Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Civil

Recycled powder (RP) is a by-product of preparing recycled aggregates from construction waste through debris removal, step-by-step crushing, screening, and mechanical strengthening. It is a fine powder with a particle size of less than 75 μm.

- recycled powder (RP)

- cement cementitious material

- mechanical properties

1. Introduction

With the rapid development of the economy, the ecological environment, natural resources, and other problems have become increasingly prominent. According to the estimation of relevant industry associations, China’s annual waste production has exceeded 2 billion tons in recent years. As a result, China’s annual production scale of waste reached 2.8 billion tons in 2020. It is expected to reach 7.3 billion tons in 2030, with construction waste already accounting for 40% to 50% of total waste [1]. Construction waste is usually disposed of by landfill or incineration, which inevitably causes many environmental problems, such as air quality and soil pollution.

In the 1980s, Buck pointed out the use of concrete waste from construction waste to prepare recycled aggregates for the green recycling of construction waste. This idea was quickly recognized, and research on the green recycling of construction waste continues today [2]. However, some developed countries have done a better job in this area, and they have reached 60% to 97% waste resource utilization rate. Among them, the European Union (90%), Japan (97%), and Korea (97%) have reached a reasonably high level [3]. For example, South Korea’s “Lifom System” decoration company separates the cement, sand, and steel in the concrete, then heats them at a high temperature of 700 °C and adds particular substances to produce recycled cement. This recycled cement complies with Korean construction standards and produces no carbon dioxide during production [4].

Currently, there are two main methods of resource utilization of construction waste: (1) preparation of recycled concrete, recycled bricks, and other construction materials. For example, Wu [5] et al. used construction brick mix waste to prepare recycled concrete pavement blocks and tested their basic mechanical properties early. The research results showed that the recycled concrete pavement bricks prepared using the raw materials and mixing ratio of construction brick and concrete waste met the requirements of relevant specifications. Soni [6] et al. used construction waste to produce crushed recycled coarse aggregate (CRCA) to replace natural sand as fine aggregates. The study demonstrated that concrete with improved compressive strength could be produced with 100% incorporation of specific CRCA as fine aggregate. (2) Used in road base pavement, foundation treatment, or subsidiary settings in road projects. For example, Cosenza [7] et al. applied recycled aggregates prepared from construction waste (mainly basalt, sandstone, and structural concrete) instead of natural aggregates in road subgrade. The research showed that the recycled mixes had good mechanical properties for road subgrade construction. Li [8] studied the road performance of construction waste fine aggregates applied to road base backfill materials. The results showed that both recycled aggregates of concrete block and brick structure could meet the strength requirements of road base materials when the compaction meets the specification requirements.

In the process of recycling construction waste, many scholars prepare it into recycled aggregates to be utilized. However, a certain amount of fine powder with a particle size of less than 75 μm, called recycled powder (RP), will be produced with this preparation of recycled aggregates. The use of RP is of great significance for the full recycling of construction waste. Schoon et al. [9] and Park et al. [10], found that RP contains some active substances and a large amount of SiO2, and the results of the study showed that 10% to 15% of the cement can be replaced by the same mass of RP in concrete. However, this untreated RP will reduce the performance of the concrete. Cwirzen [11] and Han-Young et al. [12] found that the addition of RP reduced the mechanical properties of concrete, and Singh [13] et al. also established a mathematical model of marble powder admixture and 28 d compressive strength of concrete. Foreign scholars also studied the influence of RP incorporation on concrete durability in detail. Kim [14] and Sabina [15] et al. found that the carbonation depth was positively correlated with the amount of RP in their experimental studies. Ann [16] tested that exposing recycled brick powder (RBP) concrete to high temperatures can improve the strength of concrete, and Lam [17] reported that adding 20–45% recycled brick powder (RBP) can improve the heat resistance of concrete.

Compared with developed countries, China started relatively late in this field, but domestic scholars have also made specific achievements. Mao [18] studied the chemical composition of recycled powder, fly ash, and cement. The three substances were similar in composition, differing only in the contents of Al2O3, CaO, and SiO2. It was inferred that RP has class activity and is feasible as a cementitious material instead of cement. Yu [19] compared two different mechanical crushing methods—airflow crushing and vibratory ball mill crushing—to deal with RP. It was found that the airflow-crushed RP had more uniform particles and higher activity. The mortar’s compressive strength was higher than the RP mixed with vibratory ball mill grinding. RP’s admixture was increased to improve its utilization rate and utilization range. Zhang [20] found that when the fine recycled powder content is less than 20%, the higher the content, the better the frost resistance. For resistance to sulfate erosion, the higher the content of RP, the more serious the sulfate erosion.

2. Source and Preparation of RP

2.1. Source of RP

According to the difference in the scale of preparation, the sources of RP can be divided into two categories: (1) small-scale preparation in the laboratory using waste cement-based materials to grind and prepare RP. The advantage of this RP is that the mixing ratio, age, and other factors of the raw materials can be clearly understood, which can provide reliable support for the later analysis of the experimental results. However, its disadvantages are also very obvious. Due to the varying level of laboratory equipment, the particle size distribution and fineness of the RP produced cannot be guaranteed, and the performance varies significantly. (2) Large-scale standardized preparation in factories. The advantage of this RP is that various parameters such as fineness and particle shape can be controlled through a standardized preparation process. Its disadvantage is that the composition of construction waste is complex. As a result, the performance parameters of the original material of the RP cannot be traced.

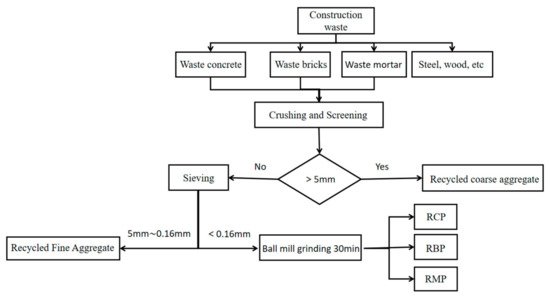

According to the different original materials, the sources of RP can be divided into three categories: (1) the fine powder particles obtained by the crushing, screening, and grinding of waste concrete are called recycled concrete powder (RCP). (2) Discarded bricks or red bricks after debris removal crushed and ground to achieve a particle size of less than 75 μm, known as a recycled brick powder (RBP). (3) The fine powder produced from the waste cement mortar after a series of processes such as crushing and grinding is called recycled mortar powder (RMP). These three different powders together make up the RP.

2.2. Preparation of RP

Regarding the preparation of RP, extensive research has also been conducted by domestic and foreign scholars. Li et al. [21] made ultrafine powder with coal gasification fine slag from seven regions as raw material. The influence of ball milling time was investigated when subjected to the particle size, specific surface area, microstructure, and phase composition of ultrafine powder. Results showed that the particle size of ultrafine powder changed before ball milling, and the specific surface area increased to 890 m2/kg when particle size decreased. With the increase of ball milling time, more spherical particles change into irregular, and angular particles, the crystal phase strength of ultrafine powder decreases the diffraction peak width increases, and it has higher reactivity. Liu [22] used aerated concrete blocks and sintered clay bricks to prepare RP. The study showed that aerated concrete blocks were more accessible to break than sintered clay bricks. However, the energy consumption of grinding aerated concrete blocks to less than 0.30 mm powder was higher than that of sintered clay brick powder. In their experiment, Liu [23], Huang [24], et al. used the RP generated in the production of recycled aggregate by construction waste in the factory. However, this kind of regenerated micro powder has a small specific surface area and low activity, which often needs to be activated in the later use process. Fu [25], Kang [26], Zhao [27], et al. used RP from discarded beams and concrete column components in their experiment in the laboratory after step-by-step crushing, screening, and grinding.

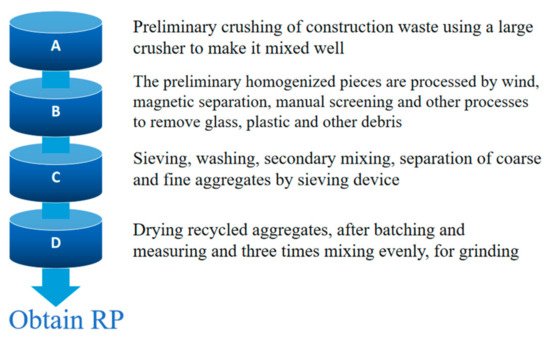

The preparation process of RP can be divided into three types according to different equipment conditions and preparation methods: (1) The RP was obtained by crushing, sieving, grinding, and processing and preparing from waste concrete in the laboratory. (2) Prepared by specialized building materials enterprises using standard industrial processes. The larger volume of construction waste is crushed for the first time, followed by removing impurities such as plastic, steel, and woodblocks from the waste using wind and magnetic separation. The impurities in the construction waste are first screened, then sorted for the second time by manual screening. Then, the mud and mortar on the surface of the fragments are separated by a professional grinding machine. The screening system crushed the coarse aggregates of different particle sizes for the second time; in the fourth step, the aggregates were ground into powder by the grinding equipment [28]. The process of industrial preparation of RP is shown in Figure 1 below. (3) RP is obtained by collecting byproducts from the preparation of regenerated aggregate. Figure 2 below shows the flow chart of the preparation of RP. Figure 5 showS the prepared RCP, RBP, and RMP, respectively.

Figure 1. Process of industrial preparation of RP.

Figure 2. Preparation process of RP in laboratory.

Figure 5. RMP.

In RP preparation, the grinding stage is crucial, and the grinding equipment and grinding time play an essential role in the performance of RP. Fediuk et al. [31] invented a grinding machine that can grind powders to nano-scale, resulting in more uniform particles and better gradation than ordinary grinding equipment. Yu [19] ground the same RP using an ultra-micro airflow crusher for 30 min and vibrating ball mill for 120 min. The RP treated with the airflow crusher was active, and it was added to the mortar instead of being used as part of the cement to enhance the hydration of the cementitious material. This can promote the strength of the mortar. The grinding time also affects the performance of the RP. Different grinding equipment grinds for different times, and the performance of the RP obtained varies. The length of grinding time determines the RP’s fineness and specific surface area. Wang et al. [32] used a ball mill to grind waste concrete particles for 60, 90, and 120 min. The specific surface areas of the powder particles were 389.32 m2/kg−1, 464.51 m2/kg−1, and 467.08 m2/kg−1, respectively. Yu et al. [33] used a crusher and a conical ball mill to make RP from brick and concrete construction waste. Its average diameter was controlled below 40 μm, which improved recycled fine powder use efficiency in concrete. Li et al. [34] found that using a ball mill to grind RP, the amount of RP with a particle size of less than 20 μm increased continuously with the increase in grinding time. When the grinding time exceeded 20 min, the grinding efficiency decreased, and the RP obtained at 30 min had the highest activity. The grinding time is not as long as possible, and beyond a certain time, continued grinding will only result in a waste of resources and has little effect in improving the activity of the RP. The optimal grinding time is related to the type of grinding equipment, the type of RP, the initial particle size of RP, and other factors. The current research on this aspect is still slightly insufficient. Determining the optimal grinding time for different equipment and different types of RP is of great significance for the industrial production of RP.

3. Fundamental Properties of RP

3.1. Physical Properties of RP

The physical properties of recycled RP vary somewhat depending on the preparation method and the source of the material. The apparent density of RP is generally 2300 kg/m3 to 2700 kg/m3, the specific surface area is 300 m2/kg to 700 m2/kg, and the bulk density is 870 kg/m3 to 920 kg/m3 [35,36,37,38,39]. Regarding the particle size of RP, due to differences in experimental materials and instruments, domestic scholars have reached different conclusions, and Gao et al. [40] measured the average particle size of RP as 29.78 μm when the construction waste was produced by particle shaping. Zhao [4] used laboratory-discarded concrete beams, which were crushed by a jaw crusher, sieved with a 0.15 mm standard square-hole sieve, and finally ball-milled in a ball mill for 30 min, resulting in an RBP with an average particle size of 42.603 μm. Xue [41] crushed and sieved the RP obtained from the waste concrete pavement and measured the average particle size to be 30.2 μm. The experimental results of various scholars differed slightly, but the average particle size of the measured RP was concentrated in the range of 30–50 μm. The physical indicators of RP are summarized in Table 1 below.

Table 1. Physical index of RP.

| Average Particle Size (μm) | Apparent Density (kg/m3) | Specific Surface Area (m2/kg) | Bulk Density (kg/m3) |

|---|---|---|---|

| 30~50 | 2300~2700 | 300~700 | 870~920 |

3.2. Chemical Composition of RP

RP is mainly divided into RCP, RBP, and RMP. These three RPs have the same main chemical composition but different contents, and their main components are SiO2, CaO, and Al2O3, respectively [42,43,44]. The content of the three components exceeds 80% of the total composition. The content of SiO2 is the highest, accounting for about 50% of the total content, mainly from the aggregate of waste raw materials and cementitious material. They are followed by CaO, mainly from cementitious material. Finally, the content of Al2O3 ranks third because the bricks are not included in the cementitious materials. The specific composition of its chemical composition is shown in Table 2 below. In concrete applications, two components—SiO2 and Al2O3—are beneficial to the mechanical properties of concrete; SiO2 particles promote volcanic ash reactions, and Al2O3 contributes to the formation of calcium alumina and improves the early mechanical properties of the cementitious material [45]. Therefore, the early mechanical properties of concrete mixed with RBP are better than those of RCP and RMP under the same conditions.

Table 2. Chemical composition of RP.

| SiO2 | CaO | Al2O3 | Fe2O3 | MgO | K2O | Na2O | SO3 | Source | |

|---|---|---|---|---|---|---|---|---|---|

| RCP | 50.93 | 18.18 | 13.55 | 6.37 | 2.75 | 3.50 | 2.45 | 0.92 | [46] |

| RBP | 60.56 | 10.07 | 17.16 | 3.46 | 1.78 | 2.50 | 1.26 | 0.34 | [46] |

| RMP | 56.64 | 17.41 | 10.54 | 5.59 | 1.24 | 3.53 | 3.02 | 0.92 | [46] |

| RCP | 62.18 | 10.24 | 10.15 | 2.49 | 1.91 | 1.73 | 1.30 | 0.47 | |

| RBP | 63.12 | 8.52 | 12.29 | 2.68 | 1.33 | 2.02 | 1.74 | 0.37 | |

| RCP | 48.25 | 27.55 | 11.09 | 4.94 | 2.42 | 2.25 | 1.20 | [47] | |

| RBP | 67.83 | 1.67 | 16.20 | 7.55 | 0.94 | [48] | |||

| RP | 63.1 | 10.2 | 10.3 | 2.5 | 1.9 | 1.8 | 1.4 | 0.5 | [32] |

| RP | 47.9 | 18.7 | 12.0 | 6.53 | 2.26 | 2.33 | 0.86 | 1.41 | [22] |

3.3. Microscopic Analysis of RP

For the microscopic analysis of RP, Jin [49] used an X-ray diffractogram (X’Pert PRO MPD) to conduct phase analysis on the RP of construction waste. The results showed that the main phase of micro-powder of construction waste was SiO2, calcium silicate hydrate (C-S-H), CaCO3, and calcium aluminate hydrate (CAH). On the other hand, Yao [50], Zhang [51], et al. used an X-ray diffractogram to analyze the phase of the RP. The results showed that the main phase of the RP was SiO2 and CaCO3 and did not contain calcium silicate hydrate or calcium aluminate hydrate. The reasons for the above phenomenon are as follows: (1) the sources of RP are waste concrete and mortar, and its main components are SiO2 and CaCO3; (2) calcium silicate hydrate and calcium aluminate hydrate will react with CO2 in the air to produce SiO2 and CaCO3. Chen [52] observed the RP and the cement with an SEM electron microscope and found that compared to the cement particles, the RP particles are primarily irregular, with many fine particles attached to the surface, which is relatively rough and has a joint surface. Lv [53] used the Japanese JSM-7610F to analyze the micromorphology of RP and found that there were more sharp angles and irregular edges in the powder’s morphology. In addition, the surface was rough with a jagged microstructure, and Lv explained that this was the main reason for the reduced compatibility of the RP cement-based materials. Under the electron microscope, the particle morphology of RP powder is crumbly and angular, displaying irregular shapes. The surface is rough and lusterless, and the particle size varies. This microstructure causes RP’s workability and water retention to deteriorate, increasing water requirement.

3.4. Activity Index

The activity index is a crucial indicator of gelling materials. According to the determination method of the activity index of RP in JG/T573-2020 “Recycled powder for Concrete and Mortar,” the RP is used instead of 30% cement to prepare mortar. After curing for 28 days, the compressive strength is measured after 28 days, and the 28 d compressive strength is compared to that of the mortar without RP to obtain the activity index of RP. Extension of the grinding time can increase the activity of the RP. The activity index of the initial RP was measured by Zhao et al. [55] as 55%, the activity index of the RP was 61% for 10 min of ball milling, and the activity index of the RP was about 72.6% for 30 min of ball milling. Kang [26] found that the activity index of RP increased from 55% to 71% after 30 min of grinding with a planetary ball mill. The particle gradation of RP affects the activity index of RP, and Fan [56] experimentally obtained that the activity index of RP was greater than 60% at 28 d. In contrast, the activity index of fly ash was relatively low. Y.H. [57] found that the activity index of 28d R.P. was higher than that of fly ash. The reasons for this situation are as follows: (1) The small particle size of RP can fill the gaps in cementitious material, which is conducive to developing the “micro-aggregates” filling effect. (2) The RP contains large amounts of Si, Al, Ca, and other elements necessary to form cementitious materials, so its activity index is extensive. The strength of the raw material used to prepare the RP also has an effect on the activity index of the RP, and Chen [58] measured that the 28 d activity indexes of the RP obtained from the preparation of C30 and C65 waste concrete were 75% and 80%, respectively. The type of grinding equipment has a significant impact on the activity index of the RP. Yu [19] used the airflow grinder to grind the RP, and the strength activity index of the RP was >0.7. According to [59], the RP activity index prepared by the ultrafine air grinder was higher than that of the RP prepared by vibration grinding.

According to the physical properties, chemical composition, microstructure, and activity index, the RP has a small particle size and a large specific surface area, which is conducive to the “micro-aggregates” filling effect. In addition to exhibiting periodic microstructure and high water absorption capacity, the activity index of RP is higher than that of fly ash. These factors make the RP potentially active, indicating the feasibility of RP as an auxiliary cementitious material. C.S. et al. [60] studied the correlation of RP and found that the average particle size of RP was small, the specific surface area was large, and the water absorption capacity was strong. They proposed the feasibility of RP as an auxiliary cementitious material.

This entry is adapted from the peer-reviewed paper 10.3390/ma15155408

This entry is offline, you can click here to edit this entry!