Similar to other types of waste, sewage sludge (SS) must be minimized, not only to respect the European Directive 2018/851 on waste, but also because the cost of sludge management is approximately 50% of the total running costs of a wastewater treatment plant (WWTP). Usually, minimization technologies can involve sewage sludge production with three different strategies: (i) adopting a process in the water line that reduces the production of sludge; (ii) reducing the water content (dewatering processes) or (iii) reducing the fraction of volatile solids (stabilization).

- sewage sludge

- wastewater

- dewatering

- minimization

- sludge line

- stabilization

- wastewater treatment plant

- biosolids

- water treatment

1. Introduction

Sewage sludge (SS) is a mixture of organic and inorganic matter and its composition strongly depends on the treatment and on the wastewater origin [1]. It can be composed of primary sludge, derived from primary sedimentation and formed by suspended sedimentary materials, secondary sludge, made up of excess biomass and, tertiary sludge, obtained in the advanced wastewater treatment stages, when nutrient (nitrogen and phosphorus) removal is required [2].

In recent years, the population growth and consequent urbanization have increased the number of wastewater treatment plants (WWTPs) and the production of SS [3,4]. Moreover, the application of more stringent requirements for WWTPs effluents quality increases the production, and worsens the quality, of the SS. For instance, in the EU, the implementation of the European Commission Directive 98/15/EC (amending Council Directive 91/271/EEC) led to a strong rise in sludge generation, up to 50% [5], with an estimate of more than 13 million Mg of dry matter in 2020. According to these data, developing urgent and effective approaches to reduce and recover SS becomes a priority [6,7].

Particularly, in order to respect the European Directive 2018/851 on waste, the first aspect to take into consideration is the minimization of the waste produced [8] and therefore, sludge [9]. Furthermore, the economic aspect has become important in recent years. Researchers show that the cost of sludge management is approximately 50% of the total running costs of the WWTP with the conventional activate sludge (CAS) process [10,11]. Moreover, also in the case of the WWTPs, as already suggested in recent years for drinking water treatment plants [12,13], some procedures for evaluating the performance of the plants and for defining optimal solutions for management in order to optimize operation and minimize the production of SS should be studied.

In 2015, 9.7 million MgDM (DM - dry matter) of SS were produced in Europe. More than 60% of the total SS was produced in Germany (around 19%) and the western countries (UK, Italy, Spain and France). By contrast, eastern countries (such as Poland, Romania, Estonia, Latvia and Lithuania) represent around 12% of SS produced in Europe [14].

In the last years, in the EU, SS recovery in agricultural use and composting quickly increased from 3 million MgDM in 1995 (42% of total production) to 4.2 million MgDM in 2005 (54% of total production); then, this value increased further (5.2 million MgDM in 2010 to 59% of total production) [14]. The EU issued the Directive 86/278/CEE (recently amended by the EU Decision 2018/853) with the aim of avoiding the application on land of SS that was dangerous for human health. Therefore, every member state has issued a national regulation on this topic [15]. For instance, currently, a high concentration of metals in sludge makes recovery in agriculture impossible [16].

Considering: (i) the framework of the ever-stricter European regulations regarding the recovery of SS in agriculture, (ii) the EU Directive 2018/851 [8] in which minimization is listed as a priority, (iii) the high costs related to SS disposal, it is clear that techniques for minimizing sludge production have become strictly necessary.

2. Advanced Treatments and Technologies

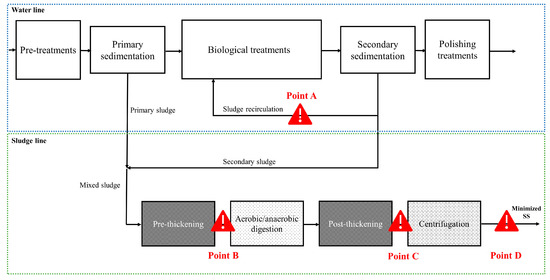

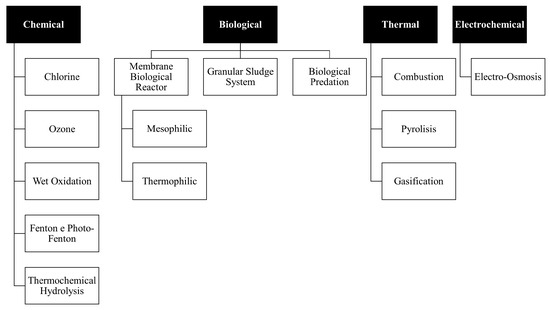

Usually, minimization technologies can involve SS production in three different ways: (i) adopting a process in the water line that reduces the production of sludge; (ii) reducing the water content (dewatering processes) or (iii) reducing the fraction of volatile solids (stabilization). Both interventions in the sludge line and those in the wastewater line are shown (Figure 2), with their respective advantages and downsides. Technical and economic aspects must be evaluated in order to choose the most appropriate technology. The advantages and the disadvantages must be considered; not only those direct (i.e., concerning sewage sludge production) but also those indirect (i.e., concerning other aspects of WWTPs). In Figure 3, the suitable advanced treatments available for the minimization of SS production are shown.

Figure 2. Points of possible application of advanced treatments in a conventional WWTP, in order to minimize the production of SS, in the water line (Point A) and in the sludge line: before hypothetical stabilization (Point B), before hypothetical centrifugation (Point C) and at the end of the line (Point D) (Figure taken from 10.3390/app9132650).

Figure 3. Suitable advanced treatments available for the minimization of SS production are shown (Figure taken from 10.3390/app9132650).

The article is from 10.3390/app9132650

This entry is adapted from the peer-reviewed paper 10.3390/app9132650