Many authors have recognized that a variety of barriers can hinder the implementation of industrial symbiosis (IS) and eco-industrial development. It is imperative to prioritize the barriers which will provide guidance for the realization of IS projects and assist practitioners and stakeholders with more effective implementation. This, in turn, will contribute to development of circular economies. Through an extensive literature review, this paper proposes a model which combines the Analytic Hierarchy Process (AHP) and the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) to evaluate the IS barriers semi-quantitatively. This model assists in identifying and prioritizing the fundamental barriers for implementation of IS in a comprehensive manner. An operating IS, the Hai Hua Group (HHG), in Shandong Province, China is used as a case study to test the proposed model. The results show that the top four generic barriers are technological, economic, safety, and informational barriers. More specifically, the barriers are information platforms, human safety and health, technology involved with extending industrial chains, product added value, and costs. The paper concludes by discussing managerial implications for promoting the establishment and operation of IS.

- industrial symbiosis

- industrial ecology

- barriers

- circular economy

- model

1. Introduction

Industrial symbiosis (IS) has been well-recognized as a key subfield of industrial ecology (IE) [1,2]. IS research is flourishing and has covered a broad range of topics and cases [3]. IS helps to increase the industrial system’s circularity [4] and is considered to be a circular economic business model [5]. It can often create economic, environmental, and social benefits [4,6,7], which assists in promoting local and regional sustainable development [8]. In recent years, IS has been considered to be a core strategy [6,9,10] and a key practical approach to promote the circular economy (CE) [4,11]. Fraccascia and Yazan [11] have argued that the catalytic role of IS in achieving a circular economy should be encouraged. In China, IS has been incorporated into national policies that were specifically formulated for CE, and has been identified as a key element for promoting national CE development [12], especially at the mesolevel [13].

A variety of barriers have been identified [3,4,6,9,14–17], which will influence the viability of IS and eco-industrial development [1]. Barriers for IS have been identified as one of the key topics which current IS research addresses [18] and are in urgent need of being examined [4,6].

The operation of IS remains a complex and dynamic process [2,19], which requires continuous improvement [2,20]. Cervo et al. [4] stressed that the “creation of a symbiosis is a multi-step process that goes from the identification of an opportunity to its implementation and operation” (p. 6). When organizations implement IS, it is important to start from understanding the barriers that they could face [21]. For operating industrial symbioses, there are still barriers hindering their full potential development [15,17,22]. Barriers can arise at different phases of the symbiotic development and the importance of a barrier will vary at different stages of the process [2,15]. Thus, it is imperative to prioritize the barriers which hinder the implementation and development of IS [2,15,20,23]. This will provide guidance for the realization of IS projects [18] and assist stakeholders and IS practitioners to create policies aiming at the fundamental barriers to improve the development of IS [14], which could also facilitate the transition to CE. However, from an extensive literature review, it shows that the current research related to IS barriers is mainly qualitative. Evaluation of the IS barriers is still very limited. Only one paper was found examining the barriers using an operating IS as a case study [15]. Furthermore, the barriers evaluated are still focused on generic barriers. No literature has been found that utilizes a model designed as a hierarchical structure embracing both the generic and the specific IS barriers.

To fill the research gap, this paper aims to uncover the nature of the various barriers and identify their significance in a semi-quantitative manner. A hierarchical evaluation model which combines the Analytic Hierarchy Process (AHP) and Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) is utilized in this study to systematically evaluate the barriers. An operating IS, the IS of Hai Hua Group (HHG) of China is taken as a case study to test the proposed model. The study results should provide managers with insights for addressing barriers to improve the operation of IS. In this paper, we have included eco-industrial parks (EIPs) in the discussion of IS because most EIP projects and studies have focused on symbiotic relationships among industries.

2. The Group AHP-TOPSIS Model for Evaluating the Barriers to Industrial Symbiosis

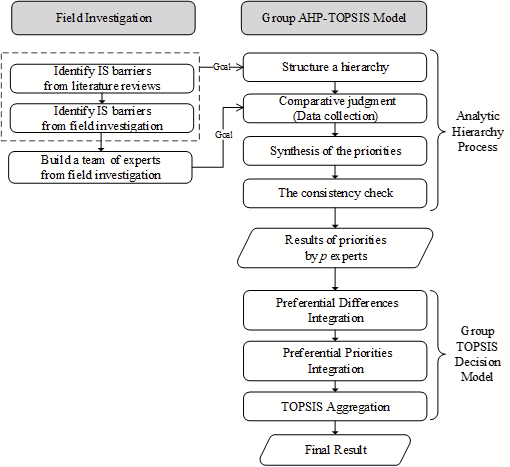

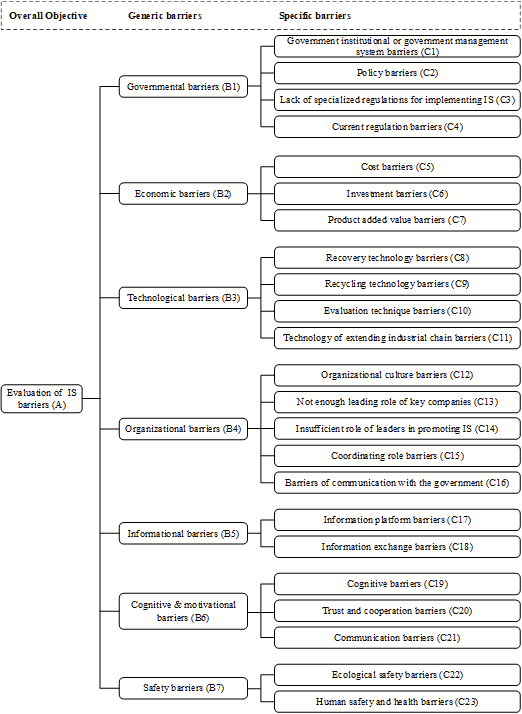

The structure of the Group AHP-TOPSIS Model proposed in this paper to systematically uncover the priority of various barriers for an operating IS is shown in Figure 1. And the hierarchical structure for IS barriers of HHG, which is composed of 7 generic barriers and 23 specific barriers is shown is Figure 2.

Figure 1. The flow chart of the Group AHP-TOPSIS Model.

Figure 2. Hierarchical structure for IS barriers of HHG.

3. Conclusions

This paper proposed a Group AHP-TOPSIS Model to semi-quantitatively evaluate the barriers which impede the implementation of IS. The model is designed as a two-level hierarchical structure, which assists in identifying the degrees of importance of generic barriers and the specific barriers corresponding to their generic barriers. This helps to uncover the barriers of IS in a more comprehensive manner.

Taking HHG as a case study, it is found that a variety of barriers exist for this operating IS, which hinders the establishment and operation of IS and transition to CE. Applying this model to HHG demonstrates that it assists in prioritizing the different barriers. It shows that at the generic barriers level, the top four degrees of importance of generic barriers are technological barriers, economic barriers, safety barriers, and informational barriers. Technological barriers are the most important generic barrier for the IS of HHG and should be given the most attention to be managed or eliminated. The top five specific barriers are information platform barriers, human safety and health barriers, technology of extending industrial chain barriers, product added value barriers, and cost barriers. Information platform barriers are the most important specific barrier and should be emphasized. The work of this paper is one of the first to be undertaken to examine the barriers to an operating IS using mathematical methods with a case study. It provides empirical evidence for the study of IS barriers and should be helpful for managers, decision-makers, and policy planners to understand the IS barriers, focus on several critical barriers, and set comprehensive efforts for improving the operation of an IS, which could facilitate the transition to a CE.

This study still has limitations; future research can be further extended in the following aspects. First, the results of the study are from one single industrial symbiosis which is operating in China; more industrial symbioses from different countries should be investigated with this model in future research. Secondly, while this model focused on an operating symbiosis, it could be combined with the maturity grid proposed by Golev et al. [15], allowing researchers to delve into yet more detail. Thirdly, this paper focused on evaluating the barriers and did not put forward measures to manage or remove the barriers. The two-level hierarchy structure included in the model should be helpful to managers for identifying more targeted measures for managing or removing these barriers. In the future, the model can be further applied and tested on other cases.

This entry is adapted from the peer-reviewed paper 10.3390/su14116815

References

- Chertow, M.R. INDUSTRIAL SYMBIOSIS: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. https://doi.org/10.1146/annurev.energy.25.1.313.

- Yeo, Z.; Masi, D.; Low, J.S.C.; Ng, Y.T.; Tan, P.S.; Barnes, S. Tools for Promoting Industrial Symbiosis: A Systematic Review. J. Ind. Ecol. 2019, 23, 1087–1108. https://doi.org/10.1111/jiec.12846.

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organ. Environ. 2015, 28, 32–53. https://doi.org/10.1177/1086026615575333.

- Cervo, H.; Ogé, S.; Maqbool, A.S.; Mendez Alva, F.; Lessard, L.; Bredimas, A.; Ferrasse, J.-H.; Van Eetvelde, G. A Case Study of Industrial Symbiosis in the Humber Region Using the EPOS Methodology. Sustainability 2019, 11, 6940. https://doi.org/10.3390/su11246940.

- Lüdeke‐Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. https://doi.org/10.1111/jiec.12763.

- Boom-Cárcamo, E.; Peñabaena-Niebles, R. Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers. Sustainability 2022, 14, 4223. https://doi.org/10.3390/su14074223.

- Côté, R.P. Exploring the Analogy Further. J. Ind. Ecol. 2000, 3, 11–12. https://doi.org/10.1162/108819899569502.

- Zhu, Q.; Côté, R.P. Integrating Green Supply Chain Management into an Embryonic Eco-Industrial Development: A Case Study of the Guitang Group. J. Clean. Prod. 2004, 12, 1025–1035. https://doi.org/10.1016/j.jclepro.2004.02.030.

- Henriques, J.; Ferrão, P.; Castro, R.; Azevedo, J. Industrial Symbiosis: A Sectoral Analysis on Enablers and Barriers. Sustainability 2021, 13, 1723. https://doi.org/10.3390/su13041723.

- Mortensen, L.; Kørnøv, L. Critical Factors for Industrial Symbiosis Emergence Process. J. Clean. Prod. 2019, 212, 56–69. https://doi.org/10.1016/j.jclepro.2018.11.222.

- Yazan, D.M.; Fraccascia, L. Sustainable Operations of Industrial Symbiosis: An Enterprise Input-Output Model Integrated by Agent-Based Simulation. Int. J. Prod. Res. 2018, 58, 392–414. https://doi.org/10.1080/00207543.2019.1590660.

- National Development and Reform Commission The Leading Action of Circular Development. Available online: http://www.gov.cn/xinwen/2017-05/04/content_5190902.htm (accessed on 23 April 2022).

- Geng, Y.; Sarkis, J.; Ulgiati, S. Sustainability, Well-Being, and the Circular Economy in China and Worldwide. Science 2016, 6278, 73–76.

- Bacudio, L.R.; Benjamin, M.F.D.; Eusebio, R.C.P.; Holaysan, S.A.K.; Promentilla, M.A.B.; Yu, K.D.S.; Aviso, K.B. Analyzing Barriers to Implementing Industrial Symbiosis Networks Using DEMATEL. Sustain. Prod. Consum. 2016, 7, 57–65. https://doi.org/10.1016/j.spc.2016.03.001.

- Golev, A.; Corder, G.D.; Giurco, D.P. Barriers to Industrial Symbiosis: Insights from the Use of a Maturity Grid: Barriers to Industrial Symbiosis. J. Ind. Ecol. 2015, 19, 141–153. https://doi.org/10.1111/jiec.12159.

- Neves, A.; Godina, R.; Azevedo, S.G.; Pimentel, C.; Matias, J.C.O. The Potential of Industrial Symbiosis: Case Analysis and Main Drivers and Barriers to Its Implementation. Sustainability 2019, 11, 7095. https://doi.org/10.3390/su11247095.

- Van Beers, D.; Bossilkov, A.; Corder, G.; Berkel, R. Industrial Symbiosis in the Australian Minerals Industry: The Cases of Kwinana and Gladstone. J. Ind. Ecol. 2007, 11, 55–72. https://doi.org/10.1162/jiec.2007.1161.

- Madsen, J.K.; Boisen, N.; Nielsen, L.U.; Tackmann, L.H. Industrial Symbiosis Exchanges: Developing a Guideline to Companies. Waste Biomass Valorization 2015, 6, 855–864. https://doi.org/10.1007/s12649-015-9417-9.

- Boons, F.; Chertow, M.; Park, J.; Spekkink, W.; Shi, H. Industrial Symbiosis Dynamics and the Problem of Equivalence: Proposal for a Comparative Framework. J. Ind. Ecol. 2016, 21, 938–952. https://doi.org/10.1111/jiec.12468.

- Grant, G.B.; Seager, T.P.; Massard, G.; Nies, L. Information and Communication Technology for Industrial Symbiosis. J. Ind. Ecol. 2010, 14, 740–753. https://doi.org/10.1111/j.1530-9290.2010.00273.x.

- Ritzén, S.; Sandström, G.Ö. Barriers to the Circular Economy—Integration of Perspectives and Domains. Procedia CIRP 2017, 64, 7–12. https://doi.org/10.1016/j.procir.2017.03.005.

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Industrial Symbiosis in the Taranto Industrial District: Current Level, Constraints and Potential New Synergies. J. Clean. Prod. 2016, 122, 133–143. https://doi.org/10.1016/j.jclepro.2016.02.056.

- Promentilla, M.A.B.; Bacudio, L.R.; Benjamin, M.F.D.; Chiu, A.S.F.; Yu, K.D.S.; Tan, R.R.; Aviso, K.B. Problematique Approach to Analyse Barriers in Implementing Industrial Ecology in Philippine Industrial Parks. Chem. Eng. Trans. 2016, 52 , 811–816. https://doi.org/10.3303/CET1652136.