Titanium is rarely used in civil engineering, with applications limited to medical implants or aerospace engineering. In conservation engineering, applications are uncommon and not well documented, and this paper aimed to summarize the state-of-the-art research of the use of titanium to reinforce or repair existing masonry structures.

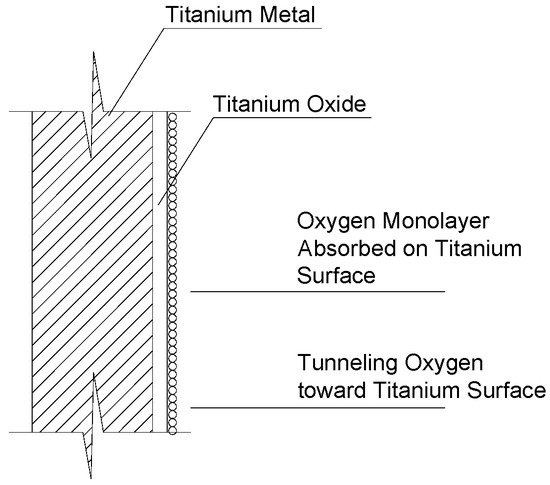

However, resistance to corrosion is surely the most important characteristic of titanium. Titanium and its alloys are easily passivated metals. The passivation film (Figure 1) on the surface is very stable and has excellent corrosion resistance. This makes titanium alloys interesting in civil engineering where interventions are often exposed to physical weathering.

Finally, another significant problem associated with the use of titanium in civil engineering is its cost. Most people associate titanium with an expensive technology. Titanium is more expensive than structural steel and stainless steel, but the cost of the material is only a small part of the overall cost of a retrofit intervention. In conservation engineering, the amount of reinforcement material is limited, and the majority of costs are from labor and installation.

2. Titanium in Civil Engineering

The use of titanium alloys in civil engineering is rare, but applications are increasing in number. This is the consequence of two important facts: (1) the cost of titanium has reduced drastically over the last decades; (2) recent collapses of civil infrastructures have highlighted the shortcomings of the use of carbon steel in structures exposed to outdoor environments.

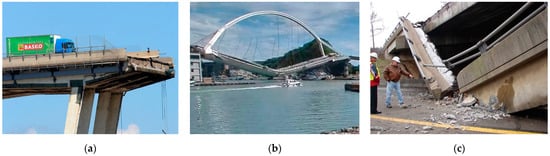

Civil structures and infrastructures have a design life typically much longer than any other aerospace or medical application. In many developed countries, concrete bridges built during the economic boom of the 1950s and 1960s often had inadequate steel reinforcement and need repair or replacement (

Figure 3). These bridges are normally still in use after 70 years, and the disadvantages of replacement are high, not only for the economic cost but also in terms of carbon emissions and low sustainability. Recently, titanium was used to rehabilitate and extend the life of bridges saving cost and time over replacement [

5,

6,

7].

Figure 3. Recent collapses of reinforced concrete bridges due to the corrosion of steel: (a) Genoa; (b) Taiwan; (c) Pennsylvania.

A study that began at Oregon State University calculated that “the overall cost for the titanium strengthening for the Mosier concrete bridge was less than 3% of the estimated cost for bridge replacement and 30% lower than rehabilitation completed using alternative materials” [

6]. By taking advantage of the unique properties of titanium, such as its high strength and corrosion resistance, it can become the most cost-effective solution when used in the right application.

The situation of old masonry structures or infrastructures is more complicated, not only because of the pre-industrial methods used for their construction but also for their long design life, often longer than 100 years. In Europe, a very large number of masonry buildings and infrastructures were constructed several centuries ago. Governments’ policy is to preserve them, not only for their cultural and social value, but also because their reuse has significant positive aspects in terms of reductions in CO2 emissions and sustainability compared to new constructions. In this context, the durability of the reinforcement materials is even more important than other characteristics.

Old masonry buildings, often made of solid bricks or rubble stone masonry, have been typically designed in the past with little or no regard for the effects of seismic loadings. Recent destructive earthquakes in Italy, Greece, Japan, and other areas of the world have clearly demonstrated that these masonry structures are particularly susceptible to the inertial forces activated during earthquakes. The poor performance of old masonry buildings both against the in-plane and out-of-plane horizontal actions, led standardization committees to significantly increase the code requirements for lateral support of existing masonry buildings [

8]. With each new earthquake, especially when they produced a significant loss to cultural heritage, reinforcement strategies have been updated and new solutions proposed. However, existing masonry buildings remain at risk because these heritage structures cannot be sufficiently improved to meet the current standards for new masonry constructions [

8,

9,

10].

Masonry constructions have demonstrated a reliable structural performance, but this is basically limited to gravitational static loads [

11]. The main problem of the masonry material is its low, almost negligible, tensile strength. Because masonry is bonded into an integral mass by mortar and blocks, it is sometimes considered to be a homogeneous material. However, masonry is clearly a combination of different materials, and this determines the performance of the masonry as a structural element. The mechanical properties of the constituent materials and the interaction of the materials as an assemblage have a significant effect on its behavior. While stones, especially when they are hard, and bricks typically exhibit satisfactory/good mechanical properties, both in compression and in tension, the mortar in old constructions is always made with limes, and its compressive strength typically ranges between 1 and 5 MPa, but its tensile and bond strengths are rarely greater than 0.1–0.15 MPa [

12]. Furthermore, mortar-to-block bonding is often very weak, especially when the assemblage is subject to shear or tensile stresses; its strength is even smaller than the mortar tensile strength. In historic buildings, it is common to find tensile cracks as a result of low-intensity seismic events and land subsidence and settlings due to the seasonal changes in moisture contents and temperature profiles within the foundations. While it is well accepted that these cracking phenomena are not very serious, the problem becomes much more serious if the buildings are located in areas exposed to seismic or flooding hazards [

13].

In the late 1990s, the use of composite materials (i.e., FRP, fiber-reinforced polymers) was proposed as a viable retrofitting method for heritage masonry structures. A large amount of research has been conducted to assess the structural response of masonry structures reinforced with epoxy-bonded FRPs. While it has been demonstrated that composite materials are able to increase the seismic capacity of masonry members, recent research has also highlighted the poor durability of these retrofits. Phenomena of mechanical degradation, debonding from masonry, and cracking deterioration were observed on FRP-reinforced masonry after only few years after application [

14,

15].

Another significant shortcoming of FRPs is their low shear and tensile strengths (along the directions perpendicular to the composite fibers). In general, FRPs exhibit a very high tensile strength along the direction of the fibers, but it is not easy in conservation engineering to apply the fibers in such a way that loads on the reinforced masonry structure will only activate the tensile strength of the composite reinforcement. Low-magnitude shear loads may produce premature cracking in the composite, especially when used under the form of FRP strips and sheets.

The use of an isotropic material, such as steel or titanium, can solve this problem. The shear strength of these metals is surely higher than any other composite material, and this can simplify the design load, also covering uncertainties in terms of the directions of the load and second-order effects.

However, this passivation film (

Figure 1) may highly reduce bonding of titanium elements with other materials. The problem needs to be better addressed; an earlier study by Osofero et al. [

16] demonstrated that titanium alloy tubes exhibit significantly lower bonding strength to mortar compared to carbon steel.

2.1. Reversibility and Multidisciplinarity in Conservation

While it is evident that reinforcement of masonry heritage structures and their protection from the effects of natural and manmade hazards (earthquakes, flooding, impacts, fire, etc.) are the mission of a structural engineer, the conservation of these structures involves many other competences. This is a peculiar situation, very different from other engineering areas where structural and cost considerations prevail in the design process. The points of view of conservators, architects, historians, and policymakers may govern the decision-making process. The concept of “heritage value” and the risk of heritage loss and its impact on societies are to be considered when intervening on a monument, and a multidisciplinary approach is necessary. This clearly may have an effect on the type of intervention and the choice of retrofit materials, sometimes overshadowing its economic cost.

It should be mentioned here the International Council on Monuments and Sites (ICOMOS) guidelines [

17] for interventions on architectural heritage structures, requiring that, “Where possible, any measures adopted should be “reversible” so that they can be removed and replaced with more suitable measures when new knowledge is acquired. Where they are not completely reversible, interventions should not limit further interventions”. This can have a significant effect on the design of interventions: epoxy-bonded reinforcements should be avoided, since these are difficult to be removed (nonreversible). Conservation bodies do not often authorize the use of materials, such as unprotected carbon steel and FRPs, for the monuments in their portfolio. Reinforced-concrete retrofits are also not recommended and often prohibited because of the low compatibility of cement-based products [

18].

Figure 4 shows examples of two nonreversible retrofit interventions: epoxy-bonded FRP and Reinforced Concrete jacketing. The use of epoxy-bonded composites to reinforce shear walls is nonreversible, because the epoxy penetrates into the masonry, and the phenomenon of “masonry peeling” occurs when someone tries to remove it. Reinforced concrete jacketing involves the use of noncompatible materials (cement), which is also difficult to be removed without damaging the masonry material.

Figure 4. Example of nonreversible retrofit interventions: (a) epoxy-bonded FRP reinforcement is very difficult to be removed, and this causes damage to the masonry material; (b) reinforced concrete jacketing can only be removed with a demolition hammer.

Although only a very small portion of heritage masonry buildings and infrastructures are listed by ICOMOS (UNESCO list), the approach used by national and local conservation bodies is similar: reversibility and compatibility are key aspects in conservation engineering. These bodies oversee tens of thousands of buildings. The number of listed buildings has increased dramatically over the last decades in Europe as a consequence of the larger interest in architectural heritage, local history, social traditions, and the development of cultural tourism. In some countries, such as Italy, public buildings are automatically listed after 70 years from their construction.

2.2. Titanium Corrosion Resistance

In conservation engineering, the most interesting use of titanium is under the form of bars to be inserted in critical weak regions of a masonry building to improve the building’s structural response. These bars are typically coupled with lime mortars, and the strengthening effects fully depend on the bonding behavior of the titanium to mortar. Despite its importance in the performance of the retrofit intervention, the bond between titanium and mortars has not been fully investigated. An interesting solution could be the use of ribs, similarly to rebar in concrete, or other forms of superficial treatments (threading, knurling, chemical treatment, etc.). The mortar between consecutive ribs can facilitate a mechanical interlock between both materials that end up anchoring the titanium rods, restraining the relative displacement. However, ribbed and threaded titanium rods are difficult to find on the market, and more research is needed to investigate the weakening effect of the oxide film on the mortar-to-titanium bond [

19].

The “history” of new materials in conservation engineering had a decisive push after the 1997 Central Italy earthquake: the collapse of the masonry vaults with the famous Giotto’s and Cimabue’s frescos at Assisi’s Basilica in Italy clearly demonstrated the limitations of traditional reinforcement and repair methods used so far in historic constructions [

20]. The timber roof of the Assisi’s Basilica had been previously replaced with a reinforced concrete structure; the increase in weight and the low deformation capacity of the new concrete roof had major roles in the collapse of the basilica.

The scientific community began to look at alternative “light” retrofitting solutions and composite materials, mainly made of carbon and glass fibers, sparking the interest of structural engineers, as a very high tensile strength and low weight are the main characteristics of FRP. However, it took several years to understand the important shortcomings of FRPs: low reversibility, chemical hazards for workers, low durability, low resistance to high temperatures, and low strength perpendicular to the direction of the fibers.

In this situation, practitioners and researchers reverted to more traditional metal reinforcements, also considering their positive ductile behavior, ease of application, reversibility, and limited cost. In order to improve the effectiveness of the metal reinforcements, new materials and methods have been experimented. An example is the use of ultrahigh strength steel fibers [

21,

22] and stainless-steel profiles [

23,

24]. Composite materials continued to be used for historic masonry reinforcement, but their application was made not with epoxy adhesives but with metal fasteners or inorganic (lime- or cement-based) mortars [

25,

26,

27].

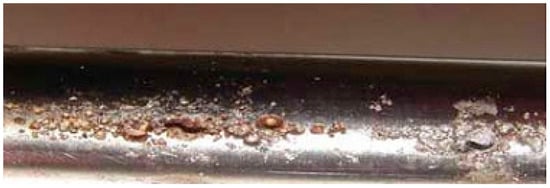

However, the corrosion problems of steel reinforcements are difficult to solve. Corrosion not only reduces the resisting steel sections (and this could compromise the reinforcement action), but rusting can seriously damage historic masonry members and cultural heritage assets. For these reasons, conservation bodies also limit the use of steel reinforcement on listed buildings. Creep is another critical aspect to consider when steel reinforcements are applied.

Corrosion-resistant materials have been investigated, and aluminum reinforcements could represent an interesting alternative, but the low modulus and low tensile strength of aluminum alloys can be problematic in many applications.

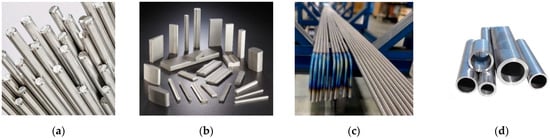

The use of stainless steels and titanium alloys was soon considered as viable. Both materials are not new: stainless steel has been employed in the military industry since late 19th century, and titanium alloys have been used in aerospace construction since the 1960s.

The main alternatives to the use of titanium are stainless steels and composite materials. New types of stainless steels with high pitting resistance equivalent (PRE) numbers entered the market in the 2010s. The PRE number depends on the steel’s chemical composition (PRE = Cr(%) + 3.3(Mo)) and provides an important indication of its corrosion resistance.

A large number of interventions and technical solutions have recently been proposed using stainless steels: confinement by wrapping of masonry columns, shear reinforcement of wall panels, out-plane-plane reinforcement of wall facades, etc. However, there is general misinformation regarding the corrosion resistance of stainless steel: a very large number of austenitic stainless steels (basic grades 304 and 316) exhibit relatively low corrosion strengths. Figure 5 shows the common pitting phenomenon of an austenitic steel. New stainless steels, namely Duplex steels, exhibit high PRE numbers. The cost of Duplex steel is, however, much higher compared to standard stainless steels and subject to market variations, especially its components (nickel, chromium, and molybdenum). The cost of high-PRE number nickel alloy 625 (PRE = 52) in November 2021 13 EUR/kg, while Ti-6Al-4V alloy costed approximately 31 EUR/kg. However, the yielding strength of stainless steels is 30–40% lower compared to a titanium alloy, and a much smaller quantity of titanium material is needed in retrofit applications, partially reducing the gap between the cost of the two types of materials.

Figure 5. Pitting corrosion on stainless steel [

28].

The PRE number of Duplex steels ranges between 24 and 55. However, several studies have highlighted that stainless steels can be subjected to corrosion phenomena, depending on the environmental conditions and their duration. Recent comparative research of the phenomenon of the corrosion of orthodontic appliances have demonstrated that titanium alloys exhibit a corrosion current density up to 50% smaller compared to stainless steels [

29,

30].