Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Electrical & Electronic

As one of the most impressive materials for wearable sensors, conductive fibers can be made from a variety of raw sources via diverse preparation strategies.

- conductive fibers

- preparation strategies

1. Introduction

Stretchable wearable devices have attracted extraordinary attention with the upsurge of interest in health monitoring systems and noninvasive human–machine interfaces. As a significant element of wearable electronics, a flexible sensor exhibits an unprecedented potential in human–machine interaction, human healthcare monitoring, electronic skin, artificial intelligence technology, etc. [1], which is capable of detecting and quantifying diverse bioinformation (body temperature, blood pressure, and respiratory patterns) with high specificity and sensitivity [2]. To accommodate the life expectancy of humans, lots of wearable sensors with diverse functions appeared [3]. Likewise, a variety of materials, such as metal sheets, metal wires, foam sheets, and plastic films, are employed to prepare wearable sensors [4,5,6,7,8]. Among them, the most popular and promising materials are conductive fibers owing to their advantages of superior flexibility, conductivity, breathability, durability, washability, biocompatibility, and so on, [3,9,10,11]. With recent advances in materials science and micro/nanofabrication, there has been active research on conductive fibers for wearable sensors.

Conductive fibers have broadly gone through three generations: (1) the first generation is flexible conductive fibers with traditional metals as raw materials, and the metals are designed to be stretchable structures, but with poor wearability, conductive instability, and other problems; (2) the second generation uses polymers as elastic conductive materials. Although their stability and conductivity are not ideal, the preparation process is simple and designable. Moreover, the material sources are wide. (3) The third generation is based on special textile yarns to fabricate composite elastic conductive fibers [1,12,13,14]. Currently, many conductive fibers manufactured by combining textile technology, mechanical technology, materials science, and electronics exhibit several advantages. Firstly, such conductive fibers have good flexibility and large deformation when being subjected to a very small external force, and their Young’s modulus ranges from MPa to KPa. Plus, they usually possess a large specific surface area of about 102–3 m2/kg as well as varying degrees of porosity up to 99%, leading to good permeability [15]. In addition, some conductive fibers possess good durability, which can remain stable under stretching, bending, twisting, and shearing at various frequencies for more than 10,000 cycles. Furthermore, other conductive fibers can work not only at room temperature, but also under extreme temperature conditions. For example, some conductive fibers can work normally at low temperatures of −268.15 °C and others can operate at high temperatures of 250 °C [16,17,18]. It is known that the normal working temperature range of the majority of conductive fibers far exceeds the operating temperature range requirements of wearable sensors. Finally, these conductive fibers show good biocompatibility and do no harm to sensitive skin. Therefore, they have been made as artificial organs instead of necrotic organs [19,20,21,22,23]. Based on the building blocks of conductive fibers, they can be classified into three categories: metal-based conductive fibers, carbon-based conductive fibers, and polymer-based conductive fibers. Each conductive fiber has its own advantages: metal-based conductive fibers have relatively high conductivity, carbon-based conductive fibers have relatively low cost, and high fraction-based conductive fibers can be prepared to make more functional sensors.

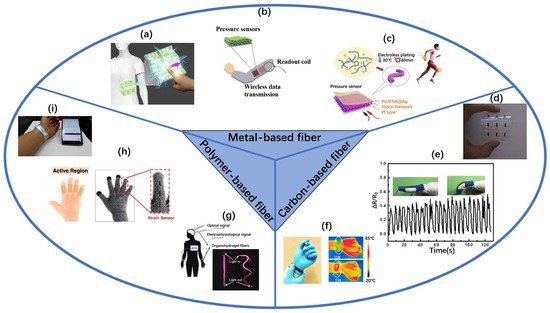

Due to the excellent features of conductive fibers mentioned above, it is perfect for them to be applied in wearable sensors, which are able to extract various signals and analytes, such as pressure, tension, humidity, temperature, etc., making it possible to monitor human health conditions [12]. Besides, wearable sensors made of conductive fibers are very soft and flexible so that they can be bent, pulled, and folded like textiles. In addition to the soft mechanical properties, the favorable biocompatibility enables them to fit well with human skin, making them particularly comfortable to wear. In terms of the superior advantages of conductive fibers, the wearable sensors made of conductive fibers can be generally divided into three main categories: pressure sensors, strain sensors, and other types of sensors according to the different applications. Pressure sensors, including resistive, capacitive, and piezoelectric, are to convert external mechanical variations to electrical signals, which is mainly used for monitoring human health condition. As one of the next-generation electronics, strain sensors composed of conductive fibers have been widely investigated owing to their excellent mechanical flexibility and stretchability compared to the traditional rigid strain sensors. Nowadays, they can be used in a variety of areas, such as electronic skin, smart textiles, soft robotics, and so on. Meanwhile, other types of sensors consisting of conductive fibers are gas sensors and humidity sensors. They are usually applied to detect toxic gases or control the temperature. All in all, no matter which type of sensors, they take advantage of the conductive fiber’s extraordinary features. Until now, lots of studies have been published to demonstrate the diverse raw materials and wearable sensors used and made for conductive fibers, respectively (as shown in Figure 1).

Figure 1. Various wearable sensors prepared from three types of conductive fibers used to detect various parameters of the human body: (a) capacitive sensors used in clothing [21], (b) an all-fabric pressure sensor with a wireless battery-free monitoring system [22], (c) piezoresistive sensor for monitoring human movement [23], (d) 3 × 3 flexible strain sensing array [24], (e) strain sensor monitors human movement [25], (f) a sensor that can be heated and monitored [26], (g) smart wireless blood pressure sensor [10], (h) a strain sensor applied to gloves [27], (i) capacitive sensor made into keyboard [28].

2. Metal-Based Conductive Fiber

Metals, as the most common conductive materials in life, show high mechanical strength, thermal conductivity, and electrical conductivity of about 5 × 105 S cm−1 [49]. For example, EGaIn, silver, aluminum, copper, nickel, and others are very suitable for making conductive layers of metal-based conductive fibers, and they have been successfully prepared as various conductive fibers with superior electrical conductivity [50,51,52]. Among them, liquid metal (EGaIn) has become a popular material to prepare metal-based conductive fibers due to its low melting point (29.8 °C), low viscosity, high surface tension, high electrical conductivity (3.4 × 104 S cm−1), and good thermal conductivity [25,53,54]. It can be well combined with various elastomers, such as PDMS and PU, which can be manufactured as a flexible resistive strain sensor, followed by capacitive pressure sensors and piezoelectric pressure sensors [55,56,57,58]. Though the cost of EGaIn is very high, it is still highly favored by researchers. In a study, Liu et al. [59] injected EGaIn into hollow PDMS fibers to prepare a liquid-metal-based conductive fiber with high conductivity and excellent tensile properties. This conductive fiber was used to develop a resistive strain sensor. Silver is also often prepared as a metal-based conductive fiber by depositing silver nanowires or nanoparticles onto elastic fibers (e.g., nylon, PU fibers), which is mainly in the form of silver nanowires or silver nanoparticles [60]. Yan et al. [61] integrated AgNWs on top of PU fibers to form a conductive fiber with high conductivity and good stability. The conductive fiber was successfully prepared as a resistive strain sensor with high sensitivity. During the preparation process, the most important thing is to ensure that the coating is uniform, continuous, and thin, maintaining good electrical conductivity. The silver-based conductive fibers are generally prepared as a resistive strain sensor. Plus, there are also metals such as aluminum, copper, and nickel that have been applied as raw materials for the metal-based conductive fiber [62,63,64]. Those metals are mainly employed as plating layers combined with various elastomers, whose cost is relatively low compared to EGaIn and silver. However, copper and nickel would reduce the conductivity of the obtained metal-based conductive fibers due to oxidation, affecting the performance of the corresponding wearable sensors. In general, metal-based conductive fibers exhibit good electrical conductivity, durability, thermal conductivity, and high mechanical strength, which are suitable for manufacturing into functional wearable sensors, such as resistive strain sensors, resistive pressure sensors, piezoelectric pressure sensors, capacitive pressure sensors, etc. [65,66,67,68].

3. Carbon-Based Conductive Fiber

The development of carbon-based materials has attracted much attention in recent years due to their potential applications in a wide range of fields, such as energy storage devices, fuel cells, sensors, and electromagnetic shielding. Carbon and its derivatives are used in the manufacture of conductive fibers because of their remarkable characteristics, such as low cost, high electrical conductivity, large specific surface area, excellent chemical stability, and good mechanical durability [69]. The most commonly used carbon and its derivatives are graphene (G), graphene oxide (GO), reduced graphene oxide (rGO), CNTs, activated carbon (AC), and CB [70]. Among them, CB is in the form of black powder, with particle diameters ranging from 10 to 100 nm [71]. Compared with other types of carbon materials, CB is often employed for preparing carbon-based conductive fibers due to its wide sources. In the preparation process of carbon-based conductive fibers, CB is mainly dispersed uniformly in a solution and then coated on the surface of elastomers or it is mixed with the elastomer to form a solution or melt which is then cured into carbon-based conductive fibers. For example, Souri et al. [72] prepared a conductive ink using CB as the main raw material and applied it to elastic cotton fabric to produce conductive fibers. Such conductive fibers are usually made as resistive strain sensors and resistive pressure sensors [73]. CNTs are allotropes of carbon, which are also often used to fabricate carbon-based conductive fibers. However, CNTs have certain toxicity, which is super harmful to humans. Thus, safety precautions need to be taken when using CNTs to manufacture carbon-based conductive fibers [74]. Usually, CNTs are connected with the surface of the fiber to obtain conductive fibers [11]. Sometimes, CNTs as conductive fillers are put into hollow elastic fibers to prepare carbon-based conductive fibers [75]. In a study, Zhou and his colleagues prepared a highly stretchable conductive fiber by uniformly filling CNTs inside thermoplastic elastomer (TPE) tubes [62]. Similarly, G, GO, rGO, AC, etc., are used in a comparable way to prepare carbon-based conductive fibers [76,77,78,79]. For example, Souri et al. [80] fabricated a type of carbon-based conductive fiber by mixing G nanosheets into conductive inks and then coating the mixer onto cotton fabrics. In terms of safety, G nanomaterials are safer compared with CNTs [75]. In addition, it possesses better mechanical flexibility than metal nanomaterials [10]. In general, carbon-based conductive fibers possess superior advantages of electrical conductivity, chemical and mechanical durability, and low cost, which can be applied to make resistive strain sensors, resistive pressure sensors, humidity sensors, etc. They play a key role in the conductive fibers, resulting in significant parts in the field of functional wearable sensors.

4. Polymer-Based Conductive Fiber

Currently, there are many types of polymers, some of which have become the material choices for manufacturing multifunctional fibers or films owing to their high electrical conductivity, good processability, lightweight, high elasticity, and strong corrosion resistance [65,66]. Typical polymers used for conductive fibers are PPy, PANI, polythiophene (PTh), PEDOT: PSS, etc. [81]. Their conductivity is usually between 10−8 and 102 S cm−1 at room temperature [82]. Commonly, the polymer-based conductive fibers are prepared by solidifying a co-blended solution of polymers and elastomers. Sometimes, the monomers of the conductive polymer are polymerized directly on the surface of the elastomer to form the conductive fiber. A few polymer-based conductive fibers are made via directly coating the conductive polymer on the elastomer surface, as with some metal-based conductive fibers. For example, Tadesse and his colleagues prepared the conductive paste PEDOT: PSS as the main materials. The conductive paste was then added to the appropriate amount of rheology modifier to increase the viscosity of the conductive paste. Finally, the conductive paste is coated on the fiber surface to form a polymer-based conductive fiber [29]. Polymer-based conductive fibers are often fabricated as resistive strain sensors, resistive pressure sensors, capacitive pressure sensors, piezoelectric sensors, etc. In addition, polymers including PPy, PAIN, PTh, etc., show different degrees of sensitivity to various gases (NH3, N2, CO, etc.), resulting in being developed as gas sensors. For instance, a polymer-based conductive fiber can be made into a wearable gas detection sensor, which uses PAIN and PAN nanofibers as the main raw materials. It possesses excellent sensitivity, fast response and recovery time, good reproducibility, and stability for NH3 at 10–2000 ppm at room temperature [83]. In summary, polymer-based conductive fibers are composed of a variety of polymers, which are not only prepared as resistive strain sensors, resistive pressure sensors, and capacitive pressure sensors, but also as diverse gas sensors [84,85]. This is an advantage that metal-based conductive fibers and carbon-based conductive fibers do not have.

This entry is adapted from the peer-reviewed paper 10.3390/s22083028

This entry is offline, you can click here to edit this entry!