2. Fruit Production and Waste Generation

Global production of fruits has been growing steadily over the past decade, and the estimated global fruit production was 883.4 metric tons (MT) in 2019, and Asia produced 512.6 MT of fruits which contributed to 58.0% of the world production. China is the first major producer of fruits globally, followed by India, Brazil, the United States, and Mexico. In 2019, the most produced fruit in the world was bananas (116.8 MT), followed by watermelons (100.4 MT), oranges (78.7 MT), mangoes, mangosteens, and guavas (55.9 MT), pineapple (28.2 MT), citrus fruits (14.5 MT), and papaya (13.7 MT) [

53].

A recently published WHO/FAO report recommends a minimum of 400 g of fruit and vegetables per day (excluding potatoes, cassava, and other starchy tubers) to improve health and for the prevention of non-communicable diseases including heart diseases, cancer, diabetes, and obesity, as well as for the prevention of several micronutrient deficiencies [

54]. Increasing concern for health has led to an increase in fresh fruit consumption over the past few years [

55]. Increasing fresh fruit consumption leads to the accumulation of fruit skins, rinds, and the residue left over at the point of consuming fruits.

Further, fruits are generally consumed directly as food or dessert. As most fruits are seasonal and have a low shelf-life, fruits are processed into various products to extend their availability all over the year. Fruits are generally processed into bottled fruits, juices, jams, marmalades, jellies, bars, pickles, canned, frozen, concentrates, dehydrated products, alcoholic beverages, and other minimally processed products [

17].

In the recent past, intensive fruit production has caused a massive generation of fruit wastes, and the improper management of these wastes can constitute a public health risk and severe environmental problems. The main solid waste in the fruit processing industry is fruit peels [

56]. In general, the non-edible portion of fruits and vegetables, such as peels, pods, seeds, and skins, are discarded during processing, and it accounts for about 10–60% of the total weight of the fresh produce [

57]. Peels are the primary by-product representing almost 30% of the total weight [

17], and can be very high in some fruits (e.g., banana 30–40%, papaya 10–20%, pineapple 29–40%, mango 25–40%, orange 30–50%) [

58,

59,

60].

Traditionally fruit wastes are used as animal feed, source of fuel, fertilizers, and various other value-added novel products, including pectin, biodiesel, bioethanol, biogas, biohydrogen, bio-oil, organic acids, enzymes, polysaccharides, flavors, coloring agents, bioactive functional phytonutrients, probiotics, edible coatings, green nanoparticles, bio-degradable plastics, biochar, biosorbent, SCP, single cell oil [

49,

56,

61,

62,

63,

64,

65].

The fruit processing industry generates massive waste, and the proper disposal increases processing costs. Generally, to reduce the production costs, these fruit wastes are discarded into the environment. Though the fruit wastes are biodegradable, if not processed further, these fruit wastes become spoiled rapidly and cause objectionable odor and give rise to immense environmental and health problems. Decaying fruit wastes are harbourage for microorganisms and attract pests, including flies which can cause infectious diseases and other serious health issues [

13,

66,

67].

Agro-industrial wastes contain phenolic compounds and other toxic compounds, which may cause deterioration of the environment when the waste is discharged into the environment [

68]. Fruit waste dumped in the landfills gradually rotten on landfills and releases methane, a potent greenhouse gas that traps 21 times more heat in the atmosphere than carbon dioxide [

67]. Therefore, recycling or reusing fruit peel is a timely requirement. Using agro-wastes in SCP production can minimize environmental pollution associated with waste disposal and fulfil the world protein demand.

3. Physico-Chemical Properties of Fruit Waste

Physico-chemical composition gives an idea about the potential of fruit wastes in SCP production. The lignocellulosic fruit peel wastes contain a large number of soluble sugars, starch, fiber (cellulose, hemicelluloses, lignin, and pectin), ash, fat, protein, and other micronutrients. Liquid peel waste contains mainly simple sugars such as sucrose, glucose, and fructose and a significant amount of minerals and nitrogen content [

58]. The solid fruit peel waste contains simple sugars (reducing and non-reducing sugars) and complex carbohydrates, such as cellulose, hemicellulose, and lignin, which can be metabolized by microorganisms [

16,

69]. The physico-chemical composition of fruit peel varies with fruit, types of cultivars, maturity level, geographic locations of cultivations, seasonal variations, and processing conditions (e.g., drying method, drying temperature, particle size) [

17,

46,

70].

Carbohydrates are an abundant component in many fruit peels (above 50% of fruits’ dry weight) [

17,

71]. Dias et al., 2020 reported that pineapple contains 83% carbohydrates, while a lower value was reported with other peels such as yellow passion fruit (59%), orange (59%), and avocado peels (8%) on a dry weight basis. Dias et al., 2020 also stated that the selected fruit peels contained a significant amount of fat and ash, and the values vary with the fruit peel varieties [

72]. Ripe banana peel contains 13.8% soluble sugar, 8% crude protein, 6.2% ether extract, and 4.8% total phenolic compounds [

73]. Rivas et al., 2008 stated that the orange peel contains 16.9% soluble sugars, 3.8% starch, fibre (9.2% cellulose, 10.5% hemicelluloses, 42.5% pectin and 0.8% lignin),3.5% ash, 2.0% fats and 6.5% proteins in dry weight [

74]. Orozco et al., 2014 reported that orange peel contains 14.5% hemicellulose, cellulose 11.9%, and a small amount of lignin 2.2% [

75]. Many studies reported a low value for lignin which makes the fruit peels amenable to the hydrolysis process [

74,

75,

76].

Furthermore, the use of fruit peel for the production of SCP is determined by its availability and low cost, composition, and absence of toxic substances and fermentation inhibitors [

35]. For instance, citrus peels, such as orange peels, are rich in essential oils and limonene, a predominant component with antimicrobial property, which hinders the digestion process of microbes or fermentation process, thus resulting in less biomass production. Therefore, prior to hydrolysis, limonene is removed from the citrus bio-waste in the pre-treatment steps [

20,

49].

4. Fruit Waste as Substrate for SCP Production

Fruit waste is rich in carbohydrates and other essential nutrients that could support microbial growth. Thus, fruit processing waste is a potential substrate for value-added products such as organic acids, methane/biodiesel, ethanol, enzyme, secondary metabolites, organic acids, and SCP [

10,

14,

15]. SCP production has gained more attention in recent decades, and a wide variety of fruit wastes have been used as substrates. The cost and the economic viability of SCP production largely depend on substrate cost [

10]. Hence, waste from various fruits can be a suitable substrate for SCP production. Fruit peel waste is lignocellulosic wastes [

77] containing simple and complex sugars that can be metabolized by microorganisms [

16]. The proximate analysis also revealed that the fruit waste contained variable amounts of carbohydrates, protein, lipid, and moisture content essential for microbial growth in SCP production [

20].

Many studies recently aimed at producing CP from various fruit peels by using solid-state, semi-solid, and liquid-state fermentation. Fruit peels such as beles fruit, watermelon, banana, papaya, mango, sweet orange, apple, pineapple, plantain, pomegranate rind, cactus pear, and virgin grape marc are some potential substrates used for microbial growth and SCP production [

18,

36,

78,

79,

80].

Table 1 shows the various microorganisms and fruit wastes used for SCP production.

These agro-wastes used as a substrate for the selected microorganisms are composed of sugar, starch, and other cellulose materials that are metabolizable by microorganisms through the secretion of extracellular enzymes [

16]. Lignocellulosic wastes such as agricultural residues and fruit peels are mainly composed of cellulose, hemicellulose, and lignin. Cellulose is converted into sugars, generally by the action of acids or cellulolytic enzymes. Starch materials such as wastes from corn, cassava, potatoes, and root crops are hydrolyzed to fermentable sugars by enzymes from malt or moulds. Cane, molasses, and fruit waste extract, like pineapple waste extract, contain valuable components, mainly sucrose, glucose, fructose, and other nutrients [

108].

5. Types of Fruit Waste

5.1. Fruit Wastes Rich in Simple Sugars

SCP production depends on the type of substrate used and the composition of the culture medium. In a liquid state fermentation system, a fruit waste extract medium is used. Fruit waste extract consists of various components with a significant amount of carbohydrates, a small amount of protein, lipid, and ash [

17,

72,

80], and they are rich in valuable components, mainly sucrose, glucose, fructose, and other nutrients [

108]. Most microorganisms readily utilize simple sugars such as carbon and energy sources, and amino acids are used as nitrogen sources [

109,

110].

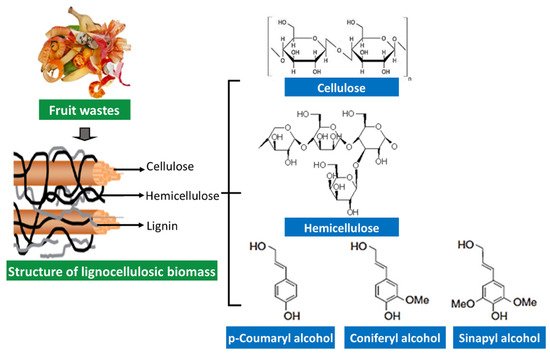

5.2. Fruit Waste Rich in Fibers

Fruit processing waste mainly consists of outer and inner shells, peels, and seeds. These fruit wastes contain fiber, and hence the waste can be categorized as structural polysaccharides-rich sources [

66]. Large amounts of agro-industrial wastes such as bagasse, straw, stem, stalk, cobs, husk, and fruit peel are mainly composed of cellulose (35–50%), hemicellulose (25–30%), and lignin (25–30%), also being called “lignocellulosic materials” [

111,

112]. Typically, cellulose forms a skeleton surrounded by hemicellulose and lignin in lignocellulosic materials and acts as a protective barrier to cell destruction by bacteria and fungi (

Figure 2).

Figure 2. Structural components of lignocellulosic biomass.

Cellulose is a homopolysaccharide composed of

β-d-glucopyranose units joined via

β-1,4 glycosidic linkage. The long chain cellulose polymers are linked together by hydrogen and Van der Waals bonds and packed into microfibrils [

68,

113]. Hemicelluloses are heterogeneous polymers that comprise five main sugars (L-arabinose, D-galactose, D-glucose, D-mannose, and D-xylose) and some organic acids (acetic and glucuronic acids). Hemicellulose has different classifications based on the main sugar in the backbone: xylans, glucans, mannans, arabinans, xyloglucans, arabinoxylans, glucuonoxylans, glucomannans, galactomannans, galactoglucomannans, and

β-glucans. In contrast, lignin is not formed by sugar units but formed by a complex three-dimensional structure of phenylpropane units. Three phenyl propionic alcohols are primary monomers of lignin;

p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol [

68,

114].