Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Civil

Concrete is a commonly used building material; however, it is subject to abrupt failure and limited energy absorption when yielding. The use of short discrete fibers has displayed a lot of potential in overcoming these issues. Sisal is a natural fiber that is renewable, inexpensive, and readily accessible. SSF is a potential reinforcement for use in concrete because of its cheap cost, low density, high specific strength and modulus, negligible health risk, easy accessibility in certain states, and renewability.

- concrete

- sustainable concrete

- natural fibers

1. Sisal Fibers (SSF)

Sisal may be readily grown in a short amount of time. Field hedges and railway lines are natural habitats for the plant [25]. According to a study, SSF is harvested around the globe at a pace of roughly 4.5 million tons per year [26]. It is made from the leaves of the sisal plant (Agave sisalana), which is now grown in tropical African, Caribbean, and Asian countries [27]. A sisal plant typically has 200–250 sisal leaves, each of which may have at least 1000–1200 fiber bundles. A sisal plant comprises 4% fiber, 0.75% cuticle, 8% dry matter, and 87.25% water in total [28]. In general, SSF is removed using retting, scraping, and mechanical processes such as decorticators [29].

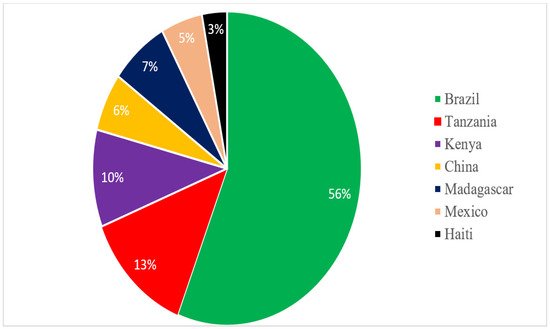

Fiber production was 281,000 tons worldwide in 2013, with Brazil generating 150,584 tons. Tanzania (34,875 tons per year), Kenya (28,000 tons per year), Madagascar (18,950 tons per year), China (16,500 tons per year), Mexico (12,000 tons per year), and Haiti (9000 tons per year) all produce sisal. It is economically possible for the country’s underdeveloped northeast religion, which supports roughly 800,000 people. Sisal ranks as sixth among fiber plants, accounting for 2% of the global plant fiber output [30]. Figure 1 shows the worldwide production of sisal plants.

Figure 1. Worldwide production of sisal plants.

Several researchers reported different chemical compositions of SSF. Sisal, for example, comprises 4356% cellulose, 79% lignin, 2124% pentosan, and 0.61.1% ash, according to Rowell [31]. Joseph et al. [32] recently found that sisal contains 85 to 88 percent cellulose. The considerable differences in chemical contents of SSF are due to its various sources, ages, testing techniques, and other factors. A study [33] discovered that the cellulose and lignin content of sisal varies between 49.62 ± 60.95 and 3.75 ± 4.40 percent depending on the plant’s age, which may be due to different sources or regain of SSF.

Sisal fibers may be added to cement to slow down the cement’s hydration process and to extend the setting durations [34]. Natural fiber composites are increasingly preferred over synthetic fiber composites due to inherent benefits, including affordability and environmental friendliness [35]. Comparing concretes that include fibers to those that do not, significant improvements in the primary strength parameters were found [36].

SSF is mostly a white, creamy color as shown in Figure 2 and ranges in length and diameter. Other qualities, such as tensile capacity and elastic modulus, change according to the source and intended use. The physical qualities of SSF have been described by several researchers. Table 1 lists the many physical characteristics of fibers as determined by previous studies.

Table 1. Characteristics of SSF.

| Authors | [37] | [38] | [39] | [40] | [41] |

|---|---|---|---|---|---|

| Specific gravity | 0.73 | - | - | - | 1.4 |

| Water Absorption (%) | 43.58 | - | - | - | - |

| Color | Creamy white | - | - | - | - |

| Elongation at Break (%) | - | 5–14 | 5–14 | 14.8 | - |

| Density (g/cm3) | 0.113 | - | 1.45 | - | - |

| Tensile capacity (MPa) | 371 ± 28 | 400–700 | 400–700 | 31–221 | 560 |

| Elastic modulus (GPa) | 12.43 ± 2.23 | 9–20 | 9000–20000 | - | - |

| Fiber length (mm) | 30 | - | - | 180–600 | 12 |

Figure 2. Sisal fibers (SSF) [42].

2. Treatments of SSF

To minimize the hydrophilicity of the fiber, two basic kinds of fiber treatments were used: bulk and surface treatments. The key difference between both treatments is that the first causes a drastic modification of the whole fiber, which nearly invariably changes its morphology and semi-crystalline phase, while the second leaves these traits practically unchanged, except for a thin outer layer [43].

Heat treatments of sisal fibers, such as wetting–drying cycles [44] or mechanical pression [45], result in a decrease in fiber area and lumen dimension, lowering moisture absorption.

The most common way to improve fiber–matrix interaction is to treat the fibers’ surfaces with different coupling agents. Coupling agents are molecules with two functions: the first is to react with the OH groups of cellulose (pore sealing) and the second is to react with the matrix’s functional groups (increased chemical linkages) [46]. Coupling agents increase the degree of crosslinking at the interface and provide perfect bonding [47]. Several studies have researched the impact of the surface treatment of sisal fibers with different coupling agents on fiber durability and fiber–matrix interaction. Silane coupling agents are efficient in altering the natural fiber–matrix interface; silane treatment of sisal fibers alters the surface topography, surface chemical structure, and thermal degradation [48]. Canovas et al. [49] impregnated sisal fiber with wood extracts (colophony, tannin, and vegetable oil), which showed excellent results in reducing water absorption (more than 50%) despite a modest drop in fiber tensile strength. Flexural experiments show that mortar reinforced with impregnated fibers has superior durability to mortar reinforced with unimpregnated fibers. Toledo Filho et al. [50] investigated the impact of treating aligned long sisal fiber with silica fume on the durability of cement-based composites, concluding that this treatment is a viable strategy for improving the composites’ strength and toughness over time.

When sisal fibers were treated with 5 and 10 percent NaOH, the moisture absorption increased by 30 and 40 percent, respectively [51]. The findings obtained indicate that the mechanical and physical characteristics of block material were enhanced by the combined effects of fibers and cement [52]. The silica treatment produced the most effective barrier against fiber biodegradation because of the inorganic basis, which increased the longevity of the composite over eight months [53]. It was discovered that the sisal fiber’s crystalline form would switch from cellulose I to cellulose II as the sodium hydroxide concentration increased [54].

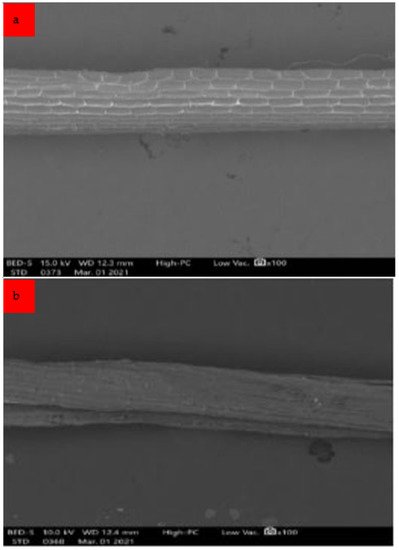

The impact of the treatment on the fiber composition and appearance was examined using scanning electron microscopy (SEM). The images in Figure 3a,b were captured at a magnification of 100. The fiber’s surface seems to be smooth, with some surface microfibrils visible. Because the microfibrils are on the primary wall of the fiber structure, they are amorphous microfibrils. Because their cellulose surface is covered by both hemicellulose and lignin components of the fiber at the main wall, which functions as a weak barrier layer between the fiber and the matrix, natural fibers have low fiber compatibility with the matrix [55]. The surface characteristic of treated SSF differs from that of untreated SSF, according to the research. The fibrillose-like structure of the untreated SSF is visible, while the fibrillose surface structure of the treated fibers is extracted [56]. Because of the boundary layer at the fiber–matrix contact, the composite’s stress distribution capacity is often limited. Chemical treatment is required to eliminate the weak boundary layer in composites for improved stress transfer performance. Figure 3b depicts SSF that has been alkaline treated. The fiber’s surface has become rougher, indicating that some surface material has been removed. Alkaline treatment of natural fibers improves fiber hydrophilicity by removing a portion of hemicellulose, lignin, and other surface contaminants that form the weak boundary layer, exposing the cellulose crystalline microfibrils to the fiber surface [57]. In this case, the treated SSF is thought to be more compatible with the matrix, and the rougher surface improves fiber–matrix adhesion even more than the raw SSF [58].

Figure 3. (a) Untreated and (b) treated SSF [59].

3. Application of SSF in Construction

Traditionally, cement has been utilized for structural purposes for decades. There is a need for alternate materials or a technique to minimize the price of housing functions due to the rising need and cost of the raw material. Roofing tiles, dividing boards, flat and corrugated sheets, and other sisal–cement composites have long been investigated in underdeveloped nations for use in the construction of low-cost dwellings and structures [131]. Because of its high thermal and acoustic insulation capabilities, as well as exceptional tensile strength and toughness, SSF takes the lead among plant fibers in the building sector. Surprisingly, research on cement composites reinforced with SSF has also revealed the material’s possibility to be employed in buildings, owing to its greater water permeability resistance [125] and mechanical qualities that are suitable for structural applications [132]. The deterioration of natural fiber-reinforced concrete over time is the biggest stumbling block to their use in the building. This constraint may be circumvented by using low alkali cement, which significantly minimizes fiber deterioration, making natural fiber-reinforced cement a viable option [133].

For fibers made from natural sources, in a variety of industries, including automotive, aerospace, marine, sports goods, and electronics, reinforced composites are quickly gaining popularity as a viable substitute for metal- or ceramic-based materials [134]. Natural fibers are used in a variety of goods, including building materials, particle boards, insulation boards, human and animal feed, cosmetics, medicines, and other biopolymers and fine chemicals [135]. As a consequence, monolithic materials are being phased out in favor of fibers and materials such as carbon, glass, and aramid fibers, which are extensively used in industries such as aerospace, automotive, construction, and sports [136]. Natural fibers are utilized as reinforcement in composites (such as cement paste, mortar, and concrete) in the construction industry because they are cost-effective in increasing tensile strength, shear strength, toughness, and energy absorption capacity [137]. Natural fiber composites provide a number of benefits over synthetic fiber composites, including cheap cost, being lightweight, high specific mechanical characteristics, nonhazardous nature, eco-friendliness, renewability, and so on. As a consequence, its use in a variety of fields, including aeronautical engineering, seems to be promising [136]. Natural fiber parts for interior components are widely produced in the automobile and aerospace industries [138]. Natural fibers are also utilized to manufacture a variety of insulation materials, such as blowing insulation, pouring insulation, impact sound insulation materials, and ceiling panels for thermal and acoustic soundproofing [139].

This entry is adapted from the peer-reviewed paper 10.3390/cryst12070952

This entry is offline, you can click here to edit this entry!