Plasma is a quasi-neutral system in a gaseous or fluid-like form that can be artificially generated in an electromagnetic field and a flow of neutral gases such as helium, argon, nitrogen, oxygen, or atmospheric air. It contains a mixture of radicals, H2O2, O3, ultraviolet radiation, charged particles, exited metastable atoms, and electric fields. Non-thermal atmospheric plasma has recently attracted great research interest as an alternative for operative solutions to problems related to safety and quality control. It is a powerful tool for the inactivation of different hazardous microorganisms and viruses, and the effective decontamination of surfaces and liquids has been demonstrated. Additionally, the plasma’s active components are strong oxidizers and their synergetic effect can lead to the degradation of toxic chemical compounds such as phenols and azo-dyes.

1. Introduction

Our contemporary society is facing many environmental challenges due to the unprecedented level of industrialization, urbanization, and exponential growth of the human population. The increasing generation and disposal of wastes, environmental pollution, source depletion, biodiversity loss, climate changes, and growing energy demand are global threats to our sustainable development and require a fundamentally new rethinking to reduce the consumer footprint on nature

[1][2][3][4]. The transformation of our linear “take-make-waste” system to the cyclic flow of materials and energy is urgent, and this is a key driver for the rapid development and promotion of the circular economy concept. The circular economy has the potential to overcome challenges by following three general principles: “(1) preserve and enhance natural capital by controlling finite stocks and balancing renewable resource flows; (2) optimize resource yields by circulating products, components, and materials in use at the highest utility; (3) foster system effectiveness by revealing and designing out negative externalities“

[5][6]. The most widely applicable aspects of the circular economy include eco-design for sustainability, an extension of the product life cycle, and implementation of “reduce, reuse and recycle” option in waste management

[7][8]. However, the closing of loops in different industrial sectors by circulation, reuse, and recycling of materials and products brings to the fore other key issues—those related to safety and the prevention of risks from secondary contamination. Ensuring a high level of uncompromising safety in circular economy practices is a priority task and an important keystone for the achievement of high social acceptance and positive user perceptions and attitudes.

When discussing safety issues, it must be taken into account that safety includes both microbiological and chemical aspects. The context of the circular economy is no exception-we must be sure that the use of waste streams from one industry/sector as a material input for another is completely safe and the possibility for the crossover of chemical or microbiological hazards is eliminated/minimized. The problem is escalating nowadays with the enormous production and use of chemicals, resulting in a global scale of chemical pollution, and the pandemic distribution of unknown viruses and multidrug-resistant bacteria

[9][10]. It is clear that we urgently need new advanced approaches ensuring both microbiological safety and the removal of potential chemical residues in different materials and products, with the quick achievement of the high safety level, easy operation, lack of residual toxicity, and wide use with no application restrictions

[11][12][13]. Facing these scientific and practical challenges, it seems that one well-known physical phenomenon—plasma—and some recently developed plasma-based technologies can effectively respond to these requirements.

Plasma is a quasi-neutral system in a gaseous or fluid-like form that can be artificially generated in an electromagnetic field and a flow of neutral gases such as helium, argon, nitrogen, oxygen, or atmospheric air. It contains a mixture of radicals, H

2O

2, O

3, ultraviolet radiation, charged particles, exited metastable atoms, and electric fields

[14][15]. The plasma active components individually are well-known sterilization agents, and as expected, their combination in plasma has a strong synergistic effect and provides high bactericidal efficiency with low costs, timesaving, and non-toxicity.

Based on the temperature of particles, there are two types of plasmas: high-temperature plasmas (fusion plasmas) and low-temperature plasmas (non-thermal or cold plasmas)

[14]. Each type of plasma has a specific application and benefits but in the field of biosafety and microbiological control of different materials and products, the leading role of non-thermal plasma is undoubted, especially the type generated at atmospheric pressure

[11][15][16][17][18][19][20][21][22][23][24][25][26][27]. Its main advantage is a simple and less expensive plasma source operating in an open space without thermal damage to treated materials. Non-thermal plasmas may be generated by direct current (DC) discharge, radio frequency discharge, dielectric barrier discharge, pulsed power, and surface wave (microwave) discharge. Microwave plasma is not in equilibrium, the electron energy distribution function is non-Maxwellian, and the temperature of the heavy particles is much lower than the electron temperature

[28]. Non-equilibrium, non-thermal atmospheric pressure plasma (also called cold atmospheric plasma—CAP) is suitable to treat living tissues, heat-sensitive materials, foods, and bio-compatible materials, and has wide use in medicine, the agro-food industry, and microbiological control. The use of CAP is not limited to alternative sterilization or therapeutic technique for biomedical application—the plasma-based approach has an important role in the solution of some critical environmental issues. Recent data show its significant potential as an effective tool in pollution control and the treatment of different polluted sources. Looking at the wide field of plasma applications from a different perspective, it is clear that this huge potential can successfully contribute to improving the microbiological and chemical safety of products and materials in the circular economy.

2. Low-Temperature Non-Equilibrium Plasma for Microbial Decontamination

For convenience, the specific fields of CAP where its germicidal effect is used can be generalized as follows: (1) plasma-aided medical therapies, (2) plasma-assisted dentistry, and (3) plasma-based decontamination and sterilization for microbiological control in agriculture, food industry, microbiology, water treatment, etc.

The interaction of CAP with living objects, bacteria, spores, and viruses has been extensively studied in the last decades, and basic principles have been defined

[29][30][31][32]. The main attention has been paid to plasma’s killing effect on bacteria (both Gram-positive and Gram-negative), bacterial spores, biofilms, and fungi. A significant efficiency of treatment has been gained with different CAP-generated configurations against a large number of pathogens with high-risk profiles:

Escherichia coli,

Listeria monocytogenes,

Salmonella enterica,

Staphylococcus sp.,

Pseudomonas aeruginosa,

Bacillus sp.; and spores such as

Candida albicans [33][34][35][36][37][38][39][40]. The bactericidal effect of CAP is clearly expressed in the treatment of biofilms on different surfaces and bacterial suspensions in liquids. Viruses and prions have been studied to a lesser extent, but in the last two years, this gap has begun to fill intensively due to the COVID-19 crisis

[41][42][43]. Many studies have demonstrated the ability of non-thermal plasma to be an effective virucidal agent. The plasma treatment reduces virus burdens on contaminated surfaces and airborne viruses. and can be applied for successful prevention and interference of virus replication

[44].

Some of the hypotheses for the inactivation mechanism of CAP on bacteria are summarized by Fernandez and Thompson as follows

[45]: the destroying effect of UV irradiation on DNA according to its power density and wavelength range

[46]; damage from the diffusion of reactive species through membranes and their reaction with cell macromolecules

[47]; the etching effect on the cell surface by direct bombardment with free radicals

[48]; erosion of the microorganisms through intrinsic photodesorption by UV

[49]. The last two lead to a massive leakage of cell content, a strongly negative effect on cell adhesion at biofilm growth, and the interruption or inhibition of biofilm quorum sensing systems

[50].

In the field of agriculture and food processing, the search for new promising and effective “cleaning” tools with a multipurpose application based on cold atmospheric plasma has also been the subject of many types of research

[16][24][51][52][53][54][55]. The growing need for “green”, un- or less processed food with high quality, safety, and preserved taste and nutrients leads to a very attractive rating of CAP as a powerful non-thermal sterilization technique. The recent studies are aimed at the treatment of food products, food processing devices, packaging materials, functionality modification of food materials, and removal of agrochemical residues

[22][56][57][58]. Non-thermal atmospheric plasma is a promising decontamination technology for the inactivation of bacteria, yeasts, molds, and fungal and bacterial spores both on the foods and on the abiotic surfaces of packages or processing equipment

[59]. The obtained results reveal promising opportunities to use CAP to ensure safety, especially in the case of the entry of waste streams in different stages of processing. The reuse of composted food wastes or activated sludge as fertilizer in agriculture, for example, may increase microbiological risk, while appropriate plasma treatment of the final product may eliminate the hazard. Additionally, plasma can be used for alternative food processing to obtain the desired color of meat products without adding chemicals, to improve the extraction of essential oils, or to extend the life of some products

[27][59].

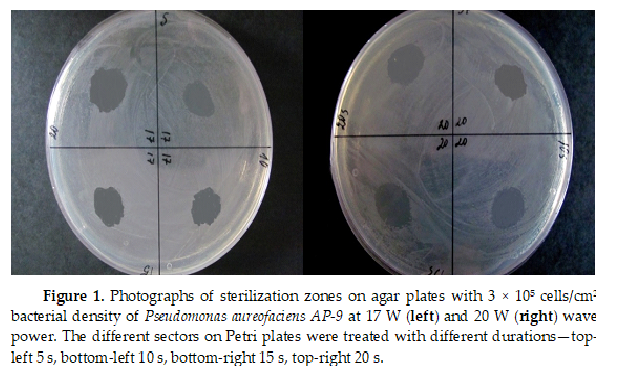

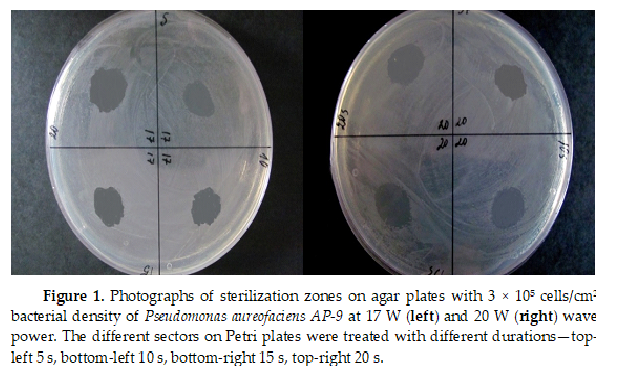

Non-equilibrium, non-thermal atmospheric pressure plasma can be generated by different sources [69,70]. We use a surface wave discharge that produced the plasma by an electromagnetic wave travelling along with the plasma-dielectric interface. The plasma is produced in argon at atmospheric pressure by a surfatron type electromagnetic wave launcher operating at 2.45 GHz. Discharge conditions are: plasma radius 0.05 cm ÷ 0.1 cm; gas flow rate 3.2 L/min. Treatment times during all the investigations are significantly short—less than a minute—and the input wave powers are under 20 W. The low gas temperature allows plasma to be in close contact with the treated samples.

The used plasma source had a clear sterilization effect on films of Pseudomonas AP-9, even at the shortest treatment time of 5 s. The boundaries of the zones were differentiated and the sterilization effect at this bacterial number (3 × 105 cells/cm2) was very stable (Figure 1). Our observations showed the absence of bacterial growth for more than 168 h in the zones, which maintained their sizes and purity.

The diameter and area of the sterilization zones depend on different factors; our results identify the following as the most important: treatment time, wave power and density of treated bacterial films. The area is larger when the exposure time and wave power are increased, but high bacterial density has a limiting action for the achievement of effective and stable sterilization. At the cell density of 90 × 105 cells/cm2, the diameter of obtained clear zones was smaller. The cell density of treated films had one of the leading roles in the achievement of effective decontamination. However, in all cases, the zone diameter was significantly larger than the diameter of the plasma torch. The generated plasma torch was 1–2 mm; the sterilization zones had a diameter of more than 5 mm. The temperature of plasma was close to room temperature and the effect of high temperature for bacteria-killing could be excluded. Probably, the diffusion of reactive species and the UV irradiation produced in the plasma torch made the sterilization zones much larger than the plasma contact area.

3. Low-Temperature, Non-Equilibrium Plasma for Removal of Hazardous Chemicals

The growing production, wide use, and subsequent discharge of different toxic and persistent pollutants in the environment are another serious threat to human and ecosystem health. The effective solution of associated environmental problems needs adequate pollution control based on innovative approaches, and plasma technologies are one of the promising new alternatives. Considerable attention of researchers has been focused on plasma-assisted removal of volatile organic compounds from polluted air, and significant results have already been achieved in this area

[60][61][62][63]. In the last years, these technologies have been applied for the treatment of gases from animal production to food processing facilities, and a high removal and energy efficiency has been achieved

[64]. Solid waste and soil treatment is another area of research interest where the focus is mainly on thermal plasma application, but some types of non-thermal plasmas have been used

[65][66]. Our efforts in the environmental field of plasma application are related to another target component—water—and its treatment for the removal of organic pollutants. The strong oxidation features of some highly energetic plasma components mean that plasma can be used successfully for the removal of unacceptable organic compounds in wastewater

[67][68][69][70][71]. In many advanced strategies for pollution control and management, plasma technologies are considered as one of the options for the substitution of expensive traditional chemical methods in water treatment and the elimination of secondary pollution in treated water. High efficiency has already been achieved in the removal of phenol and a wide range of phenolic derivates

[68][71][72][73][74], azo-dyes

[65], pharmaceutical and antibiotic compounds

[75][76][77], and carbon from plastic waste

[78]. Several configurations have been developed and applied for the removal of different organic pollutants during discharge in the gas, liquid, or hybrid liquid-gas phase, such as pulsed high-voltage electrical discharge, glow discharge, and gliding arc

[71].

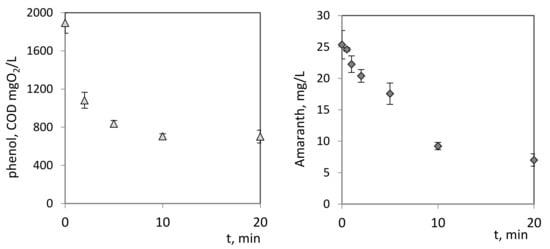

In the experimental design, we included treatment of waters with two bio-recalcitrant organic pollutants: phenol with an initial concentration of 500 mg/L (corresponding to Chemical Oxygen Demand COD = 1900 mgO2/L), and azo-dye amaranth with a concentration of approximately 25 mg/L. The volume of treated samples was the same at 35 mL; the time of treatment varied from 30 s to 20 min. The concentration of pollutants was measured before and after treatment, according to standard spectrometric methods for the determination of COD by potassium dichromate and by the reduction of amaranth absorbance at 520 nm.

Figure 2 presents the reduction in the concentration of phenol and amaranth after plasma treatment. The concentration of these two organic compounds was reduced depending on treatment time. The 2 min treatment led to 45% removal of phenol in model wastewater, assessed by reduction of organic content of water; an increase of the time to 10 min achieved 62% removal. In the other model wastewater, the concentration of the xenobiotic compound amaranth decreased gradually with the increase of exposure time. The percentage of removal was 72% with 20 min treatment.

Figure 2. Variation in concentration of xenobiotic organic compounds—phenol, measured as COD (left), and amaranth (right)—after cold plasma treatment.

These results represent a preliminary assessment of the potential of microwave plasma to be used for the removal of organic residues and pollutants. Although the times used failed to achieve complete removal of pollutants, the data show that, even with such a short impact, there was sufficient effect to continue research in the environmental field with this type of plasma source.

The most important future challenge in the field of plasma use in the circular economy context is related to the urgent need for the commercialization of these technologies. The efforts of all research groups working in the field of cold atmospheric plasma application (a small part of whose results we have been able to summarize here) have led to the elucidation of different aspects of the plasma scientific base. However, there is still a significant gap in plasma implementation for real practice, especially in industry and agriculture. This process is additionally hampered by the need for optimization of plasma-generating devices for each specific application. Nevertheless, cold atmospheric plasma has a high proven capacity for solving the urgent problems of microbial and chemical safety, and its successful wide implementation in practice is a matter of time.

This entry is adapted from the peer-reviewed paper 10.3390/pr10030554