The Value Stream Method (VSM) is widely used in manufacturing to analyze and redesign value streams. The aim is to improve processes, reduce waste and create a thorough product flow. Despite having many benefits, VSM also comes with disadvantages regarding modern dynamic production environments. It fails to meet the requirement of providing reliable information for a realistic Value Stream Design (VSD) followed by targeted improvement activities. As a result, the VSM is usually subject to uncertainty and relies on expert knowledge. Digitalization, on the other hand, is leading to an increasing availability of production data. The use of data has the potential to support the VSM with targeted data preparation. In this regard, the concept of Digital Twin (DT) offers the capability of providing the required database to systematically collect and condense this data.

1. Introduction and State of the Art

Challenges like short product life cycles, new disruptive technologies and volatile markets place stress on today’s production systems [

1,

2]. To adapt quickly to changing market demands and customer requirements, there is an increasing need for flexibility and transformability of production on the one hand. On the other hand, productivity and delivery performance targets have to be met. Both conflicting target areas are only insufficiently addressed by the static nature of classical production systems [

3]. This leads to increasing inefficiencies. Value stream management (VSMM) [

4] has the goal to systematically transform a current state value stream to a desired target state. Its major tool for creating transparency and planning change is the value stream method (VSM) [

5]. The VSM aims to identify the causes of waste throughout the value stream and eliminate them by implementing a target state [

6]. The target state is designed with the aid of design principles and guidelines. [

7] For instance, the design guidelines support the calculation of the customer cycle, the lead time, the design of the process connections and the required number of employees [

7,

8]. Finally, the developed target state is gradually realized by means of individual projects as part of an implementation plan [

6].

However, the VSM is reaching its limits regarding the current challenges mentioned. Due to singular data recording on site, the VSM only provides a snapshot of value streams and thus does not take into account the dynamic development of production systems [

9,

10]. For this reason, there is a need for further development of the VSM to meet the current dynamics of production systems. According to one study, around 66% of lean experts believe that further development of the VSM using Industry 4.0 technologies is beneficial [

2]. By merging the two approaches, the restrictions can be eliminated.

One promising Industry 4.0 technology related to the optimization of production processes is the Digital Twin (DT) [

11,

12]. DTs received specific attention in the context of digitalization and increased implementation of cyber-physical production systems (CPPS) where all entities can collect, generate or process data/information [

13]. A DT is considered as an efficient way to accomplish the interconnection between physical and virtual spaces [

14]. Within this understanding, the terms Digital Model (DM), Digital Shadow (DS) and DT are often used synonymously. However, the definitions differ in the level of data integration between the physical and digital object [

11].

A DM is the digital representation of an existing physical object with no automated data exchange between the physical and digital object. It includes a comprehensive description of the physical object based on mathematical models or any other models of a physical object, which do not need an automatic data integration. The DS is an extension of the DM. For this, an automated one-way data flow between physical and digital object must exist. A change in the physical object determines a change in the digital object but not vice versa. If further, both data flow directions are fully automated, one might refer to it as a DT. In this case, the digital object represents the controlling instance of the physical object. A change in the physical object directly leads to a change in the digital object and vice versa [

11]. Technical realization of the DT focuses on implementation for individual production processes, both in research and practice [

11,

14]. According to [

15,

16], an integration of the DT to represent an entire production system in digital space is promising as it links the existing production system with real-time data to a digital reflection. This allows us to eliminate the static character of a once created value stream map as dynamic changes of production systems are considered [

15,

16]. To the authors knowledge, the transfer and adaption of the DT concept to the complex interrelationships within a value stream to support the continuous improvement of it within VSMM has not been taken place yet. Therefore, this paper proposes a framework for the implementation of a DT at the value stream level, the so-called Digital Value Stream Twin (DVST). The DVST is defined as a comprehensive digital representation of a value stream. It includes the properties, conditions, and behaviors of a value stream through mathematical models and data. The virtual, dynamic model helps optimize the performance of a value stream. In VSMM, the DVST is used to model and present a holistic view of interrelationships and dependencies of individual production processes. The optimization of a value stream as a unit is the priority rather than the optimization of an individual production process.

3. Objectives and Definition of the Digital Value Stream Twin

It appears, that two directions are sought within the framework of VSMM [

6,

7,

8,

18]:

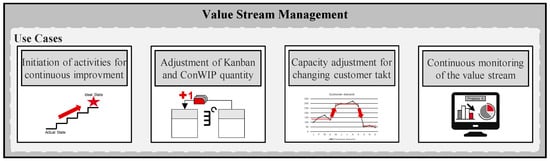

The first direction is based on the comparison of the current behaviour of the value stream against its expected performance based on target values and conditions [

3]. This includes particularly the

continuous monitoring of the value stream, e.g., inventories, lead times and overall equipment effectiveness [

15]. Furthermore, especially regarding production planning and control, the short-term

capacity adjustment for changing customer takt is an essential feature of reactive VSMM [

7]. To support this reactive improvement, a value stream Map needs to be continuously and timely updated with the latest data and values from each single process of the Value Stream.

In addition to the reactive tasks, the proactive part of VSMM aims at the

initiation of activities for continuous improvement towards the defined target state [

6,

8,

19] which is typically driven by project work. A key element of the proactive part is the lead time reduction. To achieve this, inventory monitoring through

adjustment of Kanban and ConWIP quantities is essential for VSMM [

8]. An overview of the four use cases is provided in

Figure 3. Further tasks are found in the corresponding literature [

6,

8,

15,

19].

Figure 3. Use Cases for Value Stream Management.

To support this dynamic development of a value stream, the classical value stream method—which is usually based on a static value stream map—needs to be technologically enhanced. Physical changes of the value stream must be immediately reflected within the big picture map in each relevant aspect of VSMM. This includes the processes properties and logistical interconnections, but also the information flows. For this reason, the following definition of the DVST can be derived:

The Digital Value Stream Twin is the digital representation of a value stream, including individual process steps and their properties as well as their logistical interconnections. Its holistic focus lies on the timely display of key Value Stream Indicators to support the daily operational management in reaction to abnormal conditions. Additionally, it represents the actual state of material and information flows to display the effects of project work on lead times and inventories to the value stream manager.

To make this possible, relevant data is collected and transferred automatically from the physical value stream to the digital representation, then processed and provided. The final decision regarding an adjustment in the value stream remains with the operational production management and the value stream manager, the DVST merely supports the decision-making process.

Once the objectives as well as the definition of the DVST have been derived, the requirements for technical implementation are deducted from the identified literature as follows.

This entry is adapted from the peer-reviewed paper 10.3390/systems10040102