1. Modern NIR Instrumentation—Toward Sensor Ultraminiaturization and Integration

Much of the specifics of the analytical framework based on miniaturized NIR spectrometers may be better comprehended by highlighting the decisive differences that exist between a standard laboratory stationary (i.e., benchtop) NIR spectrometer and handheld instruments. The former is nowadays a fully matured instrument that follows a rather uniform construction scheme, in which either a Michelson or a polarization interferometer is used, and the spectrum is acquired based on the Fourier-transform (FT) principle [

32]. In contrast, there are numerous optical and engineering principles implemented in the competing portable and miniaturized NIR instruments, constituting the diversity in the operational characteristics, price-per-unit factor, and the ultimate applicability of these devices.

2. General Design of an FT-NIR Benchtop Spectrometer

A construction scheme of a benchtop NIR spectrometer does not essentially differ from that of a generic instrument for optical absorption spectroscopy [

33,

34,

35]. It comprises a light source, a wavelength selector, and a detector as the main building/functional blocks, which are interconnected by optics for the propagation of the beam. While NIR spectrometers can be straightforwardly configured for transmission measurements, in which case a sample compartment is typically integrated within the spectrometer’s casing, a diffuse reflection mode of spectra acquisition is much more popular in analytical applications. This advantage results from the physical principles of NIR spectroscopy (i.e., high permeability of typical organic matter against NIR wavelengths), which make it straightforwardly applicable for obtaining good-quality reflectance spectra of samples without any prior pretreatments, such as dilution in a nonabsorbing medium (e.g., KBr powder), which is necessary for measuring mid-infrared (MIR) spectra, with the cost of a destructive method of analysis. Unlike most other instruments, NIR spectrometers can be readily equipped with fiber probes for remote scanning in diffuse reflectance mode, further adding to the versatility and practical usefulness of NIR spectroscopy.

An NIR spectrometer can be implemented using two different concepts of performing the wavelength selection. In a dispersive spectrometer, at a given time, only a narrow waveband is passed through a monochromator (e.g., a diffraction grating and optical slit system) and subsequently presented to the detector. The motion of the diffraction grating over time selects a consecutively changing waveband (i.e., narrow fragment of the wavelengths), effectively scanning the entire spectral region in which the instrument operates. As mentioned in the introduction, this mode of operation has been made obsolete in benchtop NIR spectroscopy by a superior FT spectrometer [

33,

34]. In an FT-NIR instrument, the entire measured wavelength region (i.e., broadband) is passed to the detector. Using an interferometer, either a Michelson-type or the less-popular polarization interferometer, an interferogram (i.e., a signal in the time domain) is registered by the detector. The signal in the frequency domain (i.e., the spectrum) is reconstructed from the interferogram through a Fourier transform. The primary benefits of such a solution are the gain in the optical throughput of the spectrometer and a precisely controlled wavelength axis [

33]. In contrast to full-scale benchtop spectrometers, miniaturization introduces several difficulties that effectively reduce the advantage of implementing the FT principle in the spectrometer [

5]. Certain other solutions, including multichannel devices, are feasible and offer competitive performance and cost-effectiveness. Consequently, the handheld instruments available on the market utilize diverse optical principles and engineering solutions to acquire NIR spectra [

5].

3. Functional Design Scheme of a Miniaturized NIR Spectrometer

3.1. Radiation Source

A tungsten halogen incandescent lamp is almost always used as a light source in benchtop NIR spectrometers. With a few exceptions, it is also a standard used in miniaturized devices [

14]. The emission profile of this source makes it very well suited for the NIR region, creating a simple, reliable, bright source with very good stability when thermal equilibrium is achieved. The tungsten halogen source is also preferred in miniaturized NIR spectrometers; however, there are additional requirements to make it suitable for such implementation. Energy efficiency and physical dimensions must be optimized, and the thermal stability of the source can become a problem in miniaturized devices due to a limited heat capacity or potential exposure to environmental conditions (e.g., sunlight) during field operation. For example, the insufficient thermal stability of some of earlier designs of otherwise very potent miniaturized instruments was found to negatively affect their analytical performance; as reported in a case study, additional cooling of the entire instrument with a thermocouple eliminated this shortcoming [

36]. The effect of source heating on the entire miniaturized spectrometer can be minimized by supplying the source with power only for the duration of the measurement; in some designs, this occurs automatically. Other solutions include a temperature-correction function implemented in spectrometer software, such as that for the MicroNIR 1700 ES instrument. Regardless, it is recommended that the background and dark scan are collected frequently to keep the background profile up to date during measurements.

On the other hand, a light-emitting diode (LED) is a semiconductor source that offers an extremely low power consumption and operating voltage, compactness, and durability, and has an excellent value compared to its cost [

37]. However, current technology offers LEDs that emit in a relatively narrow wavelength range that only partially covers the NIR region; for example, a gallium arsenide (GaAs) LED has a bandwidth of only 50 nm with a maximum emission at 870 nm [

38]. Consequently, these components are suitable for use in visible/short-wavelength NIR (Vis/SW-NIR) spectrometers, in which compact dimensions and cost-effectiveness of the instrument are crucial (e.g., SCiO) [

5].

3.2. Wavelength Selector

The wavelength-selection principle and its corresponding implementation in hardware are the most critical characteristics of a spectrometer, and largely determine its overall design and operating parameters [

5]. Furthermore, this element manifests the widest diversity among the designs present in the market, making it the most essential for the characterization of a given instrument. Although interferometer-based designs dominate in benchtop spectrometers, implementation of a Michelson interferometer in handheld devices involves considerable trade-offs resulting from difficulties in miniaturizing this complex element [

5]. Consequently, it is no longer far superior to other solutions, and so far no uniformly “best” concept for wavelength selection has been established for a miniaturized NIR spectrometer. The currently available portable NIR spectrometers demonstrate far-reaching diversity in this regard, with wavelength selectors ranging from the Fabry–Pérot interferometer and the Hadamard mask to multichannel devices that combine a linear variable filter (LVF) with an array detector. On the other hand, miniaturized dispersive spectrometers have been proved to be competitive; e.g., those implementing a digital micromirror system that avoids the use of movable dispersion grating, and thus are well suited to the regime of miniaturization [

5]. Complex wavelength selectors allow the use of single-element detectors, resulting in the most cost-effective combination; the alternative is the integration of an expensive array detector with a fairly simple optical filter. Several known types of wavelength selectors are subject to miniaturization using microelectromechanical system (MEMS) or micro-optoelectro-mechanical system (MOEMS) technology [

39]. These optomechanical devices are assembled with silicon using industry-standard technologies for the production of integrated circuits, and their popularization had a particularly important role in the development of miniaturized NIR spectrometers [

5].

The principle of the Hadamard transform (HT) as the wavelength-selection approach was implemented in multiple handheld NIR spectrometers [

40]. The practical advantages of Hadamard NIR spectrometers were discussed in detail by Fateley and co-workers [

41,

42]. In its simplest form of the single-encoded HT spectrometer, the light beam is focused on a slit, and after passing through the grating and the associated optics, is encoded by a multiaperture mask (Hadamard mask) and projected onto a single-pixel detector. This optical configuration results in a Hadamard-encoded signal reaching the detector and the spectrum being restored through a Hadamard transform. Theoretically, the advantages of Hadamard spectrometers were demonstrated relatively early, as they shared optical benefits with FT instruments; namely, the multiplex (Felgett), frequency accuracy (Connes), and throughput (Jacquinot) advantages, while HT spectrometers do not extensively rely on moving parts [

40]. Importantly, a programmable Hadamard mask proved to be implementable via MOEMS technology, contributing largely to the success of this solution in handheld NIR instruments.

A digital micromirror device (DMD) is a wavelength selector in which an array of microscale mirrors manufactured using MOEMS technology form the wavelength-scanning element. The implementation of a DMD enables the construction of a dispersive spectrometer in which this element is accompanied by a fixed dispersive grating instead of the moving grating characteristic of the canonical optical spectrometer [

5]. DMD design also enables the construction of a Hadamard-transform spectrometer (

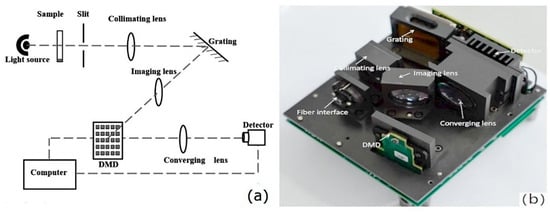

Figure 2) [

43]. In contrast to that obsolete design, a DMD-based spectrometer has no moving macroparts and offers advantages in terms of mechanical robustness, size, and cost-effectiveness of the wavelength selector element itself, while its optical configuration allows the use of an inexpensive single-pixel detector.

Figure 2. The implementation of a Hadamard-transform (HT) spectrometer by Lu et al. (

a) Scheme of the optical system; (

b) design of HT spectrometer. Reproduced (CC-BY 4.0 license) from [

43].

The Fabry–Pérot interferometer also acts as a miniaturized wavelength selector [

5]. Its scheme of operation is based on two parallel mirrors separated by a constant or variable distance, forming a Fabry–Pérot cavity. The filter is transparent only for resonant wavelengths related to the standing wave effect of the electric field generated in the optical resonator and controlled by the cavity width. Variable filter settings allow incoming polychromatic band (i.e., broadband) to be successively divided into several narrower wavelength fragments (i.e., narrow bands). Microfabrication of a programmable Fabry–Pérot interferometer is also feasible using MEMS technology. It is possible to easily reconfigure the spectrometer to work in other spectral ranges as a factory setting; for example, in NIRONE sensors.

Furthermore, while not being clearly superior in miniaturized form, the Michelson interferometer has been implemented in a number of compact NIR instruments, including those that achieved considerable commercial success; e.g., NeoSpectra sensors [

5]. Notably, a more recent generation of miniaturized FT-NIR spectrometers has emerged; for example, the Hefei SouthNest spectrometer. This design implements a relatively large mirror with a diameter of 3 cm in the interferometer, resulting in much improved optical throughput of the spectrometer compared with earlier generations of miniaturized FT-NIR devices. Michelson-interferometer-based sensors offer a wide operational spectral region and superior resolution, comparable to those offered by benchtop FT-NIR spectrometers.

In addition to the above examples, one alternative concept for a spectrometer constitutes an array detector with multiple independent photosensitive elements [

5]. While expensive, such a detector only needs to be combined with a relatively simple optical filter to work efficiently as a multichannel spectrometer that measures all wavelengths in the spectrum simultaneously without any scanning principle involved. This solution is particularly beneficial for miniaturized instruments, as it involves no moving parts even at the microscale, a high mechanical resistance, and very compact dimensions. Among the solutions implemented in the current miniaturized NIR instruments, multichannel sensors based on a linear variable filter (LVF) deserve particular attention. An LVF works as a wedge-shaped optical filter with an optical coating of a different thickness, which creates a linear variation in the transparency of the filter at different wavelengths. Designs based on an array detector and an LVF, unlike those based on MOEMS, do not have the high initial investment costs that are characteristic of semiconductor manufacturing. An LVF element is very thin itself, allowing the construction of instruments with a very short path length, further improving the properties of the multichannel spectrometer with high optical performance. Since there is no movement in the operation of the spectrometer, acquisition of a single spectrum is possible with an integration time of less than 10 ns, resulting in the ability to average a large number of spectra in an overall short collection time [

5].

3.3. Detector

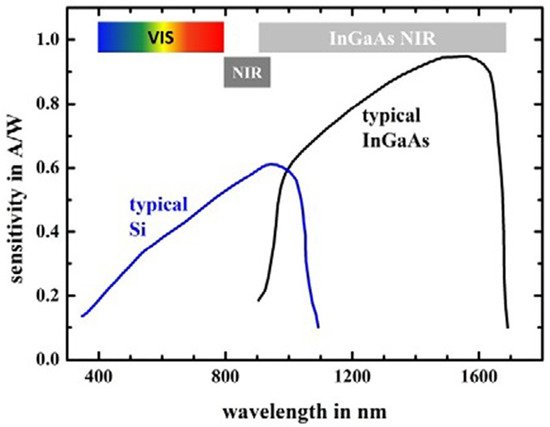

Miniaturized NIR spectrometers are usually equipped with an indium gallium arsenide (InGaAs) or “extended” InGaAs detector, although some instruments also contain silicon (Si) photovoltaic diodes [

5,

34,

44]. The size constraint seen in miniaturized spectrometers limits their optical performance. Therefore, in order to maintain an adequate signal-to-noise (S/N) ratio, the InGaAs detector is more desirable due to its high sensitivity, especially in the range of the longer wavelengths of the NIR region (

Figure 3) [

14]. The typical wavelength range for its optimal performance is around 1000–1600 nm (10,000–6250 cm

−1); however, in practice, several InGaAs-based NIR spectrometers offer good performance at adjacent wavelengths as well. Compared to other types of detectors, InGaAs detectors offer a fast response time, good quantum efficiency, and low dark current, allowing a short scan time while maintaining a good S/N [

5]. The extended InGaAs detector is suitable for instruments operating at shorter wavelengths of ca. 1700 nm. However, this type of detector has a lower sensitivity, and may require integrated cooling solutions [

44].

Figure 3. Typical quantum efficiency spectra of Si and InGaAs detectors. The colored and grey bars indicate the visible, SW-NIR, and conventional NIR (named “InGaAs NIR” in the source) wavelength ranges. Reproduced (CC-BY 4.0 license) from [

45].

Photovoltaic Si detectors maintain a reasonable sensitivity in the wavelength range from the visible region to ca. 1100 nm (9100 cm

−1), which makes them suitable for cost-effective, compact spectrometers operating only in the visible and SW-NIR regions, as presented in

Figure 3 [

5,

44]. Photodiodes used in portable spectrometers require the use of a wavelength-blocking filter to mask the detector from sunlight. The favorable affordability of this type of detector makes it particularly suitable for spectrometers oriented toward the consumer market [

5,

44].

3.4. Other Elements

Optics. NIR spectrometers are compatible with glass optics because this material does not absorb in the visible and most of the NIR region [

5,

34]. This enables the use of cheap mechanically and chemically resistant optical materials for the construction of portable NIR spectrometers [

5,

44]. However, the best performance in the long-wavelength part of the NIR region may require high-quality optics made from fused silica; i.e., without O-H impurities. To ensure reliable operation in direct contact with the sample, the optical window at the sample interface made from a scratch-resistant material is preferred. For example, some designs employ sapphire for this role, as it is a mechanically resilient material with the required transparency in the NIR wavelength range. However, it features a rather high refractive index (greater than 1.7 in the visible and NIR regions) that increases optical loss from reflection, making it more suitable for instruments with good optical throughput, such as MicroNIR multichannel spectrometers.

Connectivity, user interface, and power delivery. Modern electronics have achieved high levels of energy efficiency, which is a great advantage for portable spectrometers. These instruments follow one of two power delivery concepts: either the power supply is provided by an external source, or the unit is equipped with its own battery. For many spectrometers, the first solution is practically implemented with a universal serial bus (USB) connection, which is also used for spectrometer control and data transfer (for example, the standard version of the MicroNIR spectrometer). However, this is only possible if the total power consumption of the instrument does not exceed the capacity of the USB interface. In addition, the use of the instrument is limited by a permanent connection to the main computer (PC) via a USB cable. The second solution is needed for completely autonomous spectrometers (e.g., microPHAZIR) and those compatible with smartphone applications (e.g., Tellspec Enterprise sensor and SCiO). With this latest type of device, the data interface for transferring measured spectra and associated data can be maintained via USB as well (e.g., microPHAZIR) or via a cloud service (e.g., Tellspec Enterprise sensor and SCiO).

Closely related to the above, the user control over the instrument can also be achieved in several ways. The fully autonomous instruments feature their own user interface with a display screen and a user-input device (e.g., a keyboard), as in the case of, for example, microPHAZIR. Spectrometers that require continuous external power are typically controlled by a PC-installed application with the data interface and power delivery conveniently handled by a wired USB interface; examples include MicroNIR instruments [

5]. Many devices aimed at the consumer market are operated through an application installed on a smartphone with continuous communication with a user device over a wireless connection; i.e., Wi-Fi or a low-power Bluetooth interface.

4. Brief Overview of Selected Representative Miniaturized NIR Spectrometers

The principle of the Hadamard spectrometer was implemented in one of the first handheld NIR instruments introduced to the wide market by Polychromix, now the intellectual property of Thermo Fisher Scientific Inc. The instrument employed a programmable microscale MEMS-based Hadamard mask, a low-power tungsten lamp source, and an InGaAs single-element detector. These solutions enabled a robust, reliable, and reasonably compact instrument, given its fully autonomous operation. The device was fitted with its own power source—a lithium-ion battery—that was swappable for continued operation, a display screen, and a user interface; i.e., a keyboard.

Several successful products on the market are based on the NIRscan Digital Light Processor (DLP) module from Texas Instruments. This solution is based on a digital micromirror device (DMD) manufactured using MEMS technology, and is available as two evaluation modules (EVMs): a high-performance (HP) EVM with a DLP NIRscan sensor and a mobile sensing (MS) EVM with a DLP NIRscan Nano. The latter, more compact one is primarily suitable for cost-efficient portable spectrometers. It is implemented in the NIR-S-G1 instrument from InnoSpectra [

46], available as a customized product from, e.g., SphereOptics [

47], Sagitto [

48], Allied Scientific [

49] and Tellspec [

50]. The NIR-S-G1 spectrometer is extremely compact (82 mm × 63 mm × 43 mm; weight less than 145 g); it is equipped with li-ion battery, is operated through a mobile app, and communicates with a smartphone via a power-efficient Bluetooth interface.

A Fabry–Pérot interferometer was implemented by Spectral Engines in a miniaturized NIR spectrometer NIRONE S sensor [

51], with several variants preconfigured for different operational wavelength-range, S/N ratio, and resolution parameters (

Table 1) while maintaining very compact dimensions (25 × 25 × 17.5 mm; weight 15 g). The implementation of the Fabry–Pérot interferometer created an optical configuration of the sensor suitable for detection in a relatively large area of either the InGaAs or extended InGaAs type. The Sensor X is a compact version of the instrument optimized for cost-effectiveness and ease of production. Notably, the latest advances in Fabry–Pérot interferometer technology show promise for ultraminiaturization. For instance, Hamamatsu recently unveiled a series of ultracompact NIR sensors, differing mostly in their operational spectral regions that, however, are quite narrow and depend on the variant, ranging from 1350 to 2150 nm (7407–4651 cm

−1) [

52].

Table 1. The operational characteristics of selected miniaturized NIR spectrometers available on the market in comparison with two exemplary benchtop FT-NIR devices.

An alternative approach to a multichannel spectrometer is offered by the VIAVI MicroNIR series of instruments. These devices combine a multielement array detector (InGaAs) coupled with an LVF, enabling a very compact, mechanically robust spectrometer with superior optical performance for its size. Newer versions of the MicroNIR; e.g., the 1700 ES, improve the operational stability over time thanks to a temperature-correction function, effectively recalibrating the detector’s response depending on its temperature to mitigate the thermal capacity imposed by the compact dimensions of the device. The standard MicroNIR instrument is powered and controlled via a wired USB connection with a host PC, while the dedicated OnSite-W variant, intended for in-field operation, is equipped with battery power source and a waterproof and dustproof housing [

53].

Miniaturized FT-NIR spectrometers equipped with a Michelson interferometer are offered by, e.g., Si-Ware Systems with a NeoSpectra device (

Table 1,

Figure 4) [

54]. Recently, a new generation of FT-NIR minispectrometers appeared. For example, Hefei SouthNest Technology introduced the nanoFTIR NIR spectrometer, which operates in the full NIR range of 800–2600 nm (12,500–3846 cm

−1) while maintaining a relatively high spectral resolution of 6 nm at 1600 nm. The device has compact dimensions (14.3 × 4.9 × 2.8 cm) and is light (220 g), and can be equipped with an external light source and a fiber-optic probe compliant with the industry standard, making it suitable for online analysis. Furthermore, recently another MEMS-based FT-NIR spectrometer from Hamamatsu appeared, equipped with a large mirror (3 mm diameter) interferometer, enabling a good S/N ratio with a wide spectral range of 1100–250 nm (9090–4000 cm

−1). On the other hand, regardless of the underlying technology, many of the spectrometers are offered in a specialized variant sold as “turn-key” analyzers to be operated by personnel not trained in spectroscopy. Such analyzers are preconfigured for the intended analyses, with a specialized software suite containing spectra-processing algorithms and precalibrated models for quantitative and qualitative analyses typically performed in a given area of application. For example, several analyzers based on the microPHAZIR spectrometer appeared that are intended to be operated under minimal supervision [

55]. Exemplary configurations include, e.g., the microPHAZIR AG Handheld Analyzer, which is intended for animal feed analysis, and is preconfigured to predict major quality parameters and ingredients in these products, such as moisture, protein, fiber, starch, etc., [

56]. The other turn-key configurations of the microPHAZIR include, e.g., the microPHAZIR PC analyzer, which is intended for plastics analysis in recycling [

57]; the microPHAZIR RX analyzer, which is preconfigured for pharmaceuticals [

58]; or the microPHAZIR AS, which fulfills the role of an asbestos analyzer [

59]. Mini-NIR analyzers in particular are growing in popularity in the agri-food industry, with several examples of specialized devices; e.g., the NIR4 Farm spectrometer from AB Vista, which is intended for the analysis of feed and forage [

60]; as well as analyzers that are preconfigured for grain assessment, such as AURA’s Handheld NIR [

61] or the X-NIR Analyzer [

62].

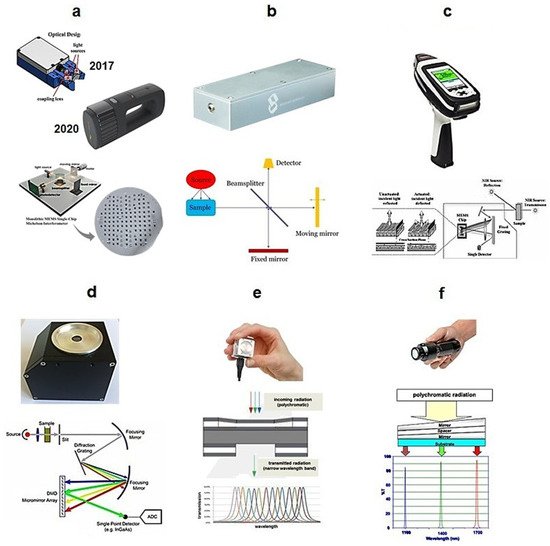

Figure 4. Principles of wavelength selectors built into different handheld NIR spectrometers: (

a) MEMS Michelson interferometer—NeoSpectra, Si-Ware, Cairo, Egypt; (

b) MEMS Michelson interferometer with a large mirror—nanoFTIR NIR, SouthNest Technology, Hefei, China; (

c) MEMS Hadamard mask—microPHAZIR, Thermo Fisher Scientific, Waltham, MA, USA; (

d) MEMS DMD—implementation of DLP NIRscan module, Texas Instruments, Dallas, TX, USA; (

e) MEMS Fabry–Pérot interferometer—NIRONE Sensor S, Spectral Engines, Helsinki, Finland; (

f) LVF—MicroNIR Pro ES 1700, VIAVI, Santa Rosa, CA, USA. Adopted (CC-BY 4.0 license) from [

7].

In the context of food analysis, attention should be given to specialized, consumer-oriented NIR spectrometers designed to accept somewhat limited overall performance with the greatest benefit of cost-effectiveness. These are the necessary trade-offs to fit the instruments into their specific niche of the market, where they are offered as “pocket food analyzers” for use by the general public [

63]. The sensor hardware is tailored to provide a sufficient optical performance, while the primary value for the intended operators originates from the associated software. These instruments offer an easy-to-use cloud service, in which the results of the analysis are displayed to the end user in a “black-box”, with underlying predictions based on precalibrated models stored in the cloud service. A good example of such a device is the Consumer Physics SCiO NIR microspectrometer [

64]. Marketed as the first “pocket” spectrometer, the unit measures 67.7 × 40.2 × 8.8 mm, weighs 35 g, and is intended primarily for everyday consumer assessment of food quality and nutritional value. The necessary economical affordability is achieved by using an LED light source and a simple 12-element Si photodiode detector, with an array of a 4 × 3 configuration, combined with optical filters across each pixel to form a 12-channel spectrometer. However, in this design, noticeable penalties in terms of optical performance were inevitable, manifested primarily in the low number of measured wavelengths. Below-average S/N levels and a narrow wavelength range covering only a fragment of the visible/SW-NIR range (740–1070 nm; 13,514–9346 cm

−1) seem sufficient for the intended applications of this device, as a number of essential quality parameters of foods can be effectively predicted from these spectra. In connection with the ultraminiaturized, consumer-oriented instruments described above, the much-anticipated NIR sensor fully integrated with a smartphone has remained a vivid concept in the past decade [

65]. While the initial prototype revealed highly promising characteristics [

66,

67], so far, no such solution has appeared on the market. However, more recent advances into ultraminiaturization; e.g., as demonstrated by Hamamatsu MEMS-FPI spectrum sensors [

65], suggest that NIR spectrometers integrated with smartphones may become commercially available in the next few years.

This entry is adapted from the peer-reviewed paper 10.3390/foods11101465