Land development typically requires stormwater control measures (SCMs) to limit runoff volume, reduce peak flow, delay discharge to streams, and reduce pollutant loads to receiving waters, with the ideal goal of mimicking the natural hydrologic system. Life cycle assessment is used to systematically evaluate the environmental impact of underground plastic recharge chambers (RCs) used for stormwater management. Using cradle-to-gate life cycle assessment and a functional unit of 1 m3 stormwater capacity, different RC structure types, manufacturing processes and materials are considered. The inventory is based on various commercially available RCs, including injection-molded or extruded polypropylene and polyvinylchloride polymers and typical installation materials and methods. A new dataset is developed to estimate the manufacture and use of recycled polypropylene granulate. TRACI 2.1 is used to investigate the midpoint life cycle impact assessment metrics, acidification, eutrophication, global warming, and fossil fuel resources.

- life cycle assessment

- green infrastructure

- stormwater management

1. Introduction

2. Infiltration Studies Involving RCs

3. Water Quality Studies Involving RCs

4. Testing of Mechanical Properties of RCs under Loads

5. LCA Studies of SCMs Other Than RCs

6. RCs as an SCM

7. Summary of Results

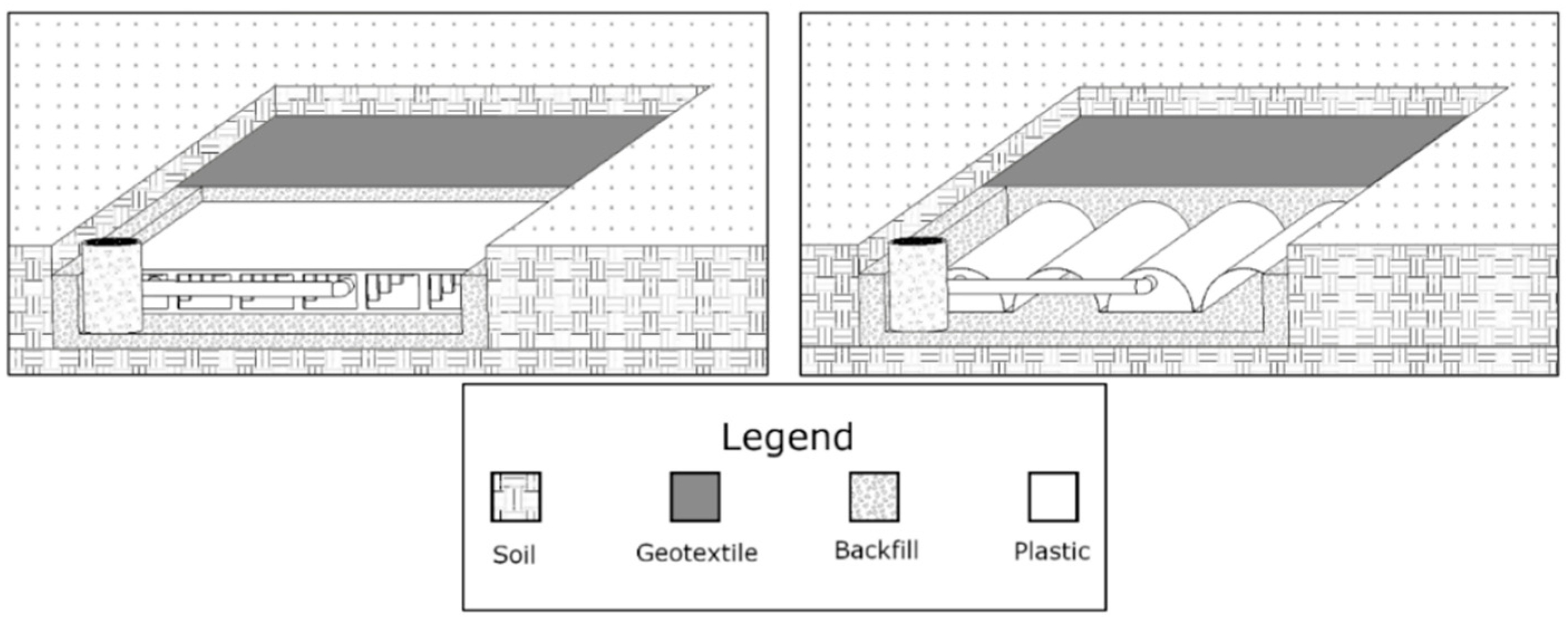

Limited available land can constrain stormwater management options in development projects. Buried solutions such as RCs can overcome those challenges while also promoting streetscapes, parks, and green spaces. The life cycle environmental impact categories evaluated for plastic RCs reveal that the box structures have higher values than the arch structures for managing stormwater, predominantly because of the higher mass of plastic used in box structures compared to arch structures. The arch structures are favored from the perspective of minimizing midpoint impact; however, the option to use the extruded process for the box structure results in lower midpoint impacts. If the design allows the use of sand, the midpoint impacts could be reduced to less than 50% of impacts for gravel assuming equivalent transport distance. However, in the case where sand needs to be transported longer distances than gravel, careful analysis of tradeoffs between backfill material impacts and transport distance impacts must be considered.

Recycling injection molding process scrap, which is common practice among RC fabricators, reduces fossil resource consumption and global warming impact compared with using primary polymeric material alone. The reduced burden comes without collection and sorting processes that are needed when using post-consumer plastic resin.

In summary, the results obtained show the dominance of the plastic and backfill transport distance in relevant potential midpoint impacts for both plastic RC design types of box and arch structures. There is wide variation in these results, which is driven by the choice of plastic and choice of manufacturing process used for the product. In general, sand as backfill material around the box structure RC installation provides a smaller global warming impact compared to gravel, although the impact of large transport distances could favor local sources of gravel over remote sources of sand.

This entry is adapted from the peer-reviewed paper 10.3390/buildings12060867

References

- US EPA. Low Impact Development (LID) Literature Review Document #EPA-841-B-00-005; United States Environmental Protection Agency, Office of Water: Washington, DC, USA, 2000.

- Hale, R. Spatial and temporal variation in local stormwater infrastructure use and stormwater management paradigms over the 20th century. Water 2016, 8, 310.

- McPhillips, L.E.; Matsler, A.M. Temporal evolution of green stormwater infrastructure strategies in three US cities. Front. Built Environ. 2018, 4.

- Hopkins, K.G.; Bhaskar, A.S.; Woznicki, S.A.; Fanelli, R.M. Changes in event-based streamflow magnitude and timing after suburban development with infiltration-based stormwater management. Hydrol. Processes 2019, 34, 387–403.

- Market Study Report. Global Stormwater Detention System Market Size, Status and Forecast 2021–2027Document #MSR3951641. 2021, p. 117. Available online: https://www.marketstudyreport.com/reports/global-stormwater-detention-system-market-size-status-and-forecast-2021-2027 (accessed on 28 March 2022).

- Bailey, J. Personal communication on recharge chambers including applications and installations. 2017.

- Bhaskar, A.S.; Hogan, D.M.; Archfield, S.A. Urban base flow with low impact development. Hydrol. Processes 2016, 30, 3156–3171.

- Bhaskar, A.S.; Hogan, D.M.; Nimmo, J.R.; Perkins, K.S. Groundwater recharge amidst focused stormwater infiltration. Hydrol. Processes 2018, 32, 2058–2068.

- Rhea, L.; Jarnagin, T.; Hogan, D.; Loperfido, J.V.; Shuster, W. Effects of urbanization and stormwater control measures on streamflows in the vicinity of Clarksburg, Maryland, USA. Hydrol. Processes 2015, 29, 4413–4426.

- Burszta-Adamiak, E.; Lomotowski, J. Modelling of percolation rate of stormwater from underground infiltration systems. Water Sci. Technol. 2013, 68, 2144–2150.

- Sparkman, S.A.; Hogan, D.M.; Hopkins, K.G.; Loperfido, J.V. Modeling watershed-scale impacts of stormwater management with traditional versus low impact development design. J. Am. Water Resour. Assoc. 2017, 53, 1081–1094.

- Drake, J.; Young, D.; McIntosh, N. Performance of an underground stormwater detention chamber and comparison with stormwater management ponds. Water 2016, 8, 211.

- Masada, T. Deflection formulas for buried chamber structures. J. Pipel. Syst. Eng. Pract. 2017, 8, 4017005.

- Masada, T. Full-scale field load testing of storm-water storage chamber structures. J. Perform. Constr. Facil. 2011, 25, 317–325.

- Masada, T.; Zhu, J.Q. Computer analysis of buried stormwater chamber structures. J. Pipel. Syst. Eng. Pract. 2015, 6, 4014013.

- Brachman, R.W.I.; LeBlanc, J.M. Short-term lateral response of a buried modular polymer stormwater collection structure to compaction and overburden pressure. J. Geotech. Geoenviron. Eng. 2017, 143, 4017070.

- Moore, I.D.; Brachman, R.W.I.; Elshimi, T.; Rahman, K. Analysis and testing to characterize the strength of buried infrastructure. In Proceedings of the 13th International Conference of the International Association for Computer Methods and Advances in Geomechanics, Melbourne, Australia, 9–13 May 2011; p. 6.

- McGrath, T.J.; Mailhot, D. Designing stormwater chambers to meet AASHTO specifications. J. ASTM Int. 2010, 7, 1–8.

- Aung, T.H.; Khabbaz, H.; Fatahi, B. Parametric study of applied stresses on infiltration modular cells installed under roads. Procedia Eng. 2016, 143, 1325–1332.

- AASHTO Standard Specifications. Available online: https://www.transportation.org/ (accessed on 11 December 2021).

- Montalto, F.; Behr, C.; Alfredo, K.; Wolf, M.; Arye, M.; Walsh, M. Rapid assessment of the cost-effectiveness of low impact development for CSO control. Landsc. Urban Plan. 2007, 82, 117–131.

- Petit-Boix, A.; Sevigne-Itoiz, E.; Rojas-Gutierrez, L.A.; Barbassa, A.P.; Josa, A.; Rieradevall, J.; Gabarrell, X. Environmental and economic assessment of a pilot stormwater infiltration system for flood prevention in Brazil. Ecol. Eng. 2015, 84, 194–201.

- Vineyard, D.; Ingwersen, W.W.; Hawkins, T.R.; Xue, X.B.; Demeke, B.; Shuster, W. Comparing green and grey infrastructure using life cycle cost and environmental impact: A rain garden case study in Cincinnati, OH. J. Am. Water Resour. Assoc. 2015, 51, 1342–1360.

- Fathollahi, A.; Coupe, S.J. Life cycle assessment (LCA) and life cycle costing (LCC) of road drainage systems for sustainability evaluation: Quantifying the contribution of different life cycle phases. Sci. Total Environ. 2021, 776, 145937.

- Hengen, T.J.; Sieverding, H.L.; Stone, J.J. Lifecycle assessment analysis of engineered stormwater control methods common to urban watersheds. J. Water Resour. Plan. Manag.-ASCE 2016, 142, 04016016.

- Andrew, R.M.; Vesely, E.T. Life-cycle energy and CO2 analysis of stormwater treatment devices. Water Sci. Technol. 2008, 58, 985–993.

- Peterson, L.A.; Awerbuch, P.M.; Spatari, S. Environmental and economic implications of stormwater management alternatives in rural development. J. Ind. Ecol. 2021, 24, 1076–1088.

- O’Sullivan, A.D.; Wicke, D.; Hengen, T.J.; Sieverding, H.L.; Stone, J.J. Life Cycle Assessment modelling of stormwater treatment systems. J. Environ. Manag. 2015, 149, 236–244.

- Byrne, D.M.; Grabowski, M.K.; Benitez, A.C.B.; Schmidt, A.R.; Guest, J.S. Evaluation of life cycle assessment (LCA) for roadway drainage systems. Environ. Sci. Technol. 2017, 51, 9261–9270.

- Flynn, K.M.; Traver, R.G. Green infrastructure life cycle assessment: A bio-infiltration case study. Ecol. Eng. 2013, 55, 9–22.

- De Sousa, M.R.C.; Montalto, F.A.; Spatari, S. Using life cycle assessment to evaluate green and grey combined sewer overflow control strategies. J. Ind. Ecol. 2012, 16, 901–913.

- Moore, T.L.C.; Hunt, W.F. Predicting the carbon footprint of urban stormwater infrastructure. Ecol. Eng. 2013, 58, 44–51.

- Rivela, B.; Cuerda, I.; Olivieri, F.; Bedoya, C.; Neila, J. Life Cycle Assessment for ecodesign of ecological roof made with Intemper TF ecological water-tank system. Mater. Constr. 2013, 63, 131–145.

- Spatari, S.; Hubler, J.F.; Hsuan, Y.G.; Marcellus, K. Beneficial use of plastic pipe in sustainable stormwater infrastructure. In Proceedings of the 1st International Specialty Conference on Sustaining Public Infrastructure, Edmonton, AB, Canada, 6–9 June 2012.

- Spatari, S.; Yu, Z.W.; Montalto, F.A. Life cycle implications of urban green infrastructure. Environ. Pollut. 2011, 159, 2174–2179.