Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Additive manufacturing (AM), commonly known as 3D printing, is a fabrication technology that has raised interest in many areas. It is a manufacturing process that builds up complex solid (or semi-solid) forms by means of a layer-by-layer process.

- 3D food printing

- mechanical properties

- techniques

1. Introduction

While the term used by the food engineering community is texture analysis, for mechanical and materials scientists, it is essentially the mechanical characterization of material properties. The so-called texturometer is known as a universal testing machine for mechanics and materialists. Therefore, many of the concepts and contributions derived from the study of the mechanical properties of 3D-printed parts can be applied when dealing with edible printed material. This was recently discussed by Peleg [1]. Several parameters, although not all, that could affect the mechanical properties of food (i.e., texture, snap, chewiness, gumminess, etc.) can be taken from the work done on non-edible materials and are related to the stiffness, strength, deformation mechanisms, hardness of the materials, and 3D-printed structures. These parameters were summarized in a recent work [2] that covers a review of the literature on the mechanical characterization of 3D-printed parts fabricated via extrusion.

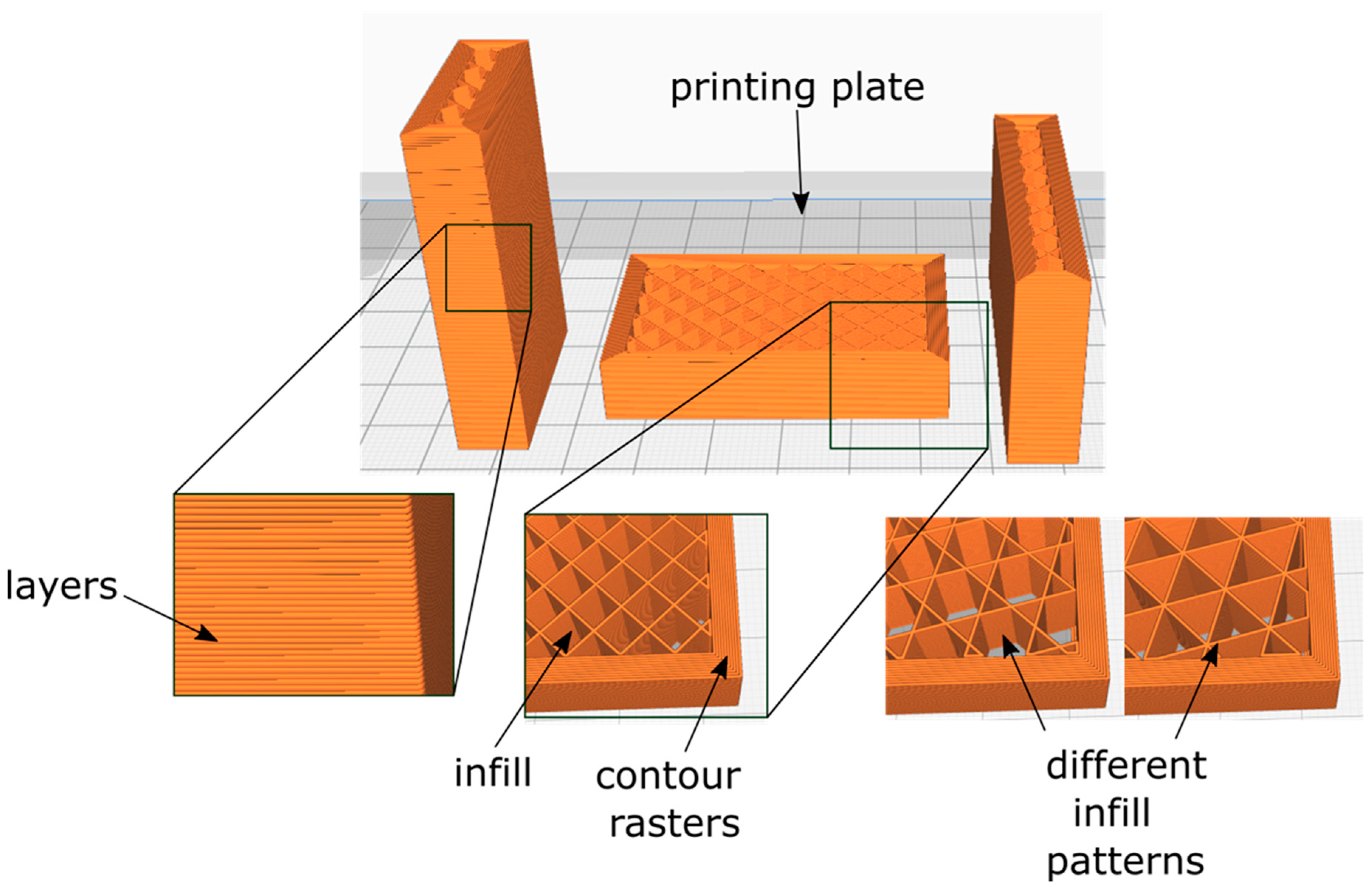

Numerous parameters have an effect on the resulting mechanical properties of 3D-printed samples: (i) building orientation, (ii) infill structure, and (iii) infill density, among others [2]. These are illustrated in Figure 1, where a computationally modeled sample shows three different orientation possibilities. (i) Building orientation is significant, as 3D-printed products are known to be anisotropic, meaning that their mechanical properties depend on direction [3]. (ii)–(iii) Infill is the lattice or tessellated arrangement used to fill 3D-printed products.

Figure 1. Printing parameters that have an influence on their mechanical properties. Diagrams obtained from CURA®.

When dealing with food, the concept of TPA is the most used for characterizing the mechanical properties of food products (material). However, when characterizing 3D-printed food using TPA, one can obtain misleading results because the measured properties may be related to specific manufacturing parameters or to sample dimensions and shapes. Results obtained from these testing procedures are specific; changes in sample dimensions and/or shapes may result in different measured properties. Proper sample design is needed so that measured properties are universal. For instance, characterization of the mechanical properties of the infill would be more useful if the samples were printed without contour rasters. When contour rasters are aligned to the principal axes of the sample, they are more likely to withstand most of the load, leading to an insignificant contribution by the infill. Most infill patterns are known to have in-plane anisotropy. A complete understanding of their mechanical properties demands samples with different infill structure orientations to characterize their dependency on the loading direction.

TPA analyses have been performed to characterize both edible printing material (mixtures and slurries prior to printing) and printed food products. This analysis has been used mainly for compression [4] and bending (usually called cutting). Characterizing the material properties prior to printing is crucial for evaluating the printability of products and the rheological and viscosity measurements, as discussed in Section 3. Several works that deal with a variety of printing materials are available, such as studies of egg white protein mixtures [5], dairy protein mixtures [6], cheese [7], methylcellulose and gum mixtures [8], lemon [9], orange [10], and potato puree [11].

In this section, the review of the literature focuses on work wherein the mechanical properties were characterized using 3D-printed samples. However, one needs to be aware that when characterizing any 3D-printed product via TPA, the results are not associated purely with the material that is being used but also with the combination of materials and the fabrication parameters, such as post-processing (Figure 1). Both, keeping the same base material while changing printing parameters and changing the base material while keeping the printing parameters constant lead to changes in mechanical properties. This makes 3D printing a versatile fabrication technique for the production of food with customized properties.

2. Effect of Infill Density

Among 3D-printing techniques, extrusion-based techniques are more frequently encountered, both with hot-extruder and non-heated processes. Extrusion machines are based on a Cartesian mechanism that uses three servomotors to control the position of the extruder in the three principal axes. This allows building parts (food) from the stack of extruded material. Extruded material is deposited in “2D” layers conformed by contour rasters and the infill. It has been shown that the infill affects the mechanical properties of the printed part [12]. The important thing in the field of food printing lies in the different sensorial perceptions of consumers provided by the variation in the internal structure patterns [13][14]. This was studied in [15], where cereal-based products were printed and compressed. Products made from chocolate extrusion were printed with different infill patterns, and their snap [buckling] properties were analyzed [16].

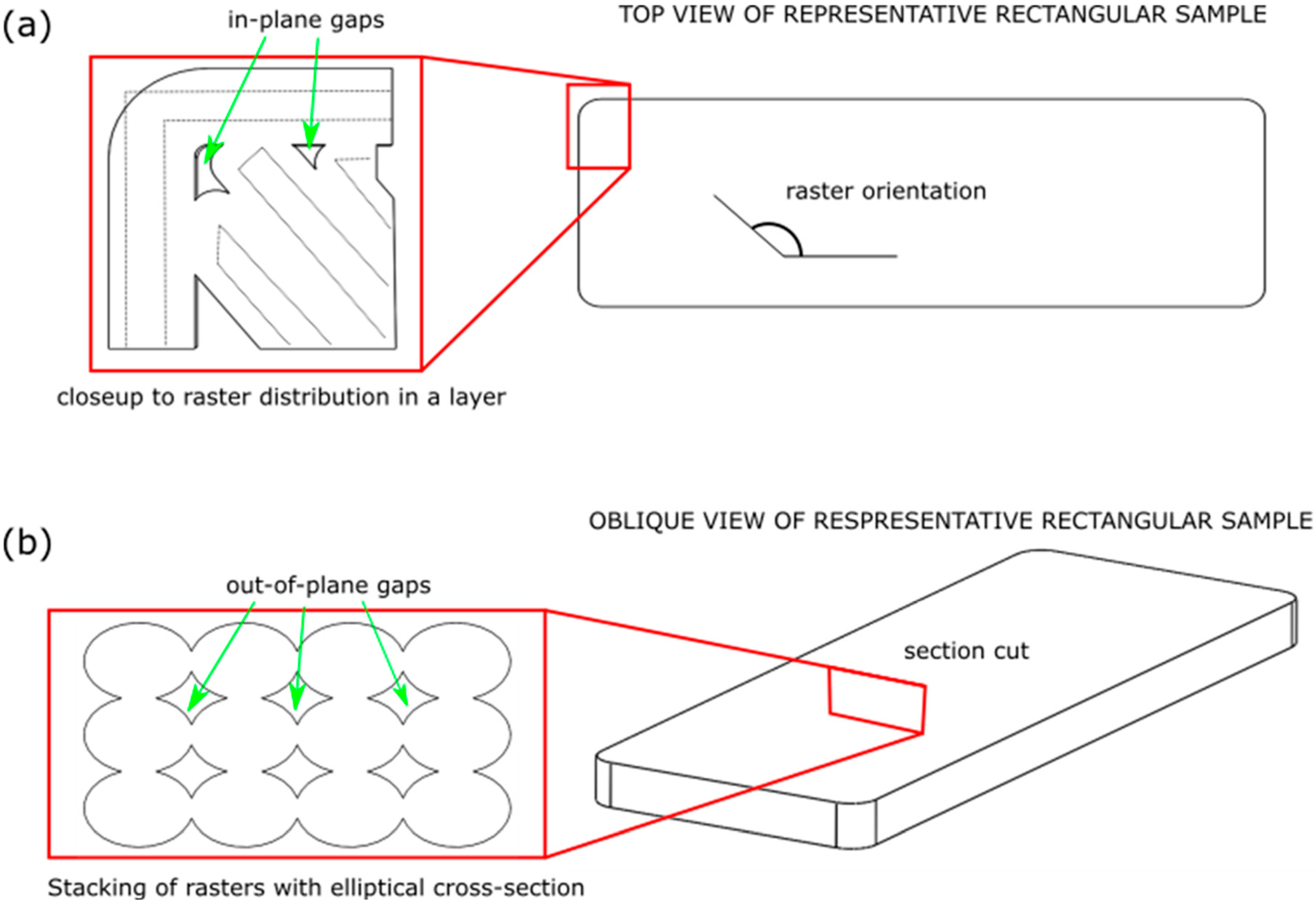

When mechanical properties show negligible differences while testing different material compositions, an alternative could be changing the printing parameters [17]. This can be achieved by manipulating the infill structure and density. The effects of infill density and topology on the texture of 3D-printed mashed potato have been determined by [18]. Minimal differences were observed when modifying the infill pattern type; this was attributed to the compressive testing direction of the samples. In this regard, consumer perception can be modified by changing printing parameters, as studied by [19], where chocolate samples were fabricated with different infill densities and compared against cast samples. The 100% filled samples resulted in lower forces at break than the casted samples (a difference of about 10 N). This demonstrates that, even when the infill percentage is set to its maximum, the extrusion raster direction and unavoidable porosity (Figure 2) affect the mechanical properties. Subsequently, reductions in the forces at break in the range of 2.6 to 1.6 times were obtained when reducing the infill percentage from 100% to 50% and 25%, respectively.

Figure 2. Inevitable porosity in parts fabricated using extrusion-based 3D-printing processes: (a) in-plane and (b) out-of-plane gaps.

Other authors presented a detailed study on mashed potato samples, where three different infill densities were tested, along with variations in contour rasters and infill patterns (Figure 2) [18]. Cylindrical samples were subjected to compression tests; as expected, a higher number of contour rasters or higher infill densities resulted in a higher measured Young’s modulus. 3D-printed samples were also compared with molded samples; even those that were printed with a 100% infill density resulted in lower properties than the molded samples. Differences obtained were in the range of 50 KPa. As mentioned, due to the nature of the process, even parts fabricated with a 100% infill density resulted in inevitable porosity. This porosity results mainly from two types of gaps: (i) in-plane gaps generated due to the impossibility of fully filling the layer (Figure 2a) and (ii) out-of-plane gaps resulting from the stacking of rasters with circular or elliptical cross-sections (Figure 2b) [20]. Additionally, differences between fully-dense printed parts and injected molded ones can be attributed to their anisotropy, inherent in parts fabricated with extrusion-based processes [3].

Finally, some authors have tested different compositions of potato by-products and yam on disc-like 3D-printed samples [21]. Samples 3D-printed with different infill densities (20%, 50%, and 80%) were subjected to three-point bending, and the PF was reported. Differences in the measured peak force were more significant for those measured at different values of infill densities (incrementing roughly 30 N for every increment in density of 30%) than the difference between different compositions (statistically insignificant in most of the cases).

3. Effect of Building Orientation

Yang et al. [9] evaluated the peak force, energy, and springiness of lemon juice gels containing potato starch (10–20 g/100 g) while keeping the printing parameters constant. As all samples were printed with the stacking direction parallel to the principal axis, differences in peak force measurements are only attributed to the composition of the base material. When a product has been 3D-printed by stacking the layers in the axis normal to the printing plate and is loaded in this same direction, the mechanical properties are governed by the local deformation at the bonding between layers.

Additionally, the anisotropy inherent in structures fabricated with extrusion-based techniques is still an open question for 3D-printed food. In order to fully characterize the mechanical properties, i.e., hardness, gumminess, strength, elasticity, and texture, testing should be performed along different directions of the printed samples [22]. A possible attempt to achieve isotropy, at least in the printing plate plane, could be achieved by making use of cellular materials [23]. Hexagonal honeycombs are known to have in-plane isotropy under specific conditions [24]. Some authors have printed pectin-based food simulants in hexagonal honeycombs structures, predicting the mechanical properties by an analytical model and finite element modeling [23]. In this work, the authors compared the structure features of the printed objects to those estimated by computational mechanical simulations and analytical models [24]. The effective Young’s modulus of the pectin-based samples showed a non-linear relationship with the geometrical parameters that defined the honeycomb; this is in agreement with what was predicted by [24].

When testing a 3D-printed air-fried potato snack along the stacking direction, the more the surface area of each layer was in contact with the previously extruded layer, the higher the hardness (peak force) measured in the samples [25]. Even with variations in infill pattern topology while keeping the infill density the same, the variations in peak force were minimal [25]. Changing the topology of the infill while keeping the density the same, the area of a single layer was almost the same as the previously deposited one. The influence of infill density may be more evident in the in-plane (building plane) properties [19][21].

4. Perspectives on the Mechanical Properties of 3D-Printed Food

The ideas exposed here allow the interested reader to form an idea of the vast parameters that can be modified to adjust the resulting mechanical properties. This is one of the advantages that characterize additive-manufactured parts (not only food). The mechanical properties that can be achieved depend upon the selection of the parameters. For example, two samples made of the same base material but tested or fabricated along direct directions result in different properties. Another example that may be encountered is having the same base material and different outer shapes and dimensions, leading to different mechanical properties. Hence, important insights need to be generated by this research that are applicable to 3D-printed food. Standards for the characterization of the mechanical properties of 3D printing food are not only a necessity but also an urgency. These standards should include not only testing setup but also manufacturing parameters.

Each work that publishes findings on the characterization of mechanical properties uses a different material (food) composition, fabricates samples with different shapes and dimensions, and tests under different conditions. Hence, a direct comparison among the data available in the literature yields inequitable results. Despite the fact that comparisons of the mechanical properties reported in different works are unfair, here Table 1 presents a summary of some of the recent works that include texture analyses. Note that a column that mentions the parameters varied and the shape of the samples is included. This is important for future research, as the properties reported are particular to these works, and readers must not take them as generalized properties, even if they use the same base materials and nutrients.

Table 1. Texture analyses performed in 3D food printed materials.

| Base Materials | 3D-Printing Parameter Studied | Properties Characterized | Shape of the Sample | Type of Test | Maximum and Minimum Values Reported | Reference |

|---|---|---|---|---|---|---|

| Protein bar with chocolate | Infill density, infill topology | ST, H, C, Ch | Square/prism | Compression | ST: 0.7–2 MPa, H: 200–400 N, C: 0.04–0.07, Ch: 0.5–2.3 N | [26] |

| Lemon juice gel | Nozzle diameter | H, SP, C, Gu | Cylindrical | Compression | H: 1.48–3.98 N, C: 0.65–0.94, SP: 0.85–0.94, Gu: 9.98–379.74 | [9] |

| Protein, starch, and fiber | Air pressure in extrusion | H | Square plate with lattice | Cutting | H: 2.9–59.8 N | [27] |

| Various gums | - | H, SP, C | Square/prism, cylindrical, and triangular | Compression | H: 1.72–2.94 N, SP: 0.75–0.9, C: 0.7–0.8 | [17] |

| Cereal based | - | H | Cylindrical with inner square structure | Compression | H: 20–52 N | [28] |

| Mashed potato | Infill density, infill topology, perimeters | H, Gu, ST | Cylindrical with infill patterns | Compression | H: 1.16–3.92, Gu: 30–150, ST: 0.0004–0.04 MPa | [18] |

| Chocolate | Infill density | H | Prismatic bars | Compression | H: 20–71 N | [19] |

| Cereal-based | Infill density, layer height | H | Cylindrical with inner square structure | Compression | H: 10–70 N | [15] |

ST: stiffness, H: hardness, C: cohesiveness, Ch: chewiness, SP: springiness, Gu: gumminess.

This entry is adapted from the peer-reviewed paper 10.3390/foods11091191

References

- Peleg, M. The instrumental texture profile analysis revisited. J. Texture Stud. 2019, 50, 362–368.

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the Mechanical Properties of FFF Structures and Materials: A Review on the Experimental, Computational and Theoretical Approaches. Materials 2019, 12, 895.

- Ahn, S.-H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257.

- Huang, M.-S.; Zhang, M.; Bhandari, B. Assessing the 3D printing precision and texture properties of brown rice induced by infill levels and printing variables. Food Bioprocess Technol. 2019, 12, 1185–1196.

- Liu, L.; Meng, Y.; Dai, X.; Chen, K.; Zhu, Y. 3D printing complex egg white protein objects: Properties and optimization. Food Bioprocess Technol. 2019, 12, 267–279.

- Liu, Y.; Liu, D.; Wei, G.; Ma, Y.; Bhandari, B.; Zhou, P. 3D printed milk protein food simulant: Improving the printing performance of milk protein concentration by incorporating whey protein isolate. Innov. Food Sci. Emerg. Technol. 2018, 49, 116–126.

- Le Tohic, C.; O’Sullivan, J.; Drapala, K.P.; Chartrin, V.; Chan, T.; Morrison, A.; Kerry, J.P.; Kelly, A.L. Effect of 3D printing on the structure and textural properties of processed cheese. J. Food Eng. 2018, 220, 56–64.

- Kim, H.W.; Bae, H.; Park, H.J. Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2017, 215, 23–32.

- Yang, F.; Zhang, M.; Bhandari, B.; Liu, Y. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT 2018, 87, 67–76.

- Azam, S.M.R.; Zhang, M.; Mujumdar, A.S.; Yang, C. Study on 3D printing of orange concentrate and material characteristics. J. Food Process Eng. 2018, 41, e12689.

- Dankar, I.; Haddarah, A.; Sepulcre, F.; Pujolà, M. Assessing Mechanical and Rheological Properties of Potato Puree: Effect of Different Ingredient Combinations and Cooking Methods on the Feasibility of 3D Printing. Foods 2020, 9, 21.

- Fernandez-Vicente, M.; Calle, W.; Ferrandiz, S.; Conejero, A. Effect of Infill Parameters on Tensile Mechanical Behavior in Desktop 3D Printing. 3D Print. Addit. Manuf. 2016, 3, 183–192.

- Yang, F.; Guo, C.; Zhang, M.; Bhandari, B.; Liu, Y. Improving 3D printing process of lemon juice gel based on fluid flow numerical simulation. LWT-Food Sci. Technol. 2019, 102, 89–99.

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Effect of additives on thermal, rheological and tribological properties of 3D printed dark chocolate. Food Res. Int. 2019, 119, 161–169.

- Severini, C.; Derossi, A.; Azzollini, D. Variables affecting the printability of foods: Preliminary tests on cereal-based products. Innov. Food Sci. Emerg. Technol. 2016, 38, 281–291.

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Optimization of chocolate 3D printing by correlating thermal and flow properties with 3D structure modeling. Innov. Food Sci. Emerg. Technol. 2017, 44, 21–29.

- Azam, R.S.M.; Zhang, M.; Bhandari, B.; Yang, C. Effect of Different Gums on Features of 3D Printed Object Based on Vitamin-D Enriched Orange Concentrate. Food Biophys. 2018, 13, 250–262.

- Liu, Z.; Bhandari, B.; Prakash, S.; Zhang, M. Creation of internal structure of mashed potato construct by 3D printing and its textural properties. Food Res. Int. 2018, 111, 534–543.

- Mantihal, S.; Prakash, S.; Bhandari, B. Texture-modified 3D printed dark chocolate: Sensory evaluation and consumer perception study. J. Texture Stud. 2019, 50, 386–399.

- Yasa, E.; Ersoy, K. Dimensional Accuracy and Mechanical Properties of Chopped Carbon Reinforced Polymers Produced by Material Extrusion Additive Manufacturing. Materials 2019, 12, 3885.

- Feng, C.; Zhang, M.; Bhandari, B.; Ye, Y. Use of potato processing by-product: Effects on the 3D printing characteristics of the yam and the texture of air-fried yam snacks. LWT-Food Sci. Technol. 2020, 125, 109265.

- Lipton, J.I.; Lipson, H. 3D Printing Variable Stiffness Foams Using Viscous Thread Instability. Sci. Rep. 2016, 6, 29996.

- Vancauwenberghe, V.; Delele, M.A.; Vanbiervliet, J.; Aregawi, W.; Verboven, P.; Lammertyn, J.; Nicolaï, B. Model-based design and validation of food texture of 3D printed pectin-based food simulants. J. Food Eng. 2018, 231, 72–82.

- Gibson, L.J.; Ashby, M.F.; Schajer, G.S.; Robertson, C.I. The mechanics of two-dimensional cellular materials. Proc. R. Soc. A Math. Phys. Eng. Sci. 1982, 382, 25–42.

- Liu, Z.; Dick, A.; Prakash, S.; Bhandari, B.; Zhang, M. Texture Modification of 3D Printed Air-Fried Potato Snack by Varying Its Internal Structure with the Potential to Reduce Oil Content. Food Bioprocess Technol. 2020, 13, 564–576.

- Zhu, S.; de Azua, I.V.R.; Feijen, S.; van der Goot, A.J.; Schutyser, M.; Stieger, M. How macroscopic structure of 3D printed protein bars filled with chocolate influences instrumental and sensory texture. LWT-Food Sci. Technol. 2021, 151, 112155.

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27.

- Severini, C.; Azzollini, D.; Albenzio, M.; Derossi, A. On printability, quality and nutritional properties of 3D printed cereal based snacks enriched with edible insects. Food Res. Int. 2018, 106, 666–676.

This entry is offline, you can click here to edit this entry!