Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Industrial

Sustainable engineering refers to the integration of social, environmental, and economic considerations into product, process, and energy system design methods. Additionally, sustainable engineering encourages the consideration of the complete product and process lifecycle during the design effort.

- sustainability

- engineering

- principle

1. Green Engineering Principles

Anastas and Warner [44] published 12 Principles of Green Chemistry—they are mainly chemicals oriented but half of them apply to engineering, too: “(1) Avoiding waste production is far better than treating or cleaning it up afterwards; (3) Feeds and products to and from a chemical process should pose as little risk to human health, and be as environmentally benign as possible; (6) Reduce energy waste and consumption by striving to operate at ambient conditions; (7) Where technically and economically possible, (chemical) feeds and raw materials should be sourced renewably; (10) Materials and chemicals should be designed, where possible, to degrade into benign and non-toxic substances at the end of their functional lives; (11) Use real time analysis for pollution prevention”.

The 12 principles of green engineering [45] include: (1) non-hazardous material and energy inputs and outputs, (2) waste prevention, (3) minimum resource usage, (4) maximum resource and time efficiencies, (5) use “output pulled” energy and materials, (6) recycle, reuse, or dispose for usable purposes, (7) the design goal shall be durability, rather than immortality, (8) avoid overcapacity, (9) design for easy recycling, (10) recycle and reuse resources within your production process, (11) design for extended use, and (12) use renewables. The principles are chemical process oriented.

The nine Sandestin principles are the result of a conference entitled Green Engineering: defining the principles, which took place in May 2003 at the Sandestin Resort in Florida [46]. The Sandestin Declaration agreed upon the following draft principles: (1) holistic approach, (2) natural ecosystems conservation, (3) life cycle thinking, (4) safe and benign material and energy inputs, (5) minimum depletion of natural resources, (6) waste prevention, (7) respect local conditions, (8) improve–innovate–invent new technologies, and (9) engage all stakeholders.

At the same time, BASF developed and tested the Eco-Efficiency Analysis using over 180 industrial applications [47]. The work mostly confirmed the 12 principles listed in the Anastas and Zimmerman paper, but it was more practice oriented, and included economic and social principles. As well as the preliminary conditions in the analysis, the environmental efficiency analysis was developed using 10 principles including: (1) customer viewpoint when calculating total cost, health, safety, and risk analysis, (2) weighting societal factors by using LCA, (3) comparing the relevance of economy versus ecology, and (4) regarding social aspects (optionally).

Eco-efficiency has developed in the last two decades. As defined by the World Business Council for Sustainable Development [48], “Eco-efficiency is achieved by the delivery of competitively priced goods and services that satisfy human needs and bring quality of life, while progressively reducing ecological impacts and resource intensity throughout the life cycle to a level at least in line with the Earth’s estimated carrying capacity. It is concerned with creating more value with less impact.” According to Lehni [48], “the most critical features of eco-efficient companies are: (1) Producing goods and services with fewer materials. (2) Producing goods and services with less energy. (3) Dispersing lower volumes of toxic materials. (4) Improved recyclability. (5) Striving to use renewable resources. (6) Making goods that last longer, and (7) Greater service intensity of products and services”.

Garcia-Serna et al. [49] presented a “broad review of disciplines and technologies concerning the design trends: The Natural Step, Biomimicry, Cradle to Cradle, Getting to Zero Waste, Resilience Engineering, Inherently Safer Design, Green Chemistry and Self-Assembly”. The core of the review paper was “Green Engineering, its main definitions, scope of application, different guiding principles, a framework for design and legislative aspects”. Thirteen sets of principles were presented, and a quick selection guide about using each one was given. Some of them are described in this paper; here is the list of six not yet described sets of principles: The Earth Charter Principle, The Coalition for Environmentally Responsible Economies (CERES) Principle, The Bellagio Principles, The Ahwahnee Principles, The Interface Steps of Sustainability, and Design for Environment (DfE) Key Strategies.

These green engineering principles were and still are environmentally stressed as shown by the name. Industry introduced additional economic and social components, which helped them to survive until the present. Eco-efficiency has slowed down the rate of hazardous human impacts on the environment. Sets of principles were described to help engineers design their objects easier and better.

2. Sustainability Principles and Practice for Engineers

The Institute of Professional Engineers New Zealand (IPENZ) started work on sustainability principles in 2003. Their time horizon was 1000 a, and they assumed that basic human needs will not change. Two years later they presented the first draft of their updated principles for engineers [50] that were further improved by numerous case studies and checklists. On this basis, they postulated three key principles (Viability of the Planet, Equity within and between generations, Solving problems holistically) with 15 principles in all [51] (Table 1).

Table 1. Three key principles with 15 principles of sustainability and engineering in New Zealand.

| Maintain the Viability of the Planet | |

|---|---|

| 1 | Humans need to maintain the integrity of global and local biophysical systems. |

| 2 | Renewable resources must be managed within sustainable harvest rates and non-renewable resource depletion rates must equal the rate at which renewable substitutes take their place. |

| 3 | Technological options must favor choices that minimize the use of resources and reduce risks. |

| 4 | The material and energy intensity used in products, processes or systems needs to be reduced significantly—by 10 to 50 times—using recycling and minimization techniques. |

| 5 | Waste streams during the life cycle of products, processes or systems must be minimized to the assimilative capacity of the local and global environments. |

| 6 | Any use and production of environmentally hazardous materials must be minimized and carried out prudently if necessary. |

| Providing for equity within and between generations | |

| 7 | Humans, now and in the future, must have equal access to choices in life that reduce significant gaps between people in areas such as health, security, social recognition, and political influence. |

| 8 | Total consumption of resources needs to be within the environment’s sustainable capacity and balanced between the affluent and those yet to fulfil their basic needs. |

| 9 | Present resource use and development must be considered over a sufficiently long timescale that future generations are not disadvantaged. |

| 10 | Those directly affected by engineering projects, products, processes, or systems must be consulted and their views incorporated into the planning and decision-making processes. |

| Solving problems holistically | |

| 11 | Problem solutions must be needs-based, rather than technology-driven. |

| 12 | Demand growth targets must be realistically assessed and if necessary managed, rather than simply meeting predictions. |

| 13 | A holistic, systems-based approach must be used to solve problems, rather than technology focusing on only single aspects of problems. |

| 14 | Unsustainable practices must be reduced to zero over time, and where practicable past degradation shall be addressed. |

| 15 | Problem solutions must be based on prudent risk management approaches. |

The Royal Academy of Engineering (RAE, United Kingdom) presented 12 “Principles of Engineering for Sustainable Development” [52], which are very useful from the operational point of view. The 12 principles (Table 2) are: “(1) Look beyond your own locality and the immediate future; (2) Innovate and be creative, (3) Seek a balanced solution; (4) Seek engagement from all stakeholders; (5) Be sure you know the needs and wants; (6) Plan and manage effectively; (7) Give sustainability the benefit of any doubt; (8) If polluters must pollute, then they must pay as well; (9) Adopt a holistic, “cradle to grave” approach; (10) Do things right, having decided on the right thing to do; (11) Beware cost reductions that masquerade as value engineering, and (12) Practice what you preach”.

Table 2. An overview of sustainable engineering principles.

| Initiative | Principles |

|---|---|

| Anastas and Warner, 6 out of 12 Principles of Green Chemistry | (1) No waste production, (2) minimum risk to humans and environment, (3) minimum energy, (4) renewable resources, (5) benign end-of-live products, (6) real time analysis for pollution prevention |

| Anastas and Zimmerman, 12 Principles of Green Engineering | (1) Non-hazardous inputs/outputs, (2) waste prevention, (3) min. resource usage, (4) max resource/time efficiency, (5) “output pulled” resources, (6) recycle, reuse, refurbish, (7) durability not immortality, (8) no overcapacity, (9) easy recycling, (10) recycle within process, (11) extended use, (12) renewables |

| Sandestin, Green Engineering principles | (1) Holistic approach, (2) natural ecosystem conservation, (3) life cycle thinking, (4) safe/benign inputs, (5) min natural resources, (6) waste prevention, (7) local conditions, (8) engage all stakeholders |

| BASF, Eco-efficiency Analysis | (1) Customer viewpoint, (2) societal factors by using LCA, (3) economy vs. ecology, (4) social aspects |

| WBCSD, Eco-efficiency principles | (1) Fewer materials and (2) energy, (3) disperse toxics, (4) recyclability, (5) renewables, (6) durability, (7) greater service intensity |

| IPENZ principles | See Table 1 |

| RAE principles | (1) Beyond locality and immediate future, (2) innovate and create, (3) balanced solution, (4) all stakeholders, (5) needs and wants, (6) plan/manage effectively, (7) benefit sustainability, (8) polluters pay, (9) holistic approach, (10) do right things right, (11) no cost reduction masquerade, (12) practice what you preach |

| SE principles | See Figure 1 and Figure 2 |

| Rosen, Key requirements for SE |

Sustainable (1) resources and (2) processes, (3) increased efficiency, (4) reduced environmental impact when using LCA, (5) other aspects: economic affordability, equity, resource demand, safety, community, social acceptability, human needs, land use, aesthetics, lifestyles, population |

The IPENZ principles are well developed, covering three main areas: environmental, equity, and systems approaches. They are weak on economic and societal sides, however. The RAE principles are short but very instructive for practicing engineers.

3. Sustainable Engineering Principles

Sustainable engineering (SE) does not harm the environment, nor does it exploit resources that belong to future generations [53]. The NAL Thesaurus [54] defines it as “the design, commercialization and use of processes and products that are feasible and economical while reducing the generation of pollution at the source and minimizing the risk to human health and the environment”. It includes all the three SD pillars. Kauffman and Lee [55] edited a handbook of SE with 66 chapters and 1285 pages written by academic researchers as well as practitioners. They brought new engineering approaches to sustainable production, and innovative operational practices.

The advantages of SE in comparison with traditional green engineering are the following [23]:

-

SE considers the whole system in which the product, process or services are used.

-

It deals not only with technical but also with non-technical issues in synergy.

-

It is designed to solve problems for the distant future, not just for the immediate period.

-

As well as the local context, it considers the global one, too.

-

It deals with political, ethical, and societal issues by interacting with experts in other disciplines.

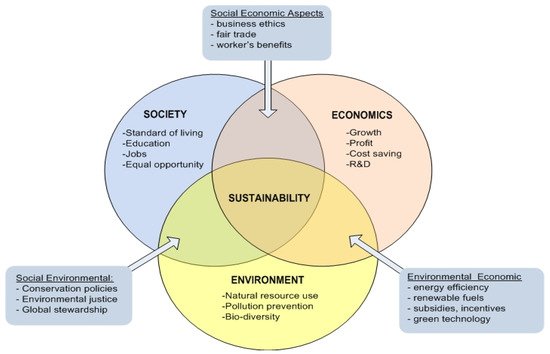

Sustainable engineering principles can be shown by a triangle, having environmental, social, and economic pillars as the corners. Figure 1 presents all the tree pillars in the form of spheres, with their most important constituents listed. The environmental aspects include the use of natural resources, pollution prevention, biodiversity, and ecological health. The social aspects include standards of living, the availability of education and jobs, and equal opportunities for all members of society. The economic factors are drivers for growth, profit, reducing costs, investments into research and development, etc. Interaction of the social and economic spheres result in the formulation of combined social–economic aspects. Those are, e.g., business ethics, fair trade, and worker’s benefits. The combination of economic and environmental interests facilitates increasing energy efficiency, the development of renewable fuels, green technologies, and creation of special incentives and subsidies for environmentally sound businesses. The intersection of social and environmental spheres leads to the creation of conservation and environmental protection policies, establishment of environmental justice, and global stewardship for the sustainable use of natural resources.

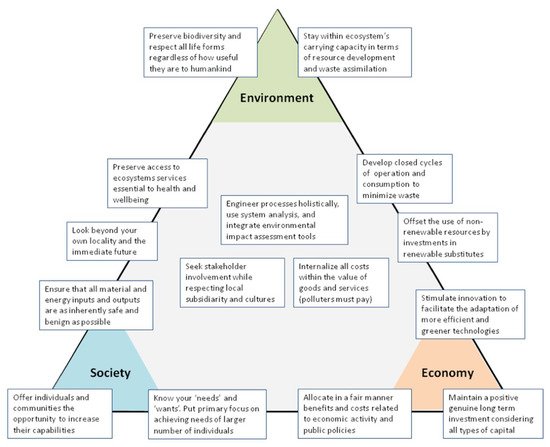

The diagram in Figure 2 presents a consolidated framework for sustainable engineering principles, which are in part adopted from the work of Gagnon et al. [57] and from the green engineering principles established by Sandestin Conference (Abraham and Nguyen, 2003). Gagnon et al. presented sets of principles that are most relevant to sustainable engineering. Based on general sustainable development principles and on specific engineering ones, they proposed a set of fifteen sustainable engineering principles, organized in a triangle. The principles that are closer to the extremities of the triangle are one-dimensional. Those on the sides are bi-dimensional; they have a stronger connection with the angle they are closer to. Three-dimensional principles are in the middle of the triangle; each of them being situated according to their links with the angles. These principles can serve as guidelines in a specific engineering project.

Figure 2. Classification of sustainable engineering principles versus environmental, social, and economic criteria.

Rosen [58] cited “5 key requirements for engineering sustainability: (1) sustainable resources, (2) sustainable processes, (3) increased efficiency, (4) reduced environmental impact when applying LCA, and (5) fulfilment of other aspects of sustainability: economic affordability, equity, meeting increased resource demand, safety, community involvement and social acceptability, human needs, appropriate land use, aesthetics, lifestyles, and population”.

All the three approaches described above are close to the modern understanding of SE. However, they do not mention circular economy and zero waste system, which is broader and deeper than just recycling—see the Circular Economy System Diagram [59]. Moreover, human capital, social responsibility, and annual reporting are not presented as societal and 3D components, respectively. Cost-Benefit Analysis using LCA is important, too. The precautionary approach has been well known for three decades, but it is not included in the existing SE principles. Therefore, it seems reasonable to update the SE Principles.

6. Updated Sustainable Engineering Principles

Sustainable engineering (SE) principles need an update to include the present state of the art in human knowledge. Table 3 presents the missing principals in the individual SE sets studied. The updated 12 principles have been synthesized, especially the above-described principles of sustainable development, SD [33], new trends, recent developments, and personal experience in the SD area. The SDGs have been respected, too. As well as the omissions mentioned in the last paragraph, more rapid climate change than expected, critical raw materials break out, pollution (especially plastics) spread, and acceleration of species extinction are suggested to modify the outdated principles. Increasing inequalities, extreme human wealth distribution, advantage of profits against the common good, the fraction of decent jobs reduction, etc. require changes in the behavior of engineers. They are expected to mitigate the negative consequences of human development and present a solid ground for long-term changes in engineering design. Sustainable engineering principles are an important vehicle towards sustainable development.

Table 3. Comparing the updated Sustainable Engineering Principles (SEP).

| Updated Sustainable Engineering Principles | Green Engineering | Eco-Efficiency Analysis | Sandestin Principles | SD Triangle Figure 2 | Sustainable Engineering Principles, Figure 3 | Sustainable Principles and Practices IPEN2 | RAE Principles of Engineering for SD |

|---|---|---|---|---|---|---|---|

| Tridimensional principles | |||||||

| Holistic approach and system thinking | holistic approach |

environmental stewardship, environmental justice | holistic process, use system analysis | use holistic systems-based approach | holistic approach | ||

| Reporting | prudent risk management | do things right | |||||

| Environmental principles | |||||||

| Sustainable consumption and production | minimum resource use, output pull, durability | environ- mental fingerprint | minimum resource depletion | resource use, pollution prevention, biodiversity | Biodiversity, know the needs and wants | minimum use of resources and risks, integrity | know the needs and wants |

| Circular economy, waste minimization, waste, and energy hierarchies | recycling, reuse, design for recycling, waste prevention | waste prevention | green technology |

closed cycles | within environmental capacity, minimum waste | ||

| Efficiency, renewable resources | maximum resource and time efficiency, renewable resources | ecosystems conservation | energy efficiency, renewable fuels | min energy and material intensity, renewable sources | |||

| Precautionary and preventive approach | non-hazardous in/outputs, no over-capacity | safe and benign inputs | conservation policies |

eco-carrying capacity, safe and benign input | minimum hazardous materials, needs-based | look beyond locality and near future | |

| Societal principles | |||||||

| Equity within, between generations |

equal opportunity | equal access to choices | |||||

| Communities, all stakeholder’s engagement | societal weighing |

respect local cond., engage all stakeholders | living standard, jobs | stakeholder interests beyond your | consult and consider directly affected stakeholders | engage all stakeholders, balanced solutions | |

| Social responsibility, CSR, decent work | business ethics, fair trade | health and well-being | no disadvantage for future generations | practice what you preach | |||

| Human capital, creativity, and innovations | improve, innovate, invent | education, workers’ benefit, R&D | stimulate innovations in greener technologies | innovate and be creative | |||

| Economic principles | |||||||

| Cost–benefit analysis when applying LCA | total costs, eco-efficiency analysis, LCA | LC thinking | growth, cost saving, profit | allocate benefits and costs | reduce unsustainable practices to zero | beware cost reduction masquerade | |

| Internalizing externalities, polluters pay |

subsidies, incentives |

internalize all costs—PMP |

polluters must pay | ||||

Environmental, social, and economic pillars are of equal importance to the future. Therefore, the updated principles (the connections with the SDG numbers are shown in parentheses) include:

- A.

-

Tridimensional principles

- 1.

-

Holistic approach, systems thinking and management (SDG 16)

- 2.

-

Precautionary and preventive approaches (SDG 13)

- 3.

-

Annual sustainability reporting using GRI (SDG 4)

- B.

-

Environmental principles

- 4.

-

Circular economy, waste minimization, sustainability hierarchies (SDG 13)

- 5.

-

Efficient use of resources, and increased share of renewables (SDGs 6, 7)

- 6.

-

Sustainable consumption and production (SDG 12)

- C.

-

Social principles

- 7.

-

Equalities within and between generations (SDGs 5, 10)

- 8.

-

Engagement of communities and all stakeholders (SDG 11)

- 9.

-

Corporate social responsibility and decent work (SDGs 1–3, 8)

- D.

-

Economic principles

- 10.

-

Human capital, innovations, and creativity (SDGs 4, 9)

- 11.

-

Cost–benefit analysis using Life Cycle Assessment (SDGs 3, 13)

- 12.

-

Internalizing externalities—polluters must pay (SDG 13)

Table 3 compares the updated SE Principles. Although it is difficult to find the adequate location of each principle, each of the sets is evidently missing at least two or more of the updated principles.

This entry is adapted from the peer-reviewed paper 10.3390/pr10050870

This entry is offline, you can click here to edit this entry!