2. Infrared Spectroscopy: The Past

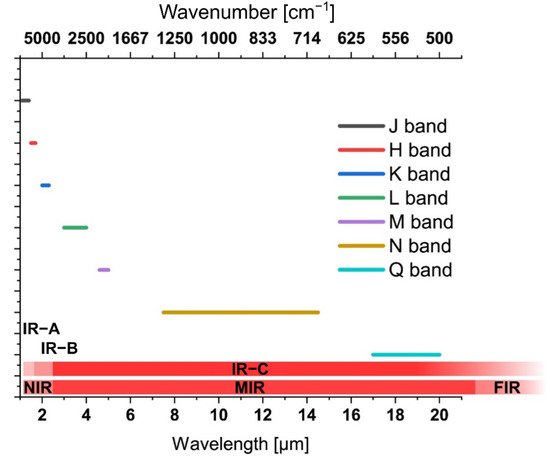

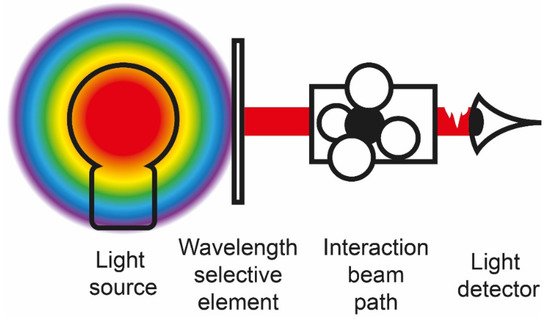

Given the close resemblance to spectroscopy in the visible spectral region, NIR spectroscopy has been developed in a straightforward fashion. Fused silica is highly transparent in the NIR and thus is an excellent choice for NIR optics. Bright light sources as well as silicon based (e.g., line array) detectors for NIR spectroscopy are readily available at a fair price. A conceptual drawing of the basic elements of a spectroscopic setup is given in

Figure 3. NIR spectroscopy provides excellent information, e.g., on the water content in analyte matrices [

3]. Furthermore, carbohydrates, proteins, fats as well as plastics can be identified in the NIR [

4]. Hence, industrial sorting machines are a main application of NIR spectroscopy as long as the broad and overlapping features in the NIR spectra are sufficient for identification, classification and quantification [

5]. Hence, NIR has its capitalizing on highly sensitive and cheap photodetector technologies, which are not useable in MIR. Worthy of note is that the NIR spectral features are the overtones of the fundamental MIR vibrations, and thus, broader—and consequently more overlapping/less discriminatory—and significantly weaker in signal strength vs. the fundamental vibrational signatures prevalent in the MIR [

6].

Figure 3. Conceptual illustration of an instrument for infrared spectroscopy. Commonly, such a setup comprises a light source, a wavelength selective element, a signal transducer, which defines the interaction path length, and a radiation detection device. This core setup is typically accompanied by sampling accessories such as sample feed conduits, flow cells, etc. as well as a robust housing and system control, signal acquisition and data evaluation electronics and appropriate–in current times multivariate–data evaluation, mining, and classification software packages.

MIR spectroscopy has clearly found widespread use in academic research facilities such as universities as well as industrial laboratories. The basic concept of accessing fundamental rotational, vibrational and roto-vibrational molecular transitions has long matured into convenient-to-operate devices, albeit requiring more specialized optics, materials, light sources and detectors than in the NIR. With IR spectroscopy gaseous, liquid and solid phase (i.e., condensed phase) samples can be accessed. Here, MIR spectroscopy enables the non-destructive probing of analytes in various matrices via their well-pronounced MIR signatures providing fundamental transitions of much higher signal strength vs. the NIR. In the early days of MIR spectroscopy, bulky devices requiring sophisticated and delicate optics, including refractive and diffractive optical components, limited the applicability or the wide acceptance of MIR spectroscopic devices as on field tools, and complementary techniques-as for example NIR spectroscopy benefitting from the optical telecommunications revolution-had progressed faster towards lower cost and portable devices. Since then, slow scanning speeds, limited energy throughput and spectral resolution since have been overcome by the development of Fourier-transform infrared (FTIR) spectroscopy. The Fellgett (i.e., high signal-to-noise ratio), Jacquinot (i.e., high throughput) and Connes (i.e., wavelength accuracy) advantages are well-known hallmarks of FTIR technologies and are classical textbook knowledge. From a technological point of view, long-lived radiation sources such as silicon carbide-based blackbody radiators along with high wavelength stability ensured via narrow-band laser sources such as helium-neon (HeNe) lasers have led to a customer-friendly mode of operation. Further technological developments have enabled the implementation of highly sensitive room temperature operated pyroelectric deuterated (L-Alanine) tri-glycine sulphate (DTGS, DLaTGS) or thermoelectrically cooled photoelectric or photovoltaic mixed-semiconductor (e.g., mercury-cadmium-telluride; MCT) detectors facilitating the evolution of MIR spectroscopy not only for routine demands, but also as a high-end research tool. Further developments have led to exceedingly robust and miniaturized interferometers (e.g., Michelson interferometers) providing fast wavelength modulation with a compact device footprint. Hence, entire system footprints on the order of magnitude of a sheet of letter sized or A4 paper and even handheld devices have since entered the markets. However, device scaling remains associated with a trade-off between the highest spectral resolution (i.e., requiring a long travel pathlength of the moving interferometer mirror), fast scanning speed, and portability resulting in dedicated device technology–and performance figures-of-merit–adapted to specific application scenarios. Yet, potent computers enabling fast-Fourier transform algorithms basically in real-time, the introduction of attenuated total reflection (ATR) based sensing techniques, and the increased quality of optical components albeit still requiring specialized MIR transparent materials such as ZnSe, CsI, KBr, CaF

2, etc. have led to MIR spectroscopy catching up with NIR methods in almost any field of application [

7].

3. Infrared Spectroscopy: The Present

Currently, basic instrumentation for NIR and MIR spectroscopic devices has been continuously refined and improved. Again, developments in several technological fields have led to significant improvements in IR spectroscopic instruments. Again, from a technological point of view the introduction of silicon-based detectors and inexpensive thermopile detectors (i.e., low cost down to few euro-cents), as well as high-end sensitive room-temperature-operated MCT detectors has enabled rapid detection schemes with high signal to noise levels. Commonly, MCT detectors had to be cooled with liquid nitrogen, requiring the respective infrastructure, or at least thermoelectric cooling (TEC) via Peltier elements, which results in some bulky cooling components as well as the need for heat dissipation. In addition, various concepts that have been developed for UV/Vis and NIR spectroscopy are increasingly transitioned into MIR spectroscopic tools. NIR spectroscopy has benefited from development pressure at telecom wavelengths. Global data communication greatly benefits from glass fibers that provide ultra-low losses down to few dB/km at adequate manufacturing efforts. As a consequence, the cost and performance of optical components such as sources, detectors, lenses and mirrors have been optimized for wavelengths around 1300 nm. Furthermore, silicon-based source and detector concepts greatly benefit from advances in microfabrication technologies derived from integrated microelectronic circuits. Yet, these co-parallel developments, interconnections within microelectronics, and UV/Vis and NIR spectroscopy benefitting from communications technology are dictated by the utilized material platforms, which is by far and large silicon. Hence, first smartphone-based handheld spectroscopic devices have emerged on the consumer marked, e.g., for the detection of nutrition values as well as potential food spoilage based on NIR techniques.

Traditionally, IR spectroscopy has relied on broadband thermal infrared emitters that emit black body radiation via resistive heating across a certain wavelength band. The respective emission is dictated by the material (e.g., tungsten (W) or SiC, etc.) and the temperature of operation. With the increasing availability of light emitting diodes (LEDs) that are capable of emitting IR wavelengths, small footprint IR sources with a reduced power consumption have recently become available and will become increasingly common within the next decades [

19,

20]. Recent progress in microfabrication has led to MEMS based sources that provide a broad selection of emission wavelength/frequencies as well as high spectral energy densities [

21]. In this context, non-coherent IR light sources such as NIR-LEDs, MEMS-based thermal infrared emitters, as well as coherent IR light sources such as inter-band cascade lasers (ICLs) [

22], and quantum cascade lasers (QCL) [

23,

24], have since become high-performance alternatives replacing traditional lead salt laser diodes or CO

2 lasers. ICLs are characterized by a particular low energy consumption, which enables applications in remote or wearable scenarios, e.g., for spectroscopic sensing of biomarkers in breath or volatile organic compounds in environmental monitoring [

25,

26]. QCLs, on the other hand, provide high emission power at the cost of increased power consumption. First, applications of QCLs for remote gas sensing or chemo/bio sensing in transmission mode, as well as spectroscopic sensing with ATR accessories have been shown to and will become more ubiquitous within the next few years. Rather limited spectral coverage of tuneable diode lasers (TDL) absorption spectroscopy (TDLAS) [

27] scenarios has recently been brought to a new level, as, e.g., broadly tuning QCLs and QCL-arrays have become available that are capable of covering broad wavelength ranges of up to 1200 cm

−1 [

28]. Those lasers have gained interest for the development of exceedingly sensitive spectroscopic applications such as cavity ring down spectroscopy (CRDS) [

26,

29,

30], providing well defined, short pulses combined with accurate wavelength selection at a compact form factor. Additionally, the 3D-printing of gas cells and even very complex optical structures such as multi-pass gas cells further increase the accessibility of complex TDLAS experiments [

31,

32,

33]. Thus, trace gas detection via IR techniques continue to be an emerging topic, in the decades to come, as those lasers ideally fit the needs for sensing narrow rotational bands in complex matrices. Recent trends in laser resonator techniques allow for the envisioning of even broader spectral coverage with complex resonator structures such as tuneable external cavities [

34] or multiple integrated DFB resonator concepts. An exciting strategy for such advanced structures are ring-or dual-ring-QCLs, whereby the quantum cascade structure is arranged in a circular way that facilitates high integration levels. The combination of a QCL source and QC detector in close vicinity are also interesting, e.g., for gas sensing scenarios and will provide an interesting alternative to, for example, existing non-dispersive infrared sensors [

35,

36]. Increased levels of control on the quality of quantum layers now enables the fabrication of devices with tailored electronic band structures at wafer scale production levels. Hence, low-cost MIR emitting IC-LEDs made, for example, from indium arsenide/antimonide phosphide (InAsSbP), are within reach. Furthermore, in the context of FTIR spectroscopy, diode lasers have recently been applied as stable and long-lived wavelength reference replacing He-Ne laser tubes, thus facilitating an additional reduction of device footprints.

Advancing from NIR wavelengths to longer wavelengths further into the mid-infrared spectral region results in demanding technological barriers, mainly concerning the development of suitable substrate materials or material mixes. Silicon (Si) and silicon dioxide (i.e., SiO

2, silica, silica glass, quartz) are suitable materials for fabricating windows or lenses in the UV/Vis and NIR range, but become increasingly opaque in the MIR. On the other hand, micro-bolometers may be fabricated from silicon, which facilitates the straightforward integration of such bolometers into integrated circuits (ICs) for MIR light detection. Bulk manufacturing capabilities that have been developed for Si and SiO

2 processing led to the availability of high-quality substrates that can be milled via computerized numerical control (CNC) machines. Such substrates are well suited for depositing such things as highly reflective metallic mirrors. Here, most metallic materials are useful for the fabrication of broadband reflective mirrors due to their high reflectivity in the MIR. It is worthy of note that, gold (Au), silver (Ag), aluminum (Al), copper (Cu) and alloys thereof (i.e., brass and bronze) are appropriate materials for the fabrication of highly reflective mirrors in the MIR. Here, the selection of the specific material is dependent on the required performance as resistivity towards, for example, corrosive media and the acceptable costs. For application in analytical spectroscopy in the MIR, substrate integrated hollow waveguides have been developed that provide a rugged and highly integrated material platform for analysing gaseous environmental and (bio)medical samples [

37,

38,

39]. Another parameter that can be crucial for the material decisions may be weight, especially in application scenarios where the device payload is critical (e.g., drone-mounted IR sensing devices). Aviation, space and high acceleration applications demand exceedingly lightweight yet robust substrate materials [

40,

41]. Here, silicon carbide (SiC) has recently emerged as a stiff, durable and lightweight substrate material for metallic mirrors that are reflective in a wide spectral window, especially covering the MIR. Most recently, SiC Mirrors were used as the primary mirrors of the EUKLID telescope by the European Space Agency’s Cosmic Vision program. Within this project, a visible imager and a near-infrared spectrometer and photometer together with a Korsch Telescope were built [

42].

As an alternative, dielectric mirrors can provide enhanced reflection performance at a narrower spectral range. However, such Bragg reflectors and photonic bandgap structures can be fabricated via gas phase deposition processes (i.e., chemical vapour deposition, CVD; physical vapour deposition PVD; molecular beam epitaxy, MBE; atomic layer deposition, ALD, etc.). Here, alternating layers of specific atomic composition can be deposited to specifically tune the reflected wavelength.

The very same principle has been introduced to prepare highly reflective coatings for MIR optics. Dichroic mirrors represent an implementation of the combination of dielectric mirrors and highly reflective coatings. With such mirrors, narrow-band radiation of different wavelengths can be combined into a single multi-colour beam. Such mirrors represent the standard way for beam combinations where diffractive elements (gratings) or tilted combinations cannot be deployed. Very recently, substrate integrated hollow waveguides (iHWGs) have been developed to achieve such a combination without the need to pass a dispersive element, i.e., the substrate material, of such a dielectric mirror [

43].

With efforts towards the reduction of moving parts and the ideally monolithic integration linear variable filter (LVF) elements have also been introduced for IR spectroscopic demands. Such filters, in combination with detector arrays fabricated, for example., from lead zirconate titanate (PZT), provide promising wavelength selective elements for robust spectroscopic sensors in the IR. It is worthy of note that such alternating structures have also been introduced as light emitting and light detecting structures [

44].

In general, dielectric materials are the material of choice in the MIR. Similar to UV/Vis and NIR optics, distinct dielectric materials are suitable for the fabrication of lenses, windows, beam-splitters, fibers and waveguides. Germanium (Ge), diamond, zinc selenide (ZnSe), zinc sulphide (ZnS), germanium based chalcogenide glasses (such as AMTIR-1 and AMTIR-3), other germanium based chalcogenide glasses (e.g., Schott IRG, Ge–Sb–Se, Ge–Ga–Sb–S)) [

45,

46], thallium bromine chloride or iodide (KRS-5, KRS-6), silver halides (AgX, AgCl

xBr

1−x) [

47,

48,

49,

50], potassium bromide (KBr), sodium chloride (NaCl) and gallium arsenide (GaAs) [

51,

52] are only some examples of materials that have been implemented as routinely deployed dielectrics in MIR spectroscopy of late. Many other chalcogenide-based materials are the topics of today’s research on spectroscopy as shown in the articles by Churbanov et al. and Denker et al. [

53,

54].

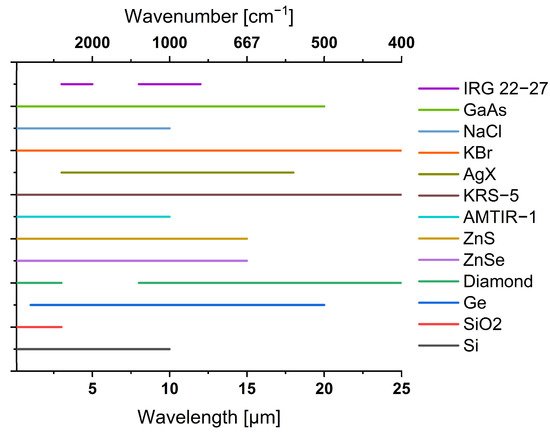

These materials are transparent in the MIR (the respective transparency regions are given in

Figure 6) and provide sufficient robustness, inertness, hardness, and pH-stability. Diamond infrared optics have gained much interest in the military, such as for defence applications for night vision or guidance systems in the form of infrared domes or windows due to their excellent durability. The formerly used ZnS and ZnSe optics were cheaper to produce but much more prone to material damage, such as abrasion and darkening. As fabrication capabilities of diamonds have made this material increasingly available for civil stakeholders, diamond has become the quasi-gold standard for vacuum windows and ATR transducer materials in the MIR [

55]. High-quality crystals as well as foreseeably reduced fabrication costs will certainly lead to a much wider implementation of diamond-based infrared optics given the advantage of being inert, non-toxic and will therefore be of increasing importance in food analysis and pharmaceutical analysis [

56]. In addition, the fabrication of waveguides such as thin-film waveguides with envisioned applications in ICs requires the existence of optical insulators (i.e., optical buffers) for which such materials are suitable. Recently, smart combinations of, e.g., freestanding diamond waveguide strips [

57,

58] and membranes as well as AgX, ZnSe [

59] or GaAs/AlGaAs [

45] -based thin-film waveguides have been developed as efficient ATR transducer elements for MIR sensing tasks. Given these trends, refined fabrication techniques are clearly resulting in the elevated quality of the fabricated structures with existing materials as well as the development of more sophisticated waveguide structures. Some, still more exotic, waveguide designs based on, e.g., slot guiding [

60], plasmonic concepts [

61], bimodal waveguides [

62], on-chip Mach-Zehnder Interferometers [

63,

64], micro-ring resonators [

65] and photonic crystals (photonic bandgap structures) have recently been presented. These structures represent a well performing alternative to more traditional rib, strip and ridge designs of photonic chemo/bio sensors and will lead to highly sensitive implementations in chemo/bio sensors for various tasks. In combination with dedicated microfluidics, highly sensitive devices may be fabricated on a small footprint requiring only a few droplets of analyte and reaction chemicals [

66].

Figure 6. Spectral transparency range of selected materials used for waveguiding applications in the infrared.

Hollow or dielectrically filled waveguide technology with metallic waveguide walls is derived from microwave/terahertz (THz) and radar technology. Such waveguides work well for distinct reflections in dedicated MIR hollow waveguide structures. However, with reduced lateral dimensions towards single mode wave guiding, fast-alternating electric fields induce high losses in the waveguide walls, leading to limited lengths of such hollow waveguides [

67,

68,

69]. Hence, dielectric waveguides (fibers) based on total internal reflection are more efficient as light guiding structures. In particular, waveguide fibers for localized light delivery are most commonly realized from solid materials instead of hollow core fibers. In this context, fibers can be utilized to route light in endoscopic scenarios, enabling IR spectroscopy to be used on inaccessible parts of a patient’s body. Such tools have already been introduced for cancer detection and cartilage evaluation [

70,

71,

72,

73]. With a foreseeable market entry of such tools, surgeons will be provided with a tool that facilitates diagnostic decision-making based on the molecular composition of the evaluated tissue. Apart from applications in medical scenarios, probes have been developed for the on-line monitoring of processes such as bio-fermenter status. IR spectroscopic monitoring facilitates the fast detection of reaction states as well as potential spoilage, allowing fast response times and elevated process control. The delivery of high intense laser light emitted from CO

2 lasers for application in industrial welding or chirurgical environments benefits from a high damage threshold and low insertion losses of hollow waveguides. Therefore, some hollow core fibers with inner walls that are tailored towards low attenuation at 10.6 µm have emerged on the market.

In addition to advancing capabilities in fabrication and material sciences that lead to advanced application scenarios, novel technological concepts and their adaption in IR spectroscopic techniques provide opportunities that have previously been inconceivable.

Similarly, utilizing the photoacoustic effect in photoacoustic spectroscopy (PAS) has enabled the non-invasive analysis of glucose concentration in interstitial fluid [

74]. Therefore, progress towards non-invasive diabetes care based on extended IR spectroscopy will be within reach in the next few of years. Additionally, PAS facilitates the acquisition of depth profiles of organic tissue and thus enables tomographic imaging. Here, screening for skin cancer is an important and emerging field for the application of IR spectroscopy.

At present, MIR spectroscopy is strongly connected to the latest developments in imaging technologies such as MIR microscopy. Previously, scanning techniques were realized by coupling an FTIR spectrometer to a movable ATR tip scanner or to a sharp atomic force microscopy (AFM) tip in so-called Nano-FTIR setups that are based on scattering type near field scanning near field optical microscopy (s-SNOM) techniques.

With the increasing availability of matrix detectors such as MCT arrays or micro-bolometer arrays in combination with fast scanning lasers, IR hyperspectral imaging has emerged from silicon based NIR techniques further into the MIR and have become a current hot-topic and will still be important in the near future.

As rapid image acquisition in reflection and transmission mode has become available, the application of this in medicine, surveillance and even defence is steadily increasing [

75].

The combination with label-free and cost-effective detection based on minimal sample volumes makes IR spectroscopy especially suitable for routine clinical laboratory applications [

76]. Considerable efforts have been made in recent years in FTIR spectroscopic imaging to study things such as the imaging of biopsy tissues [

77], fixed cells [

78] and live cells [

79,

80], including cancer cells [

81]. In particular, synchrotron infrared sources coupled to FT-IR microscopy have immense potential for clinical research [

82].

However, the long wavelengths of infrared radiation commonly limit lateral resolution in IR imaging. Very recently, smart concepts have been developed to surpass this limitation by exploiting the optical photothermal effect (O-PTIR) [

83]. By using visible light as a probe, higher lateral resolution down to the submicron range is achieved for IR imaging and, as a side-effect, Raman scattering may be acquired in the very same experiment [

84]. However, energy input is a major issue that hat to be considered when dealing with sensitive samples, as the ineffective Raman scattering process requires a considerable amount of photon flux.