Among the leading consequences of corrosion in reinforced concrete structures (RCS) the

cross section reduction in steel bars should be mentioned, coupled to a decay of their mechanical

material properties. This paper recalls the main literature findings on the topic and describes a wide

collected database of experimental tensile tests performed on naturally corroded reinforcements.

The principal predictive degradation laws available in the scientific literature to assess the residual

mechanical properties of the corroded reinforcements are synthesized. A first attempt to evaluate the

reliability of the literature decay laws to simulate the mechanical performance of naturally corroded

steel reinforcement subjected to both uniform and pitting corrosion is performed. Finally, some

remarks are suggested on both the tested naturally corroded steel reinforcement and the available

degradation laws.

1. Introduction

Corrosion is one of the most common causes of deterioration in reinforced concrete structures (RCS), affecting 70–90% of building heritage [

1]. The main macroscopic effects of corrosion in RCS are [

2]: (i) steel-to-concrete interaction variation, (ii) cracking and spalling of the concrete cover, and (iii) reinforcement cross section reduction. Each factor corresponds to a mechanical performance deterioration at the material level (i.e., the bond-slip law [

3], the strength of the cracked concrete [

4], and the reinforcement constitutive law [

5]). Consequently, the structural response of corroded RCS gradually worsens over time (increasing the corrosion level) and their service life can be compromised [

6].

A deep understanding of the materials’ mechanical properties decay is essential to assess and foresee the performance of existing corroded RCS. With specific reference to the performance of corroded reinforcements, several experimental studies have been carried out in the last few decades [

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43], most of the time analyzing the behavior of artificially corroded specimens. In the pioneering work by Almusallam [

7], steel reinforcement embedded in concrete was subjected to a high anodic current (2 mA/cm

2), obtaining a considerable pitting corrosion. Apostolopulos et al. [

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20] carried out several experimental campaigns on steel reinforcements differing in technical classes and diameters, damaged by means of laboratory salt spray corrosion. The research involved steel reinforcements, bare or embedded in concrete, exposed to different salt spray environments for variable time slots, and tested in both monotonic and low-fatigue tests. Chemical, metallographic, and fractographic analyses were typically performed. In some cases, the pits formed on the reinforcement surface were measured and statistically analyzed. Moreover, the effects of a plastic deformation applied before the corrosion were investigated [

9], as well as the performance of naturally corroded reinforcements [

12]. In the latter case, efforts were made to correlate the mass loss due to the artificial corrosion process with the one measured in exposed rebars subjected to natural corrosion. Caprili et al. [

21,

22,

23,

24] analyzed the corrosion effects on reinforcements belonging to the most representative typologies of the actual European scenario. The experimental research included tensile and low-cycle fatigue tests, different specimen diameters, and exposure conditions. Moreover, the performance of dual-phase steel grades reinforcements subjected to corrosion degradation was investigated. Monotonic and fatigue tests were performed by Ref. [

25] on corroded reinforcement extracted from beams exposed to an electrolytic procedure. The weight loss and the pit geometrical characteristics (depth and length) were measured. A trend for the mechanical properties decay of the corroded reinforcements was identified and related to the corrosion penetration; unfortunately, no formulation relating mechanical degradation and corrosion damage was provided. In Ref. [

26], the mechanical performance of naturally and artificially corroded reinforcements embedded in concrete was compared, finding significant differences attributable to the different corrosion morphology. In fact, according to tensile test results performed on mechanically indented bars [

27,

28], the pit geometry influences the reinforcements mechanical performance.

Starting from the experimental outcomes, different degradation laws for the mechanical properties in tension of corroded steel reinforcements have been statistically assessed [

26,

27,

28,

29,

30,

31,

32,

33,

34,

35] to define a useful tool for estimating the residual performance of corroded RCS.

2. Mechanical Performance of Corroded Ribbed Reinforcements

There is a general agreement about the reduction in the nominal constitutive law when a steel reinforcement corrodes: as the load capacity reduces together with the reinforcement cross section loss, the nominal stresses necessary decrease. The first work concerning the mechanical performance of corroded reinforcement was performed by Almusallam, on 6 mm and 12 mm diameters bars affected by highly localized corrosion [

7]. A slight decrease in the yield and ultimate strengths and a significant reduction in the collapse elongation was detected. Subsequently, the Hellenic school analyzed the mechanical performance corroded steel reinforcements [

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20], finding that specimens embedded in concrete present stronger superficial severe localized pitting corrosion in contrast to the bare specimens. Moreover, the experimental outcomes [

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20] highlight a trend for the mechanical properties decay as a function of the corrosion level: both the residual ductility and the collapse strength reduce, and the yield plateau progressively disappears. It is worth noting that in Refs. [

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20] the specimens were artificially corroded through a laboratory salt spray chamber, with the main aim to simulate the effects of a natural coastal environment, rich in chlorides. Similar outcomes were observed in other studies analyzing the mechanical performance of reinforcements artificially damaged by accelerated electrolytic corrosion [

25,

26,

29,

30,

31,

32,

33,

34,

35]. An example of constitutive law obtained for reinforcements subjected to uniform corrosion is reported in

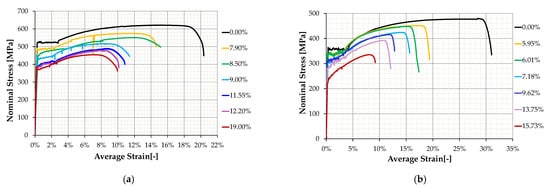

Figure 1, where a comparison between the performance of ribbed and smooth bars is moreover reported. Excepting the obvious differences in terms of both strength and ductility in absence of the corrosion, the performance of the two reinforcement typologies is similar once the degradation occurs.

Figure 1. Comparison between the mechanical performance of steel reinforcements subjected to uniform corrosion: (a) ribbed bars, (b) smooth bars. The corrosion level is expressed in terms of mass loss.

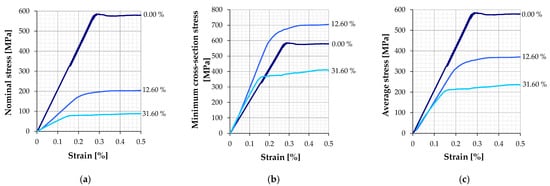

The mechanical properties decay can be observed in both the nominal and effective stresses (evaluated referring to the corroded cross section). Obviously, in the latter case the reduction is less evident. Regarding this aim, it is worth noting that a proper definition of the reference cross section plays a key role for a correct evaluation of the stress of a corroded reinforcement (Figure 2). Even if the minimum cross section governs the collapse, the adoption of this parameter is evidently not eligible in evaluating the constitutive law of the corroded reinforcement; this choice meant obtaining strength and elastic modulus higher than the uncorroded reinforcements (Figure 2b). By adopting the average cross section (evaluated on the gauge length), reasonable constitutive laws could instead be obtained (Figure 2c).

Figure 2. Local constitutive laws referred to the most corroded zone: (a) stress evaluated by considering the nominal cross section, (b) stress evaluated by considering the most corroded cross section, and (c) stress evaluated by considering the average cross section in the gauge length.

The variation of the reinforcement constitutive laws after the corrosion degradation is ascribed to the steel bar microstructure [

14,

15,

16,

17,

18,

19,

20,

26,

27,

28,

29,

30,

31,

32,

33]. However, it should be noted that the studies introducing this topic are based on specimens realized with steel reinforcements belonging to the actual manufacturing scenario, therefore characterized by a layered microstructure. As each layer has a proper mechanical behavior [

36,

37], the reinforcement constitutive law depends on the proportions between the layers’ volume: depending on the residual corroded layers, the constitutive law inevitably changes. A quite homogeneous layer reduction occurs in case of uniform corrosion, and a smooth degradation of the mechanical properties increasing the corrosion level can be observed. If, instead, the pitting corrosion develops, a greater dispersion of mechanical properties can also be detected for the same corrosion level or pit depth, due to the variable shape of pits affecting different layers at the same time. To better understand how pitting corrosion affects the reinforcement mechanical properties, experimental studies were performed on mechanically indented bars [

27,

28]. Together with the well assessed reduction in residual ductility and collapse strength, it was found that the deeper and more asymmetrical the pitting is, the worse the mechanical behavior of the corroded reinforcement. The latter outcome is confirmed observing reinforcements extracted from naturally corroded beams subjected to static loads and characterized by high pit depth [

38].

This entry is adapted from the peer-reviewed paper 10.3390/cmd3020012