The treatment and reduction of animal by-products has registered an increase in the awareness that this type of materials is underutilised and can represent a valuable resource if treated correctly. Consequently, it is no longer practical to dispose of animal by-products, especially when a significant amount of potential raw materials is produced, which can have a high economic potential through the production of new products with significant added value. The reuse and valorisation of animal by-products (ABPs) generated in the food retail sector can involve sending these by-products to another company/organisation or industry, where they will be processed in order to obtain added-value products. This type of valorisation originates an industrial symbiosis.

- agri-food business

- animal by-products

- food retail sector

- industrial symbiosis

- circular economy

1. Industrial Symbiosis

2. Implemented Industrial Processes and Technologies

| Industrial Process | Technology | Raw Materials | Final Products | Possible Uses of the Final Products | References |

|---|---|---|---|---|---|

| Rendering | Digestion (133 °C; 3 bar; 20 min) for sterilisation and stabilisation of ABPs | Muscle Bones Fats |

ABP meal | Animal feed | [59,60] |

| Animal fat | Biodiesel production | ||||

| BioRefinex | Thermal hydrolysis (180 °C; 12 bar; 40 min) + anaerobic digestion (50–60 °C; 10–35 days) |

Muscle Bones Fats |

Hydrolysed proteins | Fertilisers | [61] |

| Biogas | Fuels | ||||

| Gelatine production | Alkaline pre-treatment + thermal hydrolysis (50–100 °C; 10–36 h) | Bones | Gelatine powder | Food products Pharmaceuticals Photographic products | [64,65] |

| Chondroitin sulphate production | Enzymatic hydrolysis (60 °C; 8 h; alcalase) + alkaline hydrolysis (35 °C; 1 h; pH > 11) |

Bones | Chondroitin sulphate powder | Pharmaceuticals Cosmetics Animal feed |

[66] |

| Pyrolysis (850 °C; 20 min) |

Bones | Bio-char | Fertilisers and adsorbents | [62] | |

| Bio-oil | Fuels | ||||

| Pyrolysis gas | |||||

| Thermal hydrolysis (90–110 °C; 0.5–10 h) |

Muscle | Meat extract | Meat flavourings Animal feed |

[67] | |

| Meat powder | |||||

| Enzymatic hydrolysis (50–52 °C; 50 min; papain) |

Muscle | Protein powder | Animal feed | [68] | |

3. Emerging Low-TRL Systems

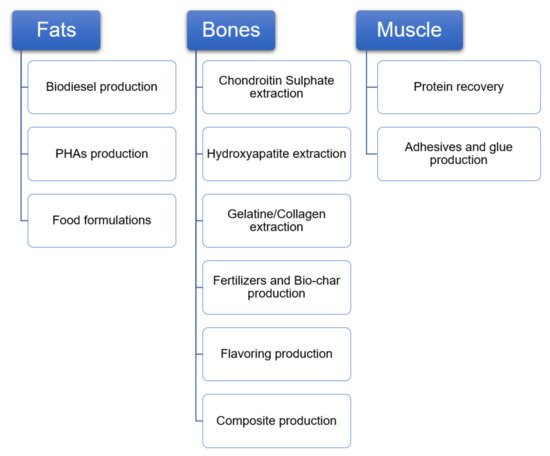

3.1. Fat Valorisation Systems

| ABP | Final Use | Experimental Procedure | Results | Reference |

|---|---|---|---|---|

| Poultry Fat | Biodiesel production | Heating (110 °C), filtration (30 °C), transesterification (methanol (6:1) and NaOH (1%); 30 °C; 90 min), decanting (1 h), evaporation (low pressure), mixing (50% (v/v) HCl (0.2%)), mixing (50% (v/v) H2O), dehydration (Na2SO4 (25%); 30 rpm), filtration | ηextraction = 40% ηbiodiesel = 87% |

[72] |

| Rendering, filtration, heating (110 °C; 1 h), esterification (methanol (40%) + H2SO4 (2.5%); 63 °C; 1 h), decanting, mixing (H2O; 65 °C), heating (110 °C), transesterification (methanol (20%) + KOH (1%)), decanting, mixing (H2O; 65 °C), heating (110 °C) | ηbiodiesel = 88.5% | [76] | ||

| Rendering, mixing (methanol (6:1)), supercritical transesterification (400 °C; 41.1 MPa; 6 min) | ηbiodiesel = 88% | [77] | ||

| Beef Fat | PHA production | PHAs—polyhydroxyalkanoates Rendering, fermentation (30 °C; pH = 6.8; aeration = 0.5 vvm; CO2 = 40%; 300–1200 rpm) |

Purity >99% Production = 0.4 g PHA/g fat Productivity = 0.36 g PHA/L.h |

[79] |

| Biodiesel production | Heating, filtration, transesterification (50 °C; KOH + methanol), decanting, washing (hot water + acetic acid), mixing (methanol), vacuum distillation, dehydration (ethylene glycol) | ηbiodiesel = 73% | [78] | |

| Pork Fat | Food formulations | Winterisation process | Decrease of 28% in the saturated fatty acid content | [80] |

3.2. Bone Valorisation Systems

| ABP | Final Use | Experimental Procedure | Results | Reference |

|---|---|---|---|---|

| Poultry Bones | Chondroitin sulphate extraction | Washing (H2O; 30 min), mixing (H2O (1.5:1)), heating (120 °C; 0.1 MPa; 120 min), filtration (100-mesh sieve), centrifugation, heat-resin static adsorption extraction, mixing (trichloroacetic acid (7% w/v); 4°C; 24 h), centrifugation (15,000× g; 20 min), mixing (ethanol (70% v/v); 24 h), centrifugation (5000× g; 5 min), drying (60 °C), mixing (H2O), ultrafiltration, freeze drying | ηCS = 0.14% % recovered = 67.4% MCS = 35.81 kDa |

[83] |

| Crushing, washing (acetone), filtration, drying (60 °C; 24 h), mixing (H2O (1.5:1) + trypsin), extraction (47 °C; 6 h), heating (10 min), filtration (100-mesh sieve), centrifugation (12,000× g; 10 min), mixing (ethanol (70%); 4 °C; 24 h), centrifugation (5000× g; 5 min), drying (60 °C) |

ηCS = 4.25% MCS = 37.18 kDa |

|||

| Hydroxyapatite extraction | Washing, drying (oven), crushing, calcination (electric furnace; Patm; 700 °C) |

% lost mass = 28.72% | [86] | |

| Flavouring production | Crushing, washing (H2O (1.5:1); 10 min), hot pressure extraction (H2O; 135 °C; 120 min), filtration (200-mesh sieve), centrifugation (16,000× g), evaporation (0.08–0.1 MPa; until 30% solids) | % recovery: Proteins = 83.51% Collagen = 96.81% Amino acids = 31.03–47.73% CCa = 4.2–4.8 mg/g |

[97] | |

| Gelatine and collagen extraction | Crushing (1–2 mm), mixing (H2O (1 g:2 mL)), heating (35 °C; 1 h), washing (H2O), filtration, acid treatment (HCl (1 g:2 mL); 10 °C; 24 h), washing (H2O), filtration, alkaline treatment (NaOH (1 g: 4 mL; Troom; 48 h), mixing (phosphoric acid until pH = 4), washing (H2O), filtration, mixing (H2O (1 g: 3 mL); 76–82 °C; 105–183 min), centrifugation (5000 g; 30 °C; 30 min), drying (oven; 42 °C) |

Gel strength = 1175.8 g Tmelting = 33.71 °C Tgelling = 25.15 °C |

[88] | |

| Fertiliser production | Dehydration (110 °C; 4–5 h), rendering (133 °C; 3 bar; 20 min), double calcination (electric furnace; 550 °C) |

Coal represents 24% of initial poultry meal mass Coal: 56.33% phosphate 30.7% calcium |

[94] | |

| Pig Bones | Bio-char production | Crushing (2–5 cm), precarbonisation (450 °C; N2 atmosphere; 10 °C/min), crushing (0.25–0.35 mm), pyrolysis (800 °C), washing (H2O) | H = 68.3% | [95] |

| Bovine Bones | Bio-char production | Washing (H2O, 90 °C; 24 h), pyrolysis (350 °C; 2 h), cooling (Troom), crushing (75–300 µm) | Adsorption capacity = 10.56 mg F/g |

[92] |

| Washing, drying (110 °C), crushing (1–2 mm), washing (acetone + H2O), filtration, drying, pyrolysis (400 °C; 2 h; 10.2 °C/min) | Removal of 41.4% of 17-β oestradiol from water | [93] | ||

| Composite production | Crushing, washing (H2O), drying, carbonisation (550 °C; 1 h), crushing (100 µm) | Composite strength increases with bone carbonisation | [96] | |

| Hydroxyapatite extraction | Washing (H2O; 1 h), washing (acetone; 2 h), drying, crushing (45–125 µm), calcination (T; 3 h; 10 °C/min) | Optimal calcination temperature ≥700 °C |

[85] | |

| Gelatine extraction | Crushing (1–3 mm), washing (H2O), demineralisation (HCl (50 g/L); 8 °C; 2 h), washing (H2O), enzymatic treatment (neutrase; pH = 9; 50 °C), heating (100 °C), mixing (pH = 7), gelatine extraction (T; 3 h), centrifugation (30 °C; 900× g), vacuum filtration, mixing (Ca(OH)2 until pH = 9), flocculation, centrifugation, ion exchange | H = 13.9% Gel strength = 243.22 g µ = 4.915 cP |

[89] |

3.3. Muscle Valorisation Systems

| ABP | Final Use | Experimental Procedure | Results | Reference |

|---|---|---|---|---|

| Poultry Muscle | Protein recovery (hydrolysis) | Rendering, mixing (H2O), enzymatic hydrolysis (7 h; 50 °C; pH adjustment with NaOH (5.4 M)), heating (85 °C; 15 min), centrifugation (1000× g; 4 °C; 30 min), freeze drying (0.045 mbar; −44 °C) Enzymes: alcalase (pH = 8) and flavourzyme (pH = 7) |

% hydrolysed = 11.13% % recovered = 58.1% |

[101] |

| Sterilisation (121 °C; 15 min), enzymatic hydrolysis (phosphate buffer (50 mM); 50–56 °C; 18 h), filtration, centrifugation (15000 rpm; 30 min), filtration, spray drying (67 °C; 4 h) Enzyme: papain |

Cproteins = 768 mg/g CCS = 89.6 mg/g CHA = 73.9 mg/g Camino acids = 44.2 mg/g |

[103] | ||

| Crushing, mixing (H2O (3:1) + NaOH), heating, enzymatic hydrolysis (52.5 °C; pH = 8 with addition of NaOH), heating (85 °C; 20 min), centrifugation (3500rpm; 20 min) Enzyme: alcalase (4.2%) |

% hydrolysed protein = 31% % recovered protein = 91% |

[102] | ||

| Crushing (3000 rpm; 3 min), mixing (H2O; 1100 rpm; 5 min), hydrolysis (40 °C; pH = 9; 60 min), centrifugation (10,000× g; 15 min), microfiltration (2 bar), ultrafiltration (2 bar), isoelectric precipitation (HCl (37%) until pH = 4), centrifugation (5000× g; 5 min), mixing (hexane + isopropanol (3:2 v/v); 1 h; 20 °C), evaporation | ηextraction = 83% ηprocess = 55% |

[107] | ||

| Crushing (2.3 mm), ISP (H2O + TiO2 (6:1); 32–34 °C), mixing (NaOH until pH = 11.5; 10 min), centrifugation (10,000× g; 10 min), mixing (HCl until pH = 5.5; 10 min), centrifugation |

Addition of TiO2 to the ISP-recovered proteins resulted in increased gel strength | [108] | ||

| Mixing (H2O; pH = 4–4.5; 3.5 h), filtration, centrifugation, evaporation (until 25° Brix), enzymatic hydrolysis (aspergillus (0.06%); 50 °C; pH = 7; 1 h), heating (10 min), enzymatic hydrolysis (trypsin/chymotrypsin (1%); 37 °C; pH = 7; 1 h), heating (10 min), centrifugation |

Inhibitory activity: Chicken extract = 1060 mg% Hydrolysed extract = 1.1 mg% |

[104] | ||

| Adhesive and glue production | Mixing (H2O (1:4 w/v); 10 min), filtration (200-mesh sieve), centrifugation (10,000× g; 4 °C; 25 min), mixing (NaOH (2 M) until pH = 11), centrifugation (10,000× g; 4 °C; 25 min), mixing (HCl (2 M) until pH = 5), centrifugation, washing (H2O), freeze drying, mixing (sodium dodecyl sulphate (3 M) or urea (3%) and NaOH (10%) until pH = 10) | Urea (3%)/SDS (3 M): Dry strength = 7.99/9.35 MPa Wet strength = 3.35/2.9 MPa Soaked strength = 5.21/8.89 MPa |

[109] |

This entry is adapted from the peer-reviewed paper 10.3390/su14052830