Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Forestry

|

Materials Science, Composites

Oil palm plantations have expanded rapidly in Southeast Asia, particularly in Indonesia and Malaysia. A lot of products, including food and other edible products, oleo-chemicals, cosmetics, personal and household care, pharmaceutical products, and biodiesels are derived from palm oil, thus making them one of the most economically important plants.

- composite panel

- biomass

- oil palm trunk

1. Comparison Wood versus Oil-Palm Trunk Biomass

1.1. Physical Properties of Oil Palm Trunk

According to Srivaro et al. [89], the water uptake (WU) of the OPT ranges between 73 and 415%. According to Srivaro et al. [90], the WU increases gradually along with the trunk height and the central region. The outer and lower zones have significantly lower values than the other two zones. The increasing trend in WU can be attributed to the distribution of parenchymatous cells, which retain more moisture than the vascular bundles. According to Lamaming et al. [91], between the parenchyma tissues and vascular bundles are comprised of different compositions of extractive, lignin, and holocellulose. By contrast, parenchyma tissues are more abundant near the apex of the OPT and the central region. Recently, Wulandari and Erwinsyah [92] reported that the highest moisture content (MC) was found at the inner and gradually decreased toward centre to the trunk’s outer part. These percentages ranged from 36 to 141%. A decrease in the percentages of parenchyma cells with a high capacity for water absorption (WA) increased the number of vascular bundles. Generally, Wulandari and Erwinsyah [92] stated that the MC of the OPT decreased as the trunk height increased.

Due to the oil palm’s monocotyledonous nature, its density values vary significantly across its trunk. Density, or specific gravity, is regarded as the most critical characteristic when utilizing OPT. It is defined as the quantity of material that is contained in a unit volume. Generally, the density is the highest at the bottom end’s peripheral region and lowest at the top end’s central core region. The density values range from 222 to 404 kg per m3 [90]. According to Srivaro et al. [90], the density of an OPT decreases linearly with trunk height and increases toward the trunk’s center; the outer region of the trunk has a density that is more than twice that of the inner region. A variety of factors cause these variations. For instance, the density across the trunk is primarily determined by the number of vascular bundles per square unit, which decreases towards the center. However, there were variations in the density along the trunk height since the vascular bundles at the top of the palm are younger.

1.2. Chemical Properties of Oil Palm Trunk

The chemical composition of OPT varies longitudinally and radially along the stem including the barks. No discernible trend exists for holocellulose, lignin, and ash content in bottom, middle, and upper parts of the oil palm meristem. However, they were significantly different from those of its bark [93]. The alpha-cellulose content, ash content, pentosan, and holocellulose within the OPT were lowest compared to those of OPF and EFB. Extractives within OPT which were indicated by water solubility (either cold or hot) and alcohol- and alkali-soluble components were in between of those of EFB and OPF [94].

Further, Onuorah et al. [94] examined the chemical properties of OPT. They reported that OPT contains more lignin than those of EFB and OPF. Ahmad et al. [95] observed that the bottom portion contained a higher lignin concentration and was significantly different than middle and top parts. This is probably due to the increased number of fibrous vascular bundles in the peripheral region [92]. These vascular bundles contain thicker and older cells, contributing to OPT’s lower end’s higher lignin content. The range of lignin content is between 17.21% and 20.47%. The ash content, which is also consistent throughout the trunk, ranges between 2.18 and 2.86% [95].

Additionally, free sugars between 2–14% were observed throughout the stem. The inner regions have a higher proportion of free sugars whereas the outer zones have the lowest free sugar content. Sucrose, glucose, and fructose are the three major free sugars in the OPT, as determined by high-performance liquid chromatography (HPLC), the most used method for analyzing sugar types and concentrations. Sucrose, the primary sugar component, remains relatively constant throughout the stem’s length. On the other hand, the glucose levels decrease as the stem height increases, whereas the fructose levels increase. However, a high variation of sugar with different content that were found in different oil palms were influenced by different methods of analysis, quantifications on different locations of the palms (inner or outer part, height), including different storage and microbial infestation [96].

1.3. Mechanical Properties of Oil Palm Trunk

The MOE which measures the material’s stiffness or rigidity, varies between 740 and 7960 MPa in the OPT, with the highest value found in the lower peripheral region. The lowest MOE is found in the central region’s core, near the trunk’s top end. The MOR, which varies similarly to the MOE, is extremely low compared to conventional timber species. Srivaro et al. [89] examined the mechanical properties of a 25-year-old OPT and compared them to those of other species such as bamboo and hardwood. The mechanical properties of the OPT reflect the density variation that was observed in both the radial and vertical directions of the trunk. The peripheral lower portion of the trunk has the highest bending strength, while the central core of the top portion of the trunk has the lowest. OPT has had the lowest bending strength, therefore OPT is more likely to be recommended for non-structural purposes.

The variation in the MOR follows the same pattern as the variation in the MOE or bending strength. The value of each strength was lower compared to bamboo, they ranged from 53 to 275 and 7 to 58 MPa (MOR), and 5 to 22 and 0.5 to 7.0 GPa (MOE). OPT has had a lower density compared to bamboo. Wulandari and Erwinsyah [92] investigated the density and specific gravity of Dura x Pisifera species of oil palm. They reported that the average values at the peripheral, central, and inner were 0.73, 0.54, 0.48 g/cm3 and 0.53, 0.26, 0.19, respectively.

1.4. The Anatomy of Oil Palm Trunk

The oil palm plant is not a woody plant. The oil palm is a monocotyledonous species; it lacks cambium, secondary growth, growth rings, ray cells, sapwood, heartwood, branches, and knots. Oil palm has an anatomical structure that is composed primarily of fibers, tracheids, vessels parenchyma, and ray parenchyma cells. OPT differs chemically from hardwood/softwood species, with differences in cellulose, hemicellulose, and lignin content [89].

The increase in the stem diameter occurs due to overall cell division and enlargement in the parenchymatous ground tissues and enlargement of the vascular bundle fibers. There are three primary sections. The cortex is first, followed by the peripheral zone, and finally by the central zone in the OPT [96,97]. Oil palm stands are typically replanted after 25 years. At replanting age, the OPT reaches a height of 7 to 13 m and a diameter of 45 to 65 cm, measured 1.5 m above ground level. When mature, the trunk tapers toward the crowns, which typically produce about 41 fronds. The anatomical characteristics of an oil palm trunk cross-section are described as follows:

- 1.

-

Cortex

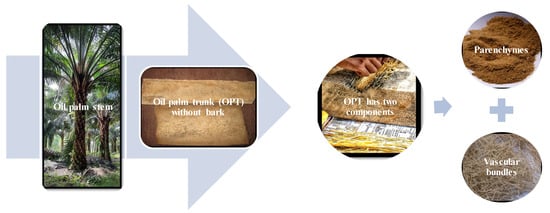

The cortex is a narrow zone measuring approximately 1.5–3.5 cm in width, covering most of the trunk. It is primarily composed of ground tissue parenchyma with numerous longitudinal fibrous strands and vascular bundles of small and irregular shape [90]. In order to better explain the two main parts within OPT, in Figure 5 exhibits the schematic separation between the two for optimization further.

Figure 5. Two main parts of an oil palm trunk (OPT). For optimization, between the parenchyma and vascular bundles have been separated.

- 2.

-

Periphery

The periphery is a region with thin parenchymal layers and dense vascular bundles that provides the palm trunk’s primary mechanical support. The peripheral region is usually densely packed with radially extended fibrous sheaths, providing the palm with mechanical strength. This region accounts for approximately 20% of the total cross-section’s area. The secondary walls of the fibers are multilayered and increase in length from the periphery to the pith. As the basal portions of the stem are older, they typically have more developed secondary walls than the top portions. Between the xylem and fiber strands are phloem cells in a single strand. According to Choowang [97], the areal number density of vascular bundles in the outer zone ranged from 68 to 115, much more compared to in the middle which had only 44 to 58 vascular bundles population/cm2.

- 3.

-

Central

The central zone accounts for approximately 80% of the total area and comprises of slightly larger and widely dispersed vascular bundles that are embedded in the parenchymatous ground tissues. Bundles become larger and more dispersed as they approach the trunk’s core. An estimation of the vascular bundle density in central region’s is approximately from 23 to 40 vascular bundles population/cm2 [97].

- 4.

-

Vascular bundles

The vascular bundles are thick, fibrous, and have a low hygroscopicity. The vascular bundle, on the other hand, is significantly less tightly packed toward the center zone, which contains more storage tissue. Fibers, xylem, vessels, protoxylem, sieve tubes, axial parenchyma, stegmata or spherical-shaped silica bodies form, and companion cells are all found inside the vascular bundle [91,98].

- 5.

-

Parenchymatous tissue

The parenchymatous ground tissue is predominantly made up of soft, spongy, and very hygroscopic of thin-walled spherical cells. Food is stored as carbohydrates in the live parenchyma cells, mostly in the form of sugars and starch. The ground parenchymatous tissue is made up of thin-walled spherical parenchyma cells that are dense and thicker in the core than in the periphery. The diameter and length of the oil palm trunk increases as a result of cell division and elongation in the parenchymatous ground tissues as well as vascular fiber [91].

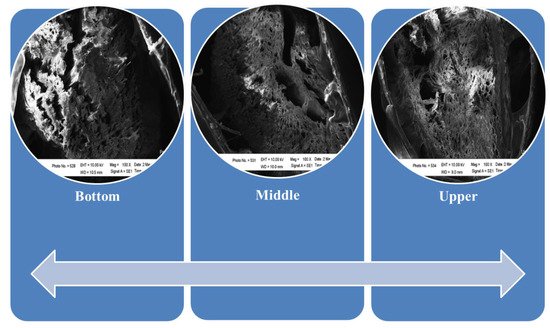

Picea abies (Norway spruce), a softwood species, has a different anatomy than the oil palm plant. Since it is a softwood, it contains earlywood (EW) and latewood (LW), which are readily visually visible. The LW is denser than the EW, and when viewed under a microscope, the cells of dense latewood have very thick walls and tiny cell cavities, whereas those of EW have thin walls and large cell cavities [99]. Macroscopically, the spruce wood consists of sapwood and heartwood whereas microscopy works revealed that wood was also arranged by tracheids which are typically ordered in a regular pattern and are nearly perfectly rectangular in cross-section [100]. Further, in spruce wood, abnormality in growth such as formation of hazel wood could be occurred [101]. In OPT, there is no differences among the bottom, middle or upper parts as shown in the scanning electron microscopy (SEM) image of Figure 6.

Figure 6. Vascular bundles of OPT showed no differences among the bottom, middle, and upper parts (100× magnifications).

Therefore, whole parts utilization of OPT is beneficial compared to wood. However, further treatment should be taken, for instance in separating between the vascular bundles and the parenchyma. In the next sub chapter, the properties of OPT for raw material of panel products are discussed.

2. Composite Panel Products Made of Oil-Palm Trunk and Its Properties

OPT has several disadvantages: low strength, low durability, poor dimensional stability, and poor machining [99]. Due to the high-density gradient along the stem’s radial and longitudinal axes, OPT is less desirable for use as lumber. As a monocotyledon, oil palm differs significantly structurally from dicotyledonous woods. In comparison to wood, oil palm is much more porous, cellular, and anisotropic. As a result, liquids such as water and low molecular weight compounds can be rapidly absorbed and transported into the cell wall and lumen. OPT has been developed for composite panel products such as traditional panels (plywood and laminated veneer lumber), particleboard, and cement board.

2.1. LVL and Plywood

The first development for a traditional composite panel from the OPT was carried out by Sulaiman et al. [40]. The purpose of this study was to determine the physical and mechanical properties of LVL that was manufactured from OPT bonded by UF, PF, melamine urea formaldehyde (MUF), and phenol resorcinol formaldehyde (PRF) adhesives. Their shear strength constructed with PRF adhesive is greater than that of panels that were bonded with alternative adhesives. The shear strength of oil palm LVL, on the other hand, was lower than that of rubberwood LVL. There are few studies on OPT plywood constructed with thermoplastic adhesives. Recently, Hashim et al. [102] reported that LVL that was manufactured from OPT performed better when adhered with a cold setting adhesive, specifically PVAc and emulsion polymeric isocyanate (EPI). PVAc and EPI, with and without toluene, were superior to rubberwood LVL in TS and WA.

To improve the poor properties of traditional composite panels that are made from OPT, the raw materials have been modified. Numerous modifications were made, including treatment with low molecular weight phenol-formaldehyde (LmwPF) resin, impregnation of OPT with UF, hot air, and microwave drying, hybridization with another material, modification of the adhesive with nanoparticles, and compression of binderless veneer panels using response surface methodology (Table 3).

Table 3. Several modifications of OPT for LVL and plywood panel.

| Product | Adhesive/ Binder |

Studies | Refs. |

|---|---|---|---|

| LVL | UF, PF, MF, and PRF | Variation of adhesive | [40] |

| Plywood | UF | UF impregnated OPT for core plywood | [36] |

| Plywood | PF | Treatment with LmwPF resin: effect of pressing pressure, the effect of resin content, and effect of hot-pressing time | [42,45,47] |

| Veneer | - | Effects of hot air and microwave drying | [46] |

| Composite-Plywood | UF and PF | Hybrid plywood from oil palm biomass | [57] |

| Composite-Plywood | MUF | Sandwich panel with OPT core overlaid with rubberwood veneer | [54] |

| Composite-Plywood | UF | Impregnated OPT with UF resin | [36] |

| Composite-Plywood | PF | Addition of OPA to hybrid plywood | [57] |

| Composite-Plywood | - | Binderless compressed veneer panel using response surface methodology | [26] |

The pre-treatment of OPS veneers with LmwPF resin enhanced the surface characteristics, density, termite, and decay resistance. Loh et al. [38,50] investigated the wettability, surface roughness, and protection of OPS veneer from subterranean termites (Coptotermes curvignathus) and white-rot fungi (Pycnoporous sanguineus). For more than 30 s, the phenolic-treated veneer surface was capable of preventing liquid penetration. Veneer that was treated with LmwPF resin increased the durability of OPS plywood by 38% and 62% against termites and white-rot fungi, respectively. However, outer-layer OPS plywood is more resistant to termites and fungal decay than inner-layer OPS plywood.

Another study successfully developed the veneer treatment with LmwPF resin by varying the resin treatment, pressing time, solid resin content, and the resin concentration on formaldehyde emission, physical, and mechanical properties of plywood [42,45,47]. The plywood that was treated with LmwPF resin outperforms commercial OPS plywood in terms of physical and mechanical properties. The results indicated that veneers that were treated with a 30% solution of LmwPF provided the optimal treatment combination for plywood’s physical and mechanical properties. The pressing time affected the pre-preg OPS plywood’s mechanical properties and bonding performance. When LmwPF resins with a solid content of 32% or greater were used, the bonding quality met the minimum requirement for interior and exterior applications that are specified in Standard EN. The LmwPF resin can be used to treat OPT veneer with a solid content of up to 32% that meets the F standard for wood products as defined by Japanese Agriculture Standard (JAS).

Another successful treatment method to enhance the plywood’s quality was used on oil palm veneer (OPV). Lekachaiworakul et al. [46] examined the effects of hot air and microwave drying on oil palm veneer’s kinetics and mechanical properties of OPV. Additionally, drying with hot air and a high-power microwave revealed increased tensile stress and shear properties. However, the mechanical properties of hot air at 70–90 °C when combined with a microwave power level of 2000 watts were superior to those of hot air at 70–90 °C when combined with a microwave power level of 3000 watts.

Hybridization has been shown to affect the bending strength in variable studies. By crossbreeding of OPEFB and OPT, plywood’s bending strength, screw withdrawal strength, and shear strength are increased [103]. Srivaro et al. [54] investigated the stiffness and bending strength of an OPT core sandwich panel that was overlaid with a rubberwood veneer when bent in the center. An increased OPT core density improved the stiffness and strength of the beam. Face fractures and core shear failures were observed, with the latter occurring more frequently when the OPT core density was low, the veneer face was relatively thick, and the span length was short.

Furthermore, H’ng et al. [36] examined the effects of UF impregnation on OPT’s physical and mechanical properties by varying the UF solid content impregnation pressure and time. The three-layered OPT board that was impregnated with a higher resin solid content and a shorter impregnation time eventually reduced the degree of WA, resulting in changes in thickness and width. Additionally, impregnation treatments on the core layer increased the MOR and shear strength of the board but decreased the MOE of the board.

2.2. Particleboard

Table 4 summarizes the various studies and modifications that are made to the OPT panel. Hashim et al. [59] successfully developed the world’s first particleboard that was made from OPT. Hashim et al. [35,37] investigated the properties of panels that were made entirely of OPT without the use of binders, focusing on the effect of particle geometry and press temperature. The particle’s size and shape affect the sample’s properties. According to the findings of this study, increasing the pressing temperature may be a viable method for improving the properties of binderless particleboard. Oil palm biomass contains significant amounts of holocellulose, lignin, starch, and sugar, that are necessary for self-bonding adhesion.

Table 4. Several studies and modifications oil palm trunk (OPT) for particleboard panel.

| Product | Adhesive/ Binder |

Studies | Ref. |

|---|---|---|---|

| Binderless Particleboard |

- | Effect of particle geometry on binderless particleboard | [37] |

| Binderless Particleboard |

- | Influence of press temperature on the properties of binderless particleboard | [35] |

| Binderless Particleboard |

- | Determine the chemical component suitability for binderless particleboard | [59] |

| Binderless Particleboard |

- | Effect of oil palm age on properties of binderless particleboard | [49] |

| Particleboard | PHA | Effect addition of PHA | [34] |

| Particleboard | PHA | Influence of steam treatment and addition of PHA. | [31] |

| Particleboard | - | Optimization of press temperature and time for binderless particleboard | [30] |

| Particleboard | UF | Effect of treated with hot water and sodium hydroxide (NaOH) on the properties of particleboard | [32] |

| Binderless Particleboard |

- | Steam treated on binderless particleboard | [26] |

| Particleboard | UF | Effects of two-step post heat-treatment on the particleboard properties. | [29] |

| Binderless Particleboard |

ADP | Addition of ammonium dihydrogen phosphate (ADP) | [28] |

| Binderless Particleboard |

- | Addition Acacia mangium particle | [44] |

| Particleboard | PVA | Addition citric acid and calcium carbonate | [25] |

Additionally, Lamaming et al. [49] conducted a successful study which demonstrated superior mechanical and physical properties for binderless panels that were made from young oil palm trunk particles. Additionally, sugar was found to improve the boards’ overall properties. The age of the oil palm affected the mechanical and physical properties of the boards that were manufactured, with sugars playing a significant role in the boards’ self-bonding.

There are several drawbacks to using a binderless form of OPT. One of them is a lack of dimension stability [59]. Baskaran et al. [34] improved the properties of binderless materials by adding PHA using freeze-dried and pure samples. The addition of freeze-dried and pure PHA to the panels improved the overall properties of the samples. Additionally, compared to panels that were made without additives or controls, the panels that were made from steam-treated oil palm particles with varying amounts of PHA had improved physical and mechanical properties [31]. PHA appears to have some potential for enhancing the fundamental properties of experimental oil palm particleboard panels without adhesives. Baskaran et al. [30] optimized the press temperature and time for binderless particleboard that was manufactured from oil palm trunk biomass using a rotatable central composite design of response surface methodology. The optimization process was completed with the aid of the response surface method and software. Compared to the Japanese Industrial Standard (JIS), the optimal solutions that were proposed in this study were satisfactory.

Other techniques for enhancing the properties of binderless particleboard include being treated with hot water/sodium hydroxide (NaOH), steamed, or heated [26,28,29,32]. The MOE and MOR of samples that were prepared from raw material that was treated with hot water were greater than those of control panels that were prepared from NaOH-treated particles [32]. Saari et al. [26] reported that steaming improved the mechanical and physical properties of the boards. Steam exposure appears to be an inexpensive way to enhance the overall properties of such panels. The two-step post-heat treatment in OPT particles can enhance the dimensional stability and biological durability of the particleboard. Regrettably, the treatment significantly reduced the mechanical strength of the particleboard [29]. According to Komariah et al. [28], particleboard containing 10% ADP exhibited the highest MOR (8.9 MPa), IB (0.53 MPa), and thickness swelling (TS) values (5.9%). Additionally, particleboards containing 10% ADP demonstrated excellent resistance to water.

According to Yusof et al. [25] adding PVA, citric acid, and calcium carbonate to the composition of particleboards may also affect their fire resistance. Additionally, the addition of wood particles may improve the properties of binderless particleboard from OPT. The study was successfully developed by the addition of Acacia mangium wood which increased the fractal dimension of the particleboard, resulting in a decrease in hydrophilicity. The reduced percentage TS and WA properties of the binderless particleboard corroborate these findings [39,40].

2.3. Cement Board

OPT could be used as a natural fiber-based filler to manufacture gypsum composites with improved fire-retardant properties. The initial and final setting times of the OPT gypsum composite were significantly longer than the rice husk (RH) one. Compared to the RH gypsum composite, the OPT gypsum composite demonstrated superior mechanical properties [27]. Additionally, Phutthimethakul et al. [56] investigated the use of flue-gas desulfurization (FGD) gypsum, construction, and demolition waste (CDW), and OPT as part of the raw materials for the manufacture of concrete bricks. The compressive strength of the concrete brick specimens containing 5.5% gypsum without CDW and OPT was 45.18 MPa. In contrast, concrete brick specimens containing 5.5% FGD gypsum, 75% CDW, and 1% OPT had a compressive strength of 26.84 MPa.

3. Future Perspective

The future prospects of the utilization of OPT can be highlighted through the success of experimental works of engineered products such as the substitution of wood panel products, such as plywood, LVL, particleboard, fiberboard, and cement board as discussed above. In other words, OPT is potential to be a raw material for composite products which are usually made from wood. Challenges arose during the conversion of the OPT into veneer and lumber because of the monocotyledon characteristics which are rich in parenchyma and the irregular dimension of the fibers, thus after seasoning defects can be found remarkably. Board-based particles or fibers can be easily produced since transforming the OPT into both forms is now simply by applying a mechanical clearing system on the site plantation, where both types of dimensions are available afterwards. However, the determination of adhesive used still needed attention, whether its function as only a glue or at the same time performed as bonding agent, preservative chemical, and impregnation material. Even though both particleboard and fiberboard can be manufactured without adhesive, called binderless, care on hot-pressing stages should be carried out carefully. Wet processes or very high moisture within the particles was able to activate hydrogen bonding, thus the particles or fibers were interconnected each other. All this will be different to cement board for which the predominant component is cement or mineral. Cement board needs measurement of hydration temperature, which indicates the suitability of OPT with cement. A benefit would arise if both Indonesia and Malaysia, as the most oil palm producing countries, produced OSB, a structural panel product, since both countries have had no data on it.

This entry is adapted from the peer-reviewed paper 10.3390/polym14091758

This entry is offline, you can click here to edit this entry!