Biosensors are ubiquitous in a variety of disciplines, such as biochemical, electrochemical, agricultural, and biomedical areas. They can integrate various point-of-care applications, such as in the food, healthcare, environmental monitoring, water quality, forensics, drug development, and biological domains. Multiple strategies have been employed to develop and fabricate miniaturized biosensors, including design, optimization, characterization, and testing. In view of their interactions with high-affinity biomolecules, they find application in the sensitive detection of analytes, even in small sample volumes. Among the many developed techniques, microfluidics have been widely explored; these use fluid mechanics to operate miniaturized biosensors. The currently used commercial devices are bulky, slow in operation, expensive, and require human intervention; thus, it is difficult to automate, integrate, and miniaturize the existing conventional devices for multi-faceted applications. Microfluidic biosensors have the advantages of mobility, operational transparency, controllability, and stability with a small reaction volume for sensing.

- biosensor

- electrochemical

- miniaturization

- microfluidics

- fabrication

- nanomaterials

- point of care (POC)

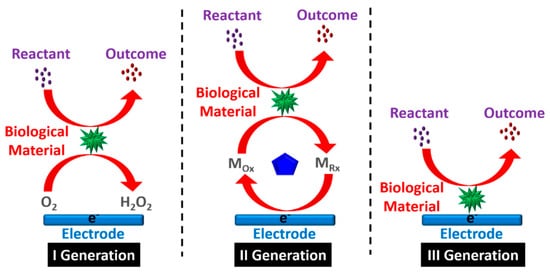

1. Evolution of Biosensors

| Year | Generation | Development Phases of Biosensor |

|---|---|---|

| 1906 | First | M. Cramer noticed voltage difference generating between parts of the electrolyte. |

| 1909 | Sorensen described the idea of pH and pH sensors. | |

| 1909–1922 | Nelson and Griffin were the first to discover that enzyme invertase could be immobilized on charcoal aluminium hydroxide [15,16]. | |

| 1922 | Hughes observed a pH determination electrode [17]. | |

| 1956 | Clark first discovered the biosensor electrode that is capable of determining blood oxygen levels [18]. | |

| 1962 | Clark also demonstrated the use of an amperometric enzyme electrode for glucose sensing [19]. | |

| 1967 | Hicks et al. [20] enhanced Clark’s work; glucose oxidase was immobilized using an enzyme-based working electrode with an oxygen sensor. | |

| 1969 | The first potentiometric enzyme electrode-based urea detection sensor was reported by Montalvo and Guilbault. | |

| 1970 | Bergveld discovered ion-sensitive field-effect transistors (ISFET) [21]. | |

| 1973 | Lubrano and Guilbault demonstrated glucose and lactate enzyme platinum electrode to detect hydrogen peroxide (H2O2) [22]. | |

| 1974 | Klaus Mosbach group developed a thermistor sensor based on a heat-sensitive enzyme [23]. | |

| 1975 | Opitz and Lubbers developed an optical biosensor for alcohol detection [24]. | |

| 1976 | Second | Clemens et al. [25] integrated an electrochemical biosensor for glucose detection into an artificial bedside pancreas. A unique semi-continuous catheter-based blood glucose analyzer was also demonstrated using VIA-based technology. |

| 1977 | La Roche introduced the lactate analyzer LA 640, which was utilized to transmit an electron from dehydrogenase to an electrode [26]. | |

| 1980 | Peterson was the first to perform in vivo blood gas analysis to create a fiber-optic pH sensor [27]. | |

| 1982 | Schultz detected glucose by using the fiber-optic biosensor [28]. | |

| 1983 | Third | Liedberg discovered the reliance-based reactions in real time using the surface plasmon resonance (SPR) method in real time [29]. |

| 1984 | For glucose detection, the first mediated amperometric biosensor was constructed using ferrocene and glucose oxidase [30]. | |

| 1987 | University of Cambridge created a pen-sized detector for assessing blood glucose levels. | |

| 1990 | Pharmacia Biacore proposed an SPR-based biosensor [31]. | |

| 1992 | i-STAT developed a handheld blood biosensor [32]. | |

| 2018 | Girbi designed a neuron-on-chip biosensor to measure the nerve impulse conduction [33]. | |

| 2021 | Kulkarni et al. [34] described an Al-foil-based electrode for sensing cysteine. |

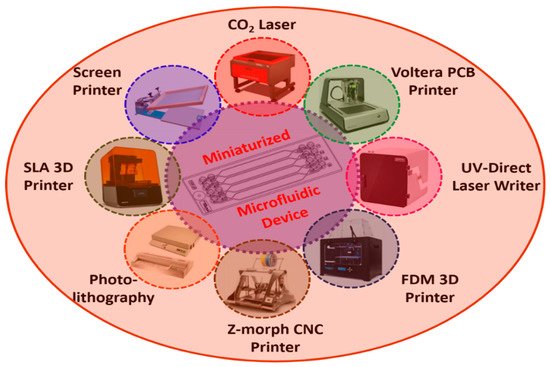

2. Miniaturized Microfluidic-Based Biosensors: Design and Fabrication

| Fabrication Instruments [Ref] | Materials | Specifications | Advantages | Disadvantages |

|---|---|---|---|---|

| CO2 Laser Ablation [101] | PMMA, polyimide | IR source, λ = 10.6 µm | Precise dissection, good efficiency | Expensive instrument |

| Voltera Ink-jet Printer [102] | Paper, PCB, polyimide | Minimum trace width = 0.2 mm | Flexible substrates | Refilling of conductive ink |

| UV-Direct Laser writer (DLW) [9] | Glass, silicon wafer | GaN laser diode, λ = 405 nm | Better resolution | Expensive instrument |

| FDM 3D printer [103] | ABS, PLA, PCL | Filament Diameter = 1.75 mm, accuracy = 100 µm | Easily scaled to any size | Less throughput, low speed, low resolution |

| Z-morph 3D printer [104] | Paper, wood, PMMA | Blue laser, λ = 420 nm | Multipurpose tool with interchangeable tool heads capable of FDM 3D printing (50 µm accuracy), CNC cutting/drilling, and PCB engraving | Slow process |

| Photolithography [105] | Dry film photoresist (DFR) | Max width = 325 mm, maximum substrate thickness = 3 mm | Photosensitive polymers are necessary | Mask is expensive |

| SLA 3D printer [103] | Various liquid resins | Layer resolution = 35 microns | Higher resolution and accuracy | Requires post-processing tasks such as cleaning with IPA and ethanol |

| Screen printer [106] | Cloth, paper | Minimum trace width = 0.4 mm | Low cost | Less accurate |

| Sothlithography [107] | PDMS | Silicone elastomer | Transparent | Low thermal conductivity |

3. Applications

3.1. Food Processing and Environmental Monitoring

3.2. Biomedical Domain

3.3. Plant Biology

3.4. Biodefense Sensing

This entry is adapted from the peer-reviewed paper 10.3390/bios12070543