Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The recycling potential (RP) indicates the ability of building materials to form a closed-loop material flow, that is, the material efficiency during its whole life cycle. Mass timber constructions and concrete buildings vary widely in RP, but the differences are difficult to calculate.

- mass timber construction

- recycling potential

- material recycling

1. Mass Timbers and Mass Timber Construction

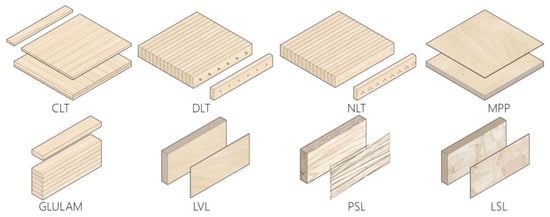

The definition of mass timber is still open to debate. In the 2018 Manual of Multistory Timber Construction, construction timber was divided into solid wood products and wood-based materials [1]. In the 2021 international mass timber report, several distinct mass timber products were included in the category. Many people confuse Engineered Wood Products (EWPs) with mass timber, when in fact mass timber is a distinct class of EWPs. Researchers argue that mass timbers belong to engineered wood products, which are building structural materials produced by finger-joint, gluing, pressing, etc., commonly including Cross Laminated Timber (CLT), Dowel Laminated Timber (DLT), Nail Laminated Timber (NLT), Mass Ply Panel (MPP), and other panel structural materials suitable for roofing and floors, also including Glued Laminated Timber (GLULAM), Laminated Veneer Lumber (LVL), Parallel Strand Lumber (PSL), Laminated Strand Lumber (LSL), and other structural materials suitable for beams and columns (Figure 1). Among them, CLT is composed of three or more layers of small-sized sawn timber or wood-based materials, which are pressed and glued in an orthogonal arrangement. It is one of the most promising mass timbers, which has a long refractory time, high strength-to-weight ratio, and is widely used [2].

Figure 1. Main species of mass timber.

Mass timber construction is a building structure system with mass timber as the main load-bearing component. In the past 30 years, the research on mass timber construction has shown a rapid upward trend, and the main research direction is Life Cycle Assessment (LCA) [3] and building performance, including fire resistance [4], earthquake resistance [5], thermal insulation [6], insect control [7], etc.

Mass timber construction in China is at an early stage of development. In the past ten years, in order to promote the green and low-carbon development of cities, China has introduced a number of policies to vigorously develop modern wood structures, and organized the construction of demonstration projects for the application of high-rise wood structure building technologies. Although the CLT system has not been well adopted and there are only a few pilot projects for scientific research, there is growing interest in CLT. In 2017, the Ministry of Housing and Urban-Rural Development of China issued a regulation on timber construction and published a new building code (GB/T 51226-2017). The regulation extended the height of timber buildings to 56 m or no more than 18 storeys in non-seismic regions. It can be expected that the timber buildings in China will develop rapidly over the next few decades.

2. Recycling Potential of Materials, Components, and Buildings

A detailed data set of materials is one of the most important cornerstones of the transition from a linear flow to a closed-loop material flow. Thus, the concepts of Material Passport (MP), Material Cycle Status (MCS), etc. have emerged. Material Passport refers to keeping a record of the material composition of a product or building through detailed information about quantities such as weight, volume, dimensions, and location [8], which usually involves the steps of data generation and input into the database, the consequent generation of materials passports, and a Circularity Index [9]. Madaster is a materials passport platform, which can conduct the circularity indicator for construction, as well as generate, store, and manage individual building portfolios. This documentation system is suitable for the evaluation of completed buildings and the continuous follow-up of material resources during the operation phase [10]. Ellen MacArthur Foundation and Granta Design developed the material circularity indicator (MCI), which gives an indication of how much of the materials constitute a product circulate. It is able to measure the level of linear and restorative flows. Moreover, it provides information about the utility of a product. Annette Hillebrandt from Universität Wuppertal summarized the Material Cycle Status of various building materials in 2019 [11], using three bars, the Material Recycling Content (MRC), Material Loop Potential (MLP), and Material End of Life (MEoL), to illustrate the recycling prospects of materials. The recycling prospects are separated into seven scenarios that can describe the material flow of a specific product or material in detail with the information from manufacturers’ specifications, German Federal Government statistics, environmental product declarations, etc. This parameter is calculated based on the type of building materials and the actual situation of recycling, which can more intuitively reflect the RP of the building material level. There are also some recycling indicators in other material databases. These parameters generally serve the end of life stage of LCA, and will specify the recyclable mass ratio according to the material recycling status in different countries or regions.

The RP of components is affected by the composition of components and the ease of material separation. Felix Heisel described the process of documenting materials and products utilized in the construction of the Urban Mining and Recycling unit within the Madaster platform. He explored the method of assessing the potential of circularity indicators, the process of which involves the building material/product level and the building element level [9]. Gaochuang Cai et al. proposed a material and component bank to manage more effectively the recycling of materials and direct reuse of components, which combined with the current building information modeling, design for deconstruction, supply chain, and LCA [12]. Lukman A. Akanbi et al. developed a disassembly and deconstruction analytics system, which would ensure that buildings are designed with DFD principles that guarantee efficient materials recovery in mind [13]. D Schwede et al. developed a scientific method for analyzing recyclability in detail that takes joining techniques into account. The ILEK RecyclingGraph Editor described structural element in recycling graphs whose components represent their material elements and connections. To identify the best form of recycling, materials are each classified on a five-level scale based on a system developed by the Austrian Institute for Healthy and Ecological Building [14].

For the RP of buildings, so far, building certification systems tend to rate recycling aspects mostly in terms of quality, especially those related to the environmental impact of material recycling in the end of life stages of LCA [15]. In recent years, the research on material recycling in the early stage of building design has a raised trend. Thormark expressed the RP of a building as the amount of embodied energy and natural resources used in a building that could be made usable through recycling after demolition. Results show that the embodied energy was 40% of the total energy of the building, which can be approximately decreased by about 17% and increased by 6% through the substitution of different materials [16]. In another study, Thormark estimated the energy usage from a building life cycle and concluded that about 37–42% of the embodied energy used in buildings can be recovered using recycling. Additionally, the RP was found to be approximately 15% of the total energy associated with the building’s lifetime [17]. Blengini examined the RP of a residential building in Turin, whereby the RP was assessed by 29%, considering the materials embodied in the building shell [18]. Takano et al. have carried out a study to analyze the influence of materials selection on life-cycle energy balance using a case study. It was discussed that selection materials for surface and inner components have a larger effect than others, and the recycling benefits of woods and plastics have large effects on the building’s life-cycle energy balance. Condeixa et al. carried out a Material Flow Analysis for the building stock of Rio de Janeiro, where they estimated the building age and the remaining lifetime in order to make assumptions for environmental impact assessments and planning strategies for efficient use of materials [19]. Meliha Honic et al. coupled building catalogues and eco-repositories to digital design tools to evaluate the RP and environmental impact of buildings, and the results are based on element-level calculation, whereby a representative exterior wall is presented. They used the recycling weight parameter in the Eco2soft tool to assess the shares of recycling and waste of material. Results show that RP of the concrete variant is better but leads to more waste, while the variant in timber has a significantly lower impact on the environment [20]. Catherine De Wolf et al. have compared existing methodologies to quantify the global warming potential (GWP) of recycled/recyclable and reused/reusable products. They show that current quantification methods do not address the full spectrum of the reuse practice due to their limited boundaries, and that a number of critical features are currently hardly quantifiable [21]. Furthermore, in the field of building environmental impact assessment, studies considering the integration of building information modeling (BIM) and LCA are increasing. Assima Dauletbek et al. considered the feasibility of using a method of BIM-enabled LCA for the refurbishment in terms of environmental compatibility, energy efficiency, and profitability. The results demonstrate the feasibility of quantitative evaluation of building parameters using the BIM-LCA tool [22]. Baoquan Cheng et al. proposed a building life cycle embodied environmental impacts evaluation approach by integrating BIM and LCA taking a reinforced concrete structure building as a demonstrator. The results showed that the material production stage is the most crucial stage to improve a building’s environmental performance [23].

This entry is adapted from the peer-reviewed paper 10.3390/su14106174

References

- Kaufmann, H.; Krötsch, S.; Winter, S. Manual of multistorey timber construction. In Manual of Multistorey Timber Construction; Detail Business Information GmbH: Munich, Germany, 2018.

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351.

- Liang, S.; Gu, H.; Bergman, R. Environmental life-cycle assessment and life-cycle cost analysis of a high-rise mass timber building: A case study in Pacific Northwestern United States. Sustainability 2021, 13, 7831.

- Barber, D. Fire safety of mass timber buildings with CLT in USA. Wood Fiber Sci. 2018, 50, 83–95.

- Sun, X.; He, M.; Li, Z.; Lam, F. Seismic performance assessment of conventional CLT shear wall structures and post-tensioned CLT shear wall structures. Eng. Struct. 2019, 196, 109285.

- Adekunle, T.O. Thermal performance and apparent temperature in school buildings: A case of cross-laminated timber (CLT) school development. J. Build. Eng. 2021, 33, 101731.

- Wang, J.; Stirling, R.; Morris, P.I.; Taylor, A.; Lloyd, J.; Kirker, G.; Lebow, S.; Mankowski, M.; Barnes, H.M.; Morrell, J.J. Durability of mass timber structures: A review of the biological risks. Wood Fiber Sci. 2018, 50, 110–127.

- Atta, I.; Bakhoum, E.S.; Marzouk, M.M. Digitizing material passport for sustainable construction projects using BIM. J. Build. Eng. 2021, 43, 103233.

- Heisel, F.; Rau-Oberhuber, S. Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster. J. Clean. Prod. 2020, 243, 118482.

- Madaster Platform. Madaster. Available online: https://docs.madaster.com/nl/nl/ (accessed on 20 December 2021).

- Annette, H.; Johanna-Katharina, S. The Recycling Potential of Building Materials. In Manual of Recycling: Buildings as Sources of Materials; Detail Business Information GmbH: Munich, Germany, 2019.

- Cai, G.; Waldmann, D. A material and component bank to facilitate material recycling and component reuse for a sustainable construction: Concept and preliminary study. Clean Technol. Environ. Policy 2019, 21, 2015–2032.

- Akanbi, L.A.; Oyedele, L.O.; Omoteso, K.; Bilal, M.; Akinade, O.O.; Ajayi, A.O.; Owolabi, H.A. Disassembly and decon-struction analytics system (D-DAS) for construction in a circular economy. J. Clean. Prod. 2019, 223, 386–396.

- Schwede, D.; Störl, E. Methode zur Analyse der Rezyklierbarkeit von Baukonstruktionen. Bautechnik 2017, 94, 1–9.

- Nautiyal, H.; Shree, V.; Khurana, S.; Kumar, N. Recycling potential of building materials: A review. In Environmental Footprints and Eco-Design of Products and Processes; Springer: Berlin/Heidelberg, Germany, 2015; pp. 31–50.

- Thormark, C. The effect of material choice on the total energy need and recycling potential of a building. Build. Environ. 2006, 41, 1019–1026.

- Thormark, C. A low energy building in a life cycle—Its embodied energy, energy need for operation and recycling potential. Build. Environ. 2002, 37, 429–435.

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 44, 319–330.

- Condeixa, K.; Haddad, A.; Boer, D. Material flow analysis of the residential building stock at the city of Rio de Janeiro. J. Clean. Prod. 2017, 149, 1249–1267.

- Honic, M.; Kovacic, I.; Rechberger, H. Improving the recycling potential of buildings through Material Passports (MP): An Austrian case study. J. Clean. Prod. 2019, 217, 787–797.

- De Wolf, C.; Hoxha, E.; Fivet, C. Comparison of environmental assessment methods when reusing building components: A case study. Sustain. Cities Soc. 2020, 61, 102322.

- Dauletbek, A.; Zhou, P. BIM-based LCA as a comprehensive method for the refurbishment of existing dwellings considering environmental compatibility, energy efficiency, and profitability: A case study in China. J. Build. Eng. 2022, 46, 103852.

- Cheng, B.; Lu, K.; Li, J.; Chen, H.; Luo, X.; Shafique, M. Comprehensive assessment of embodied environmental impacts of buildings using normalized environmental impact factors. J. Clean. Prod. 2022, 334, 130083.

This entry is offline, you can click here to edit this entry!