Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Due exceptional properties such as its high-temperature resistance, mechanical characteristics, and relatively lower price, the demand for carbon fiber has been increasing over the past years. The widespread use of carbon-fiber-reinforced polymers or plastics (CFRP) has attracted many industries.

- carbon fiber-reinforced polymer composites

- pure carbon fiber

1. Polylactide (PLA)

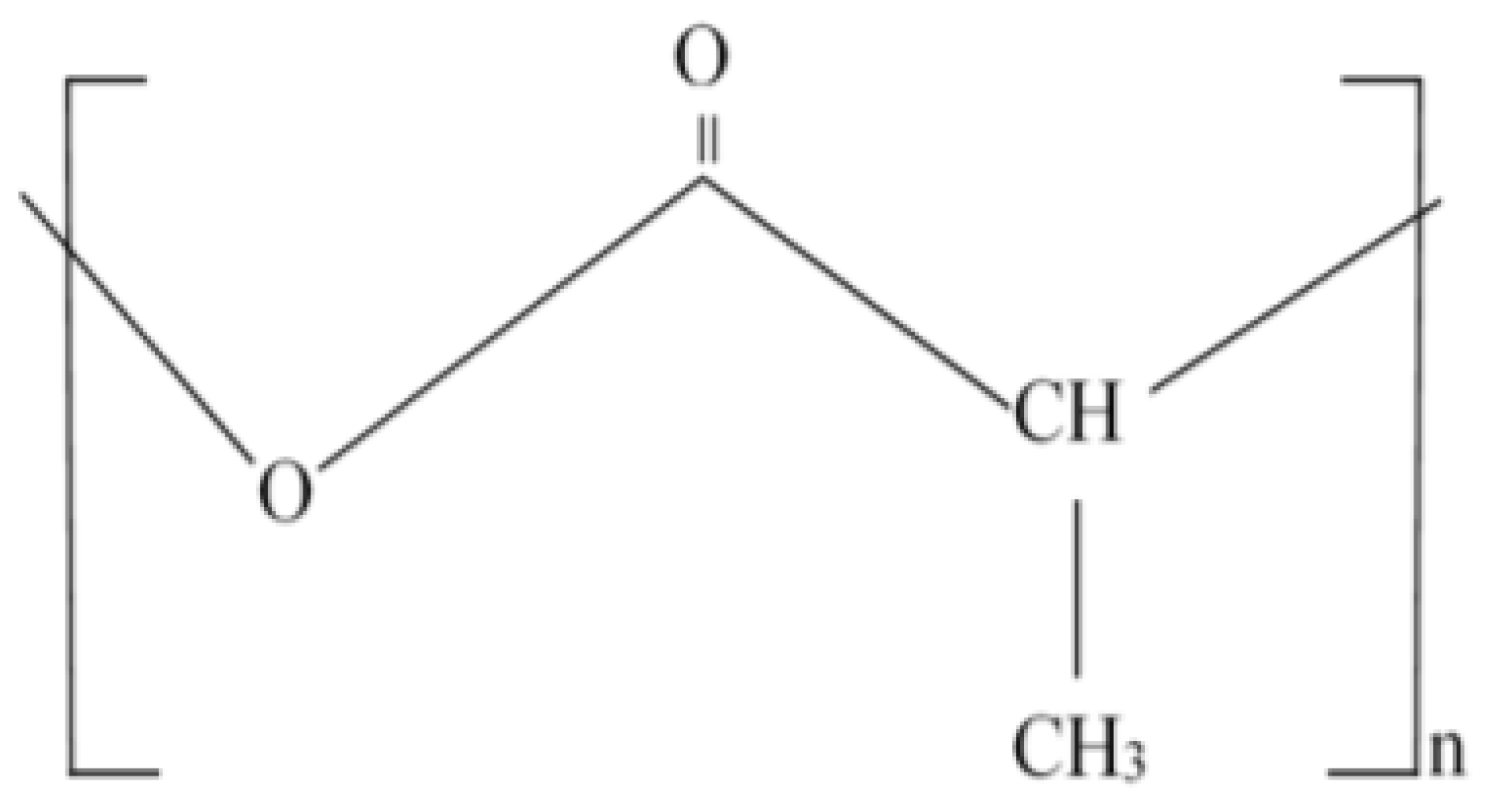

Polylactide (PLA), one of the bio-based polymers used as shown in Figure 1, is a biodegradable polymer utilized in a wide range of applications including automation, packaging, and 3D printing. Because it is easily available and convenient, polylactic acid PLA is an ideal candidate for a polymeric material; yet it lacks thermal and mechanical stability. PLA is predicted to break down at a temperature of around 400 degrees Celsius. However, because of its limited thermal stability, recycling the material and extracting valuable components from the matrices is time-consuming [1].

Figure 1. Chemical Structure of Polylactide Acid.

Polylactic acid (PLA) is an aliphatic polyester. Carothers DuPont discovered PLA in 1932 by heating lactic acid under a vacuum. PLA has piqued the interest of researchers over the last two decades due to its superior processability and characteristics when compared to other biodegradable polymers. Pre-preg is a composite material composed of “pre-impregnated” fibers and partly cured polymer matrices, including epoxy or epoxy resins, or a thermoplastic combined with fluid elastomers or resin [2][3]. PLA has been widely electrospun—pure PLA, PLA blends, and their nanocomposites created with metals, metal oxides, and carbon nanotubes—to control its functionality concerning end purposes, making it superior to petroleum-based polymers such as polyethylene (PE), polypropylene (PP), polystyrene (PS), polycarbonate (PC), and polyethylene terephthalate (PET) [4]. Due to the substantially inadequate mechanical performance of pure thermoplastic material like PLA [5], the mechanical properties can be improved by adding reinforcement material such as continuous carbon fiber (CCF) to the thermoplastic matrix to form a continuous carbon fiber reinforced polymer composite (CCFRPC), which could be used in different engineering applications, such as 3D printing. The reinforcement of natural fibers with biopolymers is an efficient technique to develop composites that are fully biodegradable [6], by incorporation of various percentages of untreated and alkali-treated Coir Fibers (CF) and pineapple leaf fibers (PALF) in PLA biocomposites and characterizations of flexural, morphological, and dynamic mechanical properties that will provide attractive consideration of these hybrid biocomposites for various lightweight uses in a broad selection of industrial applications. Unidirectional flax fabrics were used to reinforce poly(lactic acid) (PLA). Flax/PLA composites were produced by thermo-compression using as-received flax fibers and titanium dioxide (TiO2) coated flax fibers [7], to investigate the effect of annealing temperature and time, under quiescent or mechanical stress conditions, on the microstructure, interfacial adhesion, crystallization, and mechanical properties of composites.

The development of creative ways for generating sustainable solutions for manufacturing items with high durability, longer shelf-life, and quality retention after recycling is required by the goal of the plastic economy. Additionally, the effective recycling of the plastics and the multi-layer plastics is considered challenging due to their composite nature [8]. For such cases, mechanical recycling is more resource-efficient; however, it is limited to exposure to harmful substances included in the recycling process as compared to incineration and chemical recycling. To reuse the recycled materials, 3D printing can be used [9].

Commercial PLA degrades slowly under natural settings because its continued existence may harm the ecosystem. Moreover, discarding the PLA due to slow natural degradation is not a wise choice due to the loss of many useful compounds such as the hydroxyl group [10]. Therefore, customized settings of the important parameters in this regard are necessary for the degradation of PLA [11]. Furthermore, throwing out PLA can result in the loss of essential components such as hydroxyl groups. As a result, recycling PLA is crucial to limiting the use of renewable resources for such monomers [12].

PLA recycling is greatly desired because it may be used to generate environmental compatibilizers that can be utilized to improve composite products made from PLA, preserving the material’s eco-friendliness. PLA-based composites with natural fiber have numerous applications due to their easy processing, low toxicity, high mechanical strength, etc., making the need for sustainable recycling of these materials an effective need of a sustainable environment [12]. Furthermore, because PLA is substantially heavier than other commodity polymers (e.g., high-density polyethylene (HDPE)), and low-density polyethylene (LDPE), it can be easily separated based on density, making polymer retention very useful [13].

2. Carbon Fiber Reinforced Polymers (CFRP)

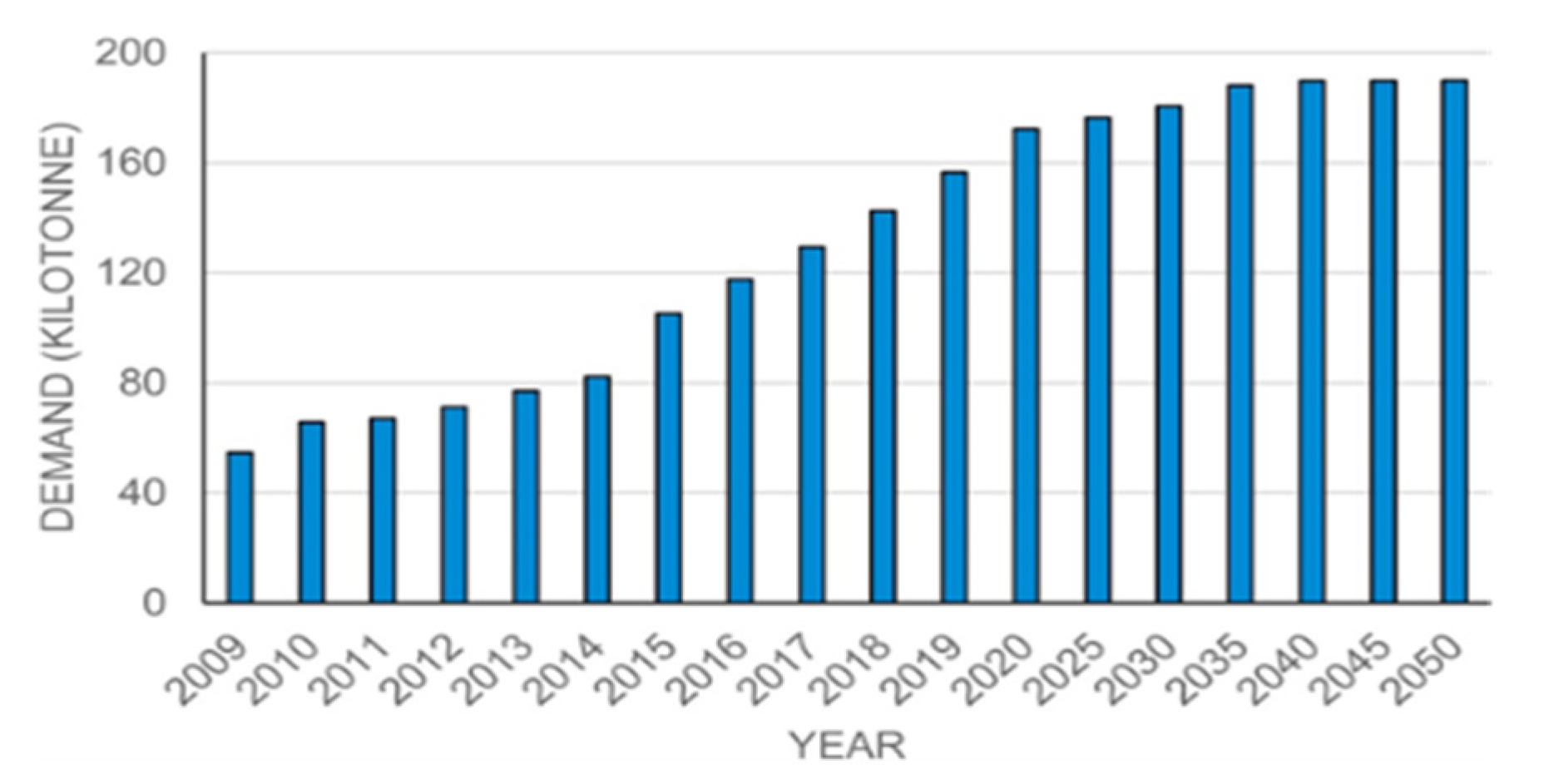

Carbon fiber reinforced polymers or plastics (CFRP) are gaining popularity owing to their wide range of applications in industries such as aviation, military, vehicle manufacturing, transportation, architecture, sports industries, and medicine [14][15]. Carbon fibers were initially created in the 1960s, and by 2006, almost 27,000 tons of carbon fibers were being produced worldwide, with that figure expected to rise to 140,000 tons by 2020 [16]. Carbon fiber demand has increased by 15% each year over the last few years, as shown in Figure 2. Therefore, the increasing demand for Carbon Fiber Reinforced Polymers (CERP) is also considered necessary due to the increasing consumption of plastic, which leads to increased plastic waste, thereby resulting in the growing demand for better and more efficient recycling [17][18][19][20][21].

Figure 2. Increasing Carbon Fiber demand over the Years [6].

Furthermore, no expensive equipment or consumables are needed, and low-skilled labor is sufficient to manufacture the parts, further reducing costs [22][23]. As a result, due to high material and manufacturing costs, upcycling waste core material has the potential to expose new products, processes, and markets for composites that were formerly unattainable to virgin composites. To counter this, the extrusion process is presented as a viable solution that assists in the degradation of polythene, making its recycling more feasible [23]. The suggested techniques may easily generate a range of flat and curved product shapes from scrap prepreg, and demonstrator components back up this assertion [24].

The parts include a curved section, a prototype RSRF prosthetic ankle/foot, and a typical hat stiffening panel [25]. Additional demonstration parts, including tubes, flat panels, and sandwich panels, have been created in the lab of United Arab Emirates University under the Department of Chemical and Petroleum Engineering [26][27].

Scrap prepreg can be used to make structural design parts that can be used to construct larger structures. Thin and thick panels, cylinders, sandwich structures with honeycomb or foam cores, hat stiffeners, and even scrap prepreg with a variety of types of fiber and resins, such as glass, carbon, and Kevlar fibers with diverse composites, have all been combined in the same part [28]. The components based on CF/epoxy have maximum expected application in the construction, both indoor and outdoor furnishing, and building structures due to their durability against humidity and the least vulnerability to insect invasion [29]. The CF/epoxy’s components are durable in the presence of humidity, and it is a great material for interior and external furnishings, as well as a basic building element because it has a low insect invasion. Container ships, which are currently composed of denser materials such as aluminum, worn steel, and wood, could benefit from the usage of prepreg trash [30].

Green environmental legislation and worldwide regulations have compelled researchers to investigate several strategies for recycling CFRP trash. However, this is difficult because the heat-stable matrices of CFRP do not melt with heating. The techniques other than heating are considered less viable due to their complex procedures. Thermo-mechanical recycling, therefore, is investigated by many researchers all around the globe as the optimum method in such a scenario [31]. Thermoset polymers are employed as matrices in structural CFRPs, accounting for about 80% of polymer composites. Mechanical strength, durability, chemical, and thermal resistance, and dimensional stability are all advantages of this material. However, because processed thermoset polymers are crosslinked, recovering the fibers is challenging as they cannot be easily heated, shaped, processed, or re-crosslinked following treatment [32]. Recycling CFRP trash reduces greenhouse-gas emissions associated with CFRP waste while also providing an inexpensive option to make high-value carbon fibers. By 2030, 6000–8000 business-related aircraft will have reached the end of their useful lives. As a result, there is an urgent need to create effective and sustainable waste management and recycling techniques for CFRPs [33].

2.1. Recycling Techniques

CFRP trash is disposed of and burned at landfills. Different techniques such as incineration, laser-based burning, etc., are employed by different public and private sectors according to the quantity of disposal, resources available, and the applications desired [34]. Several nations have adopted landfill taxes in an attempt to reduce trash disposal, as well as material recycling, such as CFRP waste. CFRP waste recycling entails not only recycling carbon fiber but also using recovered carbon fibers (rCFs) in the manufacturing of new material. Therefore, the quality alongside the quantity of the recovered or recycled carbon fiber is required as an important parameter not only for the process of recycling but also for the further application of the recycled product [35].

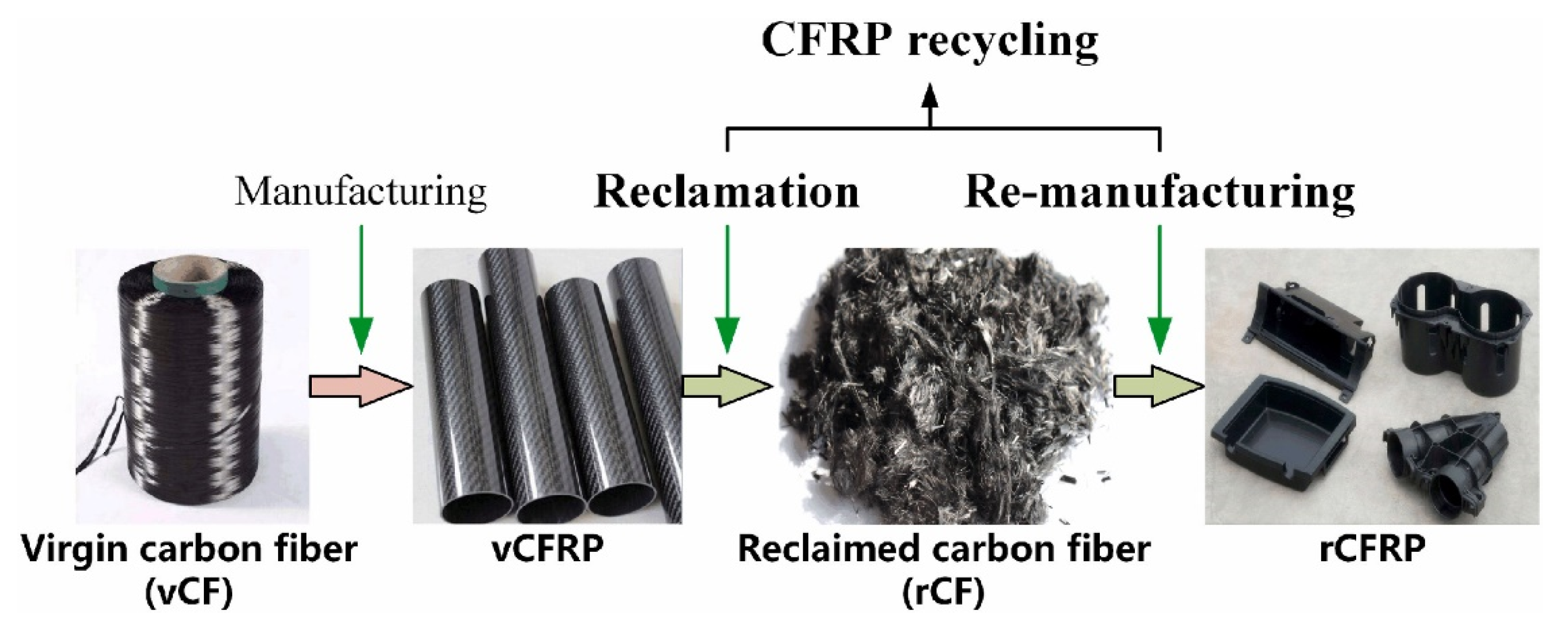

According to an article published in 2005 by Keiji Ogi, “As far as the authors know, products employing recycled CFRP have not been disclosed although some research may be undertaken in laboratories. As a result, no recycling system for CFRP wastes has been built around the globe thus far.” However, several uses have been developed since that time to properly utilize CFRP waste. Generally, recycling CFRP is divided into two stages: first, reclamation of carbon fibers from CFRP waste, then production of rCF reinforced polymer (rCFRP) as demonstrated in Figure 3 [36][37].

Figure 3. Recycling Process from Virgin Carbon Fiber to CFRP.

2.2. Mechanical Method

Mechanical recycling is the most common method of recycling CFRP [38]. This approach consists of multiple procedures for reducing waste quantity. Initially, the CFRP is chopped to a size of 50–100 mm, and then additional grinding is employed to provide a range of properties ranging from ash to fibrous [39][40]. Damage to processing equipment caused by CFRP recycling procedures raises recycling operating costs, reducing the economic margin of recycling products. The mechanical procedure is risk-free and may be finished at room temperature. This method can hold debris up to 50 mm and attain 50–65% of the tensile strength of fresh carbon fibers. The most serious risk for this method is the dust generated by the recycling mechanism [41][42][43][44][45][46][47][48][49][50][51][52].

Fused Filament Fabrication (FFF) is considered one of the latest and most effective Additive Manufacturing techniques with high expectations of sustainable manufacturing, but the mechanical properties of polymers manufactured using this method are considerably lower than those manufactured by the traditional methods. Therefore, mechanical methods of recycling can be used for such processes [53].

2.3. Pyrolysis

Pyrolysis is the thermal breakdown of polymers in the absence of oxygen in the atmosphere (300 °C to 800 °C), allowing the fibers to rebound with a high modulus. A greater temperature (around 1000 °C) can be employed, but this would result in mechanical property degradation. Carbon fibers derived from pyrolysis retained 90 percent of their original mechanical strength, according to studies. Pyrolysis is also used for the investigation of the types of binding materials used in the polymeric materials available in modern paints as implemented in the research of multi-analytical analysis of the “Orange Car Crash” study [54]. Furthermore, the polymeric framework has the potential to be utilized as oil droplets of liquid hydrocarbons. The pyrolysis method is recognized as a long-term CFRP recycling process [55].

2.4. Chemical Method

Several solvents are used in the chemical process to break down polymer resin and separate it from carbon fibers. Chemical recycling can recover high-quality carbon-6 fibers with a tensile strength of 98.9%. According to the latest stats, recycling CFRP with the chemical technique consumes 38.4 MJ/kg of energy, which is nearly equivalent to 10–30% of the total energy required to manufacture new fibers. Although [56][57][58][59][60] the chemical approach is feasible, the treatment temperature, solvents, and equipment have negative environmental consequences.

This entry is adapted from the peer-reviewed paper 10.3390/polym14112194

References

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282.

- Cheng, H.; Guo, L.; Qian, Z.; Sun, R.; Zhang, J. Remanufacturing of recycled carbon fiber-reinforced composites based on fused deposition modeling processes. Int. J. Adv. Manuf. Technol. 2021, 116, 1609–1619.

- Pakdel, E.; Wang, J.; Varley, R.; Wang, X. Recycled carbon fiber nonwoven functionalized with fluorine-free superhydrophobic PDMS/ZIF-8 coating for efficient oil-water separation. J. Environ. Chem. Eng. 2021, 9, 106329.

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618.

- Maqsood, N.; Rimašauskas, M. Characterization of carbon fiber reinforced pla composites manufactured by fused deposition modeling. Compos. Part C Open Access 2021, 4, 100112.

- Siakeng, R.; Jawaid, M.; Asim, M.; Fouad, H.; Awad, S.; Saba, N.; Siengchin, S. Flexural and dynamic mechanical properties of alkali-treated coir/pineapple leaf fibres reinforced polylactic acid hybrid biocomposites. J. Bionic Eng. 2021, 18, 1430–1438.

- Bayart, M.; Foruzanmehr, M.R.; Vuillaume, P.Y.; Ovlaque, P.; Robert, M.; Elkoun, S. Poly(lactic acid)/flax composites: Effect of surface modification and thermal treatment on interfacial adhesion, crystallization, microstructure, and mechanical properties. Compos. Interfaces 2022, 29, 17–36.

- Bonadies, I.; Capuano, R.; Avolio, R.; Castaldo, R.; Cocca, M.; Gentile, G.; Errico, M.E. Sustainable Cellulose-Aluminum-Plastic Composites from Beverage Cartons Scraps and Recycled Polyethylene. Polymers 2022, 14, 807.

- Fong, K.; Mariatti, M.; Takagi, H. Effect of Matrix and Staking Sequence of Recycled Jute/Carbon Fiber Hybrid Laminated Composites. J. Polym. Mater. 2012, 29, 437–449.

- Rihayat, T.; Hadi, A.E.; Aidy, N.; Safitri, A.; Siregar, J.P.; Cionita, T.; Irawan, A.P.; Hamdan, M.H.M.; Fitriyana, D.F. Biodegradation of Polylactic Acid-Based Bio Composites Reinforced with Chitosan and Essential Oils as Anti-Microbial Material for Food Packaging. Polymers 2021, 13, 4019.

- Ramos, M.; Fortunati, E.; Beltrán, A.; Peltzer, M.; Cristofaro, F.; Visai, L.; Valente, A.J.M.; Jiménez, A.; Kenny, J.M.; Garrigós, M.C. Controlled Release, Disintegration, Antioxidant, and Antimicrobial Properties of Poly (Lactic Acid)/Thymol/Nanoclay Composites. Polymers 2020, 12, 1878.

- Liu, W.; Huang, H.; Zhu, L.; Liu, Z. Integrating carbon fiber reclamation and additive manufacturing for recycling CFRP waste. Compos. Part B Eng. 2021, 215, 108808.

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202.

- Han, H.; Wang, X.; Wu, D. Preparation, crystallization behaviors, and mechanical properties of biodegradable composites based on poly (L-lactic acid) and recycled carbon fiber. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1947–1958.

- Puscaselu, G.R.; Besliu, I.; Gutt, G. Edible Biopolymers-Based Materials for Food Applications—The Eco Alternative to Conventional Synthetic Packaging. Polymers 2021, 13, 3779.

- Tian, X.; Liu, T.; Wang, Q. Manufacturing and recycling of 3d printed continuous carbon fiber reinforced PLA composites. In Proceedings of the International Conference on Composite Materials 2017, Xi’an, China, 20 August 2017.

- Meng, F.; McKechnie, J.; Turner, T.; Wong, K.H.; Stephen, J. PickeringEnvironmental aspects of use of recycled carbon fiber composites in automotive applications. Environ. Sci. Technol. 2017, 51, 12727–12736.

- Song, C.; Wang, F.; Liu, Y.; Wang, X.; Yang, B. Recycling carbon fiber from composite waste and its reinforcing effect on polyvinylidene fluoride composite: Mechanical, morphology, and interface properties. Polym. Compos. 2017, 38, 2544–2552.

- Shehab, E.; Meiirbekov, A.; Amantayeva, A.; Suleimen, A.; Tokbolat, S.; Sarfraz, S. A Cost Modelling System for Recycling Carbon Fiber-Reinforced Composites. Polymers 2021, 13, 4208.

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled glass fiber composites from wind turbine waste for 3D printing feedstock: Effects of fiber content and interface on mechanical performance. Materials 2019, 12, 3929.

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768.

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent progress in recycling carbon fibre reinforced composites and dry carbon fibre wastes. Resour. Conserv. Recycl. 2021, 166, 105340.

- Nie, W.; Liu, J.; Liu, W.; Wang, J.; Tang, T. Decomposition of waste carbon fiber reinforced epoxy resin composites in molten potassium hydroxide. Polym. Degrad. Stab. 2015, 111, 247–256.

- Castéran, F.; Delage, K.; Hascoët, N.; Ammar, A.; Chinesta, F.; Cassagnau, P. Data-Driven Modelling of Polyethylene Recycling under High-Temperature Extrusion. Polymers 2022, 14, 800.

- Takagi, H.; Kako, S.; Kusano, K.; Ousaka, A. Thermal conductivity of PLA-bamboo fiber composites. Adv. Compos. Mater. 2007, 16, 377–384.

- Matsuzaki, R.; Nakamura, T.; Sugiyama, K.; Ueda, M.; Todoroki, A.; Hirano, Y.; Yamagata, Y. Effects of set curvature and fiber bundle size on the printed radius of curvature by a continuous carbon fiber composite 3D printer. Addit. Manuf. 2018, 24, 93–102.

- Wang, W. Preparation and Study on Mechanical Properties of Waste Blended Fibers/PLA Composites. China Plast. Ind. 2011, 11, 95–96.

- Wang, P.; Sterkenburg, R.; Kim, G.; He, Y. Investigating the Fiber Content, Fiber Length, and Curing Characteristics of 3D Printed Recycled Carbon Fiber. Int. J. Mater. Metall. Eng. 2019, 13, 161–164.

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542.

- Starkova, O.; Platnieks, O.; Sabalina, A.; Gaidukovs, S. Hydrothermal Ageing Effect on Reinforcement Efficiency of Nanofibrillated Cellulose/Biobased Poly(butylene succinate) Composites. Polymers 2022, 14, 221.

- Sadef, Y.A.; Nizami, S.; Batool, S.A.; Chaudary, M.N.O.; Ouda, K.M.Z.; Asam, Z.K.; Habib, M.; Rehan, A. Waste-to-energy and recycling value for developing integrated solid waste management plan in Lahore. Energy Sources Part B Econ. Plan. Policy 2016, 11, 569–579.

- Di Mauro, C.; Genua, A.; Mija, A. Kinetical Study, Thermo-Mechanical Characteristics and Recyclability of Epoxidized Camelina Oil Cured with Antagonist Structure (Aliphatic/Aromatic) or Functionality (Acid/Amine) Hardeners. Polymers 2021, 13, 2503.

- Feng, N.; Wang, X.; Wu, D. Surface modification of recycled carbon fiber and its reinforcement effect on nylon 6 composites: Mechanical properties, morphology and crystallization behaviors. Curr. Appl. Phys. 2013, 13, 2038–2050.

- Math, R.K.; Goutham, R.; Prasad, K.S. Study of Effects on Mechanical Properties of PLA Filament which is blended with Recycled PLA Materials. In IOP Conference Series: Materials Science and Engineering 2018; IOP Publishing: Bristol, UK, 2018.

- Karuppannan Gopalraj, S.; Deviatkin, I.; Horttanainen, M.; Kärki, T. Life Cycle Assessment of a Thermal Recycling Process as an Alternative to Existing CFRP and GFRP Composite Wastes Management Options. Polymers 2021, 13, 4430.

- Alshammari, B.A.; Alsuhybani, M.S.; Almushaikeh, A.M.; Alotaibi, B.M.; Alenad, A.M.; Alqahtani, N.B.; Alharbi, A.G. Comprehensive Review of the Properties and Modifications of Carbon Fiber-Reinforced Thermoplastic Composites. Polymers 2021, 13, 2474.

- Awadallah, M.; Tawadros, P.; Walker, P.; Zhang, N. Comparative fuel economy, cost and emissions analysis of a novel mild hybrid and conventional vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 1846–1862.

- Bank, T.; Klamor, S.; Sauer, D.U. Lithium ion cell requirements in a real-world 48 v system and implications for an extensive aging analysis. J. Energy Storage 2020, 30, 101465.

- Capuano, R.; Bonadies, I.; Castaldo, R.; Cocca, M.; Gentile, G.; Protopapa, A.; Avolio, R.; Errico, M.E. Valorization and Mechanical Recycling of Heterogeneous Post-Consumer Polymer Waste through a Mechano-Chemical Process. Polymers 2021, 13, 2783.

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Martínez-Boggio, S. Optimization of the parallel and mild hybrid vehicle platforms operating under conventional and advanced combustion modes. Energy Convers. Manag. 2019, 190, 73–90.

- Bitsche, O.; Gutmann, G. Systems for hybrid cars. J. Power Sources 2004, 127, 8–15.

- Bubeck, S.; Tomaschek, J.; Fahl, U. Perspectives of electric mobility: Total cost of ownership of electric vehicles in Germany. Transp. Policy 2016, 50, 63–77.

- Fico, D.; Rizzo, D.; Casciaro, R.; Esposito Corcione, C. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465.

- Burke, A.; Liu, Z.; Zhao, H. Present and future applications of supercapacitors in electric and hybrid vehicles. In Proceedings of the 2014 IEEE International Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014.

- Burke, A.F. Batteries and ultracapacitors for electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 806–820.

- Capata, R. Experimental Fitting of Redesign Electrified Turbocompressor of a Novel Mild Hybrid Power Train for a City Car. Energies 2021, 14, 6516.

- Giuliani, C.; Pascucci, M.; Riccucci, C.; Messina, E.; Salzano de Luna, M.; Lavorgna, M.; Maria Ingo, G.; Di Carlo, G. Functionalized chitosan-based coatings for active corrosion protection. Surf. Coat. Technol. 2013, 226, 51–59.

- Carneiro, J.; Tedim, J.; Ferreira, M. Chitosan as a smart coating for corrosion protection of aluminum alloy 2024: A review. Prog. Org. Coat. 2015, 89, 348–356.

- Chauhan, D.S.; Srivastava, V.; Joshi, P.G.; Quraishi, M.A. PEG cross-linked chitosan: A biomacromolecule as corrosion inhibitor for sugar industry. Int. J. Ind. Chem. 2018, 9, 363–377.

- Chauhan, D.S.; Mazumder, J.; Quraishi, M.A.; Ansari, K.R. Chitosan-cinnamaldehyde Schiff base: A bioinspired macromolecule as corrosion inhibitor for oil and gas industry. Int. J. Biol. Macromol. 2020, 158, 127–138.

- Chauhan, D.S.; Mazumder, J.; Quraishi, M.A.; Ansari, K.R.; Suleiman, M.A. Microwave-assisted synthesis of a new Piperonal-Chitosan Schiff base as a bio-inspired corrosion inhibitor for oil-well acidizing. Int. J. Biol. Macromol. 2020, 158, 231–243.

- Chauhan, D.S.; Mazumder, J.; Quraishi, M.A.; Bazzi, L. Aminotriazolethiol-functionalized chitosan as a macromolecule-based bioinspired corrosion inhibitor for surface protection of stainless steel in 3.5% NaCl. Int. J. Biol. Macromol. 2020, 152, 234–241.

- Chein, R.; Huang, G. Thermoelectric cooler application in electronic cooling. Appl. Therm. Eng. 2004, 24, 2207–2217.

- Pintus, V.; Baragona, A.J.; Cappa, F.; Haiml, C.; Hierl, C.; Sterflinger, K.; Schreiner, M. Multi-Analytical Investigations of Andy Warhol’s “Orange Car Crash”: Polymeric Materials in Modern Paints. Polymers 2022, 14, 633.

- Chen, W.-H.; Liao, C.-Y.; Hung, C.-I. A numerical study on the performance of miniature thermoelectric cooler affected by Thomson effect. Appl. Energy 2012, 89, 464–473.

- Cho, B. Control of a Hybrid Electric Vehicle with Predicitive Journey Estimation. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2008.

- Da Silva, L.W.; Kaviany, M. Micro-thermoelectric cooler: Interfacial effects on thermal and electrical transport. Int. J. Heat Mass Transf. 2004, 47, 2417–2435.

- Dahmani, L.; Khennane, A.; Kaci, S. Crack identification in reinforced concrete beams using ANSYS software. Strength Mater. 2010, 42, 232–240.

- Macedo, R.G.M.d.A.; Marques, N.d.N.; Tonholo, J.; Balaban, R.d.C. Water-soluble carboxymethylchitosan used as corrosion inhibitor for carbon steel in saline medium. Carbohydr. Polym. 2019, 205, 371–376.

- Eduok, U.; Ohaeri, E.; Szpunar, J.; Akpan, I. Synthesis, characterization and application of glucosyloxyethyl acrylate graft chitosan against pipeline steel corrosion. J. Mol. Liq. 2020, 315, 113772.

This entry is offline, you can click here to edit this entry!