1. Pre-Treatment of Agricultural Waste

LCB does not only consist of cellulose (30–50%), but also hemicellulose (19–45%) and lignin (15–35%) by weight, with the other components including chlorophyll, waxes, ash, and resins [

24]. Xu et al. reported that raw corn stover consists of cellulose (44.4 ± 0.4%), hemicellulose (27.8 ± 0.3%), and lignin (19.6 ± 0.2%) [

42], while Slavutsky and Bertuzzi reported that sugarcane bagasse consists of cellulose (40.3 ± 1.6%), hemicellulose (21.4 ± 1.6%), and lignin (23.84 ± 0.9%) [

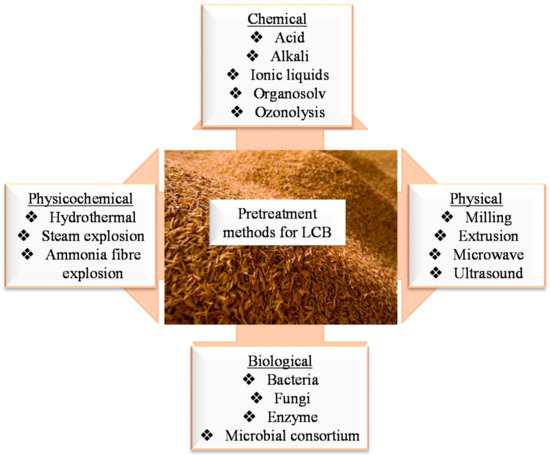

43]. Hence, the extraction of CNCs from biomass requires much effort to overcome the crucial pre-treatment stage. It is important to select adequate pre-treatment methods to remove the non-cellulosic material (hemicellulose, lignin, ash, etc.) The recently reported pre-treatment methods for the extraction of CNCs are summarized in

Figure 3. These methods are usually selected based on the type of feedstock. For instance, Santos et al. prepared CNCs from pineapple leaves, which contained several non-cellulosic materials [

33]. The pre-treatment was conducted with a sodium hydroxide aqueous solution of 2% (

w/w) to disrupt the hemicellulose and lignin bonds, and a bleaching step with an acetate buffer solution (27 g sodium hydroxide (NaOH) and 75 mL glacial acetic acid, diluted with 1 L of distilled water, and 1.7 wt% sodium chlorite (NaClO

2) in water) to remove excess non-cellulosic residue. Jiang and Hsieh used two methods to pre-treat tomato peels before the extraction of CNCs [

44]. The first method involved the use of acidified-sodium-chlorite delignification, followed by a highly effective alkali treatment using potassium hydroxide (KOH). An alternative chlorine-free route involving alkaline hydrolysis and peroxide bleaching was also developed for comparison using NaOH and 4% hydrogen peroxide (H

2O

2). In general, several steps are involved in the pre-treatment stages, including washing and cutting the raw materials into small pieces [

45]. To cleave the ester linkages and glycosidic side chains of the lignin, leading to disruption, the source is subjected to alkali pre-treatments at specific conditions. Different alkali solutions have been employed for this process, such as KOH and NaOH [

46,

47]. This is followed by bleaching (delignification), whereby excess non-cellulosic components are eliminated using sodium chlorite and hydrogen peroxide [

31,

48]. Extra steps are usually required to dewax the source and clean up the chemical residues [

26].

Figure 3. Typical and recent pre-treatment methods for LCB.

2. Extraction of CNCs

2.1. Acid Hydrolysis

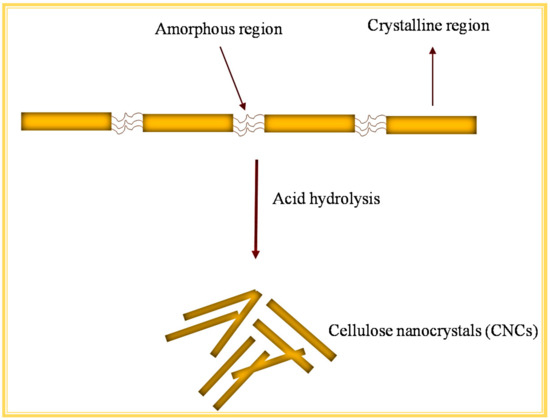

The extraction of CNCs from cellulosic fibres usually involves an acid-induced disruption process whereby the glycosidic bonds in the amorphous region are cleaved under controlled-reaction conditions [

49] as shown in

Figure 4. Various strong acids have been employed to degrade bulk cellulose effectively to release CNCs, such as sulphuric acid (H

2SO

4), phosphoric acid (H

3PO

4), hydrochloric acid (HCl), nitric acid (HNO

3), and a mixture of mineral and organic acids [

50]. Kassab et al. [

51] compared the effects of three different acids on the extraction of CNCs from tomato plant residue (H

2SO

4, H

3PO

4, and HCOOH/HCl) to form sulphated CNCs (S-CNC), phosphorylated CNCs (P-CNC) and carboxylated CNCs (C-CNC). The produced CNCs exhibited high aspect ratios (up to 98) and high crystallinity (up to 89%), and formed stable suspensions in organic solvents compared to previously reported CNCs from other sources. Wang and colleagues [

52] attempted to add phosphate groups to CNCs by phosphoric-acid hydrolysis to improve thermal stability and synthesis conditions. Their results showed that the use of phosphoric-acid medium to obtain CNCs decreased the degradation temperatures; however, thermal stability was still comparable to CNCs obtained from other biomasses that were treated with H

3PO

4 and H

2SO

4. The acid-hydrolysis treatment with H

2SO

4 to prepare CNCs has been widely investigated and appears to be used extensively when compared to other acids. This is because H

2SO

4 has been proven to be effective in the elimination of the amorphous components of cellulosic fibres and produces stable CNC suspensions.

Figure 4 illustrates the process flow diagram for the extraction of CNCs using conventional acid hydrolysis. As mentioned earlier, depending on the LCB source, cellulose fibres acquired from the pre-treatment stage are then used as a source for CNCs during this step. H

2SO

4 hydrolysis introduces sulphate groups to the surface of the extracted CNCs due to the reaction with surface hydroxyl groups of the cellulose through an esterification process, allowing for the formation of anionic sulfate groups [

50]. These anionic sulfate groups induce electrostatic repulsion between CNC molecules and promote their dispersion in water [

33]. However, the sulfate groups compromise the thermal stability of the CNCs and may contribute to lower yields [

33,

50]. The thermal stability of the sulfuric-acid-prepared CNCs can be increased by neutralizing the CNCs through dialysis [

53]. Overall, the acid-hydrolysis method is simple and can be used to extract CNCs from several agricultural residues. Different agricultural residues that have been used for the extraction of CNCs within the past decade are shown in

Table 1. The pre-treatment and extraction processes described above do not differ much; however, the source of cellulose plays a huge role in the dimensions of CNCs as well as related properties and overall yield. While this method is extensively used for CNC extraction, it contributes to high chemical waste disposal, as a result, more strategies for effective, fast, low cost, and environmentally friendly procedures are highly desired.

Figure 4. The process of CNC extraction using the conventional acid-hydrolysis method.

2.2. Oxidation

Oxidation is useful in introducing anionic groups to the cellulose molecules; briefly, it can be separated into two steps. The first step is to oxidize the surface hydroxyl group (-OH) of the pre-treated source and remove the amorphous regions [

49]. This results in a structure with negatively charged carboxyl groups (-COOH), which can facilitate the dispersion of CNCs in aqueous solutions and allow further modifications on the surface of CNCs [

54]. The most common type of oxidation is TEMPO oxidation. TEMPO (1-oxo-2,2,6,6-tétraméthylpipyridine 1-oxyle) is a stable radical that selectively mediates the oxidation of primary alcohols into carboxylic acids through an aldehyde intermediate [

55]. Usually, TEMPO-mediated oxidation is cooperative with mechanical disintegration and selectively oxidizes C6-primary hydroxyl groups of cellulose to sodium C6-carboxylate groups [

56]. Zhang et al. [

57] used TEMPO oxidation to prepare carboxylated CNCs from sugarcane bagasse pulp with further assistance of ultrasound. Previous studies have used TEMPO-mediated oxidation to prepare carboxylated CNCs; however, this method consists of several steps as well as multiple radical-generating chemicals (sodium hypochlorite (NaClO), sodium bromide (NaBr), and TEMPO reagents), which limit the sustainability of the approach [

58].

Other oxidation agents such as ammonium persulfate (APS), H

2O

2, and nitro-oxidation (using HNO

3 and NaNO

2) have also been used to prepare CNCs [

59,

60,

61]. Zhang et al. [

61] compared the effects of the preparation methods using TEMPO and acid hydrolysis. Lemon seeds were utilized to extract CNCs by H

2SO

4 (S-LSCNC), APS (A-LSCNC), and TEMPO oxidation (T-LSCNC). The results demonstrated that all CNCs maintained cellulose Iβ structure and had a good dispersion regardless of extraction methods, but the T-LSCNC had a higher yield. This is because TEMPO oxidation is also advantageous due to its ability to produce high oxidized yields of up to 90%. Khoshani et al. [

62] prepared carboxylated CNCs through one-step catalyst-assisted H

2O

2 oxidation. Similar to TEMPO, these two methods require several pre-treatment steps before the extraction of CNCs, while nitro-oxidation decreases the need to consume multiple chemicals, greatly improving the recyclability of the used chemicals [

58]. Sharma et al. [

59] used one-step nitro-oxidation to prepare carboxylated CNCs from jute fibres, while Chengbo et al. [

14] compared the extraction of CNCs using both nitro-oxidation and TEMPO-oxidation from jute fibres. TEMPO oxidation was performed on pre-treated jute, while nitro-oxidation was performed on untreated jute, and both oxidation methods were effective and resulted in carboxylated CNCs with good dispersion and high transparency. The nitro-oxidation extraction process is much less expensive, faster and more environmentally friendly than the acid hydrolysis process. The elimination of the pre-treatment step reduces the amount of chemical waste disposal. This method is also much more sustainable than the TEMPO oxidation process.

2.3. Other Methods

Other extraction methods, including but not limited to ionic liquid (ILs) hydrolysis and enzymatic hydrolysis, have been utilized to extract CNCs from agricultural waste [

49]. ILs hydrolysis has been highly explored in the field of biomass processing due to its low vapour pressure, low energy consumption, and sustainability [

63]. This hydrolysis involves two main steps, the pre-treated cellulose is immersed in an IL for a known period to allow swelling, and water is added to initiate the hydrolysis [

49]. During the reaction, the hydrogen and oxygen atoms of amorphous cellulose are easily accessible by the dissociated IL to form the electron donor–electron acceptor. The -OH groups break, leading to the selective removal of the amorphous region [

64]. The above-mentioned extraction methods require the use of chemicals, while enzymatic hydrolysis uses cellulolytic enzymes known as cellulases (mixtures of endoglucanases, exoglucanases, and cellobiohydrolases); these are an interesting class of enzymes possessing the ability to act as catalysts for the hydrolysis of the cellulose [

65]. These enzymes have specific functionalities that can selectively depolymerize the amorphous region of cellulose to prepare CNCs with high crystallinity [

65,

66]. This is the most environmentally friendly and low-cost process, as it eliminates the use of toxic chemicals and consumes relatively little energy. However, this process is relatively slow.

The preparation of CNCs through physical/mechanical processes, such as high-pressure homogenization, grinding, and steam explosion are discussed. During mechanical treatment, pre-treated cellulose pulp is subjected to high shear force, which helps extract the CNCs along the longitudinal direction [

67]. High pressure homogenization has been widely employed for the mass production of CNCs in industries due to its simplicity, high efficiency, lack of a requirement for organic solvents, and production of uniform CNCs with high yield [

37]. During the homogenization process, pre-treated cellulose pulp is diluted with water and passed through a tiny gap between the homogenizing valve and an impact ring under high pressure (69–207 MPa) and high velocity at room temperature [

67,

68]. However, high-pressure homogenization involves several passes, which results in high energy consumption [

69]. Other mechanical methods include grinding, whereby the cellulose pulp is passed between static and rotating grinding disks, which can be adjusted to reduce clogging [

68]. The above-mentioned mechanical methods require mechanical degradation tools; on the other hand, steam explosion facilitates chemical treatments and improves the removal efficiency of non-cellulosic materials through pressure [

70]. Steam explosion is a process which consist of heating biomass using saturated steam with high pressure followed by rapid decompression; in this process, the high pressure results in hydrolysis of the glycosidic and hydrogen bonds to produce CNCs [

71].

Table 1. Selected articles showing the extraction of CNCs from different agricultural residues in the past decade.

| Agricultural Residue |

Pre-Treatment Conditions |

Extraction Conditions |

CNC Diameter |

References |

| Mengkuang leaves |

Alkaline treatment using 4% NaOH at 125 °C for 2 h, bleaching using 1.7 w/v% NaClO2 at pH 4.5 and 125 °C for 4 h. |

Acid hydrolysis was carried out using 60 wt% H2SO4 solution at 45 °C |

2–5 nm |

[29] |

| Mango seed |

Alkali treatment using 2% NaOH at 100 °C for 4 h, bleaching with a solution made up of equal parts (v:v) of acetate buffer (27 g of NaOH and 75 mL of glacial acetic acid, diluted to 1 L of distilled water) and aqueous chlorite (1.7 wt% NaClO2 in water) at 80 °C for 6 h. |

Acid hydrolysis was performed at 40 °C for 10 min using H2SO4

(11.21 M). |

4.59 ± 2.22 nm |

[72] |

| Agave tequilana and barley |

The ground fibres were dispersed in an acid solution (0.2 wt% of acetic acid) of 0.27 wt% of NaClO2 and 0.7 wt% NaOH kept at 70 °C and stirred for 1.5 h. The sample was then treated with 17.5 wt% NaOH for 30 min. |

Acid hydrolysis was performed at 50 °C with 65 wt% of H2SO4. |

MCC 16 ± 6 nm

A. Tequilana 11 ± 4 nm

Barley 10 ± 4 nm |

[46] |

| Tomato peels |

Tomato peels were placed in oluene/ethanol (2:1, v/v) in a Soxhlet apparatus for 20 h to remove wax, phenolics, pigments, and oils. The bleaching was achieved by 1.4% NaClO at pH 3.5 adjusted with acetic acid kept at 70 °C for 5 h, then treated with 5% KOH solution at room temperature for 24 h and then heated at 90 °C for 2 h. |

Acid hydrolysis was performed using H2SO4 (64 wt%) at 45 °C for 30 min. |

3.5 ± 5 nm |

[44] |

| Sugarcane bagasse |

The sugarcane bagasse was pre-treated with ethanol/water (1:1 v/v) solution at a solid/liquid ratio of 1:10 at 190 °C for 2 h. The pulped bagasse was then bleached using 24% H2O2 and 4% NaOH at 70–80 °C for 1 h. |

Acid hydrolysis was performed at 50 °C in preheated 65 wt% H2SO4 for 40 min. |

6 ± 1 nm |

[73] |

| Groundnut shells |

The shells were put under Soxhlet extraction for 8 h using benzene: methanol (2:1 ratio) as solvent. The de-waxed shells were subsequently bleached by treatment at 70 °C for 2 h with 1.5% (w/v) NaClO solution at pH 3–4 adjusted by 5% glacial acetic acid. The sample was then treated with 1 M NaOH solution at 65 °C for 2 h. |

Acid hydrolysis process using 65 wt% H2SO4 for 75 min at 45 °C. |

9 nm |

[74] |

| Coffee husk |

Alkali treatment was carried out with a 4 wt% NaOH solution for 3 h, the sample was then bleached using equal parts of acetate buffer solution, NaClO (1.7 wt%), and water for 4 h. |

Acid hydrolysis

treatment was

performed using 64%,

wt H2SO4 at 50 °C

for 40 min |

20 ± 4 nm |

[75] |

| Pineapple crown waste |

Alkaline treatment was performed using 5% NaOH solution at 90 °C for 1 h, the sample was then subjected to bleaching using a mixture of 16% (v/v) H2O2 and 5% NaOH at 55 °C for 90 min. |

Acid-catalyzed hydrolysis method using 60 wt% H2SO4 at 45 °C for

1 h. |

39 ± 12 nm |

[76] |

| Cucumber peels |

The sample was pre-treated with 1 M HCl solution for 1 h at 80–85 °C, followed by alkali treatment using 1 M NaOH for 1 h at 80–85 °C. The sample was bleached using 4% (w/v) NaOCl for 1 h at 90–95 °C. |

Acid-catalyzed hydrolysis method using 60 wt% H2SO4 at 45 °C for 1 h. |

32.9 nm |

[45] |

| Corncob |

The sample was pre-treated with 1 M HCl solution for 1 h at 80–85 °C. Followed by alkali treatment using 1 M NaOH for 1 h at 80–85 °C. The sample was bleached using 4% (w/v) NaOCl for 1 h at 90–95 °C. |

Acid-catalyzed hydrolysis method using 60 wt% H2SO4 at 45 °C for 1 h. |

- |

[77] |

3. CNCs from Corncobs

Corn is a staple food in many countries, with about 1 billion tons of global annual production. In South Africa, approximately 16 million tons of corn were produced during the 2019/2020 period [

78]. About 80% of the weight of the corn ear is attributed to corncob, and, together with the other components of the corn plant besides the corn kernels, are regarded as corn residue. Common uses of corncob residue include animal bedding, animal feed, and fertilizers. The majority of generated waste is burned in farms and/or landfills. Globally, various applications for corncobs are being developed, such as detergents, adsorbants, bioenergy feedstock, and composites. They are LCB waste with high cellulose content.

Table 2 shows a few selected examples of CNC extraction processes using corncobs as a source. It is evident from the presented data that cellulose is present in varying amounts within the corn family and the isolation conditions contribute to the yield and physical properties (where CI* represents crystallinity index). Louis and Venkatachalam [

79] demonstrated in their report that NaOH concentration, reaction time, and temperature all affect the yield of cellulose during the pre-treatment stage. The concentration of H

2SO

4 also affects the physical properties of CNCs, as shown in the table and in many reports in the literature. Recently, Adejumo et al. demonstrated the use of corncob, functionalised corncob, and CNCs as methyl orange dye adsorbants [

80]. In their report, under optimum condition, CNCs had a calculated adsorption capacity of 206.67 mg/g, which was about 11.6 times greater than that of the corncob and 3.4 times higher than that of functionalized corncob [

80].

Table 2. Selected examples presenting the extraction of CNCs from corncob residue.

| Source |

Components |

Isolation Conditions |

Yield (%) |

CI* (%) |

Average Size (nm) |

References |

| Corncob |

Cellulose 34.11 ± 1.47%, lignin 15.08 ± 1.32%, hemicellulose 20.17 ± 2.43%, ash 30.06 ± 1.36%, other components 0.58 ± 0.11%. |

Ball milling machine for 2 h in DMSO |

41.21 |

70.58 |

174.27 ± 4.32 |

[81] |

| Corncob |

Cellulose 45.01 ± 0.9%, hemicellulose33.12 ± 1.1%, lignin 13.81 ± 1.3%, ash 3.1 ± 0.5, other extractives 4.96 ± 1.1%. |

60% H2SO4

at 45 °C for 1 h. |

- |

72.36 |

131.4 |

[79] |

| Corncob |

Cellulose 63.5%, xylan 2.7%, lignin 25.8%, ash 2.1%. |

64% H2SO4 at 45 °C for 1 h |

34.5 |

55.9 |

198 ± 51 |

[38] |

| Corncob |

Cellulose 63.5%, xylan 2.7%, lignin 25.8%, ash 2.1%. |

0.5% HCl and 88% CH2O2 at 95 °C for 30 min. |

66.3 |

63.8 |

421 ± 112 |

[38] |

| Corncob |

Cellulose 63.5%, xylan 2.7%, lignin 25.8%, ash 2.1%. |

TEMPO (1 mmol/L) and sodium bromide (10 mmol/L) at pH 10. |

78.4 |

49.9 |

438 ± 173 |

[38] |

4. Prospective Applications of CNCs

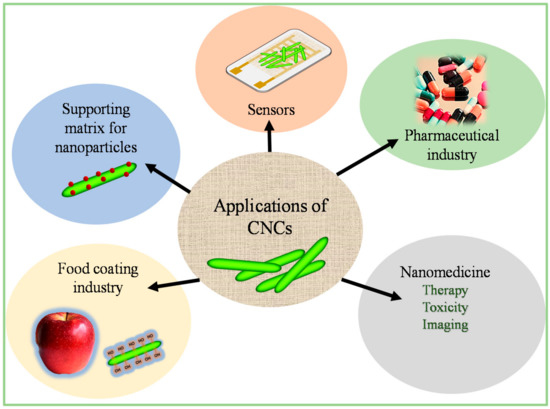

Due to the abundance of biomass waste, various pre-treatment and extraction methods, outstanding and unique nanoscale structure, excellent mechanical properties, thermal stability, biocompatibility, biodegradability, and easy surface modification, CNCs have attracted rapidly growing scientific and technological interest, and have reported application prospects in many fields, such as health care, environmental protection, and chemical engineering [

82]. Grishkewich et al. [

83] summarized the recent applications of CNCs in biomedical engineering (tissue engineering, drug delivery, biosensors, and biocatalysts), wastewater treatment (adsorbents), energy, and electronics (supercapacitors, conductive films, substrates, sensors, and energy-storage separators).

Figure 5 demonstrates the summarized recently reported applications of CNCs. CNCs have also found applications in the monitoring and improvement of food quality. Dhar et al. [

84] fabricated a poly (3-hydroxybutyrate) (PHB)/CNCs based nanocomposite films with improved gas-barrier and migration properties for food packaging applications. Peng et al. [

85] incorporated CNCs into different food-based systems containing polymers as a thickening agent. The CNCs improved the viscosity enhancement at lower particle loading. Besides these promising applications, CNC-based materials have also been applied in the fabrication of carbon-based nanomaterials. Dhar et al. used CNCs to prepare graphene with tuneable dimensions, while Souza et al. [

86] prepared luminescent nanocarbon structures. Magagula et al. prepared luminescent-nitrogen-doped spherical carbons (NCSs) and used them for the detection of Fe

3+ in aqueous solutions [

77]. The following section focuses on the recent research regarding the fabrication of CQDs from LCB waste.

Figure 5. Different applications for CNCs reported in the literature.

This entry is adapted from the peer-reviewed paper 10.3390/ijms23084310