Three FRP shapes are used in Structural Engineering applications: FRP profiles for new construction, FRP rebars and FRP strengthening systems. Applications in bridges, buildings, railway platforms, cooling towers and repair and rehabilitation of existing structures are presented. FRP is a strong and lightweight sustainable material with lower carbon footprint than traditional materials. However, FRPs are not as widely used as expected. FRP use in repair and rehabilitation has seen significant growth, though, over last two decades. The major challenges have been steel-like FRP elements, lack of ductility, almost no legal design guidelines and inadequate knowledge about fire and durability performance. The future of FRPs can be promising if engineers use this material more for net-zero carbon construction, and to effectively deal with climate emergency.

- FRP connections

- hybrid joints

- all-FRP structures

- pultruded FRP structures

- bolted joints

- plate-to-plate connections

- beam-to-column joints

- FRP applications

- FRP buildings and bridges

- climate emergency

- net-zero carbon construction

1. Introduction

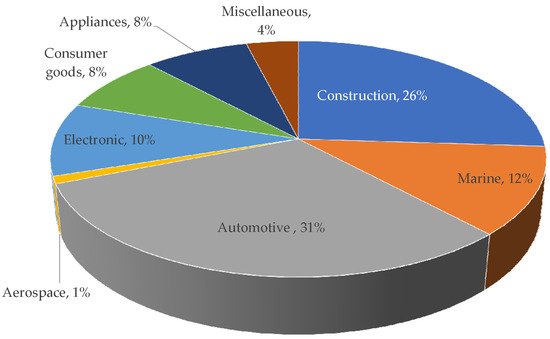

2. FRP Applications

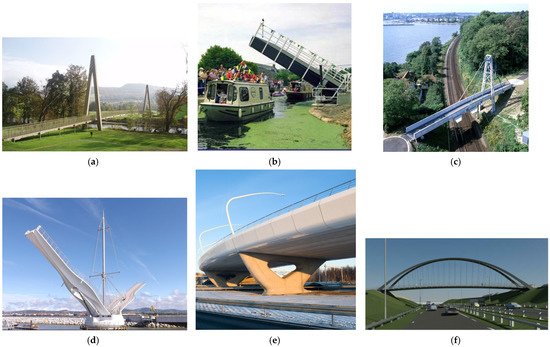

2.1. All-FRP New-Build Structurs

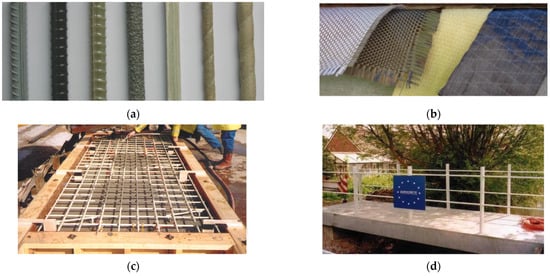

2.2. FRP as Reinforcement

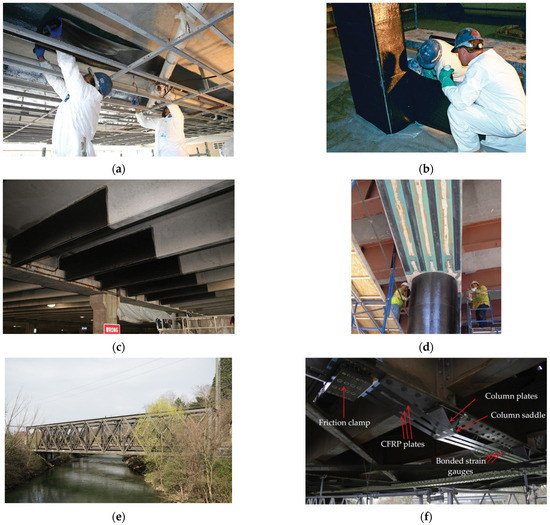

2.3. FRP in Strengthening Applications

3. Challenges and future trends

4. Conclusions

This entry is adapted from the peer-reviewed paper 10.3390/fib10030027

References

- Correia, J.R. Fibre-Reinforced Polymer (FRP) Composites. In Materials for Construction and Civil Engineering, Science, Processing, and Design; Goncalves, M.C., Margarido, F., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 501–556. ISBN 978-3-319-08235-6.

- Bank, L.C. Composites for Construction—Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006.

- Ali, H.T.; Akrami, R.; Fotouhi, S.; Bodaghi, M.; Saeedifar, M.; Yusuf, M.; Fotouhi, M. Fiber reinforced polymer composites in bridge industry. Structures 2021, 30, 774–785.

- Anandjiwala, R.D.; Blouw, S. Composites from Bast Fibres-Prospects and Potential in the Changing Market Environment. J. Nat. Fibers 2007, 4, 91–109.

- Duflou, J.R.; Deng, Y.; Van Acker, K.; Dewulf, W. Do fiber-reinforced polymer composites provide environmentally benign alternatives? A life-cycle-assessment-based study. MRS Bull. 2012, 37, 374–382.

- Correia, J.R.; Bai, Y.; Keller, T. A review of the fire behaviour of pultruded GFRP structural profiles for civil engineering applications. Compos. Struct. 2015, 127, 267–287.

- Qureshi, J.; Nadir, Y.; John, S.K. Bolted and bonded FRP beam-column joints with semi-rigid end conditions. Compos. Struct. 2020, 247, 112500.

- Qureshi, J.; Nadir, Y.; John, S.K. Cyclic Response of Bolted and Hybrid Pultruded FRP Beam-Column Joints between I-Shaped Sections. Fibers 2021, 9, 66.

- Fiberline Composites. Fiberline Design Manual; Fiberline Composites A/S: Kolding, Denmark, 2002.

- Vallée, T.; Tannert, T.; Meena, R.; Hehl, S. Dimensioning method for bolted, adhesively bonded, and hybrid joints involving Fibre-Reinforced-Polymers. Compos. Part B Eng. 2013, 46, 179–187.

- Masuelli, M.A. Introduction of Fibre-Reinforced Polymers—Polymers and Composites: Concepts, Properties and Processes. In Fiber Reinforced Polymers The Technology Applied for Concrete Repair; Masuelli, M.A., Ed.; IntechOpen: London, UK, 2013; ISBN 978-953-51-0938-9.

- Strongwell. Strongwell Design Manual; Strongwell Corporation: Bristol, VA, USA, 2010.

- Creative Pultrusions. The new and Improved Pultex Pultrusion Design Manual; Creative Pultrusions Inc.: Alum Bank, PA, USA, 2004.

- Pre-Standard for Load and Resistance Factor Design (LRFD) of Pultruded Fiber Reinforced Polymer (FRP) Structures (Final). Available online: http://dev1.kreysler.com/information/specifications/specs-resources/LRFD%20PreStandard%20-%20Revised%20FINAL%20-%20Nov%209%202010.pdf (accessed on 11 November 2021).

- Mottram, J.T.; Henderson, J. (Eds.) Fibre-Reinforced Polymer Bridges—Guidance for Designers; Construction Sector Group: London, UK, 2018; ISBN 9780860177944.

- CNR-DT 205/2007. Guide for the Design and Construction of Structures Made of FRP Pultruded Elements, CNR—Advisory Committee on Technical Recommendations for Construction; National Research Council of Italy: Rome, Italy, 2008.

- Clarke, J.L. Structural Design of Polymer Composites- EUROCOMP Design Code and Handbook; E and FN Spon: London, UK, 1996.

- Ascione, F.; Lamberti, M.; Razaqpur, A.G.; Spadea, S. Strength and stiffness of adhesively bonded GFRP beam-column moment resisting connections. Compos. Struct. 2017, 160, 1248–1257.

- Kelly, G. Load transfer in hybrid (bonded/bolted) composite single-lap joints. Compos. Struct. 2005, 69, 35–43.

- Kelly, G. Quasi-static strength and fatigue life of hybrid (bonded/bolted) composite single-lap joints. Compos. Struct. 2006, 72, 119–129.

- Weitzenböck, J.R.; McGeorge, D. Science and technology of bolt-adhesive joints. Adv. Struct. Mater. 2011, 6, 177–199.

- Anonymous. Guide to the Structural Use of Adhesives; The Institution of Structural Engineers: London, UK, 1999; ISBN 1874266433.

- Keller, T. Towards Structural Forms for Composite Fibre Materials. Struct. Eng. Int. 1999, 9, 297–300.

- Keller, T.; Nikolaos, A.T.; Anastasios, P.V.; de Castro, J. Effect of Natural Weathering on Durability of Pultruded Glass Fiber–Reinforced Bridge and Building Structures. J. Compos. Constr. 2016, 20, 4015025.

- Zafari, B. STARTLINK Building System and Connections for Fibre Reinforced Polymer Structures. Ph.D. Thesis, University of Warwick, Coventry, UK, 2012.

- DuraComposites GFRP Station Platform. Available online: https://www.duracomposites.com/rail/grp-composite-station-platforms/ (accessed on 11 November 2021).

- Singleton, M.; Hutchinson, J. Development of Fibre-Reinforced Polymer Composites in Building Construction. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; Zachar, J., Claisse, P., Naik, T.R., Ganjian, E., Eds.; Università Politecnica delle Marche: Ancona, Italy, 2010.

- Skinner, J.M. A critical analysis of the Aberfeldy footbridge Scotland. In Proceedings of the Bridge Engineering 2 Conference; University of Bath: Bath, UK, 2009; Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.580.4202&rep=rep1&type=pdf (accessed on 20 December 2021).

- Burgoyne, C.J. Advanced Composites in Civil Engineering in Europe. Struct. Eng. Int. 1999, 9, 267–273.

- Braestrup, M.W. Footbridge Constructed from Glass-Fibre-Reinforced Profiles, Denmark. Struct. Eng. Int. 1999, 9, 256–258.

- Hobbs, M. Design and fabrication of two 30 m long moulded FRP decks for the Pont y Ddraig lifting footbridge. In Proceedings of the Second International Conference on the use of Fibre-Reinforced Polymer Composites in Bridge Design, London, UK, 11–12 September 2014.

- Smits, J. Fiber-Reinforced Polymer Bridge Design in the Netherlands: Architectural Challenges toward Innovative, Sustainable, and Durable Bridges. Engineering 2016, 2, 518–527.

- Nepomuceno, D.D.T.; Bennetts, J.; Webb, G.T.; Langhorne, M.; Johnson, M.; Macdonald, J.H.G.; Tryfonas, T.; Vardanega, P.J. Assessing the Potential Value of a SHM Deployment on a Proposed Footbridge. In Proceedings of the Advances and Challenges in Structural Engineering, 2nd GeoMEast International Congress and Exhibition on Sustainable Civil Infrastructures, Cairo, Egypt, 24–28 November 2018; Rodrigues, H., Elnashai, A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 151–166.

- Keller, T. Overview of fibre-reinforced polymers in bridge construction. Struct. Eng. Int. J. Int. Assoc. Bridg. Struct. Eng. 2002, 12, 66–70.

- Canning, L.; Luke, S. Development of FRP Bridges in the UK—An Overview. Adv. Struct. Eng. 2010, 13, 823–835.

- Alampalli, S.; Kunin, J. Load Testing of an FRP Bridge Deck on a Truss Bridge. Appl. Compos. Mater. 2003, 10, 85–102.

- Bank, L.C. Application of FRP Composites to Bridges in the USA. In Proceedings of the International Colloquium on Application of FRP to Bridges, Japan Society of Civil Engineers (JSCE), Tokyo, Japan, 20 January 2006; pp. 9–16.

- The International Handbook of FRP Composites in Civil Engineering, 1st ed.; Zoghi, M. (Ed.) CRC Press: Abingdon, Oxon, UK, 2013.

- Smale, K. Delivering Differently|Fibre Reinforced Polymers. Available online: https://www.newcivilengineer.com/archive/delivering-differently-fibre-reinforced-polymers-18-01-2016/ (accessed on 11 November 2021).

- Kendall, D.; Smith, I.; Young, C.; Gough, W.; Cross, A. Dawlish FRP footbridge—The first FRP bridge at a UK railway station. In Proceedings of the FRP Bridge Conference, London, UK, 13–14 September 2012; NetComposites: London, UK, 2012; pp. 101–117.

- CEB-FIP Fib Bulletin 40. FRP Reinforcement in RC Structures; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2007; ISBN 978-2-88394-080-2.

- Design Guidance for Strengthening Concrete Structures Using Fibre Composite Materials, Concrete Society Technical Report 55, 3rd ed.; The Concrete Society: Crowthorne, UK, 2012.

- Arya, C.; Clarke, J.L.; Kay, E.A.; O’Regan, P.D. TR 55: Design guidance for stengthening concrete structures using fibre composite materials: A review. Eng. Struct. 2002, 24, 889–900.

- ACI 440.1R-15. Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars; American Concrete Institute: Farmington Hills, MI, USA, 2015; ISBN 978-1-942727-10-1.

- Design of Concrete Bridge Beams Prestressed with CFRP Systems; NCHRP Research Report. 907; Belarbi, A.; Dawood, M.; Poudel, P.; Reda, M.; Tahsiri, H.; Gencturk, B.; Rizkalla, S.H.; Russell, H.G. (Eds.) The National Academies Press: Washington, DC, USA, 2019; ISBN 978-0-309-48069-7.

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.-C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238.

- CEB-FIP Fib Bulletin 14. Externally Bonded FRP Reinforcement for RC Structures; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2001; ISBN 2-88394-054-1.

- ACI 440. 2R-17. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2017; ISBN 978-1-945487-59-0.

- Machida, A.; Uomoto, T. Recommendation for Design and Construction of Concrete Structures Using Continuous Fiber Reinforcing Materials; Japan Soc. of Civil Engineers: Tokyo, Japan, 1997.

- FRP Rehabilitation of Reinforced Concrete Structures; ISIS Design Manual, No. 4; ISIS Canada Corporation: Winnipeg, MB, Canada, 2008.

- CNR-DT 200 R1/2013. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures; National Research Council, Advisory Committee on Technical Recommendations for Construction: Rome, Italy, 2013.

- AASHTO-2013. Guide Specifications for Design of Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

- Bonded Repair and Retrofit of Concrete Structures Using FRP Composites—Recommended Construction Specifications and Process Control Manual; NCHRP REPORT 514; The National Academies Press: Washington, DC, USA, 2003; ISBN 978-0-309-43205-4.

- Use of Fiber-Reinforced Polymers in Highway Infrastructure; NCHRP SYNTHESIS 512; Kim, Y.J. (Ed.) The National Academies Press: Washington, DC, USA, 2017; ISBN 978-0-309-39004-0.

- Field Inspection of In-Service FRP Bridge Decks; NCHRP REPORT 564; The National Academies Press: Washington, DC, USA, 2006; ISBN 978-0-309-42533-9.

- Recommended Guide Specification for the Design of Externally Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements; NCHRP REPORT 655; The National Academies Press: Washington, DC, USA, 2010; ISBN 978-0-309-15485-7.

- Design of FRP Systems for Strengthening Concrete Girders in Shear; NCHRP REPORT 678; The National Academies Press: Washington, DC, USA, 2011; ISBN 978-0-309-15531-1.

- Wu, H.C.; Eamon, C.D. Strengthening of Concrete Structures Using Fiber Reinforced Polymers (FRP): Design, Construction and Practical Applications; Woodhead Publishing/Elsevier: Duxford, UK, 2017; ISBN 978-0-08-100641-2.

- Guadagnini, M. Use of composite materials in structural applications:a European perspective. In Proceedings of the Second International Conference on the use of Fibre-Reinforced Polymer Composites in Bridge Design, London, UK, 11–12 September 2014.

- Teng, J.G.; Chen, J.F.; Smith, S.T.; Lam, L. Behaviour and strength of FRP-strengthened RC structures: A state-of-the-art review. Proc. Inst. Civ. Eng.-Struct. Build. 2003, 156, 51–62.

- Alkhrdaji, T. Strengthening of Concrete Structures using FRP Composites. STRUCTURE Magazine National Council of Structural Engineers Associations, 16 June 2015; pp. 18–20.

- Ghafoori, E.; Motavalli, M.; Nussbaumer, A.; Herwig, A.; Prinz, G.S.; Fontana, M. Design criterion for fatigue strengthening of riveted beams in a 120-year-old railway metallic bridge using pre-stressed CFRP plates. Compos. Part B Eng. 2015, 68, 1–13.

- Hu, W.; Li, Y.; Yuan, H. Review of Experimental Studies on Application of FRP for Strengthening of Bridge Structures. Adv. Mater. Sci. Eng. 2020, 2020, 8682163.

- Burgoyne, C.; Balafas, I. Why is FRP not a financial success? In Proceedings of the 8th International Symposium on Fiber-Reinforced Polymer Reinforcement for Concrete Structures (FRPRCS-8), Patras, Greece, 16–18 July 2007; Triantafillou, T., Ed.; University of Patras: Patras, Greece, 2007.

- Girão Coelho, A.M.; Mottram, J.T. A review of the behaviour and analysis of bolted connections and joints in pultruded fibre reinforced polymers. Mater. Des. 2015, 74, 86–107.

- Kendall, D. Developments in FRP bridge design. Reinf. Plast. 2010, 54, 38–42.