Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Green & Sustainable Science & Technology

Hydrotalcites are known in the bibliography as LDHs (Layered double hydroxides). Hydrotalcites, as such, are not good CO2 absorbents due to poor basic properties and presence of entities that hinder CO2 adsorption and are therefore subjected to thermal treatment (around 500 °C) to obtain nearly amorphous metastable mixed solid solutions known as calcined layered double hydroxides (CLDHs). There are several parameters that can make hydrotalcites suitable for use as CO2 sinks.

- CO2 sinks

- calcined hydrotalcite

- one-coat mortar

- CO2 curing

2. Calcined Hydrotalcite to Capture CO2

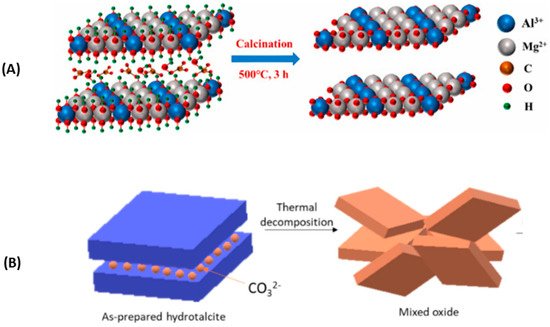

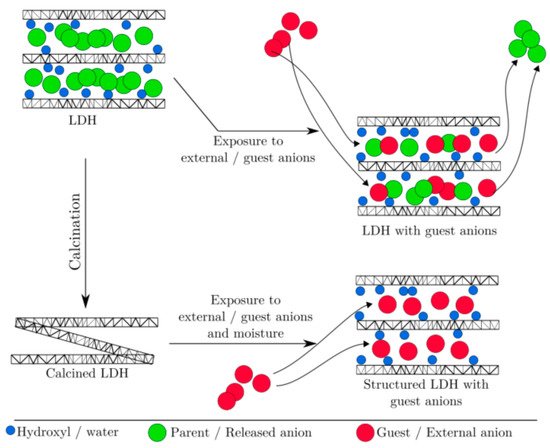

Calcined hydrotalcite or its use under high temperatures (around 400 °C so that the hydrotalcite becomes oxide and can be rebuilt in contact with CO2). LDH are poor CO2 adsorbents in their natural or unburned form, which is due to a poor basic property and the presence of entities that hinder CO2 adsorption. Hence, they are subjected to thermal treatment to obtain nearly amorphous metastable mixed solid solutions (CLDHs) [19]. Figure 1 shows two diagrams representing what happens during the calcination of hydrotalcite of Mg3AlCO3 as shown (A) by W.J. Long et al. [77] and (B) by Lauermannová et al. [73]. Both schemes attempt to represent the collapse of the structure due to the loss of interlayer anions and moisture.

2.1. Thermal Behaviour of Hydrotalcite by TGA/DTA

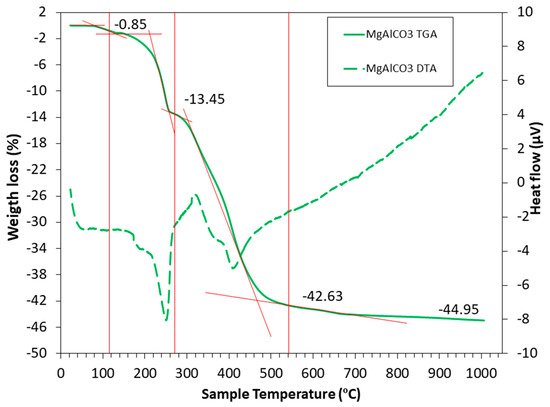

LDH undergoes several stages until it reaches CLDHs. There is even research that attempts to explain this process in great detail and focuses on it alone [80,81]. It is very important to choose a suitable calcination temperature, avoiding it being too high (to avoid higher energy consumption), or being too low (not producing the collapse of the structure and hindering a higher CO2 capture). To distinguish the different stages, it is useful to rely on thermogravimetric analysis (TGA) and differential thermal analysis (DTA) carried out by Suescum-Morales et al. [33], shown in Figure 2. It should be noted that different variations in temperature ranges may be encountered, approximately as shown below.

Figure 2. TGA (solid lines) and DTA (dotted lines) for commercial hydrotalcite of MgAlCO3 [33].

First of all, a loss of humidity is observed, up to a temperature of about 105 °C. The second stage occurs from 105 to 270 °C, where the water hydration of the hydrotalcite structure is lost (leading to a decrease in basal spacing) [82,83,84]. There are authors who indicate that between 200 and 300 °C, the OH− groups attached to Al3+ are lost [19]. The third stage, from 270 to 540 °C, is where the dehydroxilation of the hydrotalcite takes place and the loss of the carbonate anion of the interlayer in the form of CO2 occurs. The layer structure collapses (Figure 1), and the LDH converts to a mixed-oxide MgO-like phase [85]. In the last stage, from 540 to 1000 °C, very small weight losses are observed, attributed to the loss of residual OH− groups.

From the above, it can be seen that the calcination temperature affects the capacity to capture CO2 in CLDHs. Different structural characteristics are presented in the different stages of thermal decomposition. From this analysis, the ideal calcination temperature of the hydrotalcite under study can be determined, which is characteristic and unique depending on the type of hydrotalcite. Most research indicates that the calcination temperature of a Mg-Al LDH is around 400 °C [86,87,88]. However, the performance of a TGA/DTA for each specific case would allow observing the exact calcination temperature.

2.2. Thermal Behaviour of Hydrotalcite by XRD

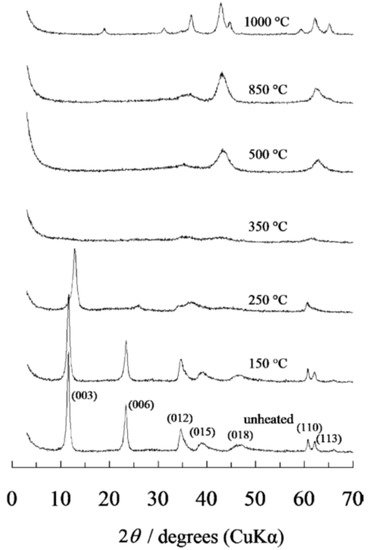

The appropriate calcination temperature can also be determined by XRD temperature variation analysis. The thermal decomposition sequence of Mg-Al-CO3 hydrotalcite is well documented. Miyata, 1980 and Hibino et al., 1995 [82,89] studied the XRD variation at different temperatures, shown in Figure 3 (non-calcined, 150, 250, 350, 500, 850 and 1000 °C). The diffraction patterns of MgO can be identified between 400 °C and 850 °C, given the amorphous nature of Al2O3 at this temperature. For 900 °C the spinal phase (MgAl2O3) was formed. Given these experiences, the following chemical equations can be posed, with the different temperature ranges, to help us understand the process (Equations (3)–(5)):

Mg6Al2(OH)16CO3⋅4H2O →Mg6Al2(OH)16CO3+4H2O 100<T<250 ℃ (3)

Mg6Al2(OH)16CO3→6Mg(Al)O +8H2O +CO2400<T<850 ℃ (4)

6MgO +Al2O3→MgAl2O4+5MgO 900<T<1000 ℃ (5)

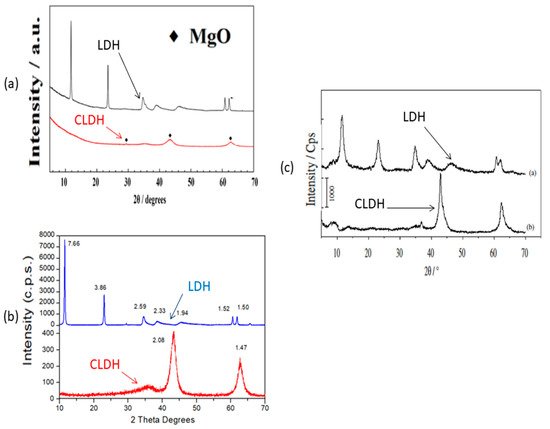

Figure 4 shows the similar XRD obtained by several authors by calcination at 500 °C for different periods: firstly, the XRD obtained by W.J. Long et al. [77] (Figure 4a) shows how at a temperature of 500 °C for 3 h the layered structure collapses and also shows the production of mixed oxides. Figure 4b shows a similar result, but in this case using a calcination time of 2 h, and the same temperature (500 °C) [33]. This leads to a large saving of energy in the calcination of LDH, with a consequent lowering of the carbon footprint. Already, Z. Yang et al. [67] calcined at 500 °C for 3 h, obtaining a similar result. Even Q.Tao et al. [90] heated at 500 °C for 4 h, obtaining similar results (Figure 4c). Similar results in XRD were obtained by S.I. Garcés Polo et al. [91] for CLDH. None of the previous authors [33,67,77,91] indicated the amount of sample used in the calcination, which may have led to these observed differences. Although different calcination temperatures have been used with similar results, there are no economic studies of the cost of calcination; studies of this type, with times, temperatures and quantities of LDH to be calcined, would be very useful for these materials in industrial applications. It would also be very important to carry out a real carbon footprint calculation (UNE EN 15804:2012), which determines the real CO2 sink capacity in each specific case (amount of hydrotalcite, type of furnace, etc.). Only two studies have been found that indicate the amount of hydrotalcite calcined (100 and 1 g respectively) [92,93]. Annotations of this type, i.e., what quantity is fed into the LDH kiln, are very important in order to maximise the efficiency of the calcination process.

Figure 3. XRD of MgAlCO3 formed between room temperature and 1000 °C [94].

2.3. Thermal Behaviour of Hydrotalcite by SEM/TEM

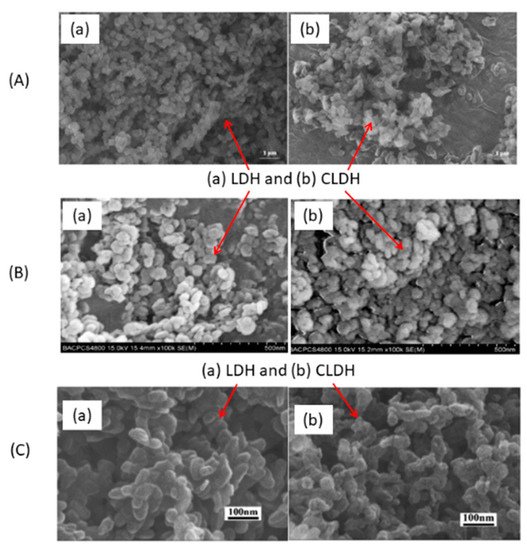

Figure 5a shows SEM images of commercial LDH and CLDH Mg-Al from W.J. Long et al. [77]. After 3 h at 500 °C, the structure collapses. A decrease in size was also observed. P. Cai et al. [95] obtained similar results (Figure 5b) with the same temperature and time of calcination. After 4 h at 450 °C on Mg-Al LDH, C. Geng et al. [96] observed a decrease in particle size, and the hexagonal shape was hardly noticeable (Figure 5c). No other studies using different temperatures (different at 500 °C) and calcination times have been found that show SEM images of LDH and CLDH. Studies along these lines could fill this information gap.

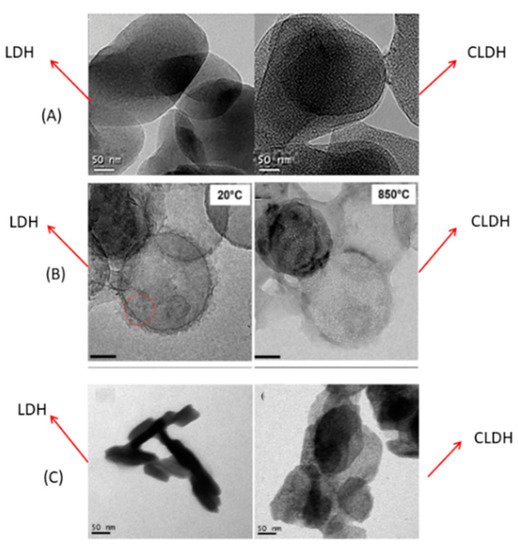

Figure 6A shows the TEM images of LDH and CLDH, after 2 h at 500 °C, obtained by Suescum-Morales et al. [33]. In CLDH, small pores were formed, attributable to the dehydration process, dehydroxilation of the OH− groups, and to the decomposition of the interlayer carbonate. C Hobbs et al. [97] studied the evolution of a Mg-Al LDH under different temperatures using a rate of 10 °C/min (Figure 6B). At a temperature of 20 °C (LDH), they have a well-defined platelet shape; the porous structure is clearly visible at 850 °C. S Luo et al. [98] also obtained the same porous structure in CLDH, as shown in Figure 6C.

Different heating rates have been used in LDH calcination; a heating rate of 10 °C/min was used in Mg/Al LDH by several authors [99,100,101,102] and a heating rate of 5 °C /min was used by [103]. It is known that if the heating rate is slower, the thermal effects are better observed (better porous structure). However, if the ramp is slower, it takes more time and wastes more energy; if the heating is too fast, the porous structure will be worse. These differences should be extensively studied, both from an energy point of view (higher consumption and, therefore, higher carbon footprint produced by the kiln when the larger ramp is used), and from the point of view of the efficiency of the CLDH itself. Another very important aspect is the kinetics of LDH, which has been extensively discussed in other research [104,105].

7. Combined Use of Hydrotalcites and Cement-Based Materials

The good and promising results obtained by the scientific community as adsorbents of hydrotalcites suggest the idea of incorporating them into construction materials, such as cement-based materials [66,67,68,69,70]. The ion exchange is the key feature that makes the use of LDH/CLDH in building materials attractive. These, together with the memory effect of CLDH, are the two suitable factors for the ion exchange and capture mechanism shown in Figure 10 [75].

Figure 10. Schematic representation of the LDH/CLDH structure and ion exchange/captured mechanism represented by Zahid M. Mir [75] (open access).

In recent years, LDH/CLDH have emerged as a new class of engineering materials [75], which can aid in the corrosion control of concrete structures and potentially prolong their service life. Calcined hydrotalcite improves the durability of cement-base materials. One of the first findings mixing hydrotalcites with concrete dates back to 2004 [126]. In 2013, there were two very important contributions in this field [69,126].

This includes the use of LDH as an additive to improve the thermal insulation of the intumescent fire retardant (IFR) coating [71]. Wu et al. [72] indicated that the structure regeneration of CLDHs in a cement paste environment was also revealed [69]. After calcination, a large number of active sites produced were improving the effect of CLDH on cement [72]. Since hydrotalcites may be incorporated into various building materials mixtures, mortars, concretes and backfills, their applications as accessible and affordable materials is prospective [73,74,75]. However, research in the field of hydrotalcites and cement-based materials is still insufficient [72,76].

It is also difficult to find studies that add LDH or CLDH to alkaline activated materials [77,78]. Mixing LDH/CLDH in alkali-activated materials to improve the durability of these materials may be a very interesting field for the scientific community.

It is even more difficult to find studies in which CLDHs are used as additives in order to increase the CO2 capture capacity of cement-based materials. Ma et al. [79] reported the adsorption of CO32− by CLDH seven times faster than LDH due to the release of anions after calcination, which can be very beneficial for CO2 capture. Suescum-Morales et al. [3,59] added different percentages of CLDH (Mg3AlCO3) in a one-coat mortar in order to increase the CO2 capture capacity. Adding 5% of calcined hydrotalcite increased the CO2 capture capacity by 8.52% with respect to the reference mortar. One m2 of one-coat mortar with 5% of calcined hydrotalcites cleans 5540 m3 of air [3]. The use of these one-coat mortars in building facades is a very promising strategy due to the large surface area exposed to the atmosphere. Studies along these lines should be reinforced to improve this information gap.

This entry is adapted from the peer-reviewed paper 10.3390/chemengineering6040050

This entry is offline, you can click here to edit this entry!