The production of micropropagated plants in plant-tissue-culture laboratories and nurseries is the most important method for propagation of many economic plants. Micropropagation based on tissue-culture technology involves large-scale propagation, as it allows multiplication of a huge number of true-to-type propagules in a very short time and in a very limited space, as well as all year round, regardless of the climate.

- acclimatization

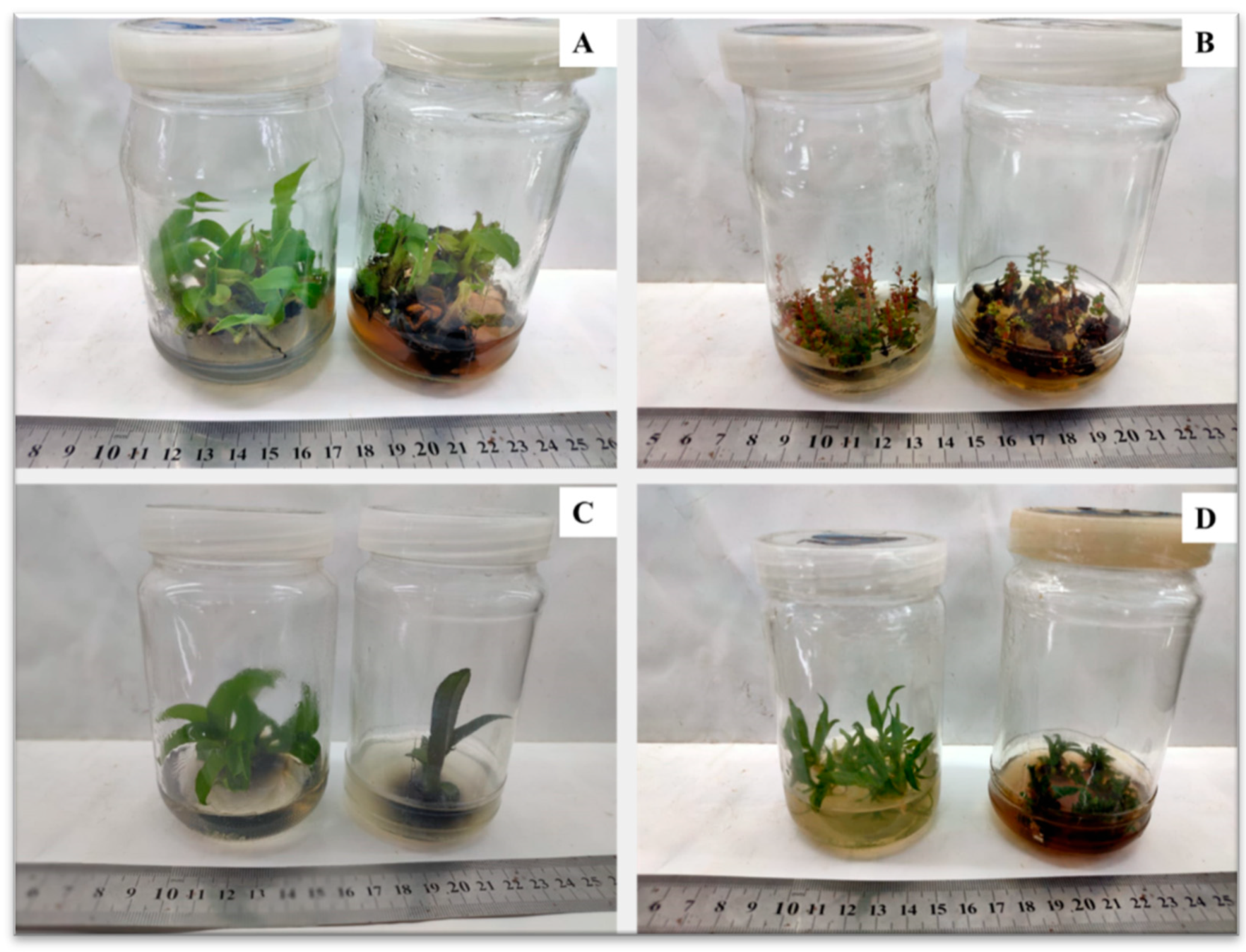

- browning

- contamination

- delay of subculture

- hyperhydricity

- recalcitrance

- somaclonal variations

- totipotency

1. Introduction

2. Problems Associated with Plant Micropropagation

2.1. Problems Originated Due to Technical Reasons

2.1.1. Contamination of Plant-Tissue Cultures

|

Studied Plants |

Surface-Sterilization Methods and Sterilized Items |

Main Findings of the Study |

Refs. |

|---|---|---|---|

|

Potato (Solanum tuberosum L.) |

Ultraviolet-C radiation to explants for 10 min |

The external contamination of explants has been reduced. |

[32] |

|

Mulberry (Morus alba L.) |

Mercuric chloride at 0.2% for 10 min to shoot tips and auxiliary buds |

Minimum percentage of contamination and highly percentage of survival in correlation with shoot development were noticed for all mulberry cultivars under investigation. |

[33] |

|

Guayusa (Ilex guayusa Loes.) |

70% ethanol for 2 min + 2.5% sodium hypochlorite + five drops of Tween-20 for 25 min to apical stem segment |

Surface sterilization with ethanol and sodium hypochlorite resulted in 100% surface-sterilized stakes. |

[34] |

|

Eucalyptus (Eucalyptus obliqua) |

Active chlorine added to culture media at 0.005% for establishment and 0.003% for shoot multiplication and elongation |

Active chlorine at 0.005% led to the lowest fungal contamination rate in the establishment stage, where at 0.003% resulted in maximum number of shoots per explant and the greatest shoot length in the multiplication stage. |

[35] |

|

Guava (Psidium guajava L.) |

Silver nanoparticles (AgNPs) at 50 mg L−1 directly to shoot tips for 5 min or at 5 mg L−1 added to culture medium |

AgNPs at 50 mg L−1 yielded a contamination rate of 40%, where at 5 mg L−1 reduced shoot contamination rate to 50% compared to controls (80%) and enhanced multiplication rate of the shoots by 180%, as an alternative method for surface sterilization of explants which are easily damaged by commonly used surface sterilizing. |

[36] |

|

Rosmarinus officinalis L. |

Bio-synthesized of silver nanoparticles via Rubia tinctorum L. using cell culture were applied for surface sterilization of stem explants |

Sterile explant percentages varied between 40 and 97% and no browning was observed. This method could be used in surface sterilization of explants which have a browning problem caused by their phenolic contents. |

[37] |

|

Sargassum fusiforme |

A crude extract of a medicinal herbal plant Tarragon (Artemisia dracunculus) was used for surface sterilization of explants (leaf, stipe, and stolon) cultured in vitro |

The crude extract of A. dracunculus showed a high microbial sterilization effect with (90, 80, and 20%) for leaves, stipes and stolons, respectively. It has very low toxicity to plant tissues compared to chemical sterilants. |

[38] |

|

Chinaberry (Melia azedarach L.) |

Dipping leaf explants in 2 g L−1 benomyl for 2 h + 7% hydrogen peroxide (H2O2) for 10 min + 2% NaOCl for 12 min for surface sterilization |

The lowest contamination percentage of explants and browning as well as the highest percentage of callus induction and growth were observed. |

[39] |

|

Carnation (Dianthus caryophyllus) |

Sodium dichloroisocyanurate (NaDCC) was applied as a medium sterilizer to culture medium at 0.02 g L−1 instead of autoclave sterilization |

Contamination rate recorded below 5%, sodium isocyanurate has the potential to substitute media autoclaving in plant-tissue culture. |

[40] |

|

Butterfly pea Clitoria ternatea L. |

0.1% Bavistin solution + 70% ethanol, and 0.1% HgCl2 was used for surface sterilization of nodal explants |

Microbial contamination was eliminated and then surface sterilized nodal explants were used for shoot multiplication induction. |

[41] |

|

Orchid (Angraecum rutenbergianm Kraenzl) |

0.5% (w/v) NaDCC solution + 2 mL L−1 Plant Preservative Mixture (PPM™) was used for surface sterilization of Seed capsules |

87.5% of the total number of capsules was disinfected and the seeds inside them were clean after 3 months of culture. Both NaDCC and PPM were essential to suppress microbial growth. |

[42] |

|

Applied Substance (Name and Concentration) |

Plant Species/Cultivar |

Success of Decontamination |

Refs. |

|---|---|---|---|

|

Kanamycin and streptomycin sulphate at 10 μg ml−1 each were added to shoot multiplication medium +2 mg L−1 BAP +10 mg L−1 adenine sulfate |

Guadua angustifolia Kunth |

Bacterial growth was inhibited and intensive formation of high-quality shoots was observed. |

[48] |

|

Antibiotics (timentin at 150 mg L−1 + gentamycin at 30 mg L−1 were added to culture medium |

Camellia sinensis var. sinensis |

They were effective to eliminate bacterial endophytic up to 24 days with 0% contamination. |

[49] |

|

Antibiotic, cefotaxime at 62.5 mg L−1 was supplemented to ½ Murashige and Skoog (MS) medium for establishment |

Jerusalem artichoke (Helianthus tuberosus L.) |

It recorded 0% contamination 100% survival of stem nodes cultures. |

[45] |

|

Copper sulfate (CuSO4 5H2O) at 60 mg L−1 was added to MS medium +3 mg L−1 BA + 1 mg L−1 KIN for shoot multiplication |

Banana (Musa sp.) |

The growth of the endophytic bacteria was inhibited by recording 0% contamination. |

[46] |

|

Copper sulfate (CuSO4 5H2O) at 70 mg L−1 was supplemented to MS medium + 5 mg L−1 BA for shoot multiplication |

Philodendron selloum |

It eliminated the endogenous bacteria contamination to 0%, without decline in growth of in vitro shoots. |

[44] |

Abbreviations: Benzylaminopurine (BAP), Murashige and Skoog (MS), benzyladenine (BA).

2.1.2. Delay of Subculture and Burned Plantlets

2.2. Problems Originated Due to Physiological Reasons

2.2.1. Browning of Plant-Tissue Cultures

2.2.2. In Vitro Rooting Difficulty and Failure of Subsequent Acclimatization

2.3. Problems Originated Due to Genetical Reasons

2.3.1. Somaclonal Variation

This entry is adapted from the peer-reviewed paper 10.3390/horticulturae8080677

References

- Bridgen, M.; Van Houtven, W.; Eeckhaut, T. Plant Tissue Culture Techniques for Breeding. In Ornamental Crops, Handbook of Plant Breeding; Van Huylenbroeck, J., Ed.; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 127–144.

- Neumann, K.-H.; Kumar, A.; Imani, J. Plant Cell and Tissue Culture—A Tool in Biotechnology Basics and Application, 2nd ed.; Springer Nature Switzerland AG: Cham, Switzerland, 2020; pp. 1–11.

- Viana, C.M.; Freire, D.; Abrantes, P.; Rocha, J.; Pereira, P. Agricultural land systems importance for supporting food security and sustainable development goals: A systematic review. Sci. Total Environ. 2022, 806, 150718.

- Bidabadi, S.S.; Jain, S.M. Cellular, Molecular, and Physiological Aspects of In Vitro Plant Regeneration. Plants 2020, 9, 702.

- Rani, A.; Donovan, N.; Mantria, N. Review: The future of plant pathogen diagnostics in a nursery production system. Biosens. Bioelectron. 2019, 145, 111631.

- Pe, P.P.W.; Naing, A.H.; Soe, M.T.; Kang, H.; Park, K.I.; Kim, C.K. Establishment of meristem culture for virus-free and genetically stable production of the endangered plant Hosta capitata. Sci. Hortic. 2020, 272, 109591.

- Kumar, M.K.; Sandeep, B.V.; Rao, S.P. Development of salt tolerant callus cultures by somatic hybridization between Oryza sativa and mangrove grass Myriostachya wightiana. Ann. Agrar. Sci. 2018, 16, 396–404.

- Wang, M.; Ji, Y.; Feng, S.; Liu, C.; Xiao, Z.; Wang, X.; Wang, Y.; Xia, G. The non-random patterns of genetic variation induced by asymmetric somatic hybridization in wheat. BMC Plant Biol. 2018, 18, 244.

- Park, S. Plant Tissue Culture Techniques and Experiments, 5th ed.; Academic Press: Cambridge, MA, USA; Elsevier Inc.: London, UK, 2021; pp. 1–23.

- Naing, A.H.; Adedeji, O.S.; Kim, C.K. Protoplast technology in ornamental plants: Current progress and potential applications on genetic improvement. Sci. Hortic. 2021, 283, 110043.

- Sánchez, M.A.; Coronado, Y.M.; Coronado, A.C.M. Androgenic studies in the production of haploids and doubled haploids in Capsicum spp. Rev. Fac. Nac. Agron. Medellín 2020, 73, 9047–9056.

- Dhiman, K.M.; Sharma, L.; Singh, A.; Sharma, M.M. Ex situ Conservation Using In vitro Methods of an Endangered Plant Sterculia urens Roxb.: A High Volume Trade Plant for Gum. Ind. Crops Prod. 2020, 158, 113015.

- Karakas, F.P.; Bozat, B.G. Fluctuation in secondary metabolite production and antioxidant defense enzymes in in vitro callus cultures of goat’s rue (Galega officinalis) under different abiotic stress treatments. Plant Cell Tissue Organ Cult. 2020, 142, 401–414.

- Soleimani, S.H.; Bernard, F.; Amini, M.; Khavari-Nezhad, R.A. Cadmium accumulation and alkaloid production of Narcissus tazetta plants grown under in vitro condition with cadmium stress. Plant Physiol. Rep. 2020, 25, 51–57.

- Fortini, E.A.; Batista, D.S.; Mamedes-Rodrigues, T.C.; Felipe, S.H.S.; Correia, L.N.F.; Chagas, K.; Silva, P.O.; Rocha, D.I.; Otoni, W.C. Gas exchange rates and sucrose concentrations affect plant growth and production of favonoids in Vernonia condensata grown in vitro. Plant Cell Tissue Organ Cult. 2021, 144, 593–605.

- Kyzioł, A.; Łukasiewicz, S.; Sebastian, V.; Kustrowski, P.; Kozieł, M.; Majda, D.; Cierniak, A. Towards plant-mediated chemistry—Au nanoparticles obtained using aqueous extract of Rosa damascena and their biological activity in vitro. J. Inorg. Biochem. 2021, 214, 111300.

- Gregorio, N.; Herbohn, J.; Harrison, S. Small-scale Forestry Development in Leyte, Philippines: The Central Role of Nurseries. Small-Scale For. 2004, 3, 337–351.

- Degrande, A.; Tadjo, P.; Takoutsing, B.; Asaah, E.; Tsobeng, A.; Zac Tchoundjeu, Z. Getting Trees In to Farmers’ Fields: Success of Rural Nurseries in Distributing High Quality Planting Material in Cameroon. Small-Scale For. 2013, 12, 403–420.

- Marshall, M.; Sutherland, R.; Hulme, P.E. Assessing the role of plant trade networks in the vulnerability of forest nurseries to plant pathogens. Australas. Plant Pathol. 2021, 50, 671–681.

- Seliem, M.K.; Abdalla, N.A.; El-Ramady, H.R. Response of Phalaenopsis Orchid to Selenium and Bio-NanoSelenium: In Vitro Rooting and Acclimatization. Env. Biodiv. Soil Secur. 2020, 4, 277–290.

- Gaspar, T. Vitrification in Micropropagation. In High-Tech and Micropropagation I; Biotechnology in Agriculture and Forestry; Bajaj, Y.P.S., Ed.; Springer: Berlin/Heidelberg, Germany, 1991; Volume 17, pp. 116–126.

- Pandey, S.; Sundararajan, S.; Ramalingam, S.; Pant, B. Effects of sodium nitroprusside and growth regulators on callus, multiple shoot induction and tissue browning in commercially important Valeriana jatamansi Jones. Plant Cell Tissue Organ Cult. 2020, 142, 653–660.

- Teixeira da Silva, J.A.; Nezami-Alanagh, E.; Barreal, M.E.; Kher, M.M.; Wicaksono, A.; Gulyás, A.; Hidvégi, N.; Magyar-Tábori, K.; Mendler-Drienyovszki, N.; Márton, L.; et al. Shoot tip necrosis of in vitro plant cultures: A reappraisal of possible causes and solutions. Planta 2020, 252, 47.

- Pawełkowicz, M.E.; Skarzyńska, A.; Mróz, T.; Bystrzycki, E.; Pląder, W. Molecular insight into somaclonal variation phenomena from transcriptome profiling of cucumber (Cucumis sativus L.) lines. Plant Cell Tissue Organ Cult. 2021, 145, 239–259.

- Ranghoo-Sanmukhiya, V.M. Somaclonal Variation and Methods Used for Its Detection. In Propagation and Genetic Manipulation of Plants; Siddique, I., Ed.; Springer Nature: Singapore, 2021; pp. 1–18.

- Thakur, M.; Rakshandha; Sharma, V.; Chauhan, A. Genetic fidelity assessment of long term in vitro shoot cultures and regenerated plants in Japanese plum cvs Santa Rosa and Frontier through RAPD, ISSR and SCoT markers. S. Afr. J. Bot. 2020, 140, 428–433.

- Loyola-Vargas, V.M.; Ochoa-Alejo, N. An Introduction to Plant Tissue Culture: Advances and Perspectives. In Plant Cell Culture Protocols, Methods in Molecular Biology; Loyola-Vargas, V.M., Ochoa-Alejo, N., Eds.; Springer Nature: New York, NY, USA, 2018; Volume 1815, pp. 3–13.

- FAO/IAEA. Low-Cost Options for Tissue Culture Technology in Developing Countries. In Proceedings of the Technical Meeting Organized by the Joint FAO/IAEA Division of Nuclear Techniques in Food and Agriculture, Vienna, Austria, 26–30 August 2002; Available online: https://www-pub.iaea.org/mtcd/publications/pdf/te_1384_web.pdf (accessed on 14 June 2022).

- Gangopadhyay, M.; Nandi, S.; Roy, S.K.B. An efficient ex plant sterilization protocol for reducing microbial contamination of Solanum tuberosum CV. ‘Kufri jyoti for establishing micropropagation in rainy season. J. Basic Appl. Plant Sci. 2017, 1, 25.

- Jugreet, B.S.; Mahomoodally, M.F. Essential oils from 9 exotic and endemic medicinal plants from Mauritius shows in vitro antibacterial and antibiotic potentiating activities. S. Afr. J. Bot. 2020, 132, 355–362.

- Bhatia, S.; Sharma, K.; Dahiya, R.; Bera, T. Modern Applications of Plant Biotechnology in Pharmaceutical Sciences; Academic Press: Cambridge, MA, USA; Elsevier: London, UK, 2015; pp. 31–107.

- Singh, C.R. Review on problems and its remedy in plant tissue culture. Asian J. Biol. Sci. 2018, 11, 165–172.

- Taha, H.; Ghazy, U.M.; Gabr, A.M.M.; EL-Kazzaz, A.A.A.; Ahmed, E.M.M.; Haggag, K.M. Optimization of in vitro culture conditions affecting propagation of mulberry plant. Bull. Natl. Res. Cent. 2020, 44, 60.

- Carvalho, S.D.; Ortega, M.; Orellana, M.; Rodríguez, M.; Folta, K.M.; Torres, M.L. In vitro propagation of the Amazonian medicinal plant guayusa (Ilex guayusa) and effects of light in the growth and development of this shade tolerant plant. Plant Cell Tissue Organ Cult. 2021, 147, 503–517.

- Molinari, L.V.; Souza, D.M.S.C.; Avelar, M.L.M.; Fernandes, S.B.; Gonçalves, D.S.; Faria, J.C.T.; de Carvalho, D.; Brondani, G.E. Effects of chemical sterilization of the culture media, porous membranes and luminosity on in vitro culture of Eucalyptus grandis × Eucalyptus urophylla. J. For. Res. 2021, 32, 1587–1598.

- Andújar, I.; González, N.; García-Ramos, J.C.; Bogdanchikova, N.; Pestryakov, A.; Escalona, M.; Concepción, O. Argovit™ silver nanoparticles reduce contamination levels and improve morphological growth in the in vitro culture of Psidium friedrichsthalianum (O. Berg) Nied. SN Appl. Sci. 2020, 2, 2110.

- Nartop, P. Green Sterilization of Rosmarinus officinalis L. Stem Surfaces with Silver Nanoparticles Synthesized Using Rubia tinctorum L. Cell Culture Extracts. Iran J. Sci. Technol. Trans. A Sci. 2018, 42, 411–414.

- Ahmed, N.; Mohamed, H.F.; Xu, C.; Lin, X.; Huang, L. A novel surface sterilization method using Artemisia dracunculus extract for tissue culturing of endangered species Sargassum fusiforme. Plant Cell Tissue Organ Cult. 2022, 149, 135–145.

- Ahmadpoor, F.; Zare, N.; Asghari, R.; Sheikhzadeh, P. Sterilization protocols and the effect of plant growth regulators on callus induction and secondary metabolites production in in vitro cultures Melia azedarach L. AMB Express 2022, 12, 3.

- Urtiga, C.D.C.; Silva-Cardoso, I.M.D.A.; Figueiredo, S.A. Low sodium isocyanurate concentrations as a substitute to medium autoclaving in plant tissue culture. Plant Cell Tissue Organ Cult. 2019, 139, 601–604.

- Rency, A.S.; Pandian, S.; Ramesh, M. Influence of adenine sulphate on multiple shoot induction in Clitoria ternatea L. and analysis of phyto-compounds in in vitro grown plants. Biocatal. Agric. Biotechnol. 2018, 16, 181–191.

- Kendon, J.P.; Rajaovelona, L.; Sandford, H.; Fang, R.; Bell, J.; Sarasan, V. Collecting near mature and immature orchid seeds for ex situ conservation: ‘in vitro collecting’ as a case study. Bot. Stud. 2017, 58, 34.

- El-Banna, A.N.; El-Mahrouk, M.E.; Dewir, Y.H.; Farid, M.A.; Abou Elyazid, D.M.; Schumacher, H.M. Endophytic Bacteria in Banana In Vitro Cultures: Molecular Identification, Antibiotic Susceptibility, and Plant Survival. Horticulturae 2021, 7, 526.

- Seliem, M.K.; El-Mahrouk, M.E.; El-Banna, A.N.; Hafez, Y.M.; Dewir, Y.H. Micropropagation of Philodendron selloum: Influence of copper sulfate on endophytic bacterial contamination, antioxidant enzyme activity, electrolyte leakage, and plant survival. S. Afr. J. Bot. 2021, 139, 230–240.

- Abdalla, N.A.; Ragab, M.E.; El-Miniawy, S.M.; Arafa, N.M.; Taha, H.S. A New Aspect for In vitro Propagation of Jerusalem Artichoke and Molecular Assessment Using RAPD, ISSR and SCoT Marker Techniques. Egypt. J. Bot. 2021, 61, 203–218.

- Abou Elyazid, D.M.A.; Salama, A.-M.; Zanaty, A.M.E.; Abdalla, N. In Vitro Propagation and Acclimatization of Banana Plants: Antioxidant Enzymes, Chemical Assessments and Genetic Stability of Regenerates as a Response to Copper Sulphate. Plants 2021, 10, 1853.

- Ray, S.S.; Ali, N. Biotic Contamination and Possible Ways of Sterilization: A Review with Reference to Bamboo Micropropagation. Braz. Arch. Biol. Technol. 2016, 59, e160485.

- Alagarsamy, K.; Shamala, L.F.; Wei, S. Influence of media supplements on inhibition of oxidative browning and bacterial endophytes of Camellia sinensis var. sinensis. 3 Biotech 2018, 8, 356.

- Neri, D.; Cioccolanti, T.; Zuccherelli, G.; Navacchi, O.; Giorgi, V.; Lodolini, E.M. Micropropagation Effects on Juvenile Traits, Flower Differentiation, and Tree Architecture in Young Olive Trees. Agronomy 2020, 10, 1742.

- Naing, A.H.; Kim, S.H.; Chung, M.Y.; Park, S.K.; Kim, C.K. In vitro propagation method for production of morphologically and genetically stable plants of different strawberry cultivars. Plant Methods 2019, 15, 36.

- Malhotra, E.V.; Kamalapriya, M.; Bansal, S.; Meena, D.P.S.; Agrawal, A. Improved protocol for micropropagation of genetically uniform plants of commercially important cardamom (Elettaria cardamomum Maton). In Vitro Cell. Dev. Biol. Plant. 2021, 57, 409–417.

- Sirikonda, A.; Jogam, P.; Ellendula, R.; Kudikala, H.; Mood, K.; Allini, V.R. In vitro micropropagation and genetic fidelity assessment in Flemingia macrophylla (Willd.) Merr: An ethnomedicinal plant. Vegetos 2020, 33, 286–295.

- El-Mahrouk, M.E.; El-Shereif, A.R.; Hafez, Y.M.; Abdelaal, K.A.; El-Hendawy, A.S.; Migdadi, H.; Al-Obeed, R.S. Micropropagation of Banana: Reversion, Rooting, and Acclimatization of Hyperhydric Shoots. HortScience 2019, 54, 1384–1390.

- Mendonça, E.G.; Batista, T.R.; Stein, V.C.; Balieiro, F.P.; de Abreu, R.J.; Pires, M.F.; de Souza, P.A.; Paiva, L.V. In vitro serial subculture to improve rooting of Eucalyptus urophylla. New Forest 2020, 51, 801–816.

- Siddique, I.; Javed, S.B.; Al-Othman, M.R.; Anis, M. Stimulation of in vitro organogenesis from epicotyl explants and successive micropropagation round in Cassia angustifolia Vahl.: An important source of sennosides. Agrofor. Syst. 2013, 87, 583–590.

- Khamushi, M.; Ardakani, M.D.; Zarei, A.; Aliabad, K.K. An efficient protocol for micropropagation of old cypress of Abarkuh (Cupressus sempervirens var. horizontalis ) under in vitro condition. Plant Cell Tissue Organ Cult. 2019, 138, 597–601.

- Vujović, T.; Ružić, D.J.; Cerović, R. In vitro shoot multiplication as influenced by repeated subculturing of shoots of contemporary fruit rootstocks. Hort. Sci. 2012, 39, 101–107.

- Norton, M.E.; Norton, C.R. Change in shoot proliferation with repeated in vitro subculture of shoots of woody species of Rosaceae. Plant Cell Tissue Organ Cult. 1986, 5, 187–197.

- Remphrey, W.R.; Palmer, C.E.; Blouw, M.J. In vitro branching in relation to repeated subculture in two cultivars of Potentilla fruticosa. Plant Cell Tissue Organ Cult. 1993, 32, 235–240.

- Hamad, A.M.; Taha, R.M. Effect of sequential subcultures on in vitro proliferation capacity and shoot formation pattern of pineapple (Ananas comosus L. Merr.) over different incubation periods. Sci. Hortic. 2008, 117, 329–334.

- Peng, X.; Zhang, T.-T.; Zhang, J. Effect of subculture times on genetic fidelity, endogenous hormone level and pharmaceutical potential of Tetrastigma hemsleyanum callus. Plant Cell Tissue Organ Cult. 2015, 122, 67–77.

- Hassanein, A.M.; Salem, J.M.; Faheed, F.A.; El-nagish, A. Effect of anti-ethylene compounds on isoenzyme patterns and genome stability during long term culture of Moringa oleifera. Plant Cell Tissue Organ Cult. 2018, 132, 201–212.

- Zhao, S.; Wang, H.; Liu, K.; Li, L.; Yang, J.; An, X.; Li, P.; Yun, L.; Zhang, Z. The role of JrPPOs in the browning of walnut explants. Plant Biol. 2021, 21, 9.

- Dobránszki, J.; Jámbor-Benczúr, E.; Hudák, I.; Magyar-Tábori, K. Model experiments for establishment of in vitro culture by micrografting in apple. Int. J. Hortic. Sci. 2005, 1, 47–49.

- Dobránszki, J.; Teixeira da Silva, J.A. Micropropagation of apple—A review. Biotechnol. Adv. 2010, 28, 462–488.

- Teixeira da Silva, J.A.; Guly, A.; Magyar-Tabori, K.; Wang, M.R.; Wang, Q.-W.; Dobránszki, J. In vitro tissue culture of apple and other Malus species: Recent advances and applications. Planta 2019, 249, 975–1006.

- Li, J.; Gao, C.; Miao, Y.; Liu, Z.; Cui, K. Development of a highly efficient callus induction and plant regeneration system for Dendrocalamus sinicus using hypocotyls as explants. Plant Cell Tissue Organ Cult. 2021, 145, 117–125.

- Magyar-Tábori, K.; Dobránszki, J.; Hudák, I. Effect of cytokinin content of the regeneration media on in vitro rooting ability of adventitious apple shoots. Sci. Hortic. 2011, 129, 910–913.

- Dewir, Y.H.; Murthy, H.N.; Ammar, M.H.; Alghamdi, S.S.; Al-Suhaibani, N.A.; Alsadon, A.A.; Paek, K.Y. In vitro Rooting of Leguminous Plants: Difficulties, Alternatives, and Strategies for Improvement. Hortic. Environ. Biotechnol. 2016, 57, 311–322.

- Shaik, N.M.; Arha, M.; Nookaraju, A.; Gupta, S.K.; Srivastava, S.; Yadav, A.K.; Kulkarni, P.S.; Abhilash, O.U.; Vishwakarma, R.K.; Singh, S.; et al. Improved method of in vitro regeneration in Leucaena leucocephala. Physiol. Mol. Biol. Plants 2009, 15, 311–318.

- Zayova, E.; Petrova, M.; Nikolova, M.; Dimitrova, L. Effect of Medium Salt Strength on the Micropropagation, Phenolic Content and Antioxidant Activity of Arnica montana L., Threatened Plant Species. Bio. Bulletin. 2016, 2, 6–13.

- Rezali, N.I.; Sidik, N.J.; Saleh, A.; Osman, N.I.; Adam, N.A.M. The effects of different strength of MS media in solid and liquid media on in vitro growth of Typhonium flagelliforme. Asian Pac. J. Trop. Biomed. 2017, 7, 151–156.

- Dewir, Y.H.; Aldubai, A.A.; Kher, M.M.; Alsadon, A.A.; El-Hendawy, S.; Al-Suhaibani, N.A. Optimization of media formulation for axillary shoot multiplication of the red-peeled sweet potato (Ipomoea batatas Lam.) ‘Abees. Chil. J. Agric. Res. 2020, 80, 3–10.

- Dewir, Y.H.; El-Mahrouk, M.E.; Murthy, H.N.; Yoeup, H.P. Micropropagation of Cattleya: Improved in vitro rooting and acclimatization. Hortic. Environ. Biotechnol. 2015, 56, 89–93.

- Nayak, N.R.; Rath, S.P.; Patnaik, S. In vitro propagation of three epiphytic orchids, Cymbidium aloifolium (L.) Sw., Dendrobium aphyllum (Roxb.), Fisch. and Dendrobium moschatum (Buch-Ham) Sw. through thidiazuron-induced high frequency shoot proliferation. Sci. Hortic. 1997, 71, 243–250.

- Alghamdi, S.S.; Dewir, Y.H.; Khan, M.A.; Migdadi, H.; EL-Harty, E.H.; Aldubai, A.A.; Al-Aizari, A.A. Micropropagation and germplasm conservation of four chickpea (Cicer arietinum L.) genotypes. Chil. J. Agric. Res. 2020, 80, 487–495.

- Hasançebi, S.; Kara, N.T.; Çakir, Ö.; Ari, Ş. Micropropagation and root culture of Turkish endemic Astragalus chrysochlorus (Leguminosae). Turk. J. Botany 2011, 35, 7.

- Isutsa, D.K.; Pritts, M.P.; Mudge, K.W. A protocol for rooting and growing apple rootstock microshoots. Fruit Var. J. 1998, 52, 107–116.

- Dobránszki, J.; Magyar-Tábori, K.; Jámbor-Benczúr, E.; Lazányi, J.; Bubán, T.; Szalai, J. Influence of aromatic cytokinins on shoot multiplication and their post-effects on rooting of apple cv. Húsvéti rozmaring. Int. J. Hortic. Sci. 2000, 6, 84–87.

- Rescalvo-Morales, A.; Monja-Mio, K.; Robert, M.L.; Sánchez-Teyer, L.F. Telomere length in Agave tequilana Weber plants during the in vitro to ex vitro transition. Plant Cell Tissue Organ Cult. 2019, 136, 133–140.

- Dev, R.; Singh, S.K.; Dayal, V.; Kumar, K.; Singh, T. Standardization of in vitro Hardening Strategies for Tissue Cultured Wine Grape (Vitis vinifera L) Genotypes. Int. J. Curr. Microbiol. App. Sci. 2019, 8, 2108–2117.

- Teixeira da Silva, J.A.; Hossain, M.M.; Sharma, M.; Dobránszki, J.; Cardoso, J.C.; Songjun, Z. Acclimatization of in Vitro-derived Dendrobium. Hortic. Plant J. 2017, 3, 110–124.

- Shah, S.; Thapa, B.B.; Chanda, K.; Pradhan, S.; Singh, A.; Varma, A.; Thakur, L.S.; Joshi, P.; Pant, B. Piriformospora indica promotes the growth of the in-vitro-raised Cymbidium aloifolium plantlet and their acclimatization. Plant Signal. Behav. 2019, 14, e1596716.

- Cantabella, D.; Dolcet-Sanjuan, R.; Casanovas, M.; Solsona, C.; Torres, R.; Teixido, N. Inoculation of in vitro cultures with rhizosphere microorganisms improve plant development and acclimatization during immature embryo rescue in nectarine and pear breeding programs. Sci. Hortic. 2020, 273, 109643.

- De Araújo, R.C.; Rodrigues, F.A.; Nadal, M.C.; Ribeiro, M.D.; Antonio, C.A.C.; Rodrigues, V.A.; de Souza, A.C.; Pasqual, M.; Doria, J. Acclimatization of Musa spp. seedlings using endophytic Bacillus spp. and Buttiauxella agrestis strains. Microbiol. Res. 2021, 248, 126750.

- Hoang, N.N.; Kitaya, Y.; Shibuya, T.; Endo, R. Effects of supporting materials in in vitro acclimatization stage on ex vitro growth of wasabi plants. Sci. Hortic. 2020, 261, 109042.

- Acquaah, G. Clonal propagation and in vitro culture. In Principles of Plant Genetics and Breeding, 2nd ed.; Acquaah, G., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 146–170.

- Jevremović, S.; Subotić, A.; Miljković, D.; Trifunović, M.; Petrić, M.; Cingel, A. Clonal fidelity of chrysanthemum cultivars after long term micropropagation by stem segment culture. VII International symposium on in vitro culture and horticultural breeding. Acta Hortic. 2012, 961, 211–216.

- Krishna, H.; Alizadeh, M.; Singh, D.; Singh, U.; Chauhan, N.; Eftekhari, M.; Sadh, R.K. Somaclonal variations and their applications in horticultural crops improvement. 3 Biotech 2016, 6, 54.

- Chin, C.K.; Lee, Z.H.; Mubbarakh, S.A.; Antony, J.J.J.; Chew, B.L.; Subramaniam, S. Effects of plant growth regulators and activated charcoal on somaclonal variations of protocorm-like bodies (PLBs) of Dendrobium Sabin Blue orchid. Biocatal. Agric. Biotechnol. 2019, 22, 101426.

- Bradaï, F.; Sánchez-Romero, C.; Martín, C. Somaclonal variation in olive (Olea europaea L.) plants regenerated via somatic embryogenesis: Influence of genotype and culture age on genetic stability. Sci. Hortic. 2019, 251, 260–266.

- Mirani, A.A.; Teo, C.H.; Markhand, G.S.; Abul-Soad, A.A.; Harikrishna, J.A. Detection of somaclonal variations in tissue cultured date palm (Phoenix dactylifera L.) using transposable element-based markers. Plant Cell Tissue Organ Cult. 2020, 141, 119–130.

- Dhurve, L.; Kumar, A.; Bhaskar, J.; Sobhana, A.; Francies, R.M.; Mathew, D. Wide variability among the ‘Mauritius’ somaclones demonstrates somaclonal variation as a promising improvement strategy in pineapple (Ananas comosus L.). Plant Cell Tissue Organ Cult. 2021, 145, 701–705.

- Noormohammadi, Z.; Habibollahi, H.; Farahani, F.; Sheidai, M. Molecular analysis of somaclonal variation in Linum usitatissimum and L. album. Plant Gene 2020, 24, 100261.

- Solano, M.C.P.; Ruız, J.S.; Arnao, M.R.; Castro, O.C.; Tovar, M.E.G.; Bello, J.J.B. Evaluation of in vitro shoot multiplication and ISSR marker based assessment of somaclonal variants at different subcultures of vanilla (Vanilla planifolia Jacks). Physiol. Mol. Biol. Plants 2019, 25, 561–567.