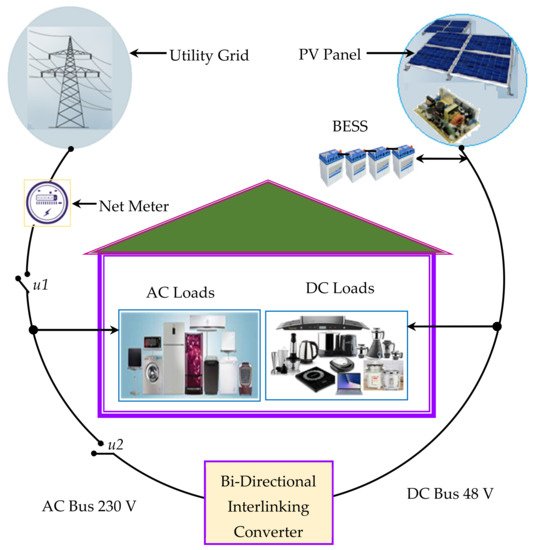

A novel energy management system for a hybrid microgrid has been developed that uses a new control algorithm termed Inefficient Power Conversion Elimination Algorithm (IPCEA). The proposed algorithm compares the Net Transferable Power (NTP) available at the DC side with the loss rate across the converter. The converter is switched off (or disconnected from the grid and load) if the NTP is less than 20% of the converter rating to avoid low-efficiency power conversion. The solar PV system is connected to the DC bus to supply the DC loads while the AC loads are supplied from the AC source (utility power). An auxiliary battery pack has been integrated to the DC side to feed DC loads during the absence of solar energy. Battery Energy Storage System (BESS) has been deployed to manage energy distribution effectively. Power distribution is managed using a centralized microgrid controller, and the load demand is met accordingly. Thereby, power generated by solar PV can be utilized effectively. Microgrid technology's effectiveness is emphasized by comparative analysis, and the achievements have been discussed in detail and highlighted using a prototype model.

The proposed study intends to design a novel switching strategy to incorporate a hybrid microgrid in the distribution system effectively. It comprises the following conventional electrical installation with an intelligent microgrid distribution system:

i) To implement a renewable-based IPCEA considering the availability of Net Transferable Power (NTP) at DC bus and the rate of converter loss to minimize low efficient power conversion.

ii) To effectively manage battery energy within the DC side of the microgrid to minimize the charge cycle and improve its performance.

iii) To decrease the stress on the utility grid by reducing the rate of power exchange.

- AC/DC microgrid

- Hybrid microgrids

- Energy Management Systems

- Battery Energy Storage Systems

- Power losses

- Power electronics

1. Hybrid Microgrid System Description

-

SoC—Battery State of Charge

-

Q—Battery Capacity

-

IB—Battery Current

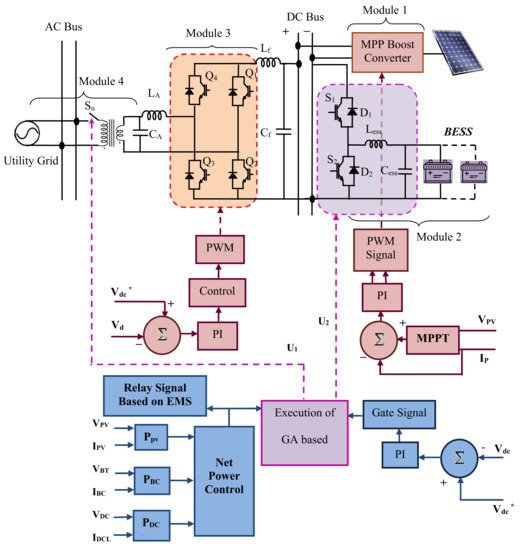

2. Proposed Microgrid Controller Configuration

-

Q1, Q2, Q3, Q4—Bidirectional interlinking converter IGBT switches

-

S1, S2,—Bidirectional DC converter IGBT switches

-

D1, D2,—Bidirectional DC converter diodes

-

VPV—Solar PV voltage

-

IPV—Solar PV current

-

PPV—Solar PV power

-

VBT—Battery voltage

-

IBC—Battery current

-

PBC—Battery power

-

Idcl—DC load current

-

Pdcl—DC load power

-

Vdc—DC link voltage

-

Vdc*—Reference DC link voltage

-

Su—Utility grid voltage

-

LA—AC side filter inductor

-

CA—AC side filter capacitor

-

Lf—DC link filter inductor

-

Cf—DC link filter capacitor

-

Less—Battery side filter inductor

-

Cess—Battery side filter capacitor

-

BESS—Battery energy storage system

-

δ = Duty cycle

-

VBT = Battery voltage

-

VDC = Microgrid DC bus voltage

-

ma = Modulation index

-

Vcontrol = Voltage obtained from controller

-

Vtriangle = Triangular carrier wave voltage

-

ϕ = Angle at which voltage is injected into utility grid

-

LA = AC side smoothing inductor

-

VAC = AC voltage at inverter terminal

-

Vug = Utility grid voltage

-

Sin ϕ = Sine of angle between inverter voltage and utility grid voltage

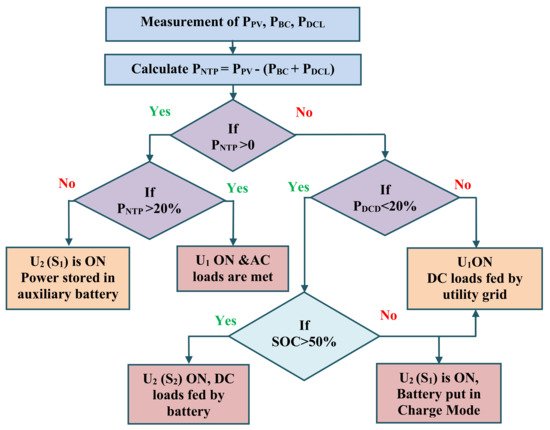

3. Design Procedure of the IPCEA Based Microgrid EMS

-

PNTP—Net transferable power at DC side

-

PPV—Power from PV array

-

PBC—Battery Charging Power

-

PDCL—DC power load demand

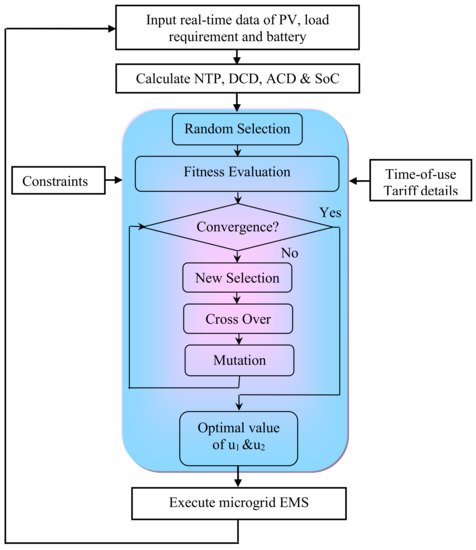

4. Genetic Algorithm for Cost Minimization

-

Step 1: The input parameters include instantaneous solar PV power, AC- and DC-side load demand, and the battery’s state of charge.

-

Step 2: Calculation of NTP using Equation (10) and load demands using real-time data.

-

Step 3: Execution of the genetic algorithm.

-

PGS—Grid-side power

-

CGS—Cost of the grid power

-

PACD—AC-side power demand

-

PConv—Power loss across converter

-

PDCD—DC-side power demand

-

PBL—Power loss across battery

-

PPV—Power from PV array

-

SOC limits: 90%>SoC(t)>50%

-

Power transfer switch u1 enabled if PNTP&PDCD>20% of PCR

-

When PNTP<20% and PDCD<20%, switch u2 is enabled to access the battery power.

-

Selection of population (random, size = 50).

-

Fitness evaluation (Individual).

-

Check for criterion satisfaction.

-

If the condition is not satisfied, another new population set is selected (roulette wheel selection).

-

Go for cross-over (single cross-over).

-

The mutation rate is fixed as 0.2.

-

Check for convergence.

-

Step 4: Execution of microgrid energy management.

This entry is adapted from the peer-reviewed paper 10.3390/su132413882

References

- How to Determine Transformer Efficiency? Electrical Engineering. Available online: https://www.engineeringenotes.com/electrical-engineering/transformer/how-to-determine-transformer-efficiency-electrical-engineering/27945 (accessed on 23 March 2021).

- What Is the Effect of under Load Transformer for Energy Losses? Electrical Engineering. Available online: https://www.researchgate.net/post/what_is_the_effect_of_underload_transformer_for_energy_losses (accessed on 16 June 2021).

- Suresh, K.; Devishree, J. Evaluation of transformer loading and energy loss for increasing energy efficiency in distribution system. In Proceedings of the 12th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Hua Hin, Thailand, 24–27 June 2015.

- Zeh, A.; Müller, M.; Naumann, M.; Hesse, H.; Jossen, A.; Witzmann, R. Fundamentals of Using Battery Energy Storage Systems to Provide Primary Control Reserves in Germany. Batteries 2016, 2, 29.

- Hesse, H.C.; Schimpe, M.; Kucevic, D.; Jossen, A. Lithium-Ion Battery Storage for the Grid—A Review of Stationary Battery Storage System Design Tailored for Applications in Modern Power Grids. Energies 2017, 10, 2107.