Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Petroleum

There has been growing interest in fuel supply chains regarding transport safety and LNG reloading. This is due to the increasing consumption of this gas in the economy to create sustainable transport systems. Poland is in the phase of energy transformation, which increases the demand for this type of alternative fuel. For this reason, the number of logistic operations carried out by Polish sea terminals handling LNG deliveries is increasing.

- LNG

- risk assessment

- logistic handling

1. Introduction

LNG is a gas mixture of hydrocarbons in the following proportions: methane 87–99 mol%, ethane 0.1–5.5 mol%, propane 0–4 mol%, butane 0–2.5 mol%, nitrogen 0.02–1 mol%, and traces of sulfur (less than four ppmv) and CO2 (50 ppmv) [1]. For this reason, the transport of LNG fuel is included in the transport of hazardous substances that may affect human life, the environment, and financial aspects of society. Other logistic operations, in particular LNG reloading, can also be dangerous. The main risks associated with this include fires and explosions, which may occur from leaks and spills in ignition sources [2]. An essential aspect in this situation is the presence of ignition. Mokhatab et al. [1] emphasize that in the event of failure to ignite, LNG quickly evaporates and spreads without harmful effects on the environment (when diluted below the ignition limit). However, in the event of ignition, LNG presents four potential fire-risk scenarios: vapor cloud flash fire, jet fire, pool fire, and vapor cloud explosion.

For this reason, the literature emphasizes that in the event of failure to ignite, LNG quickly evaporates and spreads without harmful effects on the environment (when diluted below the ignition limit). There are numerous publications on risk assessment related to the transport and handling of LNG and the safety of its storage. According to the literature review [2,3], these publications have been systematically growing in the last decade.

Poland is currently in a phase of energy transformation in transport. This transformation consists of a gradual departure from traditional energy carriers and instead favors alternative fuels. Liquefied natural gas (LNG) is currently of particular interest among these fuels. Many publications by Polish authors emphasize numerous benefits related to the development of this fuel sector in Poland (including [4]). The growing interest in this fuel is also confirmed by various reports, including [5]. According to this report, in 2020, the increase in the amount of LNG delivered by sea was recorded as 9.7% compared to 2019. The report also indicated that the ongoing energy transformation of Poland would also result in a dynamic increase in demand for LNG. The importance of this fuel for the stability of the country’s power system will also increase [5]. For this reason, it is expected that the number of logistic operations related to the handling of LNG fuel transport by water will increase in the coming years.

Poland’s critical liquefied natural gas installation is the LNG terminal in Świnoujście. This terminal is one of the most critical investments implemented in Poland in recent years. Its operation aims to improve the security of gas fuel supplies to Poland, allowing LNG to be received by sea from any direction [5]. Most of the LNG from the terminal in Świnoujście is delivered to customers via the gas network. The liquefied gas is additionally reloaded to cisterns adapted for LNG transport. All reloading processes are carried out following [6] instructions. This manual has also become the starting point for identifying potential adverse events during logistic operations related to LNG deliveries at the terminal.

2. Description of LNG Terminal in Świnoujście

The terminal is located on the west end of the Polish coastline, in the southernmost part of the Baltic Sea—Pomeranian Bay, next to the estuary of Świna river, at the outer port of Świnoujście (Figure 1).

Figure 1. LNG terminal in Świnoujście—the location and main facilities (based on [45]).

The approach fairway has a minimum width of 200 m, and depth, also in an outer port basin, is 14.5 m. Therefore, the Port Regulations allows entry and maneuvering of a vessel with a maximum draught of 12.5 m, length of 320 m and breadth of 51 m. This is why, most often, deliveries are made by Q-flex gas carriers. The typical Q-flex LNG carrier is 315 m in length, 50 m in breadth, 12.5 m in draught, and a capacity of about 200,000 cubic meters of LNG.

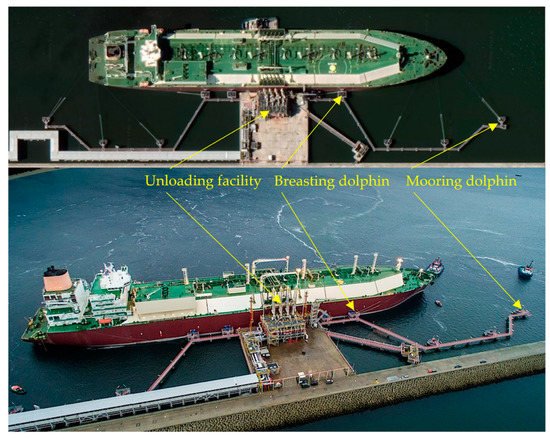

The unloading jetty consists of four breasting and six mooring dolphins equipped with 22 quick-release mooring hooks (Figure 2). The unloading facility is located on the main platform of the jetty, which includes three arms to transfer liquified natural gas from the ship to the storage tank and one arm for vapor return.

Figure 2. Unloading jetty and LNG carrier (based on [45]).

The safety of LNG carrier operations on the approach and in the outer port depends on weather conditions. Strong winds can cause interruptions to work or the need to anchor at the roadstead. In an average year, there are 13 days with winds exceeding 10 m/s, mostly from east, northeast, and north directions.

The maximum wave heights on the approach fairway are as follow:

-

2 m, at a distance more significant than 46 km from the entrance to the outer port at the boundary wind speed of 25 m/s;

-

1 m, at a distance between 15 and 46 km from the entrance to the outer port at the boundary wind speed of 10 m/s;

-

0.6 m, up to 15 km from the entrance to the outer port at the boundary wind speed of 10 m/s.

The maximum value of minimum water levels on the approach fairway and the outer port, referred to as the “Amsterdam 500” system, is 480 cm. The observations carried out between 2011 and 2014 indicate that the mean water level equals 509 cm and the probability that the level drops below 480 cm is less than 5% [46].

The currents are strongly related to wind force and direction. At the outer port entrance, the maximum current velocity is 1.0 m/s and decreases to 0.5 m/s at a distance of 15 km and zero from 46 km.

The primary purpose of the LNG terminal in Świnoujście is to diversify sources of natural gas for the national grid. The liquified gas is delivered by LNG carriers, transferred to two storage tanks of 160,000 cubic meters each, and injected into the grid after regasification. A relatively small amount of LNG is shipped inland by truck cisterns to supply local grids or specific facilities. The terminal’s future activity will also include the transfer of LNG from land tanks to bunker ships or smaller LNG carriers. Today’s regasification capability is 5.0 bln cubic meters per year, and in 2024 it will increase to 8.3 bln, which is more than half of total gas consumption in Poland.

The terminal must be constantly supplied with liquified natural gas to achieve the primary purpose. During the first five years of operation, 130 LNG carriers were unloaded, which is about two vessels per month. To reach the first level, 5 bln cubic meters of natural gas from four LNG carriers are needed, and by the 2024 level—six or more if we include reselling of LNG. Therefore, the service of LNG carriers is not a daily routine, and the reception of LNG is one of the most critical moments during the terminal operation. During this period, two different systems have to be connected and co-operated to transfer an enormous amount of fuel as a cryogenic liquid in a relatively short time. Therefore, each gas carrier must conduct the compatibility study in compliance with the “Authorisation Procedure for LNG Vessels Arriving at the LNG terminal in Świnoujście” [47]. Only those vessels confirmed by the study are admitted to arrive and unload.

Within 24 h after departure from the loading port, the ship’s master is obligated to submit a notice of departure to the terminal operator. Then, notification of arrival should be submitted seven days and subsequently 96, 72, 48, 24, 12, and 6 h before arrival, according to the estimated arrival time to the terminal. The reception operations can be divided into three phases: the approach to the terminal, the transfer of LNG, and leaving the terminal.

We can consider that the first phase begins when the LNG carrier is passing the N-1 buoy, which means 43 km from the entrance. From this point, the vessel should proceed with the assistance of two pilots and the passive assistance of a tug. At a distance of 26 km from the entrance, the LNG carrier may obtain permission to enter the port as long as [48]:

-

Wind speed is less than 12.5 m/s;

-

Wave heights do not exceed 1.5 m;

-

Water level guarantees 2 m of under keel clearance;

-

The speed of the current, within a distance of 2 km before breakwater heads, does not exceed 0.26 m/s;

-

Visibility is at least 3 km.

The LNG carrier has to use active tug assistance with connected stern tow if permission is granted. When the vessel approaches 6 km, another tug must be connected with a bow tow, and fire-fighting vessel assistance must be provided. The following two tugs have to join the LNG carrier at a distance of 2 km to the outer port entrance as ordered by the pilot. In addition, all other vessels navigating in the vicinity of the Świnoujście port must not disturb the LNG carrier. When the gas carrier enters the outer port of Świnoujście, it has to rotate to the moor starboard side. The maximum approach transverse speed and angle are respectively 0.05 m/s and 2°. The first phase is completed when the LNG carrier is alongside the berth, all mooring lines are hooked and secured by the linesmen team, and the gangway is in place.

During the whole stay of the LNG carrier alongside the berth, the pilot must be present on board, and the assistance of two tugs and a fire-fighting vessel has to be kept.

At the beginning of the second phase, “the LNG unloading procedure and pre-discharge” meeting occur. The meeting attended by the master of the ship, the chief officer, and on the part of the terminal, the loading master, involves the [48]:

-

Confirmation of the unloading schedule;

-

Exchange of any required information concerning the system and equipment of the Ship and the Terminal;

-

Arrangement of all cargo data and requirements concerning the unloading;

-

Arrangement of the D1011-PIC-12 BOG vapor return controller set point;

-

Carrying out of a safety inspection aboard (by the loading master or a person indicated by him and carrier’s duty officer or a person indicated by him) confirming that all safety requirements have been met before the unloading operation.

-

Filling a “Ship Shore Safety Checklist, SSSCL” or an equivalent document [49].

After filling in the SSSCL, consent to connect the unloading arms is issued. The connection shall be carried out after the arm operators have ensured no contamination exists inside the manifold, that the ship’s crew has correctly installed adequate unloading filters, and that the vapor return (BOG) arm is connected and disconnected from the last one.

When the arms are connected, leak and pressure tests are executed, and measurement devices are also checked. The whole unloading line, which includes the arms and pipes leading to storage tanks, has to be cooled down. This produces a significant amount of LNG vapor; therefore, the BOG handling system is to be configured. The emergency shut-down procedure is tested before and after cooling down the unloading line. When the tests’ results are positive, the unloading of LNG can be commenced. The design unloading rate equals 12,000 m3/h with a ship manifold pressure of 4.5 bar, which shall not be exceeded. During the unloading, the pressure and temperature in the ship’s tanks and storage tanks are controlled by the actual discharge rate and amount of vapor return. Cargo is sampled with appropriate intervals to calculate the amount and composition of LNG.

When LNG discharging is completed, the unloading line is drained, purged with nitrogen, and the final measurement is taken. Following this, the post-discharge meeting is arranged to evaluate the unloading operation propose improvements for the next deliveries. After solutions to all issues and problems regarding safety and communications, the LNG carrier receives approval for further calls. At the end of the second phase, the unloading arms are disconnected, post-discharge documentation is prepared, and the vessel waits for permission to leave.

The last phase of reception operations begins when the LNG carrier obtains permission to depart from the port. The hydrometeorological conditions must be as follows:

-

Wind speed—less than 12.5 m/s;

-

Wave height—less than 1.5 m;

-

Visibility—minimum 3 km;

-

Current speed beyond breakwater heads—less than 0.26 m/s.

Similar assistance from pilots, tugs, and fire-fighting vessels is required when gas carriers leave the LNG terminal [48].

This entry is adapted from the peer-reviewed paper 10.3390/en15082750

This entry is offline, you can click here to edit this entry!