The construction industry’s high energy consumption and carbon emissions significantly burden the ecological environment. Numerous solid wastes and greenhouse gases (GHG) are generated as high-energy-consuming and high-emission products during the construction process. Thirty percent of China’s total energy consumption comes from construction projects.

- construction industry

- life-cycle assessment (LCA)

- carbon-footprint calculation

1. Introduction

2. Carbon Footprint Life-Cycle Assessment

2.1. Carbon Emissions from Construction

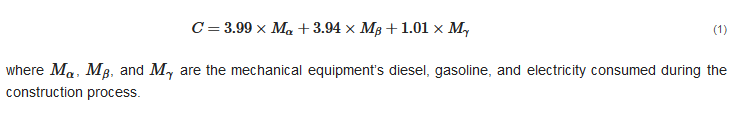

Several calculation methods are usually used for carbon-emission calculation, where the measurement method uses specific, approved standards or instruments to measure the concentration, flow rate, and footprint path. The inputs and outputs must be comprehensively analyzed [10], and such a work process is complex and time-consuming [11]. The emission-coefficient method calculates the total footprints based on the average value of the quantity of emitted gas [12]. The carbon-emission coefficient method is relatively simple, straightforward, and easy to understand; it is based on activity data and carbon-emission coefficients. However, it is also relatively extensive when compared with other methods. Therefore, the carbon-emission coefficient method was selected to calculate the carbon emissions during the building phase.

Several studies combining carbon footprints have also already been conducted. In this context, case studies determine the boundary range of carbon footprints and the correlation between energy and carbon share embodied in different levels of building energy efficiency [2]. Moreover, these case studies can correlate building energy consumption and carbon emissions [13] and verify reductions in building energy consumption and carbon emissions using a scientific construction-management system [14]. Different structural methods calculate energy consumption and carbon emissions, such as LCA [15]. A carbon-emission calculation model [16] has been established, and identification shows that energy, building materials, and machinery are the primary carbon-emission sources [17]. A carbon-emission law is established and analyzed according to the influence of base cost on carbon emissions [1]. Energy consumption and carbon emission for different building materials can be analyzed in building components in the production, transportation, and installation phases [18]. Authors [1,19] proposed an accurate calculation of the carbon emissions from precast concrete piles during their construction process using the LCA theory combined with an energy-analysis tool. At present, the analysis methods for determining the factors influencing building carbon emissions include ecological emission [20], the logarithmic mean divisia index decomposition method [21], and emission intensity [22]. Research indicates that emission intensity is the largest share of carbon-emission factors in the construction industry.

Research on carbon footprints in the construction field is mainly based on data from international organizations or foreign institutions. Buildings are divided into detailed stages, and their total carbon footprints are obtained using the carbon-emission calculation method. However, a construction period of two to five years for projects can be regarded as a micro life cycle [23], and studying the carbon footprint in detail is extremely necessary. Previous studies generally considered that the construction-operation phase caused many emissions, and the construction-operation period occupied most of its entire life cycle [24]. Therefore, the evaluation period significantly affected the evaluation results. The literature mentioned above did not consider emission reduction in the construction process due to construction scale, design period, and construction period. On the other hand, it calculated carbon emissions per unit construction area per year. As a result, it obtained comparable calculation results, which guided the optimization of the construction-material production process, transportation, construction, and waste disposal during the construction delivery stage.

2.2. Basic Issues of Carbon Footprints during Construction

2.2.1. Types of GHG and Their Measurement Units

2.2.2. International Carbon-Emission Accounting Standards

2.3. Determination of Carbon-Emission Factors for Building Materials

2.3.1. Semifinished Materials

Sand and gravel are basic materials used in building construction. A study of the literature reveals that different scholars have calculated sand and gravel carbon emission factors in different ways [29,30]. The carbon-emission factors of sand and gravel are then calculated. A literature search found that the average electricity consumption per cubic meter of sand is 1.32 kW·h, and fuel oil is 0.76 kg [29]. The packing density of sand is 1450 kg/m3, and gravel is 1560 kg/m3 [12]. Subsequently, the sand and gravel carbon-emission factor is computed by combining the carbon-emission factor of electricity and fuel oil. The calculation formula is expressed as sand carbon emissions: 1.32 × 1.01 + 0.76 × 3.9 = 4.297 (kg/m3); sand: (1.32 × 1.01 + 0.76 × 3.90)/1.45 = 2.964 (kg/t); and stone: (1.32 × 1.01 + 0.76 × 3.90)/1.56 = 2.755 (kg/t).

2.3.2. Steel

| Recovery Rate | Large-Scale Steel | Small- and Medium-Sized Steel | Hot-Rolled Steel Bar | Cold-Rolled Steel Bar |

|---|---|---|---|---|

| 0 | 3.744 | 3.003 | 3.154 | 3.938 |

| 10% | 3.519 | 2.823 | 2.965 | 3.702 |

| 20% | 3.295 | 2.643 | 2.766 | 3.465 |

| 30% | 3.07 | 2.462 | 2.586 | 3.229 |

| 40% | 2.845 | 2.282 | 2.397 | 2.993 |

| 50% | 2.621 | 2.102 | 2.208 | 2.757 |

| 60% | 2.396 | 1.922 | 2.019 | 2.52 |

| 70% | 2.172 | 1.742 | 1.829 | 2.284 |

| 80% | 1.947 | 1.562 | 1.64 | 2.048 |

| 90% | 1.722 | 1.381 | 1.451 | 1.811 |

| 100% | 1.498 | 1.201 | 1.262 | 1.575 |

| Building Material Name | Unit | Carbon-Emission Factor kgCO2/kg | Scope of Application | ||

|---|---|---|---|---|---|

| 90% | 50% | 0% | |||

| Large steel | kg | 1.722 | - | 3.744 | Section steel |

| Small and medium steel | kg | 1.382 | - | 3.003 | Angle steel, flat steel, steel formwork, Steel bracket, etc. |

| Hot-rolled strip | kg | - | 2.757 | 3.154 | Cold drawn steel wire |

| Cold-rolled strip | kg | - | 2.208 | 3.938 | Rebar, round steel |

2.4. Carbon-Emission Factors of Some Decoration Materials

2.4.1. Water-Discharge Factor

2.4.2. Wood

2.5. Carbon-Emission Factors of Construction Machinery

This entry is adapted from the peer-reviewed paper 10.3390/su14095180