Encapsulation based on supercritical fluids has shown several advantages as green technology for the production of functional ingredients with enhanced stability and tailored protection from environmental factors. Thanks to the inherent absence of organic solvent, the low temperature of the process to reach the supercritical state and the capacity to dissolve lipid soluble bioactives, it allows obtaining functional ingredient easily designed to tailor the controlled release of the bioactive, or to reach specific levels of taste, odor and color. The present entry aims to highlight the pros and cons of the encapsulation techniques based on supercritical fluids giving emphasis to their innovative aspects that could be of interest to the food industry.

- supercritical fluids

- encapsulation

- food grade bioactive compounds

1. Introduction

Encapsulation is a common strategy to entrap active ingredients within a carrier material. In food formulation, it is very common to entrap sensitive actives like antioxidants, vitamins or unsaturated oils into a shell made from food grade polymers. The result is a powder, usually with enhanced storage stability and superior protection against light, temperature, pH or oxygen [1]. Recent developments on encapsulation technologies have contributed not only to enhance the chemical stability of the bioactive compounds, but also to tailor specific properties of the powder formulations, like their microstructures and the final rate of release [2].

The capacity to encapsulate active ingredients and protect them from degradation is of great economic importance. It is worth to note that functional ingredients reached a market of about 9.36 billion dollars in 2015 and the plan is to obtain about 41.74 billion dollars by 2021 with a computed annual growth rate of 6% [1]. The main food and dietary supplements are sold around the globe in the form of encapsulate comprise emulsions, dispersions and water-soluble powdered preparations. Nowadays, such encapsulated products can be found in the market as food ingredients and supplements [2]. However, some challenges are still open and mainly related to their efficiency to preserve the functional properties of the bioactive compounds during storage, processing, or even after the consumption and flow through the gastrointestinal tract.

From a technological point of view, the challenge to preserve the functional activity of the bioactive is even more complicated nowadays by the growing demand of powder ingredients that are free from solvents residues, show high flowability, little or no shrinkage in time, negligible diffusion of the active towards the surface and negligible impact on the food quality attributes once incorporated in the formulation.

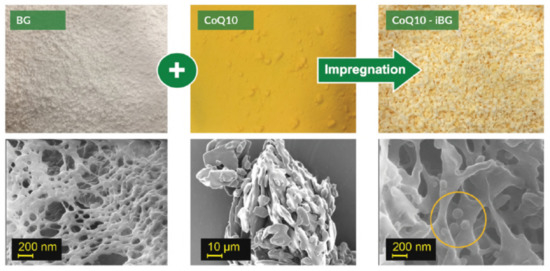

Accordingly, the type of encapsulation technology plays a major role in the final success of a formulation. Through the years, several encapsulation technologies have been developed with the aim to protect bioactive compounds. The most relevant examples include spray drying, freeze drying, spray-chilling, extrusion, coacervation, electrospinning and fluidized bed. On the other hand, research studies on some other techniques, such as those using supercritical fluids, have shown only recently their performance and possible applicability at industrial scale [1,3,4].

2. Techniques Used for the Encapsulation of Bioactive Compounds

Through the years, a number of technologies have been developed, like spray drying, spray-bed-drying, fluid-bed coating, spray-chilling, or spray-cooling, to encapsulate active agents. Most of them are based on a drying step as they involve a previous step of emulsification to solubilize the bioactive compounds in water or oil and produce water in oil emulsions, oil in water emulsions, or water in oil in water double emulsions [6].

Spray drying is the most widely used encapsulation technique in the food industry. It is a flexible, continuous and economical operation able to produce particles of good quality attributes with size less than 40 μm. However, this technique presents several disadvantages such as the complexity of the equipment, the non-uniform conditions achieved in the drying chamber and the not always easy control of the particle size of the particles [7]. About 80–90% of encapsulated products present on the market are produced by spray drying. The rest of them are mainly prepared by spray-chilling, vacuum, or freeze-drying just to name some.

In particular, vacuum and freeze-drying are processes often applied as alternative to spray drying. Vacuum drying is faster and cheaper compared to freeze drying as it operates at a temperature above the freezing point of the solvent. However, the produced particles are not uniform in shape and size. On the other hand, freeze-drying presents several disadvantages linked to the high energy input and long processing times required to obtain encapsulates. Moreover, during the process, a barrier with an open porous structure between the bioactive compound and its surroundings is often formed. This favors the formation of a high-porous wall, which offers poor protection when a prolonged release of the bioactive compound is required [8].

3. Industrial Scale Applications

4. Future Perspectives and Final Remarks

In conclusion, encapsulation techniques based on the use of SC-CO2 have received increasing attention thanks to the ability of the solvent to produce ingredients with desired functional properties. Although some of these techniques already found their application at the industrial scale, more studies are needed to improve the processes through the optimization of the processing variables to obtain standardized encapsulated bioactives. The published data demonstrate that these techniques have some advantages over the existing conventional ones. However, the fundamental aspects of the formation of micro and nanoparticles seem still obscure for some of the processes. This aspect clearly indicates that an extensive research is required to reduce the limitations linked to the understanding of the functionalities of the final products.

This entry is adapted from the peer-reviewed paper 10.3390/foods9101395