The globalization of the floricultural sector creates more competition, challenging the innovation and reorganization of some ornamental and horticultural nurseries, which started to look at flowers as food products. This research aims to quantify the environmental impact of the emerging productive process of edible flowers through the LCA – Life Cycle Analysis method, due to the higher awareness towards sustainability. Two model species and two types of final products were chosen, using a “cradle to gate” approach.

- Life Cycle Assessment

- Greenhouse gas emissions

- Potted Plants

- Begonia semperflorens

- Viola cornuta

- nursery crops

- Annual bedding plants

- Container

- Introduction

Nowadays, due the increasing competition and decreasing profit margins in the floricultural sector [1][2][3], some ornamental and horticultural nurseries are starting to consider flowers as food products [4][5], both to react to the crisis in the sector by diversifying their product, but also to satisfy the increasing demand for more attractive and high quality foodstuff [6][7][8]. Moreover, since many of the edible flowers contain bioactive compounds, they can potentially be developed as new crops with health benefits [9][10][11][12][13][14]. Nurseries should consider some other factors too in the production of edible flowers: efficient input use, cost savings, enhanced product quality, and the sustainable nature of production or manufacturing [3], due to the heightened awareness towards eco-sustainability [15]. Currently, the evaluation of sustainability is important in the study of agricultural systems, which provide the raw material used in other activities [16]. For greenhouse growers, sustainable production means applying the best management practices to enhance plant quality and reduce negative environmental impacts while sustaining or increasing profits [3]. Thus, in a society increasingly directed towards organic and sustainable products, with increasing focus on the environmental burden, it becomes important to assess the sustainability of a basic production system, quantifying its impact and deciding the reducing measures to adopt, also giving additional value to the analyzed products in terms of eco - sustainability [16][17][18].

Life Cycle Assessment (LCA) is a standardized methodology for investigating the environmental impact of a product, a production process, or a system [19][20], by identifying and quantifying objectively and transparently inputs and outputs of energy and material usage, and their associated environmental impacts, in order to reduce them [17][21]. LCA has been used to assess the production system components of various types of nursery crop groups, such as trees and shrubs [3][22], vegetables [23][24][25], wine [26], fruits, and berries [27][28][29], to determine their respective contributions to emissions and variable costs of inputs and processes in the green industry [22].

At present, few LCA studies have been carried out in the floricultural sector if compared to those of other agricultural products [20][30], analyzing the greenhouse gases (GHG) emissions of the production cycles of cut flowers and ornamental plants (e.g., roses, lilies, cyclamens) [17][20], comparing two or more different plant production systems or nurseries, assessing different scenarios for the reduction of the environmental burdens produced by cultivation [19][31][32], or to review the application of LCA in floriculture [30]. A specific study applying the LCA approach to edible flowers has been recently performed for the first time, evaluating the production of Begonia x semperflorens - cultorum hort (commonly referred to as Begonia semperflorens) and Viola cornuta L. [33], begonias and pansies, which are often produced and consumed as edible flowers [6]. B. semperflorens was assumed to be representative of the species reproduced by cuttings, while V. cornuta was representative of species reproduced by seed. The analysis focused on two types of edible flower products to reveal possible differences in environmental impact over the whole production cycle: flowering potted plants (PP) and packaged flowers (in small and large containers – SC and LC) ready to be consumed.

The life cycle assessment (LCA) methodology is useful to understand which are the most impactful phases on the environment by simplifying the process [21][34], and allowing the evaluation of opportunities for environmental improvements over the whole life cycle [21].

Four main steps were followed for this LCA study [33].

- Goal and scope definition

The purpose of this study was to measure different types of emissions of the production process of a flowering potted plant compared to the production of packaged flowers ready to be consumed. Two edible flowers were chosen among the most produced species: B. semperflorens (reproduced by cutting) and V. cornuta (reproduced by seed), two annual bedding plants which differ in their propagation method. In order to model the production system, it was necessary to set some boundaries, virtual limits to select the internal components of the system to analyze [16]. In this study, we used the “cradle to gate” approach: it considered the product’s life, from the supply and manufacture of the raw materials, following them through all the steps of production, until the completion of the final product [31].

Moreover, the definition of a suitable functional unit, to which all the outcomes are referred, was important to allow comparisons of alternative goods and services through the LCA method. We used a unit of weight, i.e., 1 g of fresh edible flowers, in order to compare the burden caused by the production of the two different final products.

- Life Cycle Inventory (LCI).

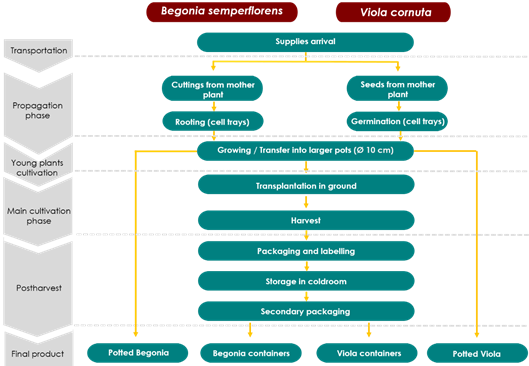

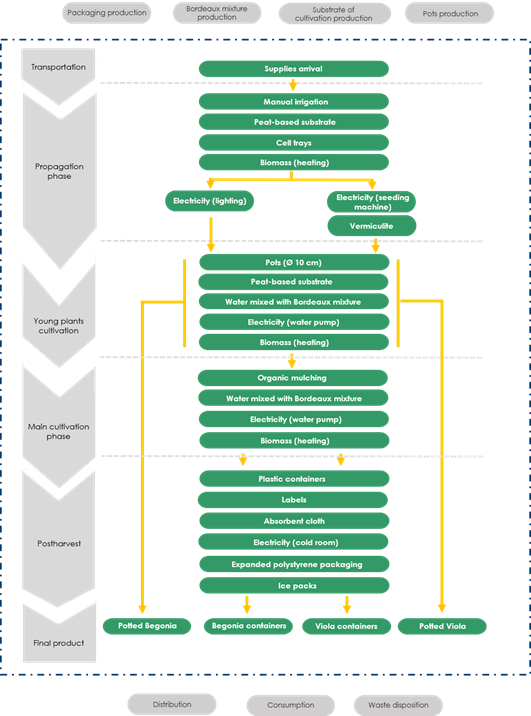

The life cycle of begonias and pansies edible flowers’ production was modelled through interviews with the nursery’s growers, considering all the inputs and outputs [21][35]. This step resulted in a flow diagram [15] (Figures 1-2), representing the production process. The primary data thus obtained were collected in a database and then processed by a specific LCA software, SimaPro 8.5.0.0. (PRē Sustainability – The Netherlands), in order to transform them into the environmental burdens and to quantify the different impact categories.

Figure 1. Schematic illustration of the production cycle of packaged flowers and flowering potted plants of B. semperflorens and V. cornuta edible flowers in the nursery [33].

Figure 2. Schematic illustration of the boundary (blue square) and inputs (green labels) considered for the production cycle of packaged flowers and flowering potted plants of B. semperflorens and V. cornuta edible flowers in the nursery. Grey labels outside the boundary were not considered in the analysis (cradle to gate approach) [33].

- Life Cycle Inventory Analysis (LCIA)

The environmental relevance of all the inputs and outputs of edible flowers production was assessed [21], so to understand how great was their contribution to the overall environmental load [15]. To quantify the environmental impacts, data previously collected were classified into different environmental issues of concerns as Impact Categories. The contribution of each emission to a certain impact category was evaluated through an equivalence factor that expresses its effects in relation with a reference parameter [15][36]. For this case study, four Impact Categories were chosen:

- Global Warming Potential (GWP). It is used to estimate the contribution of greenhouse gases (CO2, CH4, N2O, hexafluoride, etc.) to the greenhouse effect [31][37]. The emissions are measured in terms of the reference gas CO2, and expressed in kg of CO2 equivalent (CO2 eq) [37].

- Acidification Potential (AP). Acidification is a phenomenon whereby precipitation is unusually acidic (it has substandard levels of pH). Acid rain is caused by emissions of SO2, NOX, and NH3. The AP is measured in kg of sulphur - dioxide equivalent (SO2 eq) [37].

- Eutrophication Potential (EP). EP measures the emissions into water of phosphates and nitrates, causing an abnormal proliferation of vegetation in the aquatic ecosystem. It is expressed in kg of PO43- eq [37].

- Photochemical Ozone Creation Potential (POCP). Photochemical ozone is formed by the reaction of volatile organic compounds and nitrogen oxides in the presence of heat and sunlight, forming the ozone in the troposphere. It is usually expressed in kg of ethylene equivalent (C2H4 eq) [37].

In order to have a clearer way to interpret data, each one of the two species of edible flowers was divided into three groups: (i) large container (LC) containing 25 g of flowers, (ii) small container (SC) containing 12.5 g of flowers, and (iii) potted plant (PP).

- Interpretation

It presents the results of the study through the Impact Categories and suggests some possible measures to reduce the burden on the environment [21][38].

The life cycle inventory analysis (LCIA) results per gram of freshly harvested flowers showed that the production of V. cornuta edible flowers resulted in a higher environmental impact than the wax begonias’ one in the Global Warming Potential (GWP) and in the Photochemical Ozone Creation Potential (POCP) indicators, regardless of the type of final product. On the contrary, B. semperflorens’ production cycle showed higher values than violas in the Acidification Potential (AP) and in the Eutrophication Potential (EP) indicators, probably because there were fewer wax begonia plants in the greenhouse than viola ones, thus worse absorption of the nutrients in the substrate, causing a slightly higher impact of wax begonias in the AP and EP categories.

All indicators evaluated showed lower emissions values for the potted plant (PP) product (which did not include the post-harvest phases in its production cycle, thus needing less resources) than the container (LC and SC) product, both for wax begonias and violas. Regarding B. semperflorens, the percentage increase from the potted plant to the flowers’ container ranged from 10% to 15% among the impact categories, while concerning V. cornuta, the percentage increase from the potted plant to the flowers’ container ranged from 8% to 17% among the impact categories.

As far as the flowers’ containers are concerned, lower impacts were obtained using the large plastic container rather than the small one: wax begonias percentage increase from the large container to the small one ranged from 3% to 5% among the impact categories, while violas percentage increase ranged from 3% to 6% among the impact categories. Actually, 1 g of fresh flowers packed in small containers and then in polystyrene packaging showed higher values in all the four impact categories evaluated than 1 g of fresh flowers packed in large containers.

In conclusion, this work showed that the production of only the large containers should be a way to reduce the emissions in the post-harvest phase (diminishing the amount of plastic used), even if probably this would not be economically sustainable for the nursery as normally the private customers prefer small containers of fresh flowers.

Additionally, the nursery could increase the sale of flowering potted plants, as they require fewer resources, and there is a minor use of packaging, highly reducing the need of post-harvest treatments, thus reducing the environmental burden.

Moreover, the consumer can diminish food wastes, leaving on the plant the flowers he does not need. However, a consumer who buys a potted plant can only have one flower species and a minor number of flowers to use, if compared with the variety and the grams packed in a container. Probably this solution too would not be economically advantageous for the nursery.

Bio-degradable plastic packaging could be adopted, so that the end of life could have a minor impact on the environment [39].

The use of biodegradable pots [40] could reduce the impacts by reducing the use of plastic pots, even though some of these pots show unsuitable mechanical performances, and they are more expensive than plastic pots [40].

Lastly, the use of biodegradable and bio-based foam for cushioning packaging instead of Expanded Polystyrene (EPS) could be another option, using renewable and more sustainable raw materials (biomass instead of fossil fuel) and reducing landfill disposal [41].

As highlighted, there are great opportunities to reduce emissions in edible flower’s production; thus, it could be interesting to enlarge this environmental analysis to the whole of the edible flower productive chain, through a “cradle to grave” approach, thus also considering the impacts related to the distribution of the edible flower’s product to the final consumer, consumption, conservation or waste of edible flowers, and ultimate disposal of the packaging, in order to have a complete overview of this emerging type of food product. The scientific data about the environmental pressure of the different edible flower products could also help consumers to make more informed and sustainable choices.

The full article can be found here: https://www.mdpi.com/2073-4395/10/4/579

References

- Crisi della floricoltura . La Stampa. Retrieved 2020-9-22

- Ingram, D.L.; Hall, C.R.; Knight, J.; Analysis of Production System Components of Container-grown Chrysanthemum for Their Impact on Carbon Footprint and Variable Costs Using Life Cycle Assessment.. HortScience 2018, 53 (8), 1139-1142, .

- Ingram, D.L.; Hall, C.R.; Knight, J.; Global Warming Potential, Variable Costs, and Water Use of a Model Greenhouse Production System for 11.4-cm Annual Plants Using Life Cycle Assessment. HortScience 2018, 53, 441-444, .

- Pardossi, A.; Minuto, A.; Benvenuti, S. Belli, buoni e sani: I fiori eduli irrompono sul mercato. Floricultore 2016, 12, 36–43

- Demasi, S.; Falla, N.M.; Caser, M.; Scariot, V.; Postharvest aptitude of Begonia semperflorens and Viola cornuta edible flowers. Adv. Hortic. Sci. 2020, 34, 13-20, 10.13128/ahsc7444.

- Jiri Mlcek; Otakar Rop; Fresh edible flowers of ornamental plants – A new source of nutraceutical foods. Trends in Food Science & Technology 2011, 22, 561-569, 10.1016/j.tifs.2011.04.006.

- E.N. Aquino-Bolaños; T.A. Urrutia-Hernández; M. López Del Castillo-Lozano; J.L. Chavéz-Servia; I. Verdalet-Guzmán; Physicochemical Parameters and Antioxidant Compounds in Edible Squash (Cucurbita Pepo) Flower Stored under Controlled Atmospheres. Journal of Food Quality 2013, 36, 302-308, 10.1111/jfq.12053.

- Landi, M.; Ruffoni, B.; Combournac, L.; Guidi, L.; Nutraceutical value of edible flowers upon cold storage. Ital. J. Food Sci. 2018, 30, 336-347, .

- Monica R. Loizzo; Alessandro Pugliese; Marco Bonesi; Maria Concetta Tenuta; Francesco Menichini; Nataša Poklar Ulrih; Rosa Tundis; Edible Flowers: A Rich Source of Phytochemicals with Antioxidant and Hypoglycemic Properties. Journal of Agricultural and Food Chemistry 2015, 64, 2467-2474, 10.1021/acs.jafc.5b03092.

- Luana Fernandes; Susana Casal; José Alberto Pereira; Jorge Saraiva; Elsa Ramalhosa; Edible flowers: A review of the nutritional, antioxidant, antimicrobial properties and effects on human health. Journal of Food Composition and Analysis 2017, 60, 38-50, 10.1016/j.jfca.2017.03.017.

- Tânia C.S. P. Pires; Lillian Barros; Celestino Santos-Buelga; Isabel C.F.R. Ferreira; Edible flowers: Emerging components in the diet. Trends in Food Science & Technology 2019, 93, 244-258, 10.1016/j.tifs.2019.09.020.

- H. Friedman; I. Rot; O. Agami; Y. Vinokur; V. Rodov; N. Reznick; N. Umiel; I. Dori; L. Ganot; D. Shmuel; et al. EDIBLE FLOWERS: NEW CROPS WITH POTENTIAL HEALTH BENEFITS. Acta Horticulturae 2007, 755, 283-290, 10.17660/actahortic.2007.755.36.

- Onanong Kaisoon; Izabela Kończak; Sirithon Siriamornpun; Potential health enhancing properties of edible flowers from Thailand. Food Research International 2012, 46, 563-571, 10.1016/j.foodres.2011.06.016.

- V. Scariot; W. Gaino; Sonia Demasi; M. Caser; B. Ruffoni; Flowers for edible gardens: combinations of species and colours for northwestern Italy. Acta Horticulturae 2018, 1215, 363-368, 10.17660/actahortic.2018.1215.67.

- Maurizio Bevilacqua; Marcello Braglia; Gionata Carmignani; Francesco Zammori; LIFE CYCLE ASSESSMENT OF PASTA PRODUCTION IN ITALY. Journal of Food Quality 2007, 30, 932-952, 10.1111/j.1745-4557.2007.00170.x.

- Gabriele L. Beccaro; A. K. Cerutti; I. Vandecasteele; Luca Bonvegna; Dario Donno; Giancarlo Bounous; Assessing environmental impacts of nursery production: methodological issues and results from a case study in Italy. Journal of Cleaner Production 2014, 80, 159-169, 10.1016/j.jclepro.2014.05.062.

- Giovanni Russo; B. De Lucia Zeller; ENVIRONMENTAL EVALUATION BY MEANS OF LCA REGARDING THE ORNAMENTAL NURSERY PRODUCTION IN ROSE AND SOWBREAD GREENHOUSE CULTIVATION. Acta Horticulturae 2008, 801, 1597-1604, 10.17660/actahortic.2008.801.198.

- Dewayne L. Ingram; Life cycle assessment of a field-grown red maple tree to estimate its carbon footprint components. The International Journal of Life Cycle Assessment 2012, 17, 453-462, 10.1007/s11367-012-0398-7.

- G. Lazzerini; S. Lucchetti; F.P. Nicese; Green House Gases(GHG) emissions from the ornamental plant nursery industry: a Life Cycle Assessment(LCA) approach in a nursery district in central Italy. Journal of Cleaner Production 2016, 112, 4022-4030, 10.1016/j.jclepro.2015.08.065.

- Marie-Theres Wandl; Helmut Haberl; Greenhouse gas emissions of small scale ornamental plant production in Austria - A case study. Journal of Cleaner Production 2017, 141, 1123-1133, 10.1016/j.jclepro.2016.09.093.

- 21. Hiloidhari, M.; Baruah, D.; Singh, A.; Kataki, S.; Medhi, K.; Kumari, S.; Ramachandra, T.; Jenkins, B.; Thakur, I.S.; Emerging role of Geographical Information System (GIS), Life Cycle Assessment (LCA) and spatial LCA (GIS-LCA) in sustainable bioenergy planning. Bioresour. Technol. 2017, 242, 218-226, .

- Dewayne L. Ingram; Charles R. Hall; Joshua Knight; Modeling Container-grown Euphorbia pulcherrima Production System Components: Impacts on Carbon Footprint and Variable Costs Using a Life Cycle Assessment. HortScience 2019, 54, 262-266, 10.21273/hortsci13641-18.

- S. Foteinis; Efthalia Chatzisymeon; Life cycle assessment of organic versus conventional agriculture. A case study of lettuce cultivation in Greece. Journal of Cleaner Production 2016, 112, 2462-2471, 10.1016/j.jclepro.2015.09.075.

- Alessandra Fusi; Valentina Castellani; Jacopo Bacenetti; Giacomo Cocetta; Marco Fiala; Riccardo Guidetti; The environmental impact of the production of fresh cut salad: a case study in Italy. The International Journal of Life Cycle Assessment 2016, 21, 162-175, 10.1007/s11367-015-1019-z.

- Benyamin Khoshnevisan; Shahin Rafiee; Mahmoud Omid; Hossein Mousazadeh; Sean Clark; Environmental impact assessment of tomato and cucumber cultivation in greenhouses using life cycle assessment and adaptive neuro-fuzzy inference system. Journal of Cleaner Production 2014, 73, 183-192, 10.1016/j.jclepro.2013.09.057.

- Anna Ferrari; Martina Pini; Devid Sassi; Elisabetta Zerazion; Paolo Neri; Effects of grape quality on the environmental profile of an Italian vineyard for Lambrusco red wine production. Journal of Cleaner Production 2018, 172, 3760-3769, 10.1016/j.jclepro.2017.06.241.

- Cristiana Peano; Claudio Baudino; Nadia Tecco; Vincenzo Girgenti; Green marketing tools for fruit growers associated groups: application of the Life Cycle Assessment (LCA) for strawberries and berry fruits ecobranding in northern Italy. Journal of Cleaner Production 2015, 104, 59-67, 10.1016/j.jclepro.2015.04.087.

- Elisabet Vinyes; Luis Asin; Simó Alegre; Pere Muñoz; Jesús Boschmonart; Carles M. Gasol; Vinyes Elisabet; Asin Luis; Alegre Simó; Muñoz Pere; et al. Life Cycle Assessment of apple and peach production, distribution and consumption in Mediterranean fruit sector. Journal of Cleaner Production 2017, 149, 313-320, 10.1016/j.jclepro.2017.02.102.

- Zhanling Zhu; Zhihang Jia; Ling Peng; Qian Chen; Liu He; Yuanmao Jiang; Shunfeng Ge; Life cycle assessment of conventional and organic apple production systems in China. Journal of Cleaner Production 2018, 201, 156-168, 10.1016/j.jclepro.2018.08.032.

- Konstadinos Abeliotis; Sofia-Anna Barla; Vassilis Detsis; George Malindretos; Life cycle assessment of carnation production in Greece. Journal of Cleaner Production 2016, 112, 32-38, 10.1016/j.jclepro.2015.06.018.

- G. Lazzerini; S. Lucchetti; F.P. Nicese; Analysis of greenhouse gas emissions from ornamental plant production: A nursery level approach. Urban Forestry & Urban Greening 2014, 13, 517-525, 10.1016/j.ufug.2014.02.004.

- Giovanni Russo; Giacomo Scarascia-Mugnozza; B. De Lucia Zeller; ENVIRONMENTAL IMPROVEMENTS OF GREENHOUSE FLOWER CULTIVATION BY MEANS OF LCA METHODOLOGY. Acta Horticulturae 2008, 801, 301-308, 10.17660/actahortic.2008.801.30.

- Nicole Mélanie Falla; Simone Contu; Sonia Demasi; Matteo Caser; Valentina Scariot; Environmental Impact of Edible Flower Production: A Case Study. Agronomy 2020, 10, 579, 10.3390/agronomy10040579.

- Maurizio Cellura; Sonia Longo; Marina Mistretta; Life Cycle Assessment (LCA) of protected crops: an Italian case study. Journal of Cleaner Production 2012, 28, 56-62, 10.1016/j.jclepro.2011.10.021.

- Elena Tamburini; Elisa Anna Fano; Maria Gabriella Marchetti; Elisa Fano; Giuseppe Castaldelli; Life Cycle Based Evaluation of Environmental and Economic Impacts of Agricultural Productions in the Mediterranean Area. Sustainability 2015, 7, 2915-2935, 10.3390/su7032915.

- Stranddorf, H.K.; Hoffmann, L.; Schmidt, A. Impact Categories, Normalisation and Weighting in LCA; Environmental news; Danish Ministry of the Environment, Environmental Protection Agency: Copenhagen, Denmark, 2005; Volume 78

- LCIA Methods—Impact Assessment Methods in Life Cycle Assessment and Their Impact Categories . OpenLCA Site. Retrieved 2020-9-22

- Stefanie Hellweg; L. Milà I Canals; Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109-1113, 10.1126/science.1248361.

- Jariyasakoolroj, P.; Leelaphiwat, P.; Harnkarnsujarit, N. Advances in research and development of bioplastic for food packaging. J. Sci. Food Agric. 2019

- Evelia Schettini; Gabriella Santagata; Mario Malinconico; Barbara Immirzi; Giacomo Scarascia-Mugnozza; Giuliano Vox; Recycled wastes of tomato and hemp fibres for biodegradable pots: Physico-chemical characterization and field performance. Resources, Conservation and Recycling 2013, 70, 9-19, 10.1016/j.resconrec.2012.11.002.

- Francesco Razza; Francesco Degli-Innocenti; Antonio Dobon; Cesar Aliaga; Carmen Sanchez; Mercedes Hortal; Environmental profile of a bio-based and biodegradable foamed packaging prototype in comparison with the current benchmark. Journal of Cleaner Production 2015, 102, 493-500, 10.1016/j.jclepro.2015.04.033.