP) | 47 (49) | 630 (449) | 50 | 49 (30) |

| Compliant towers (CT) | 3 (1) | 76 (46) | 3 | 4 (2) |

| AGGREGATE | 191 (213) | 997 (806) | 95 | 82 (91) |

- (a)

-

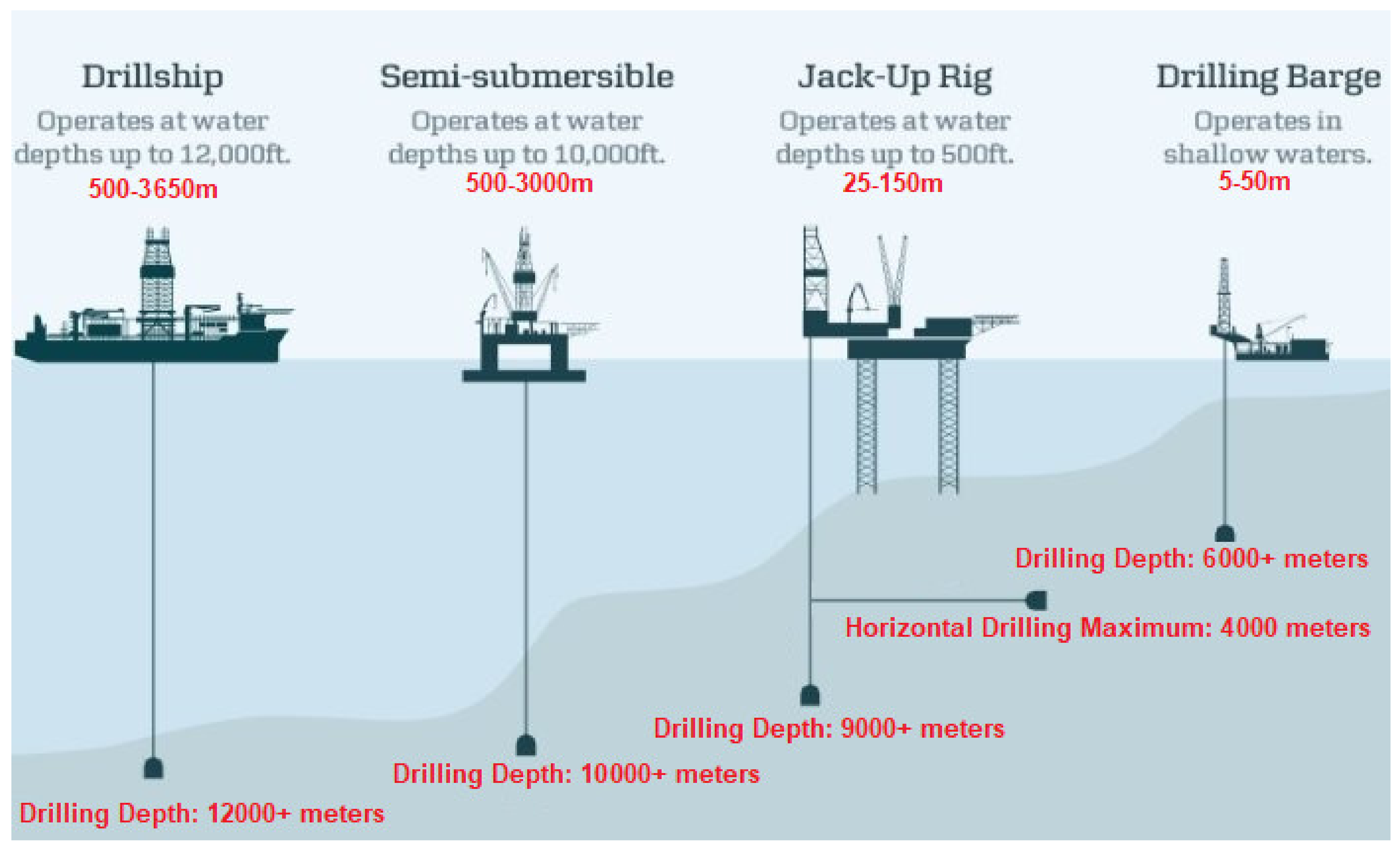

Jack-up rig or Tender rig for extraction of oil/gas, drilling and templates (jackets) in water depths up to 150 m;

- (b)

-

A semi-submersible drilling rig with a template (jacket) platform for extraction of oil/gas, at sea depths of 150 to 300 m;

- (c)

-

A semi-submersible drilling rig with guyed-tower platforms for oil/gas extraction at depths of 300 to 400 m;

- (d)

-

Semi-submersible drilling rig with tension leg platform or semi-submersible oil/gas extraction platform for water depths of 400 m to 1800 m;

- (e)

-

Drillship rig with tension leg, subsea system, or spar platforms for oil/gas extraction in depths greater than 1800 m;

- (f)

-

Floating production storage and offloading (FPSO) are found operating in water depths ranging from 200 m to more than 3000 m [260] and depending on the environmental condition, they are maintained in position using either a spread or turret mooring system.

2.1. Floating Production Systems

2.2. Fixed Offshore Platform Design

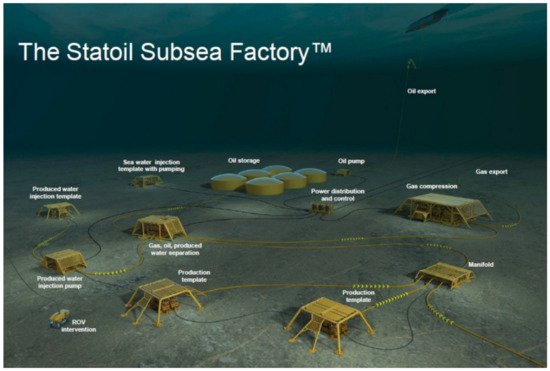

2.3. Subsea System

| Key Parameters | Heavy Oil Fields | Oil Fields | Gas/Condensate Fields |

|---|---|---|---|

| Colder (heavy/complex fluids) | Cold transport | Cold flow | Sour/Acid gas issues |

| Colder (arctic environment) | Harsh environment | Under ice | Under ice |

| Deep water (deeper environment) | 2000 m | 3000 m | 3000 m |

| Longer power | 50 MW | 20 MW | 100 MW |

| Longer transport | 50 km | 200 km | 250 km |

3. Types of Offshore Platforms

3.1. Moveable Offshore Drilling Platforms

3.2. Drilling Barges

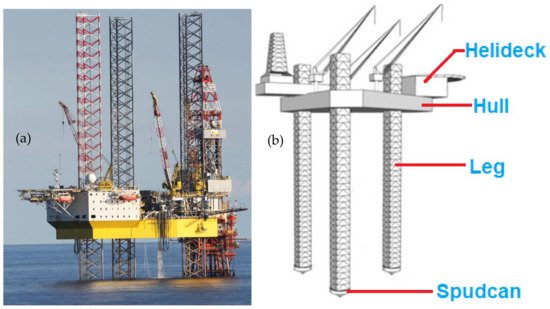

3.3. Jackup Drilling Platforms/Rigs

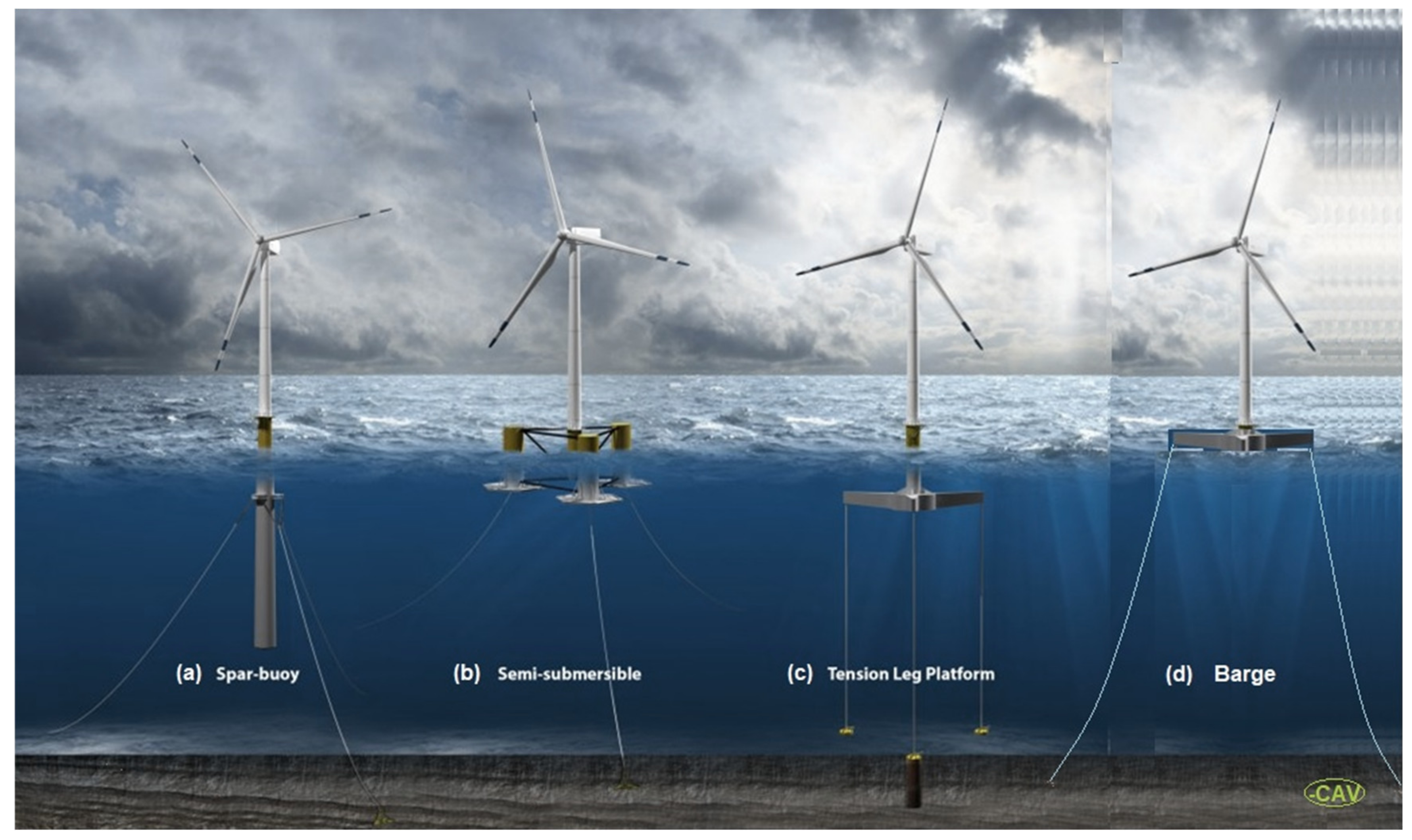

3.4. Offshore Wind Turbine Platforms

| Name | Installation Year | Diameter | Tower Height | Capacity | Status |

|---|---|---|---|---|---|

| Hornsea 2 | 2002 | 167 m | 190 m | 1396 MW | Active |

| Burbo Bank Extension | 2017 | 164 m | 113 m | 800 MW | Active |

| Westermost Rough | 2014 | 154 m | 102 m | 600 MW | Active |

| Anholt | 2012 | 120 m | 82 m | 360 MW | Active |

| Horns Rev 2 | 2009 | 93 m | 68 m | 230 MW | Active |

| Nysted | 2003 | 82.4 m | 69 m | 230 MW | Active |

| Middelgrund | 2000 | 76 m | 64 m | 200 MW | Active |

| Vindeby | 1991 | 35 m | 35 m | 4.95 MW | Inactive |

This entry is adapted from the peer-reviewed paper 10.3390/jmse10081074

References

- Chakrabarti, S.K. Handbook of Offshore Engineering, 1st ed.; Elsevier: Plainfield, IL, USA, 2005; Volume 1.

- Haritos, N. Introduction to the analysis and design of offshore structures—An overview. Electron. J. Struct. Eng. (eJSE) 2007, 7, 55–65. Available online: https://ejsei.com/EJSE/article/download/65/64 (accessed on 12 February 2022).

- Söding, H.; Blok, J.J.; Chen, H.H.; Hagiwara, K.; Isaacson, M.; Jankowski, J.; Jefferys, E.R.; Mathisen, J.; Rask, I.; Richer, J.-P.; et al. Environmental forces of offshore structures: A state-of-the-art review. Mar. Struct. 1990, 3, 59–81.

- Amiri, N.; Shaterabadi, M.; Reza Kashyzadeh, K.; Chizari, M. A comprehensive review on design, monitoring, and failure in fixed offshore platforms. J. Mar. Sci. Eng. 2021, 9, 1349.

- Amaechi, C.V.; Reda, A.; Butler, H.O.; Ja’e, I.A.; An, C. Review on fixed and floating offshore structures. Part II: Sustainable design approaches and project management. J. Mar. Sci. Eng. 2022, 10, 973.

- El-Reedy, M. Offshore Structures: Design, Construction and Maintenance; Imprint: Gulf Professional Publishing; Elsevier: London, UK, 2012.

- Bai, Y.; Bai, Q. Subsea Engineering Handbook; Elsevier: Oxford, UK, 2010.

- Wilson, J. Dynamics of Offshore Structures, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2022.

- Ladeira, I.; Márquez, L.; Echeverry, S.; Le Sourne, H.; Rigo, P. Review of methods to assess the structural response of offshore wind turbines subjected to ship impacts. Ships Offshore Struct. 2022. ahead-of-print.

- Jaculli, M.A.; Leira, B.J.; Sangesland, S.; Morooka, C.K.; Kiryu, P.O. Dynamic response of a novel heave-compensated floating platform: Design considerations and the effects of mooring. Ships Offshore Struct. 2022. ahead-of-print.

- Al-Sharif, A.A. Design, fabrication and installation of fixed offshore platforms in the Arabian Gulf. In Proceedings of the Fourth Saudi Engineering Conference, Dhahran, Saudi Arabia, 5–8 November 1995; pp. 99–105.

- Al-Yafei, E.F. Sustainable Design for Offshore Oil and Gas Platforms: A Conceptual Framework for Topside Facilities Projects. Ph.D. Thesis, School of Energy, Geoscience, Infrastructure & Society, Heriot Watt University, Edinburgh, UK, 2018. Available online: https://www.ros.hw.ac.uk/bitstream/handle/10399/3513/Al-YafeiE_0418_egis.pdf?sequence=1&isAllowed=y (accessed on 12 February 2022).

- Kreidler, T.D. The Offshore Petroleum Industry: The Formative Years, 1945–1962. Ph.D. Thesis, History Department, Texas Tech University, Lubbock, TX, USA, 1997. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.455.2343&rep=rep1&type=pdf (accessed on 12 February 2022).

- Sadeghi, K. An overview on design, construction and installation of offshore template platforms suitable for Persian Gulf oil/gas fields. In Proceedings of the First International Symposium on Engineering, Artificial Intelligence and Applications, Kyrenia, Cyprus, 6–8 November 2013.

- Sadeghi, K. Significant guidance for design and construction of marine and offshore structures. GAU J. Soc. Appl. Sci. 2008, 4, 67–92. Available online: https://www.researchgate.net/publication/250310894_Significant_Guidance_for_Design_and_Construction_of_Marine_and_Offshore_Structures (accessed on 6 July 2022).

- Sadeghi, K.; Dilek, H. An Introduction to the design of Offshore Structures. Acad. Res. Int. 2019, 10, 19–27. Available online: http://www.savap.org.pk/journals/ARInt./Vol.10(1)/ARInt.2019(10.1-03).pdf (accessed on 12 February 2022).

- Bernitsas, M.M.; Kokarakis, J.E. Importance of nonlinearities in static riser analysis. Appl. Ocean. Res. 1988, 10, 2–9.

- Liao, M.; Wang, G.; Gao, Z.; Zhao, Y.; Li, R. Mathematical modelling and dynamic analysis of an offshore drilling riser. Shock. Vib. 2020, 2020, 8834011.

- Bernitsas, M.M.; Kokarakis, J.E.; Imron, A. Large deformation three-dimensional static analysis of deep water marine risers. Appl. Ocean. Res. 1985, 7, 178–187.

- Patel, M.H.; Sarohia, S.; Ng, K.F. Finite-element analysis of the marine riser. Eng. Struct. 1984, 6, 175–184.

- Burke, B.G. An analysis of marine risers for deep water. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–2 May 1973.

- Bae, Y.; Bernitsas, M.M. Importance of nonlinearities in static and dynamic analyses of marine risers. In Proceedings of the International Offshore and Polar Engineering Conference, Hague, The Netherlands, 11–16 June 1995; Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE95/All-ISOPE95/ISOPE-I-95-125/23069 (accessed on 6 July 2022).

- Wang, Y.; Gao, D.; Fang, J. Coupled dynamic analysis of deepwater drilling riser under combined forcing and parametric excitation. J. Nat. Gas Sci. Eng. 2015, 27, 1739–1747.

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Gillet, N.; Wang, C.; Ja’e, I.A.; Reda, A.; Odijie, A.C. Review of composite marine risers for deep-water applications: Design, development and mechanics. J. Compos. Sci. 2022, 6, 96.

- Toh, W.; Tan, L.B.; Jaiman, R.K.; Tay, T.E.; Tan, V.B.C. A comprehensive study on composite risers: Material solution, local end fitting design and global response. Mar. Struct. 2018, 61, 155–169.

- Amaechi, C.V.; Gillett, N.; Odijie, A.C.; Hou, X.; Ye, J. Composite risers for deep waters using a numerical modelling approach. Compos. Struct. 2019, 210, 486–499.

- Amaechi, C.V. Local tailored design of deep water composite risers subjected to burst, collapse and tension loads. Ocean Eng. 2022, 250, 110196.

- Roberts, D.; Hatton, S.A. Development and qualification of end fittings for composite riser pipe. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013. Paper Number: OTC-23977-MS.

- Amaechi, C.V.; Gillet, N.; Ja’e, I.A.; Wang, C. Tailoring the local design of deep water composite risers to minimise structural weight. J. Compos. Sci. 2022, 6, 103.

- Pham, D.-C.; Sridhar, N.; Qian, X.; Sobey, A.J.; Achintha, M.; Shenoi, A. A review on design, manufacture and mechanics of composite risers. Ocean Eng. 2016, 112, 82–96.

- Amaechi, C.V.; Wang, F.; Hou, X.; Ye, J. Strength of submarine hoses in Chinese-lantern configuration from hydrodynamic loads on CALM buoy. Ocean Eng. 2019, 171, 429–442.

- Amaechi, C.V.; Wang, F.; Ye, J. Numerical studies on CALM buoy motion responses and the effect of buoy geometry cum skirt dimensions with its hydrodynamic waves-current interactions. Ocean Eng. 2022, 244, 110378.

- Gao, Q.; Zhang, P.; Duan, M.; Yang, X.; Shi, W.; An, C.; Li, Z. Investigation on structural behavior of ring-stiffened composite offshore rubber hose under internal pressure. Appl. Ocean Res. 2018, 79, 7–19.

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. Review on the design and mechanics of bonded marine hoses for Catenary Anchor Leg Mooring (CALM) buoys. Ocean Eng. 2021, 242, 110062.

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. An overview on bonded marine hoses for sustainable fluid transfer and (un)loading operations via Floating Offshore Structures (FOS). J. Mar. Sci. Eng. 2021, 9, 1236.

- Gao, P.; Gao, Q.; An, C.; Zeng, J. Analytical modeling for offshore composite rubber hose with spiral stiffeners under internal pressure. J. Reinf. Plast. Compos. 2021, 40, 352–364.

- Tonatto, M.L.; Tita, V.; Araujo, R.T.; Forte, M.M.; Amico, S.C. Parametric analysis of an offloading hose under internal pressure via computational modeling. Mar. Struct. 2017, 51, 174–187.

- Amaechi, C.V.; Wang, F.; Ye, J. Mathematical modelling of marine bonded hoses for single point mooring (SPM) systems, with catenary anchor leg mooring (CALM) buoy application—A review. J. Mar. Sci. Eng. 2021, 9, 1179.

- Amaechi, C.V.; Wang, F.; Ja’e, I.A.; Aboshio, A.; Odijie, A.C.; Ye, J. A literature review on the technologies of bonded hoses for marine applications. Ships Offshore Struct. 2022. ahead-of-print.

- Wichers, I.J. Guide to Single Point Moorings; WMooring Inc.: Houston, TX, USA, 2013; Available online: http://www.wmooring.com/files/Guide_to_Single_Point_Moorings.pdf (accessed on 17 May 2022).

- Petrone, C.; Oliveto, N.D.; Sivaselvan, M.V. Dynamic analysis of mooring cables with application to floating offshore wind turbines. J. Eng. Mech. 2015, 142, 1–12.

- Mavrakos, S.A.; Papazoglou, V.J.; Triantafyllou, M.S.; Hatjigeorgiou, J. Deep-water mooring dynamics. Mar. Struct. 1996, 9, 181–209.

- Mavrakos, S.A.; Chatjigeorgiou, J. Dynamic behavior of deep-water mooring lines with submerged buoys. Comput. Struct. 1997, 64, 819–835.

- Ja’e, I.A.; Ali, M.O.A.; Yenduri, A.; Nizamani, Z.; Nakayama, A. Optimisation of mooring line parameters for offshore floating structures: A review paper. Ocean Eng. 2022, 247, 110644.

- Amaechi, C.V.; Wang, F.; Odijie, A.C.; Ye, J. Numerical investigation on mooring line configurations of a Paired Column Semisubmersible for its global performance in deep water condition. Ocean Eng. 2022, 250, 110572.

- Xu, S.; Ji, C.Y.; Soares, C.G. Experimental and numerical investigation a semi-submersible moored by hybrid mooring systems. Ocean. Eng. 2018, 163, 641–678.

- Xue, X.; Chen, N.Z.; Wu, Y.; Xiong, Y.; Guo, Y. Mooring system fatigue analysis for a semi-submersible. Ocean. Eng. 2018, 156, 550–563.

- Wang, K.; Er, G.K.; Iu, V.P. Nonlinear vibrations of offshore floating structures moored by cables. Ocean. Eng. 2018, 156, 479–488.

- Harnois, V.; Weller, S.D.; Johanning, L.; Thies, P.R.; Le Boulluec, M.; Le Roux, D.; Soule, V.; Ohana, J. Numerical model validation for mooring systems: Method and application for wave energy converters. Renew. Energy 2015, 75, 869–887.

- Wang, Z.; Bai, Y.; Wei, Q. Mechanical properties of glass fibre reinforced pipeline during the laying process. Ships Offshore Struct. 2022. ahead-of-print.

- Liu, W.; Bai, Y.; Gao, Y.; Song, X.; Han, Z. Analysis of the mechanical properties of a reinforced thermoplastic composite pipe joint. Ships Offshore Struct. 2021, 17, 1515–1521.

- Liu, W.; Gao, Y.; Shao, Q.; Cai, W.; Han, Z.; Chi, M. Design and analysis of joints in reinforced thermoplastic composite pipe under internal pressure. Ships Offshore Struct. 2022, 17, 1276–1285.

- Ochoa, O.O.; Salama, M.M. Offshore composites: Transition barriers to an enabling technology. Compos. Sci. Technol. 2005, 65, 2588–2596.

- Langena, I.; Skjbtadb, O.; Haver, S. Measured and predicted dynamic behaviour of an offshore gravity platform. Appl. Ocean. Res. 1998, 20, 15–26.

- Chandrasekaran, S.; Uddin, S.A.; Wahab, M. Dynamic analysis of semi-submersible under the postulated failure of restraining system with buoy. Int. J. Steel Struct. 2020, 21, 118–131.

- Zhao, W.; Zou, L.; Wan, D.; Hu, Z. Numerical investigation of vortex-induced motions of a paired-column semi-submersible in currents. Ocean. Eng. 2018, 164, 272–283.

- Anastasiades, K.; Michels, S.; van Wuytswinkel, H.; Blom, J.; Audenaert, A. Barriers for the circular reuse of steel in the Belgian construction sector: An industry wide perspective. Proc. Inst. Civ. Eng.-Manag. Procure. Law 2022, 1–14.

- Odijie, A.C.; Quayle, S.; Ye, J. Wave induced stress profile on a paired column semisubmersible hull formation for column reinforcement. Eng. Struct. 2017, 143, 77–90.

- Odijie, A.C.; Ye, J. Effect of vortex induced vibration on a paired-column semisubmersible platform. Int. J. Struct. Stab. Dyn. 2015, 15, 1540019.

- Chandrasekaran, S.; Srivastava, G. Design Aids for Offshore Structures under Special Environmental Loads, Including Fire Resistance; Springer: Singapore, 2017; ISBN 978-981-322-10-7608-7.

- Barltrop, N.D.P.; Adams, A.J. Dynamics of Fixed Marine Structures, 3rd ed.; Butterworth Heinemann: Oxford, UK, 1991.

- Brebbia, C.A.; Walker, S. Dynamic Analysis of Offshore Structures, 1st ed.; Newnes-Butterworth & Co. Publishers Ltd.: London, UK, 1979.

- Chandrasekaran, S. Dynamic Analysis and Design of Offshore Structures, 2nd ed.; Springer: Singapore, 2018; ISBN 978-981-10-6089-2.

- Leffler, W.L.; Pattarozzi, R.; Sterling, G. Deepwater Petroleum Exploration & Production: A Nontechnical Guide; PennWell: Tulsa, OK, USA, 2011; ISBN 9781593702533.

- Fang, H.; Duan, M. Offshore Operation Facilities; Imprint: Gulf Professional Publishing; Elsevier: Waltham, MA, USA, 2014.

- Aird, P. Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology Application; Imprint: Gulf Professional Publishing; Elsevier: Cambridge, MA, USA, 2019.

- Joshi, S.D. Horizontal Well Technology; Pennwell Books: Tulsa, OK, USA, 1991.

- Stewart, G. Well Test Design and Analysis; Pennwell Books: Tulsa, OK, USA, 2011.

- Azar, J.J.; Samuel, R. Drilling Engineering; Pennwell Books: Tulsa, OK, USA, 2007.

- Samie, N.N. Practical Engineering Management of Offshore Oil and Gas Platforms; Imprint: Gulf Professional Publishing; Elsevier: Cambridge, MA, USA, 2016.

- Clews, R.J. Project Finance for the International Petroleum Industry; Academic Press: Cambridge, MA, USA, 2016; ISBN 978-0-12-800158-5.

- Chandrasekaran, S.; Jain, A.K. Ocean Structures, Construction, Materials, and Operations; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-149-87-9742-9.

- Laik, S. Offshore Petroleum Drilling and Production, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018.

- Speight, J.G. Handbook of Offshore Oil and Gas Operations; Imprint: Gulf Professional Publishing; Elsevier: Waltham, MA, USA, 2011.

- Grace, R.D. Blowout and Well Control Handbook; Imprint: Gulf Professional Publishing; Elsevier: Cambridge, MA, USA, 2017.

- Wan, R. Advanced Well Completion Engineering; Imprint: Gulf Professional Publishing; Elsevier: Waltham, MA, USA, 2011.

- Byrom, T.G. Casing and Liners for Drilling and Completion: Design and Application, 2nd ed.; A Volume in Gulf Drilling Guides; Imprint: Gulf Professional Publishing; Elsevier: Waltham, MA, USA, 2015.

- Caenn, R.; Darley, H.C.H.; Gray, G.R. Composition and Properties of Drilling and Completion Fluids, 7th ed.; Imprint: Gulf Professional Publishing; Elsevier: Cambridge, MA, USA, 2017.

- Devereux, S. Practical Well Planning and Drilling Manual; Pennwell Books: Tulsa, OK, USA, 1998.

- Veatch, R.W., Jr.; King, G.E.; Holditch, S.A. Essentials of Hydraulic Fracturing: Vertical and Horizontal Wellbores; Pennwell Books: Tulsa, OK, USA, 2017.

- Raymond, M.S.; Leffler, W.L. Oil & Gas Production in Nontechnical Language; Pennwell Books: Tulsa, OK, USA, 2017.

- Crumpton, H. Well Control for Completions and Interventions; Imprint: Gulf Professional Publishing; Elsevier: Cambridge, MA, USA, 2017.

- Sadeghi, K. An overview of design, analysis, construction and installation of offshore petroleum platforms suitable for Cyprus oil/gas fields. GAU J. Soc. Appl. Sci. 2007, 2, 1–16. Available online: https://cemtelecoms.iqpc.co.uk/media/6514/786.pdf (accessed on 12 February 2022).

- Yan, J.; Qiao, D.; Ou, J. Optimal design and hydrodynamic response analysis of deep-water mooring systems with submerged buoys. Ships Offshore Struct. 2018, 13, 476–487.

- Ormberg, H.; Larsen, K. Coupled analysis of floater motion and mooring dynamics for a turret-moored ship. Appl. Ocean Res. 1998, 20, 55–67.

- Qiao, D.; Ou, J. Global responses analysis of a semi-submersible platform with different mooring models in South China Sea. Ships Offshore Struct. 2012, 8, 441–456.

- Bargi, K.; Hosseini, S.R.; Tadayon, M.H.; Sharifian, H. Seismic response of a typical fixed jacket-type offshore platform (SPD1) under sea waves. Open J. Mar. Sci. 2011, 1, 36–42.

- Jang, J.; Jyh-Shinn, G. Analysis of maximum wind force for offshore structure design. J. Mar. Sci. Technol. 1999, 7, 43–51.

- Thiagarajan, K.P.; Finch, S. An investigation into the effect of turret mooring location on the vertical motions of an FPSO vessel. J. Offshore Mech. Arct. Eng. 1999, 121, 71–76.

- Ja’e, I.A.; Ali, M.O.A.; Yenduri, A.; Nizamani, Z.; Nakayama, A. Effect of various mooring materials on hydrodynamic responses of turret-moored FPSO with emphasis on intact and damaged conditions. J. Mar. Sci. Eng. 2022, 10, 453.

- Sheng, W.; Tapoglou, E.; Ma, X.; Taylor, C.J.; Dorrell, R.M.; Parsons, D.R.; Aggidis, G. Hydrodynamic studies of floating structures: Comparison of wave-structure interaction modelling. Ocean Eng. 2022, 249, 110878.

- Hirdaris, S.E.; Bai, W.; Dessi, D.; Ergind, A.; Gu, X.; Hermundstad, O.A.; Huijsmans, R.; Iijima, K.; Nielsen, U.D.; Parunov, J.; et al. Loads for use in the design of ships and offshore structures. Ocean Eng. 2014, 78, 131–174.

- Lee, Y.; Incecik, A.; Chan, H.S. Prediction of global loads and structural response analysis on a multi-purpose semi-submersible. In Proceedings of the ASME 2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005; American Society of Mechanical Engineers Digital Collection. pp. 3–13.

- Newman, J.N. Marine Hydrodynamics; IT Press: London, UK, 1977; Reprint in 1999.

- Chakrabarti, S.K. Hydrodynamics of Offshore Structures; WIT Press: Southampton, UK, 2001; Reprint.

- Faltinsen, O.M. Sea Loads on Ships and Offshore Structures; Cambridge University Press: Cambridge, UK, 1990.

- Bishop, R.E.D.; Price, W.G. Hydroelasticity of Ships; Cambridge University Press: New York, NY, USA, 2005.

- Singh, R. Corrosion Control for Offshore Structures; Imprint: Gulf Professional Publishing; Elsevier: Waltham, MA, USA, 2015.

- Chandrasekaran, S.; Uddin, S.A. Postulated failure analyses of a spread-moored semi-submersible. Innov. Infrastruct. Solut. 2020, 5, 1–16.

- Sarpkaya, T. Wave Forces on Offshore Structures, 1st ed.; Cambridge University Press: New York, NY, USA, 2014.

- Clauss, G.; Lehmann, E.; Östergaard, C. Offshore Structures: Volume I: Conceptual Design and Hydromechanics, 1st ed.; English Translation; Springer: London, UK, 2012.

- McCormick, M.E. Ocean Engineering Mechanics with Applications; Cambridge University Press: New York, NY, USA, 2010.

- Holthuijsen, L.H. Waves in Oceanic and Coastal Waters, 1st ed.; Cambridge University Press: New York, NY, USA, 2007.

- Dean, R.G.; Dalrymple, R.A. Water Wave Mechanics for Engineers and Scientists-Advanced Series on Ocean Engineering; World Scientific: Singapore, 1991; Volume 2.

- Sorensen, R.M. Basic Coastal Engineering, 3rd ed.; Springer: New York, NY, USA, 2006.

- Sorensen, R.M. Basic Wave Mechanics: For Coastal and Ocean Engineers; John Wiley and Sons: London, UK, 1993.

- Boccotti, P. Wave Mechanics and Wave Loads on Marine Structures; Elsevier B.V. & Butterworth-Heinemann: Waltham, MA, USA, 2015.

- Boccotti, P. Wave Mechanics for Ocean Engineering; Elsevier B.V.: Amsterdam, The Netherlands, 2000.

- Seyed, F.B.; Patel, M.H. Mathematics of flexible risers including pressure and internal flow effects. Mar. Struct. 1992, 5, 121–150.

- Dareing, D.W. Mechanics of Drillstrings and Marine Risers; ASME Press: New York, NY, USA, 2012; 396p, Available online: https://doi.org/10.1115/1.859995 (accessed on 15 February 2022).

- Sparks, C. Fundamentals of Marine Riser Mechanics: Basic Principles and Simplified Analyses, 2nd ed.; PennWell Books: Tulsa, OK, USA, 2018.

- Bai, Y.; Bai, Q. Subsea Pipelines and Risers, 1st ed.; Elsevier Ltd.: Oxford, UK, 2005; Reprint 2013.

- Bai, Y.; Bai, Q.; Ruan, W. Flexible Pipes: Advances in Pipes and Pipelines; Wiley Scrivener Publishing: Beverly, MA, USA, 2017.

- Sævik, S. On Stresses and Fatigue in Flexible Pipes. Ph.D. Thesis, Department Marine Structures, Norwegian Institute Technology, Trondheim, Norway, 1992. Available online: https://trid.trb.org/view/442338 (accessed on 15 February 2022).

- Amaechi, C.V. Novel Design, Hydrodynamics and Mechanics of Marine Hoses in Oil/Gas Applications. Ph.D. Thesis, Engineering Department, Lancaster University, Lancaster, UK, 2022.

- Ali, L.; Khan, S.; Bashmal, S.; Iqbal, N.; Dai, W.; Bai, Y. Fatigue crack monitoring of T-type joints in steel offshore oil and gas jacket platform. Sensors 2021, 21, 3294.

- Paik, J.K.; Lee, D.H.; Park, D.K.; Ringsberg, J.W. Full-scale collapse testing of a steel stiffened plate structure under axial-compressive loading at a temperature of −80 °C. Ships Offshore Struct. 2021, 16, 255–270.

- He, K.; Kim, H.J.; Thomas, G.; Paik, J.K. Analysis of fire-induced progressive collapse for topside structures of a VLCC-class ship-shaped offshore installation. Ships Offshore Struct. 2022. ahead-of print.

- Ali, L.; Khan, S.; Iqbal, N.; Bashmal, S.; Hameed, H.; Bai, Y. An experimental study of damage detection on typical joints of jackets platform based on electro-mechanical impedance technique. Materials 2021, 14, 7168.

- Zhang, X.; Ni, W.; Sun, L. Fatigue analysis of the oil offloading lines in FPSO system under wave and current loads. J. Mar. Sci. Eng. 2022, 10, 225.

- Soares, C.G.; Garbatov, Y. Reliability of maintained ship hulls subjected to corrosion. J. Ship Res. 1996, 40, 235–243.

- Soares, C.G.; Garbatov, Y. Fatigue reliability of the ship hull girder accounting for inspection and repair. Reliab. Eng. Syst. Saf. 1996, 51, 341–351.

- Hussein, A.; Soares, C.G. Reliability and residual strength of double hull tankers designed according to the new IACS common structural rules. Ocean Eng. 2009, 36, 1446–1459.

- Soares, C.; Garbatov, Y. Reliability of maintained, corrosion protected plates subjected to non-linear corrosion and compressive loads. Mar. Struct. 1999, 12, 425–445.

- Teixeira, A.P.; Soares, C.G.; Netto, T.A.; Estefen, S.F. Reliability of pipelines with corrosion defects. Int. J. Press. Vessel. Pip. 2008, 85, 228–237.

- Aboshio, A.; Uche, A.O.; Akagwu, P.; Ye, J. Reliability-based design assessment of offshore inflatable barrier structures made of fibre-reinforced composites. Ocean Eng. 2021, 233, 109016.

- Chojaczyk, A.A.; Teixeira, A.P.; Neves, L.C.; Cardoso, J.B.; Soares, C.G. Review and application of Artificial Neural Networks models in reliability analysis of steel structures. Struct. Saf. 2015, 52, 78–89.

- Gaspar, B.; Teixeira, A.P.; Soares, C.G. Assessment of the efficiency of Kriging surrogate models for structural reliability analysis. Probabilistic Eng. Mech. 2014, 37, 24–34.

- Santala, M.J. API RP-2MET Metocean 2nd edition; Updates to the Gulf of Mexico regional annex. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018.

- Stear, J.B. Development of API RP2 Met: The new path for Metocean. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2008.

- Stear, J. Use of RP 2MET annex Gulf Metocean conditions with 2A and 2SIM. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2012.

- Stear, J. SS: New API codes: Updates, new suite of standards/“RP 2MET: An API standard for Metocean”. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010.

- Puskar, F.; Robert, S. SS: New API codes: Updates, new suite of standards—API bulletin 2HINS—Guidance for post-hurricane structural inspection of offshore structures. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010.

- Zwerneman, F.; Digre, K.A. SS: New API codes: Updates, new suite of standards: API RP 2A-WSD, the 23rd edition. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010.

- O’Connor, P.E.; Versowsky, P.; Day, M.; Westlake, H.; Bucknell, J. Platform assessment: Recent Section 17 updates and future API/industry developments. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005.

- Versowski, P.; Rodenbusch, G.; O’Connor, P.; Prins, M. Hurricane impact reviewed through API. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006.

- Balint, S.W.; Orange, D. Panel discussion: Future of the Gulf of Mexico after Katrina and Rita. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006.

- Maxwell, P.; Verret, S.M.; Haugland, T. Fixed platform performance during recent hurricanes: Comparison to design standards. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2007.

- Westlake, H.S.; Puskar, F.J.; O’Connor, P.E.; Bucknell, J.R. The development of a recommended practice for Structural Integrity Management (SIM) of fixed offshore platforms. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006.

- Wisch, D.J.; Mangiavacchi, A. Alignment of API offshore structures standards with ISO 19900 series and usage of the API suite. In Proceedings of the Off-Shore Technology Conference, Houston, TX, USA, 30 April–3 May 2012.

- Wisch, D.J.; Puskar, F.J.; Laurendine, T.T.; O’Connor, P.E.; Versowsky, P.E.; Bucknell, J. An update on API RP 2A section 17 for the assessment of existing platforms. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2004.

- Lotsberg, I. Background for revision of DNV-RP-C203 fatigue analysis of offshore steel structure. In Proceedings of the ASME 2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005; Volume 3, pp. 297–306.

- Horn, A.M.; Lotsberg, I.; Orjaseater, O. The rationale for update of S-N curves for single sided girth welds for risers and pipelines in DNV GL RP C-203 based on fatigue performance of more than 1700 full scale fatigue test results. In Proceedings of the ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018. Volume 4: Materials Technology, Paper No. V004T03A024.

- Lotsberg, I. Development of fatigue design standards for marine structures. In Proceedings of the ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering, Trondheim, Norway, 25–30 June 2017. Volume 9: Offshore Geotechnics; Torgeir Moan Honoring Symposium, Paper No. V009T12A005.

- Lotsberg, I. Fatigue design recommendations for conical connections in tubular structures. In Proceedings of the ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering, Trondheim, Norway, 25–30 June 2017. Volume 4: Materials Technology, Paper No. V004T03A026.

- Echtermeyer, A.T.; Osnes, H.; Ronold, K.O.; Moe, E.T. Recommended practice for composite risers. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002.

- Echtermeyer, A.; Steuten, B. Thermoplastic composite riser guidance note. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013.

- Echtermeyer, A.T.; Sund, O.E.; Ronold, K.O.; Moslemian, R.; Moe, E.T. A new recommended practice for thermoplastic composite pipes. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017; Available online: http://iccm-central.org/Proceedings/ICCM21proceedings/papers/3393.pdf (accessed on 15 July 2022).

- Lotsberg, I.; Fjeldstad, A.; Ronold, K.O. Background for revision of DNVGL-RP-C203 fatigue design of offshore steel structures in 2016. In Proceedings of the ASME 2016 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, Korea, 19–24 June 2016. Volume 4: Materials Technology, Paper No. V004T03A015.

- Lotsberg, I.; Sigurdsson, G. A new recommended practice for inspection planning of fatigue cracks in offshore structures based on probabilistic methods. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Volume 5: Materials Technology; Petroleum Technology, Paper No. V005T03A005.

- Lotsberg, I. Background for new revision of DNV-RP-C203 fatigue design of offshore steel structures. In Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010; Volume 6, pp. 125–134.

- Lotsberg, I.; Skjelby, T.; Vareide, K.; Amundsgård, O.; Landet, E. A new DNV recommended practice for fatigue analysis of offshore ships. In Proceedings of the 25th International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 4–9 June 2006; pp. 573–580, Volume 3: Safety and Reliability; Materials Technology; Douglas Faulkner Symposium on Reliability and Ultimate Strength of Marine Structures.

- API RP 2MET; Derivation of Metocean Design and Operating Conditions. American Petroleum Institute (API): Washington, DC, USA, 2012.

- American Petroleum Institute (API). API 2INT-MET Interim Guidance on Hurricane Conditions in the Gulf of Mexico; Bulletin 2INT-MET; American Petroleum Institute (API): Washington, DC, USA, 2007; Available online: https://law.resource.org/pub/us/cfr/ibr/002/api.2int-met.2007.pdf (accessed on 12 February 2022).

- American Petroleum Institute (API). Interim Guidance for Design of Offshore Structures for Hurricane Conditions; API Bulletin 2INT-DG; American Petroleum Institute (API): Washington, DC, USA, 2007.

- American Petroleum Institute (API). Interim Guidance for Assessment of Existing Offshore Structures for Hurricane Conditions; API Bulletin 2INT-EX; American Petroleum Institute (API): Washington, DC, USA, 2007.

- American Petroleum Institute (API). API RP 95F, Gulf of Mexico MODU Mooring Practices for the 2007 Hurricane Season—Interim Recommendations, 2nd ed.; American Petroleum Institute (API): Washington, DC, USA, 2007.

- American Petroleum Institute (API). API RP 2SM, Recommended Practice for Design, Manufacture, Installation, and Maintenance of Synthetic Fiber Ropes for Offshore Mooring, 1st ed.; American Petroleum Institute (API): Washington, DC, USA, 2001; Addendum in 2007.

- American Petroleum Institute (API). API-RP-2AWSD, Recommended Practice for Planning Designing and Construction Fixed Offshore Structure—Working Stress Design, 21st ed.; American Petroleum Institute (API): Washington, DC, USA, 2007.

- American Petroleum Institute (API). API-RP-2SK, API Recommended Practice 2SK, Design and Analysis of Stationkeeping Systems for Floating Structures, 3rd ed.; American Petroleum Institute (API): Washington, DC, USA, 2005.

- American Petroleum Institute (API). API RP 2SK, Design and Analysis of Stationkeeping Systems for Floating Structures, 3rd ed.; American Petroleum Institute (API): Washington, DC, USA, 2005.

- American Petroleum Institute (API). API RP 2I, In-Service Inspection of Mooring Hardware for Floating Structures, 3rd ed.; American Petroleum Institute (API): Washington, DC, USA, 2008.

- American Petroleum Institute (API). API RP 2Q, Recommended Practice for Design and Operation of Marine Drilling Riser Systems, 2nd ed.; American Petroleum Institute: Washington, DC, USA, 1984.

- American Petroleum Institute (API). Bulletin on Comparison of Marine Drilling Riser Analyses; API 16J Bulletin; American Petroleum Institute (API): Washington, DC, USA, 1992.

- American Petroleum Institute (API). Recommended Practice 2RD: Design of Risers for Floating Production Systems (FPSs) and Tension-leg Platforms (TLPs); American Petroleum Institute (API): Washington, DC, USA, 1998.

- American Petroleum Institute (API). Design of Flat Plat Structure; American Petroleum Institute (API): Washington, DC, USA, 2008.

- American Petroleum Institute (API). Recommended Practice for Fitness-for-Service; API 579; American Petroleum Institute: Washington, DC, USA, 2000.

- American Petroleum Institute (API). Design, Selection, Operation and Maintenance of Marine Drilling Riser Systems; API RP 16Q; American Petroleum Institute: Washington, DC, USA, 2010.

- American Petroleum Institute (API). Qualification of Spoolable Reinforced Plastic Line Pipe; API 15S; American Petroleum Institute: Washington, DC, USA, 2013.

- American Petroleum Institute (API). Specification for Unbonded Pipe; API 17J; American Petroleum Institute: Washington, DC, USA, 2013.

- Det Norske Veritas (DNV). Strength Analysis of Min Structures of Column Stabilized Units (Semisubmersible Platforms); DNV-CN-31; Det Norske Veritas: Oslo, Norway, 1987.

- Det Norske Veritas (DNV). Fatigue Strength Analysis of Offshore Steel Structures; DNV-RP-C203; Det Norske Veritas: Oslo, Norway, April 2010.

- Det Norske Veritas (DNV). Structural Design of Offshore Units (WSD Method); DNV-OS-C201; Det Norske Veritas (DNV): Oslo, Norway, 2011.

- Det Norske Veritas (DNV). Structural Design of Self-Elevating Units (LRFD Method); DNV-OS-C104; Det Norske Veritas (DNV): Oslo, Norway, 2012.

- Det Norske Veritas (DNV). Composite Risers: Recommended Practice; DNV-RP-F202; Det Norske Veritas: Oslo, Norway, 2010.

- Det Norske Veritas (DNV). Dynamic Risers: Recommended Practice; DNV-OS-F201; Det Norske Veritas: Oslo, Norway, 2010.

- Det Norske Veritas (DNV). Composite Components: Recommended Practice; DNV-OS-C501; Det Norske Veritas (DNV): Oslo, Norway, 2013.

- Det Norske Veritas (DNV). Riser Fatigue: Recommended Practice; DNV-RP-F204; Det Norske Veritas (DNV): Oslo, Norway, 2010.

- Det Norske Veritas (DNV). Design of Titanium Risers: Recommended Practice; DNV-RP-F201; Det Norske Veritas: Oslo, Norway, 2002.

- Det Norske Veritas (DNV). Environmental Conditions and Environmental Loads: Recommended Practice; DNV-RP-C205; Det Norske Veritas (DNV): Oslo, Norway, 2007.

- Det Norske Veritas (DNV). Offshore Classification Projects—Testing and Commissioning: Class Guideline; DNVGL-CG-0170; Det Norske Veritas (DNV): Oslo, Norway, 2015.

- Det Norske Veritas & Germanischer Lloyd (DNVGL). Offshore Loading Buoys; DNVGL-OS-E403; Det Norske Veritas & Germanischer Lloyd (DNVGL): Oslo, Norway, 2015.

- Det Norske Veritas & Germanischer Lloyd (DNVGL). DNVGL-CG-0128: Buckling. October 2015. Available online: https://rules.dnvgl.com/docs/pdf/DNVGL/CG/2015-10/DNVGL-CG-0128.pdf (accessed on 15 July 2022).

- Det Norske Veritas & Germanischer Lloyd (DNVGL). Global Performance Analysis of Deepwater Floating Structures; DNVGL-RP-F205; Det Norske Veritas & Germanischer Lloyd (DNVGL): Oslo, Norway, 2017.

- Det Norske Veritas & Germanischer Lloyd (DNVGL). Recommended Practice: Technology Qualification; DNVGL-RP-A203; Det Norske Veritas (DNVGL): Oslo, Norway, 2019.

- Det Norske Veritas & Germanischer Lloyd (DNVGL). Recommended Practice: Thermoplastic Composite Pipes; DNVGL-RP-F119; Det Norske Veritas & Germanischer Lloyd (DNVGL): Oslo, Norway, 2015; Available online: https://www.dnvgl.com/oilgas/download/dnvgl-st-f119-thermoplastic-composite-pipes.html (accessed on 15 February 2022).

- American Bureau of Shipping (ABS). Subsea Riser Systems: Guide for Building and Classing; American Bureau of Shipping (ABS): Houston, TX, USA, 2017; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/offshore/123_guide_building_and_classing_subsea_riser_systems_2017/Riser_Guide_e-Mar18.pdf (accessed on 15 February 2022).

- American Bureau of Shipping (ABS). Guide for Buckling and Ultimate Strength Assessment for Offshore Structures; American Bureau of Shipping (ABS): Houston, TX, USA, 2004.

- American Bureau of Shipping (ABS). Rules for Building and Classing Marine Vessels 2022—Part 5D, Offshore Support Vessels for Specialized Services; American Bureau of Shipping (ABS): Houston, TX, USA, 2022; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/other/1_marinevesselrules_2022/mvr-part-5d-jan22.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Rules for Building and Classing Steel Barges 2022; American Bureau of Shipping (ABS): Houston, TX, USA, 2022; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/special_service/10_barges_2022/barge-rules-jan22.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Rules for Certification of Cargo Containers 1998; American Bureau of Shipping (ABS): Houston, TX, USA, 1998; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/equipment_and_component_certification/13_certofcargocontainers/pub13_cargocontainers.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Guide for the Certification of Offshore Mooring Chain; American Bureau of Shipping (ABS): Houston, TX, USA, 2017; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/survey_and_inspection/39_certificationoffshoremooringchain_2017/Mooring_Chain_Guide_e-May17.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Guide for Building and Classing Accommodation Barges 2021; American Bureau of Shipping (ABS): Houston, TX, USA, 2021; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/special_service/48_accommbarges_2021/accommodation-barge-guide-dec21.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Guide for the Classification of Drilling Systems 2021; American Bureau of Shipping (ABS): Houston, TX, USA, 2021; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/offshore/57_Classification_of_Drilling_Systems_2021/cds-guide-feb21.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Rules for Building and Classing Facilities on Offshore Installations 2022; American Bureau of Shipping (ABS): Houston, TX, USA, 2022; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/offshore/63_facilities_2022/fac-rules-jan22.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Rules for Building and Classing Floating Production Installations 2022; American Bureau of Shipping (ABS): Houston, TX, USA, 2022; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/offshore/82_FPI_2022/fpi-rules-jan22.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Guidance Notes on the Application of Fiber Rope for Offshore Mooring; American Bureau of Shipping (ABS): Houston, TX, USA, 2022; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/offshore/90_fiberrope_2021/fiber-rope-gn-june21.pdf (accessed on 17 May 2022).

- American Bureau of Shipping (ABS). Rules for Building and Classing High Speed Craft 2022—Part 3, Hull Construction and Equipment; American Bureau of Shipping (ABS): Houston, TX, USA, 2022; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/special_service/61_highspeedcraft_2022/hsc-part-3-jan22.pdf (accessed on 17 May 2022).

- ISO 13624-1:2009; Petroleum and Natural Gas Industries—Drilling and Production Equipment—Part 1: Design and Operation of Marine Drilling Riser Equipment. International Organization for Standardization (ISO): Geneva, Switzerland, 2009.

- ISO/TR 13624-2:2009; Petroleum and Natural Gas Industries—Drilling and Production Equipment—Part 2: Deepwater Drilling Riser Methodologies, Operations, and Integrity Technical Report. International Organization for Standardization (ISO): Geneva, Switzerland, 2009.

- ISO 13625:2002; Petroleum and Natural Gas Industries—Drilling and Production Equipment—Marine Drilling Riser Couplings. International Organization for Standardization (ISO): Geneva, Switzerland, 2002.

- ISO 13628-1:2005; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 1: General Requirements and Recommendations. International Organization for Standardization (ISO): Geneva, Switzerland, 2005.

- 203. ISO 13628-2:2006; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 2: Unbonded Flexible Pipe Systems for Subsea and Marine Applications. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 13628-3:2000; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 3: Through Flowline (TFL) Systems. International Organization for Standardization (ISO): Geneva, Switzerland, 2000.

- ISO 13628-4:2010; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 4: Subsea Wellhead and Tree Equipment. International Organization for Standardization (ISO): Geneva, Switzerland, 2010.

- ISO 13628-5:2009; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 5: Subsea Umbilicals. International Organization for Standardization (ISO): Geneva, Switzerland, 2009.

- ISO 13628-6:2006; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 6: Subsea Production Control Systems. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 13628-7:2005; Petroleum and natural gas industries—Design and Operation of Subsea Production Systems—Part 7: Completion/Workover Riser Systems. International Organization for Standardization (ISO): Geneva, Switzerland, 2005.

- ISO 13628-8:2002; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 8: Remotely Operated Vehicle (ROV) Interfaces on Subsea Production Systems. International Organization for Standardization (ISO): Geneva, Switzerland, 2002.

- ISO 13628-9:2000; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 9: Remotely Operated Tool (ROT) Intervention Systems. International Organization for Standardization (ISO): Geneva, Switzerland, 2000.

- ISO 13628-10:2005; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 10: Specification for Bonded Flexible Pipe. International Organization for Standardization (ISO): Geneva, Switzerland, 2005.

- Tahar, A.; Kim, M. Hull/mooring/riser coupled dynamic analysis and sensitivity study of a tanker-based FPSO. Appl. Ocean Res. 2003, 25, 367–382.

- Ja’e, I.A.; Ali, M.O.A.; Yenduri, A. Numerical Validation of Hydrodynamic Responses and Mooring Top Tension of a Turret Moored FPSO Using Simulation and Experimental Results. In Advances in Civil Engineering Materials. Lecture Notes in Civil Engineering; Awang, M., Ling, L., Emamian, S.S., Eds.; Springer: Singapore, 2022; Volume 223.

- Ja’e, I.A.; Ali, M.O.A.; Yenduri, A. Numerical studies on the effects of mooring configuration and line diameter on the restoring behaviour of a turret-moored FPSO. In Proceedings of the 5th International Conference on Civil, Structural and Transportation Engineering, Virtual Conference, 12–14 November 2020; Available online: https://avestia.com/ICCSTE2020_Proceedings/files/paper/ICCSTE_321.pdf (accessed on 17 May 2022).

- Ali, M.O.A.; Ja’e, I.A.; Hwa, M.G.Z. Effects of water depth, mooring line diameter and hydrodynamic coefficients on the behaviour of deepwater FPSOs. Ain Shams Eng. J. 2019, 11, 727–739.

- Montasir, O.A.A.; Yenduri, A.; Kurian, V.J. Mooring system optimisation and effect of different line design variables on motions of truss spar platforms in intact and damaged conditions. China Ocean Eng. 2019, 33, 385–397.

- Montasir, O.A.A. Numerical and Experimental Studies on the Slow Drift Motions and the Mooring Line Responses of Truss Spar Platform. Ph.D. Thesis, Universiti Teknologi Petronas, Seri Iskandar, Malaysia, 2012.

- Otteren, A. A mathematical model for dynamic analysis of a flexible marine riser connected to a floating vessel. Model. Identif. Control 1982, 3, 187–209.

- Bureau of Ocean Energy Management (BOEM). Deepwater Gulf of Mexico Report 2019; BOEM 2021-005; Bureau of Ocean Energy Management (BOEM), U.S. Department of the Interior: Washington, DC, USA, 2019. Available online: https://www.boem.gov/sites/default/files/documents/about-boem/Deepwater-Gulf-of-Mexico-Report-2019.pdf (accessed on 12 July 2022).

- Craig, J.; Gerali, F.; Macaulay, F.; Sorkhabi, R. (Eds.) The history of the European oil and gas industry (1600s–2000s). In History of the European Oil and Gas Industry; Special Publications; Geological Society: London, UK, 2018; Volume 465, pp. 1–24. Available online: https://sp.lyellcollection.org/content/specpubgsl/early/2018/06/20/SP465.23.full.pdf (accessed on 12 February 2022).

- Craig, J. Drilling: History of onshore drilling and technology. In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature Switzerland AG: Clam, Switzerland, 2021.

- Craig, J. History of oil: The premodern era (thirteenth to mid-nineteenth centuries). In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature Switzerland AG: Clam, Switzerland, 2021.

- Craig, J. History of oil: The birth of the modern oil industry (1859–1939). In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature Switzerland AG: Clam, Switzerland, 2021.

- Craig, J. History of oil: Regions and uses of petroleum in the Classical and Medieval periods. In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer Nature Switzerland AG: Clam, Switzerland, 2020.

- Purcell, P. Oil and Gas Exploration in East Africa: A Brief History. GEO EXPRO Magazine, 1 September 2014. Available online: https://www.geoexpro.com/articles/2014/09/oil-and-gas-exploration-in-east-africa-a-brief-history (accessed on 12 July 2022).

- Glennie, K.W. History of exploration in the southern North Sea. In Petroleum Geology of the Southern North Sea: Future Potential; Ziegler, K., Turner, P., Daines, S.R., Eds.; Special Publications 123; Geological Society: London, UK, 1997; pp. 5–16.

- Macini, P.; Mesini, E. History of petroleum and petroleum engineering. In Petroleum Engineering—Upstream, Vol IV; Eolss Publishers Co. Ltd.: Oxford, UK, 2018.

- Kontorovich, A.E.; Eder, L.V.; Filimonova, V.; Mishenin, M.V.; Nemov, V.Y. Oil industry of major historical centre of the Volga-Ural petroleum province: Past, current state, and long-run prospects. Russ. Geol. Geophys. 2016, 57, 1653–1667.

- Krzywiec, P. Birth of the oil industry in the northern Carpathians. In Proceeding of the Geological Society Conference on European Oil & Gas Industry History, London, UK, 3–4 March 2016; pp. 32–33.

- Krzywiec, P. The birth and development of the oil and gas industry in the Northern Carpathians (up until 1939). In History of the European Oil and Gas Industry; Craig, J., Gerali, F., MacAulay, F., Sorkhabi, R., Eds.; Special Publications; The Geological Society: London, UK, 2018; Volume 465, pp. 165–190.

- Spencer, A.M.; Chew, K. Petroleum exploration history: Discovery pattern versus manpower, technology and the development of exploration principles. First Break 2009, 27, 35–41.

- Zhang, G.; Qu, H.; Chen, G.; Zhao, C.; Zhang, F.; Yang, H.; Zhao, Z.; Ma, M. Giant discoveries of oil and gas fields in global deepwaters in the past 40 years and the prospect of exploration. J. Nat. Gas Geosci. 2019, 4, 1–28.

- Clauss, G.; Lehmann, E.; Ostergaard, C. Offshore Structures; Volume I: Conceptual Design and Hydromechanics; Springer: London, UK, 1992; p. 64.

- Ahmad, O. An overview of design, construction, and installation of gravity offshore platforms. Int. J. Adv. Eng. Sci. Appl. 2021, 3, 27–32.

- Department of Trade and Industry (DTI). An Overview of Offshore Oil and Gas Exploration and Production Activities; Prepared by Hartley Anderson Limited for Department of Trade and Industry (DTI); Department of Trade and Industry (DTI): Aberdeen, UK, 2001. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/197799/SD_SEA2EandP.pdf (accessed on 12 February 2022).

- Chalke, A.; Nalawade, S.; Khadake, N. Review on analysis of offshore structure. Int. Res. J. Eng. Technol. 2020, 7, 1241–1245. Available online: https://www.irjet.net/archives/V7/i8/IRJET-V7I8202.pdf (accessed on 12 February 2022).

- Sarhan, O.; Raslan, M. Offshore petroleum rig platforms—An overview of analysis, design, construction and installation. Int. J. Adv. Eng. Sci. Appl. 2021, 2, 7–12.

- Elrahim, M.K.A.; Husban, M. Analysis of the Lebanese oil and gas exploration in the Mediterranean Sea: An overview and analysis of offshore platforms. Int. J. Adv. Eng. Sci. Appl. 2021, 2, 25–29.

- Kharade, A.; Kapadiya, S. Offshore engineering: An overview of types and loadings on structures. Int. J. Struct. Civ. Eng. Res. 2014, 3, 16–28.

- Sadeghi, K.; Bichi, A. Offshore tower platforms: An overview of design, analysis, construction and installation. Acad. Res. Int. 2018, 9, 62–70. Available online: http://www.savap.org.pk/journals/ARInt./Vol.9(1)/ARInt.2018(9.1-08).pdf (accessed on 6 July 2022).

- Sadeghi, K.; Guvensoy, A. Compliant tower platforms: A general guidance for analysis, construction, and installation. Acad. Res. Int. 2018, 8, 37–56. Available online: https://www.researchgate.net/publication/323706788_Compliant_tower_platforms_general_guidance_for_analysis_construction_and_installation (accessed on 6 July 2022).

- Sadeghi, K.; Tozan, H. Tension leg platforms: An overview of planning, design, construction and installation. Acad. Res. Int. 2018, 9, 55–65. Available online: http://www.savap.org.pk/journals/ARInt./Vol.9(2)/ARInt.2018(9.2-06).pdf (accessed on 6 July 2022).

- Sadeghi, K.; Al-koiy, K.; Nabi, K. General guidance for the design, fabrication and installation of jack-up platforms. Asian J. Nat. Appl. Sci. 2017, 6, 77–84. Available online: http://www.ajsc.leena-luna.co.jp/AJSCPDFs/Vol.6(4)/AJSC2017(6.4-08).pdf (accessed on 22 May 2022).

- Esteban, M.D.; Couñago, B.; López-Gutiérrez, J.S.; Negro, V.; Vellisco, F. Gravity based support structures for offshore wind turbine generators: Review of the installation process. Ocean Eng. 2015, 110, 281–291.

- Shell. Shell’s Deep Water Portfolio in the Gulf of Mexico. Available online: https://www.shell.us/energy-and-innovation/energy-from-deepwater/shell-deep-water-portfolio-in-the-gulf-of-mexico.html (accessed on 26 August 2020).

- bp America. Our Platforms—Gulf of Mexico. Available online: https://www.bp.com/en_us/united-states/home/where-we-operate/gulf-of-mexico/our-platforms.html (accessed on 26 August 2020).

- Bureau of Safety and Environmental Enforcement (BSEE). FAQS/How Many Platforms Are in the Gulf of Mexico? Available online: https://www.bsee.gov/subject/decommissioning-faqs (accessed on 26 August 2020).

- Chitwood, J.E.; McClure, A.C. Semisubmersible Drilling Tender Unit. SPE Drill. Eng. 1987, 2, 104–110.

- Lim, E.F.H.; Ronalds, B.F. Evolution of the production semisubmersible. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000. Paper No. 63036-MS.

- Ochoa, O.O. Composite Riser Experience and Design Guidance; MMS Project Number 490; Offshore Technology Research Center: Austin, TX, USA, 2006. Available online: https://www.bsee.gov/sites/bsee.gov/files/tap-technical-assessment-program//490aa.pdf (accessed on 13 January 2022).

- Chandrasekaran, S.; Nagavinothini, R. Offshore triceratops under impact forces in ultra-deep arctic waters. Int. J. Steel Struct. 2020, 20, 464–479.

- Odijie, A.C. Design of Paired Column Semisubmersible Hull. Ph.D. Thesis, Engineering Department, Lancaster University, Lancaster, UK, 2016.

- Odijie, A.C.; Wang, F.; Ye, J. A review of floating semisubmersible hull systems: Column stabilized unit. Ocean Eng. 2017, 144, 191–202.

- Yu, L.C.; King, L.S.; Hoon, A.T.C.; Yean, P.C.C. A review study of oil and gas facilities for fixed and floating offshore platforms. Res. J. Appl. Sci. Eng. Technol. 2015, 10, 672–679.

- Zhang, J.; Koh, C.G.; Trinh, T.N.; Wang, X.; Zhang, Z. Identification of jack-up spudcan fixity by an output-only substructural strategy. Mar. Struct. 2012, 29, 71–88.

- Ronalds, B.F. Applicability ranges for offshore oil and gas production facilities. Mar. Struct. 2005, 18, 251–263.

- Reddy, D.; Swamidas, A. Essentials of Offshore Structures: Theory and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013.

- Tan, X.; Li, J.; Lu, C. Structural behaviour prediction for jack-up units during jacking operations. Comput. Struct. 2003, 81, 2409–2416.

- Hartman, L. Top 10 Things You Didn’t Know About Offshore Wind Energy; US Department of Energy (DOE), Wind Energy Technologies Office: Washington, DC, USA, 2021. Available online: https://www.energy.gov/eere/wind/articles/top-10-things-you-didnt-know-about-offshore-wind-energy (accessed on 30 May 2022).

- Murugaiah, S. A Review Study of Floating, Production, Storage and Offloading (F.P.S.O.) Oil and Gas Platform. Bachelor’s Thesis, Department of Petrochemical Engineering, Universiti Tunku Abdul Rahman, Kampar, Malaysia, 2015. Available online: http://eprints.utar.edu.my/1759/1/A_Review_Study_of_Floating%2C_Production%2C_Storage_and_Offloading_(FPSO)_Oil_and_Gas_Platform.pdf (accessed on 30 May 2022).

- Wells, B.A.; Wells, K.L. Mr. Charlie, First Mobile Offshore Drilling Rig; American Oil & Gas Historical Society (AOGHS): Washington, DC, USA, 2018; Available online: https://aoghs.org/offshore-history/mr-charlie-first-mobile-offshore-drilling-rig/ (accessed on 30 May 2022).

- Menon, J. What Are Jack Up Barges? Marine Insight. 2021. Available online: https://www.marineinsight.com/offshore/jack-up-barges/ (accessed on 30 May 2022).

- Wang, C.M.; Utsunomiya, T.; Wee, S.C.; Choo, Y.S. Research on floating wind turbines: A literature survey. IES J. Part A Civ. Struct. Eng. 2010, 3, 267–277.

- Renewable Energy Magazine (REM). Horns rev 2 offshore wind farm in Denmark topped 10 billion kWh. Renewable Energy Magazine, 5 February 2021. Available online: https://www.renewableenergymagazine.com/wind/horns-rev-2-offshore-wind-farm-in-20210205 (accessed on 30 May 2022).

- Rosa-Aquino, P. Floating wind turbines could open up vast ocean tracts for renewable power. The Guardian, 29 August 2021. Available online: https://www.theguardian.com/environment/2021/aug/29/floating-wind-turbines-ocean-renewable-power (accessed on 30 May 2022).