Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Concern about environmental problems, including the greenhouse effect, directly related to the gases produced by vehicles, has led governments and various organizations to promote standards on fuel use and gas emissions.

- electric vehicle

- charging station

- charging infrastructure

1. Introduction

The energy supply to charge electric vehicles plays a vital role in sustainability with the large-scale introduction of electric vehicles (EV). Electric mobility contributes directly to reducing greenhouse gases, noise, and visual pollution compared to traditional mobility. Human mobility plays a vital role in the development and growth of society; on the contrary, with classic mobility, the environmental cost becomes severe and unfavorable for future generations due to the current climate change [1].

In this sense, replacing fuel-based vehicles with battery-electric vehicles arises, with deployment being a challenging issue. Proper planning is required to locate the correct number of charging stations (CS) in optimal locations. Different methods have been proposed to identify and size CS without considering factors such as traffic flow, road networks, structures, capacity constants, and geographical considerations. For this reason, to choose candidate sites for the optimization process, conventional gas stations (fossil fuels), bus stops, and parking lots are considered [2].

2. Bibliometric Analysis

In recent years, the number of publications about CS and EV has grown dramatically; such is the case that a search in Scopus for the keywords “electric vehicle charging station” gives a total of 5719 articles as results for the period (2001–2021); similarly, a search in Web Of Science (WoS) for the keywords “electric vehicle charging station” gives a total of 2285 articles as results for the period (2001–2021). Researchers used the VOSviewer software for the data analysis, which allows researchers to make a graphical representation of the papers with the highest impact from the bibliographic information. Consequently, VOSviewer creates a map that suggests the weight of each article and the distance between each one, defined by the degree of co-occurrence of terms. In addition, the larger the element’s size in the graph, the higher the frequency of occurrence in the literature investigated. The smaller the distance between one part and another, the higher the degree of co-occurrence.

3. Electric Vehicle Charging Infrastructure Standards

There are many regulations about EV and their repercussions on society and transport users in the global environment. Generally, and thanks to the trend towards massification of transport in certain European territories, standards were developed and adopted to establish measures to ensure the safety of individuals and the proper handling of vehicle elements. Standardization concerning EV charging can be divided into three areas: standards for EV charging components (International Organization for Standardization (ISO)), criteria for EV grid integration (Institute of Electrical and Electronics Engineers (IEEE) and Underwriters Laboratories (UL)), and standards for safety (National Fire Protection Association (NFPA) and the National Electrical Code (NEC) [3][4].

Several standards are available; manufacturers use the society of Automotive Engineers (SAE) and IEEE in the US, and IEC is used in much of Europe. Japan and China have their standards with Chademo and Guobiao (GB/T). In SAE, the term “level” of power is considered, while IEC believes the term “mode” to indicate the power level [5][6].

The only charging mode that includes 120 V is the SAE J1772 standard, unlike the other standards with higher charging voltages even in their lowest charging modes. SAE J1772 offers a lower voltage (500 V) in the full charging mode than 1000 V of the other standards. The lowest current is the GB/T-20234 standard at 10 A, compared to 16A for the different standards. SAE J1772 supports a maximum current of 200 A, GB/T-20234 with 250 A, and IEC 62196 with 400 A. In alternating current charging modes, SAE J1772 has a charging power of 1.9 kW, the lowest, compared to GB/T-20234 with 27.7 kW and IEC 62196 with 3.8 kW. In direct current charging modes, IEC 62196 offers 400 kW, the highest, compared to 250 kW offered by GB/T-20234 and 100 kW by SAE J1772.

Safety is an essential part of electric vehicle charging and grid integration. NFPA and NEC focus specifically on safety and security. The NFPA 70 standard addresses grid integration and electric vehicles, providing instructions for equipment wiring and customer safety at the point of connection to the grid. NEC 625 “Electric Vehicle Charging Systems” addresses installation for EV charging infrastructure. NEC 626 “Truck Parking” manages the parking area and external infrastructure for EV charging.

4. Charging Station Design

The criteria and recommendations described in the NEC 2020 national electrical code are considered to design the charging station for EVs.

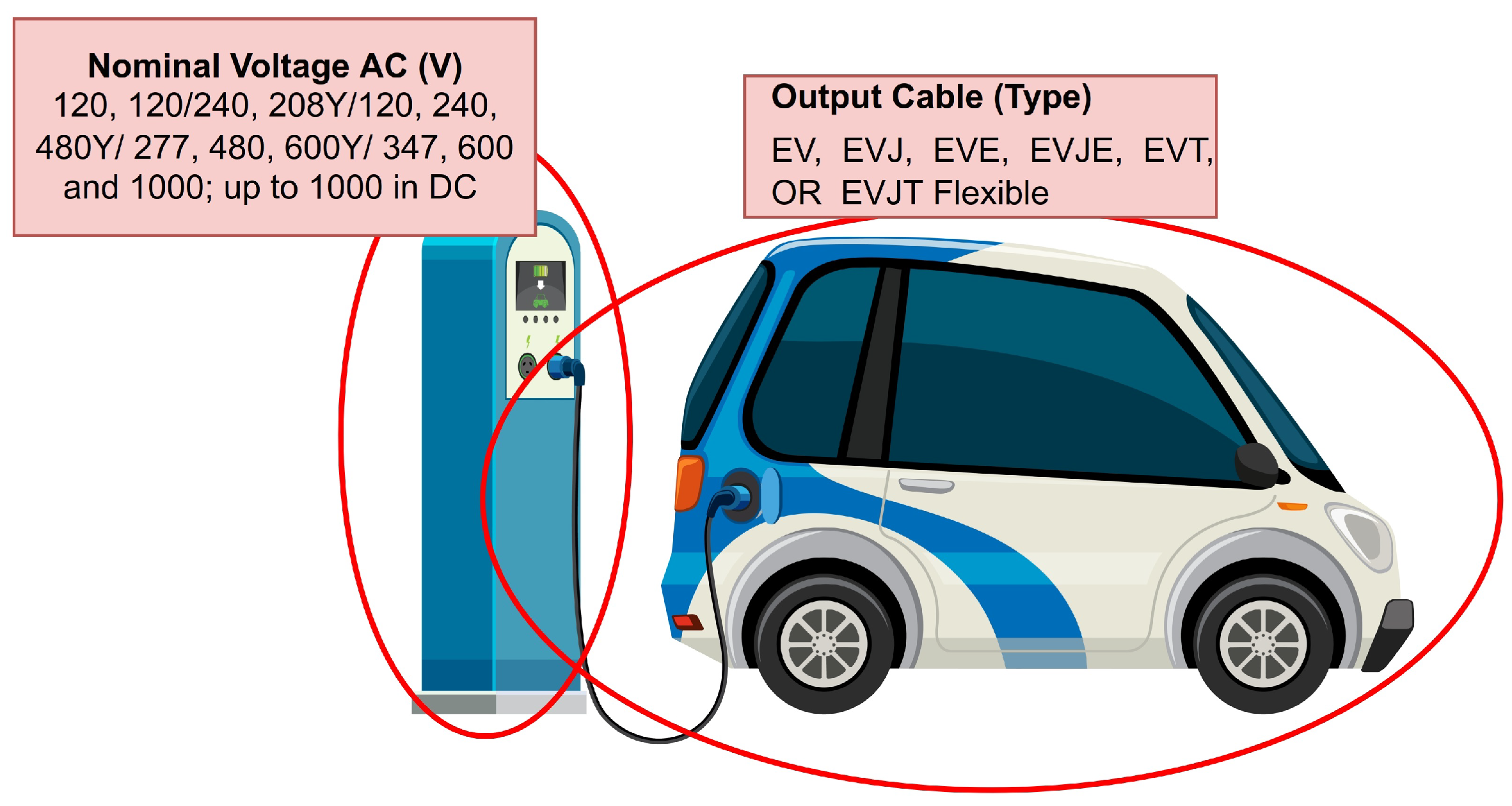

In the case of the power supply equipment that makes up the charging station, it must contemplate an adequate nominal voltage for the load to be supplied; then, EV recharging operation is assumed to be a continuous load if the manufacturer does not specify a nominal voltage, the voltages presented in Figure 1 will be considered. The EV cable for power supply for EV shall be of the types EV, EVJ, EVE, EVJE, EVT, or EVJT flexible; the length of the line shall not exceed 7.5 m (25 ft) unless equipped with a suitable management system.

Figure 1. Voltages for power supply and output cable.

Installation

Outlets installed for EV charging shall be fed by a single circuit and may not have branch circuits. The overcurrent protection of the charging station equipment shall be designed for continuous service and shall not be less than 125% of the maximum load of the equipment. In the case of discontinuous shipments taken from the same feeder, the overcurrent device shall be not be less than the sum of the intermittent loads plus 125% of the continuous loads.

Back-feeding energy through the electric vehicle and supply equipment to the primary system shall be avoided during a loss of prime source unless the system has been designed for that purpose. The charging station coupling shall be located at a height of not less than 450 mm (18 in) from the floor for indoor locations; for outdoor areas, the size shall be 600 mm (24 in) from the floor.

Suppose electric vehicle charging is performed indoors and the charging equipment requires ventilation. In that case, the ventilation shall include the supply and exhaust air equipment, mechanical fans with direct ventilation to the outside shall be used, and positive pressure ventilation is considered in buildings. The mechanical ventilation equipment shall be electrically connected to the EV charging equipment and remain in operation during the entire EV charging cycle. The methods specified in Section 625 of the NEC 2020 determine the required mechanical ventilation.

This entry is adapted from the peer-reviewed paper 10.3390/su14148248

References

- Campaña, M.; Inga, E.; Cárdenas, J. Optimal sizing of electric vehicle charging stations considering urban traffic flow for smart cities. Energies 2021, 14, 4933.

- Morán, J.; Inga, E. Characterization of Load Centers for Electric Vehicles Based on Simulation of Urban Vehicular Traffic Using Geo-Referenced Environments. Sustainability 2022, 14, 3669.

- Brown, A.; Lommele, S.; Schayowitz, A.; Klotz, E. Electric Vehicle Charging Infrastructure Trends from the Alternative Fueling Station Locator: First Quarter 2020; ONREL NREL/TP–5400–77508, 1660251, MainId:27444; ICF: Golden, CO, USA, 2020.

- Das, H.; Rahman, M.; Li, S.; Tan, C. Electric vehicles standards, charging infrastructure, and impact on grid integration: A technological review. Renew. Sustain. Energy Rev. 2020, 120, 109618.

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 22.

- Stochastic, A.; Parameters, O. A Method of Analyzing the Residual Values of Low-Emission. Energies 2021, 14, 6859.

This entry is offline, you can click here to edit this entry!