Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

For piezoresistive sensors, conductive polymers such as thermoplastic polyurethane (TPU), fiber-reinforced polymer (RFP), and Parylen-C polymer film can be used to increase sensor flexibility. For piezoelectric sensors, using piezoelectric ceramics such as ethyl cellulose-poly lead zirconate titanate piezoelectric ceramics (ECS-PolyPZT) and PZT-ferroperm as the sensing material can produce high piezoelectric coefficients.

- piezoresistive material

- gait analysis

1. Piezoresistive Sensing Mechanisms and Suitable Materials

With the piezoresistive technique, by imposing external force on a material, the resistance of the material dynamically changes according to the external force. Through constructing readout circuits and connecting them with material, the change in resistivity can be reflected through the changes in the output voltage [1]. Hence, the relationship between output voltage and applied force can be formulated, enabling the measurement of external force.

Chen et al. [2] and Gao et al. [3] have reported that piezoresistive representative materials consist of conductive ink, conductive polymers (fabrics and foams), and metal liquids. For these three kinds of materials, the process of achieving the piezoresistive effect varies. For conductive ink and polymers, the original materials are nonconductive; hence, their conductivity can be adjusted through methods such as doping fillers or heating. For metal liquids, which are already conductive, the major focus of the process is constructing metal gauge pieces with metal liquids because gauges produce different responses under external force in multiple directions.

1.1. Piezoresistive Sensing Mechanism of Conductive Polymers

To reflect a force with electric signals, piezoresistive sensing material should be conductive or semiconductive. Therefore, adjusting the conductivity of polymers is needed to transform polymers into piezoresistive sensing materials. According to the original conductivity, conductive polymers can be categorized into extrinsic and intrinsic polymers, each of which has different sensing mechanisms.

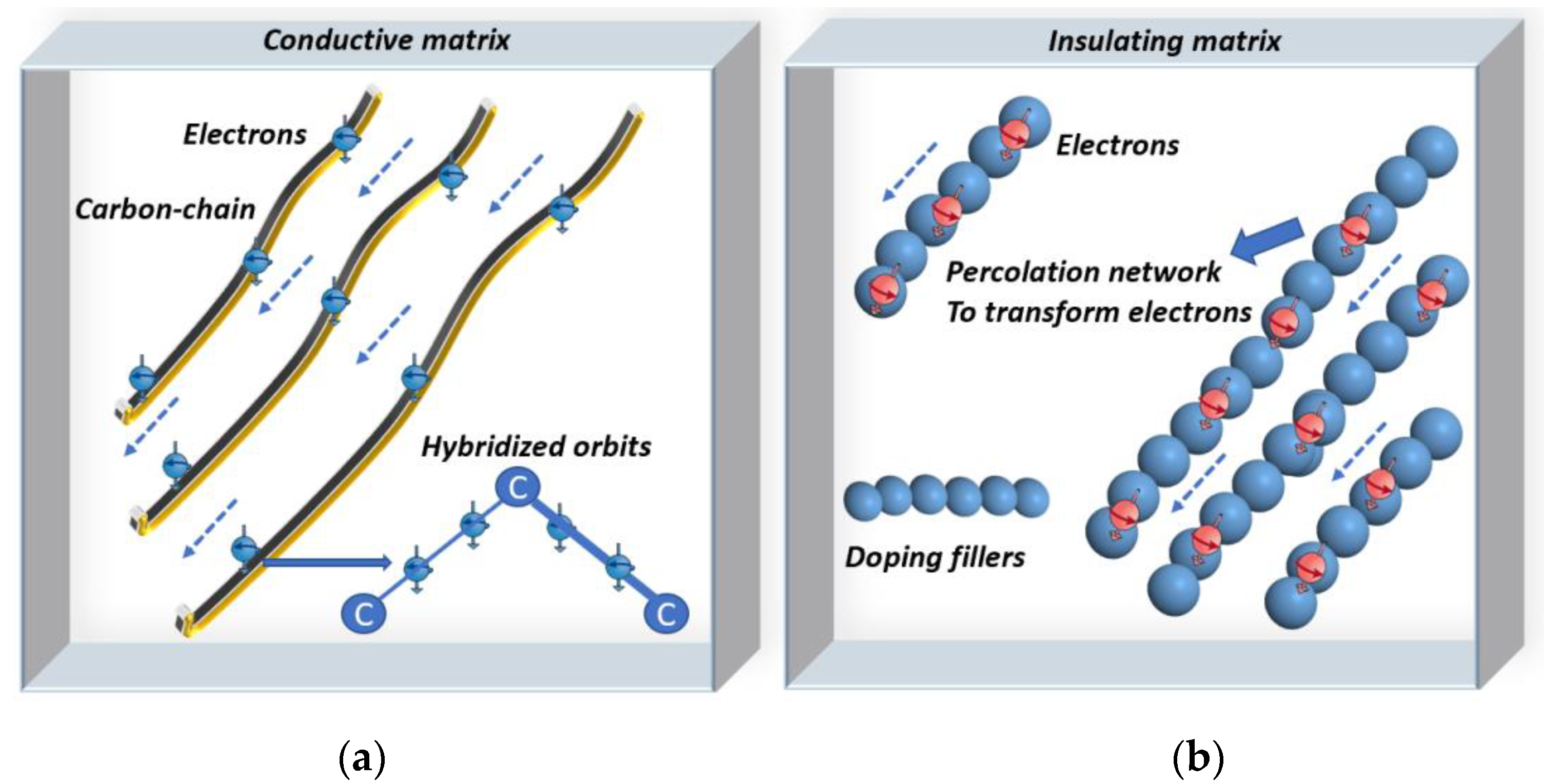

The processing of the extrinsic polymers focuses on doping the raw nonconductive material with a conductive material. When the concentration of added conductive fillers meets the percolation threshold, the conductive filler forms a percolation network that permits the electrons to move from one filler particle to another one [4]. This is also known as electron tunneling, which indicates the material has become conductive, which enables the conductivity of extrinsic polymers to be adjusted to achieve piezoresistivity [5].

Intrinsic polymers are named as such because of their hybridized orbits and special chemical bonds. Electrons connected by three sigma bonds can dwell in the p-z orbit. Thus, breaking the sigma bonds can release the restricted electrons, which can then transfer to the carbon chains. To achieve this purpose, suitable methods include doping particles into intrinsic polymers or heating. Therefore, the released electrons increase the conductivity of the material to achieve piezoresistivity [4][5][6]. Figure 1 illustrates the mechanisms of conductive intrinsic and extrinsic polymers.

1.2. Piezoresistive Sensing Mechanism of Conductive Ink

The general types of conductive ink include carbon nanoparticles, metallic compounds, and metal nanoparticles [7]. In pressure sensors, carbon nanotubes and metallic compounds are most frequently applied [8][9]. On the one hand, the resistivity of metallic particles is relatively lower than that of conductive polymers [7], producing increased piezoresistivity. On the other hand, carbon nanotubes possess high flexibility and stretchability [7]. Therefore, compounds of carbon nanotubes and metallic particles are suitable for piezoresistive force sensors.

Processing conductive ink to attain the piezoresistive effect is simple. This can be achieved by heating the material because high temperatures break the metal–carbon composites into metallic particles, which can transfer electrons. Another method involves inserting special particles such as Au or Ag into the solvent at a particular ratio to produce a conductive liquid solution for further fabrication such as combining carbon nanotubes in [7][10]. Using these two methods, the raw material can become conductive or semiconductive.

1.3. Piezoresistive Sensing Mechanism of Metal Liquids

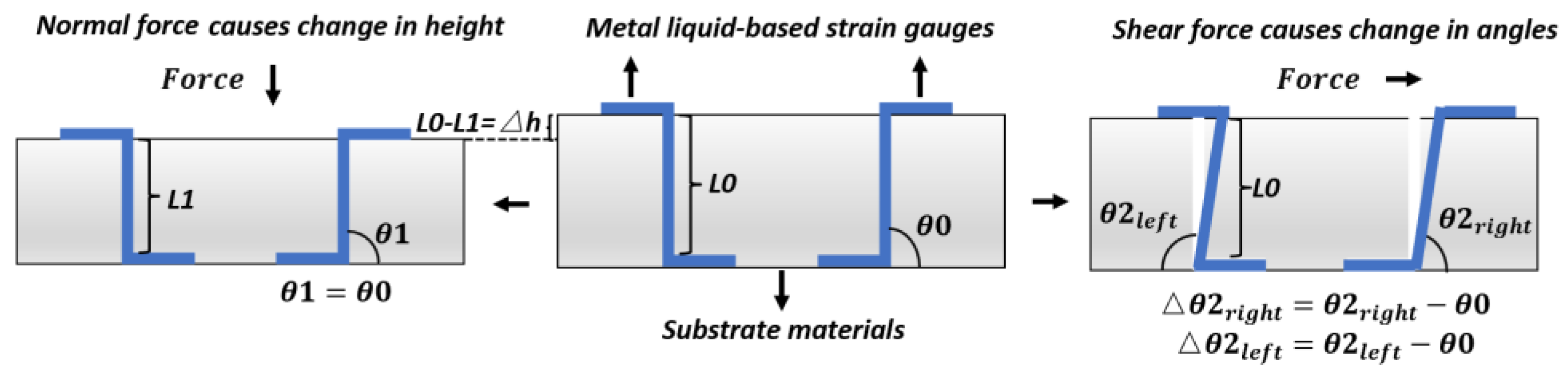

Unlike conductive ink and conductive polymers, metal liquids are naturally conductive. They are usually fabricated into strain gauges for force sensing. The working mechanism of metal liquid is determined by strain gauges, which show different deformations under force in multiple directions. Strain gauges are embedded in a substrate material, instead of being tiled over the substrates. In most current products, S-shaped strain gauges are fixed in symmetry but in opposing angles [11].

Constructing strain gauges with metal liquids enables the piezoresistive measurement of shear and normal forces [12]. Once an external force is applied, strain gauges present different deformations according to the direction of the force. For example, shear force causes strain gauges to show opposite deformation angles. With an applied normal force, they show the same deformation length, instead of being at angles to one another. Thus, their resistances alter differently [13][14]. As for the normal force, theoretically, when a normal force is applied, two gauges present the same change, and the output signals are the same [13][14]. The gauge-deforming process is demonstrated in Figure 2.

2. Piezoelectric Sensing Mechanisms and Suitable Materials

The phrase “piezoelectric effect” was first created in 1880 to describe the electric physical polarization phenomenon, which appears in the interaction between an external force and a non-centrosymmetric material [15]. The interaction process is principally influenced by the direction and strength of the external force. For instance, when vertically compressing a piezoelectric material, positive charges accumulate on the upper surface, while negative charges gather on the lower surface. Thus, polarization is formed. By connecting a polarized material with readout circuits, the electric signals reflect the change in applied force [16].

To quantify this effect, the following formula was established to describe the piezoelectric effect and correlation between polarization and imposed pressure:

where represents the polarization of the materials in direction , represents the piezoelectric strain factor, and represents the strain in direction . The degree of polarization reflects the magnitude of the force.

For most application scenarios, polarization and force both appear in 3-dimensional directions, so is most frequently used to assess the performance of a material and calculate the values of the force [17][18]. is also used for measuring shear stress.

The material has opposite responses to tensing and compressing [16]. This indicates that the piezoelectric effect is reversible, and this feature has enabled the design of energy harvest systems [17]. Hence, this kind of system is suitable for long-time gait feature supervision [19].

Since 1880, several kinds of material have been developed as the sensing material in piezoelectric sensors. They can be chiefly classified into four types: natural biological materials, natural crystals, piezoelectric polymers, and piezoelectric ceramics [20].

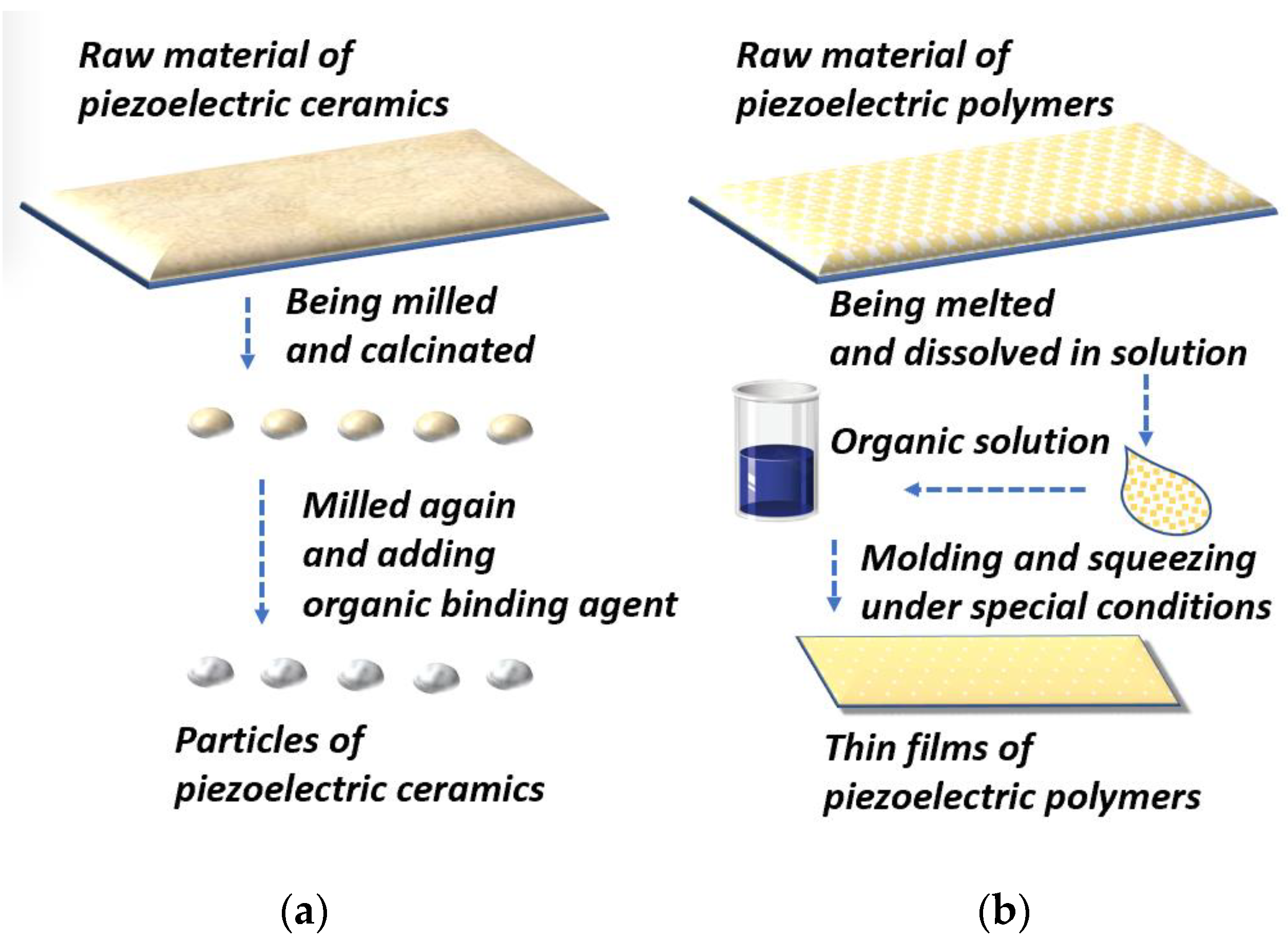

To fabricate force sensors, piezoelectric polymers and ceramics are most frequently used because their properties can be adjusted in synthetic processes according to demands [20][21][22]. In applications, the plantar stress detection (PSD) process often involves bending and deforming. This requires sensing material to be flexible and stretchable. Additionally, to attain a high d33, materials should be small. To achieve these targets, piezoelectric ceramics are often milled into small particles, whereas piezoelectric polymers are usually transmuted into thin layers. These processes will be described in the following sections and Figure 3.

2.1. Piezoelectric Ceramics

Piezoelectric ceramics are brittle and rigid and are formed by large particles. Thus, they cannot be directly applied in PSD sensors because the process of detecting plantar force often involves bending and deforming. Therefore, materials should be designed to have high stretchability and piezoelectric coefficients [2][23].

The ceramic most commonly used for piezoelectric force sensors is PZT (Pb[Zr(x)Ti(1−x)]O3). The manufacture of PZT can be divided into four steps: First, the raw PZT material is wet milled, which uniformly distributes the proportions of the ingredients. Second, the obtained particles are dried for further calcination, which is conducted in a pure chemical environment to prevent contamination. Third, after being calcinated under high temperature, for instance, around 1000 °C, the desired PZT phase is produced [24]. Fourth, the powders are milled again to ensure homogeneity and prepare them for the adjunction of an organic binding agent. Finally, the water in the composites evaporates, which indicates that the PZT for the piezoelectric sensor has been fabricated [24].

2.2. Piezoelectric Polymers

The rigidity of ceramics hinders the stretchability of PSD sensors. To address this issue, organic piezoelectric polymer-based thin films were designed. Their merits include mechanical durability and flexibility. The most representative material is polyvinylidene fluoride (PVDF), which is the material can be used to demonstrate the physical manufacturing process of piezoelectric polymers.

The fabrication of PVDF can be briefly described as radically polymerizing monomer vinylidene difluoride at 10–150 °C and 10 to 300 atm. Polymerization can be divided into four steps [25][26]: First, the raw material is melted. Melted products are shaped in molds of the desired shapes at a relatively higher temperature. Second, the molded and cooled products are dissolved in a suitable solution to obtain the desired chemical properties. The solvent is evaporated from the composites, resulting in the final product having a porous shape. Third, the polymers are transformed into thin films. In this step, polymers are processed in a high-pressure environment and electric fields. Finally, the polymers are squeezed into thin films for further production of piezoelectric sensors [26][27][28].

This entry is adapted from the peer-reviewed paper 10.3390/ma15144837

References

- Chen, J.; Dai, Y.; Grimaldi, N.S.; Lin, J.; Hu, B.; Wu, Y.; Gao, S. Risk of falling assessment on different types of ground using the instrumented TUG. In Proceedings of the 2015 IEEE International Conference on Systems, Man, and Cybernetics, Hong Kong, China, 9–12 October 2015.

- Chen, J.-L.; Dai, Y.-N.; Grimaldi, N.S.; Lin, J.-J.; Hu, B.-Y.; Wu, Y.-F.; Gao, S. Plantar Pressure-Based Insole Gait Monitoring Techniques for Diseases Monitoring and Analysis: A Review. Adv. Mater. Technol. 2022, 7, 2100566.

- Radwan, A.; Sucasas, V.; Rodriguez, J.; André, P.S.; Antunes, P.F. Insole optical fiber sensor architecture for remote gait analysis—An e-health solution. IEEE Internet Things J. 2017, 6, 207–214.

- Shuo, G.; Dai, Y.; Nathan, A. Tactile and Vision Perception for Intelligent Humanoids. Adv. Intell. Syst. 2022, 4, 2100074.

- Nauman, S. Piezoresistive sensing approaches for structural health monitoring of polymer composites—A review. Energy 2021, 2, 197–226.

- Yakhmi, J.V.; Saxena, V.; Aswal, D.K. 2—Conducting Polymer Sensors, Actuators and Field-Effect Transistors. In Functional Materials; Banerjee, S., Tyagi, A.K., Eds.; Elsevier: London, UK, 2012; pp. 61–110.

- Ma, Z.; Shi, W.; Yan, K.; Pan, L.; Yu, G. Doping engineering of conductive polymer hydrogels and their application in advanced sensor technologies. Chem. Sci. 2019, 10, 6232–6244.

- Jung, K.C.; Son, J.H.; Chang, S.H. Self-Powered Smart Shoes with Tension-Type Ribbon Harvesters and Sensors. Adv. Mater. Technol. 2021, 6, 2000872.

- Zhao, Z.; Li, Q.; Dong, Y.; Gong, J.; Li, Z.; Qiao, X.; Zhang, J. A wearable sensor based on gold nanowires/textile and its integrated smart glove for motion monitoring and gesture expression. Energy Technol. 2021, 9, 2100166.

- Michael, Z.; Grainger, L. Additive manufacturing of metallic materials. In Additive Manufacturing; Butterworth-Heinemann: Oxford, UK, 2018; pp. 53–103.

- Yoo, J.; Kim, D.-Y.; Kim, H.; Hur, O.-N.; Park, S.-H. Comparison of Pressure Sensing Properties of Carbon Nanotubes and Carbon Black Polymer Composites. Materials 2022, 15, 1213.

- Cheung, Y.-N.; Zhu, Y.; Cheng, C.-H.; Chao, C.; Leung, W.W.-F. A novel fluidic strain sensor for large strain measurement. Sens. Actuators A 2008, 147, 401–408.

- Shi, X.; Cheng, C.H.; Zheng, Y.; Wai, P.K.A. An EGaIn-based flexible piezoresistive shear and normal force sensor with hysteresis analysis in normal force direction. J. Micromech. Microeng. 2016, 26, 105020.

- Shi, X.; Ching, H.S.; Chen, C.; Like, W.; Yongping, Z. A piezoresistive normal and shear force sensor using liquid metal alloy as gauge material. In Proceedings of the 2012 7th IEEE International Confenrence on Nano/Micro Engineered and Molecular Systems (NEMS), Kyoto, Japan, 5–8 March 2012; pp. 483–486.

- Shi, X.; Cheng, C.-H. Artificial hair cell sensors using liquid metal alloy as piezoresistors. In Proceedings of the 2013 8th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Suzhou, China, 7–10 April 2013; pp. 978–981.

- Goldacker, T.; Abetz, V.; Stadler, R.; Erukhimovich, I.; Leibler, L.J.N. Non-centrosymmetric superlattices in block copolymerlends. Nature 1999, 398, 137–139.

- Briscoe, J.; Jalali, N.; Woolliams, P.; Stewart, M.; Weaver, P.M.; Cain, M.; Dunn, S. Measurement techniques for piezoelectric nanogenerators. Energy Environ. Sci. 2013, 6, 3035–3045.

- Gao, S. A Multi-Functional Touch Panel for Multi-Dimensional Sensing in Interactive Displays. Master’s Thesis, University of Cambridge, Cambridge, UK, 2017.

- Berlincourt, D.; Jaffe, H.; Shiozawa, L.R. Electroelastic Properties of the Sulfides, Selenides, and Tellurides of Zinc and Cadmium. Phys. Rev. 1963, 129, 1009–1017.

- Mariani, B.; Rouhani, H.; Crevoisier, X.; Aminian, K. Quantitative estimation of foot-flat and stance phase of gait using foot-worn inertial sensors. Gait Posture 2013, 37, 229–234.

- Navneet, S.; Anand, S.C.; Shah, T.H. Energy harvesting and storage textiles. In Handbook of Technical Textiles; Woodhead Publishing: Sawston, UK, 2016; pp. 357–396.

- Soin, N.; Shah, T.H.; Anand, S.C.; Geng, J.; Pornwannachai, W.; Mandal, P.; Siores, E. Novel 3-D spacer all fibre piezoelectric textiles for energy harvesting applications. Energy Environ. Sci. 2014, 7, 1670–1679.

- Qi, Y.; McAlpine, M.C. Nanotechnology-enabled flexible and biocompatible energy harvesting. Energy Environ. Sci. 2010, 3, 1275–1285.

- Almusallam, A.; Torah, R.N.; Zhu, D.; Tudor, M.J.; Beeby, S.P. Screen-printed piezoelectric shoe-insole energy harvester using an improved flexible PZT-polymer composites. J. Phys. Conf. Ser. 2013, 476, 012108.

- PZT about PZT-Properties. Available online: https://www.americanpiezo.com/piezo-theory/pzt.html (accessed on 18 April 2022).

- Sepehri, A. Development of Micro 3D Structured Polyvinylidene Fluoride (PVDF) Thin Film. Master’s Thesis, San Diego State University, San Diego, CA, USA, 2012.

- Polyvinylidene Fluoride (PVDF): Properties, Production, & Applications. Available online: https://matmatch.com/learn/material/polyvinylidene-fluoride-pvdf (accessed on 18 April 2022).

- Roopa, T.S.; Murty, N.; Swathi, H.S.; Angadi, G.; Harish, D.V.N. Synthesis and characterization of spin-coated clay/PVDF thin films. Bull. Mater. Sci. 2019, 42, 1–8.

This entry is offline, you can click here to edit this entry!