Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Business

The aircraft maintenance sector has high complexity with many intermediaries, multiple actors sharing data and needs to ensure high data security. The implementation of Blockchain technology can significantly contribute to the aforementioned characteristics.

- blockchain

- maintenance

- repair and overhaul (MRO) organizations

- technology implementation

- smart contracts

- data sharing

- aviation

- aircraft

- airplane

1. Introduction

Maintenance, Repair and Overhaul (MRO) is complex, as various regulatory policies, varied customer portfolios, heavy reliance on parts supply chains, human reliance and tight time schedules make it challenging to capture and manage information effectively. is becoming an increasingly urgent requirement in supply chains, and the lack of transparency prevents the verification of the actual value of items and can cause strategic and reputational competitive issues [1]. Similarly, the need to trace and verify parts in maintenance is of significant importance for MRO, with strict requirements outlined by airworthiness authorities to guarantee the safety of aircrew and passengers [1]. The maintenance sector has high complexity with many intermediaries, multiple actors sharing data and needs to ensure high data security. Vastly improved data storage and communication technology is a major opportunity for improving aviation’s performance [2] [3]. Moreover, counterfeit products within the aircraft parts supply chain compromise safety standards. The implementation of Blockchain technology can significantly contribute to the characteristics mentioned above and can assist with the elimination of any counterfeit products within the aircraft parts supply that compromise safety standards.

Blockchain technology is claimed to be one of the most influential and innovative technologies currently [4]. Blockchain can be described as a distributed ledger, a chain of ‘blocks’ in chronological order where each block has a record of the activities that have taken place on the network since the last block was added to the chain [5]. Efficiency gains enabled by Blockchain could increase industry revenue by as much as 4%, or US$40bn, while cutting MRO costs by approximately 5%, or US$3.5bn [6]

Some studies have reported the benefits of Blockchain (e.g., [7][8][9][10]). Some research has been conducted in aviation. For example [11], examined Blockchain for flight data sharing in air traffic control; [12]looked at Blockchain in Controller Pilot Data Link Communication (CPDLC) from a technical perspective but did not evaluate its adoption willingness. Several piloting programs across various sectors have been trialed, but the technology penetration levels for Blockchain remain minimal.

Research into Blockchain is at an early stage in terms of theoretical grounding, methodological diversity and empirically grounded work [13]. With most of the research being undertaken on the benefits of Blockchain and the use cases, conducting more research on organizational practices and decision-making around the adoption of Blockchain technologies. Blockchain can be a disruptive technology for design, organization, operations and general management. Therefore, the resistance to implementing Blockchain needs to be further explored.

2. Blockchain Technology

Blockchain is a digitally distributed transaction ledger in that information is stored and maintained (but not duplicated) on a decentralized database, which belongs to multiple entities sharing information [5]. Distributed ledgers are ideal when the supply chains are large and complex, such as in aircraft maintenance, as it ensures high security and safety, and there can be multiple organizations involved. Blockchain is a continually growing list of records called blocks that are permanently linked to a chain. Within MROs, data could be inputted manually into a Blockchain by authorized staff or automatically by maintenance management systems. According to Blockchain rules, once data is entered into the system, it is shared with all participants on the Blockchain, and that block of data entered cannot be altered.

If implemented in MROs, the aftermarket blocks would contain data on aircraft parts, such as (1) Where they came from, (2) Which airline operated them, (3) How many hours were they operated for, (4) When and what failed, and (5) Who, when and where they were repaired. This is commonly known as Back-to-Birth traceability (or BtB). Blockchain uses cryptography instead of signatures to ensure security. In the MRO industry, it would only collect the maintenance data necessary for safe transfers and, in the case of a private Blockchain, transferring sensitive data [6].

Currently, Blockchain systems can be categorized into three groups, private, public and consortium Blockchain. The primary distinction between private and public Blockchain is who can participate in the network [14]. Public and private Blockchains can also be classified as permissionless and permissioned, respectively. Permissionless refers to a situation in which anyone can join and participate in the network. Anybody can create a personal address and interact on the network by adding entries to the ledger and submitting transactions. The public or permissionless Blockchain network is used in most digital currencies worldwide. Consortium Blockchain is only publicly available to a selected few parties. The consensus process is active and controlled by a public party that sets the rules and guidelines for the Blockchain. It is only partly decentralized, as the Blockchain copies are only distributed amongst certain entities.

The main characteristics of Blockchain are (a) Digital Signatures, (b) Data Integrity, (c) Smart Contracts, (d) Alternative consensus algorithms, (e) Proof-of-Work and (f) Peer to Peer. The individuals on the network use digital signatures in Blockchain to ensure that the new blocks created are legitimate and authentic. Digital signatures are an extra layer of security. The use of hashing algorithms guarantees integrity [15]. Encrypted data being sent can be altered without being detected by a hacker. If the data were hacked, the signature would change; thus, it would be invalid. They secure the data and the identity of the individual creating it. Ownership of digital signatures is bound to a user and the individuals they intend to share it with. Nevertheless, a signature is auditable and verifiable, so the owner cannot deny its existence.

Data integrity is a fundamental component of information security and safety. It is achieved in Blockchain with hashing; hashing can confirm that it has not been tampered with [16]. Each block within the Blockchain produces a hash value into a digest; the digest publishes the proof that the data in the block is secure and its integrity remains. Blockchain is immutable and allows for confidence in the quality of data. Blockchain plays a significant role in avoiding fraudulent transactions. Cryptography and its decentralized nature make Blockchain impossible to modify data or hack the system.

The smart contract, also known as a cyptrocontract, can be programmed electronically and automatically enforces itself when the conditions determined in advance are met [17]. The fundamental objective of a smart contract is to reduce transactional costs while providing superior security. Given the complex nature of the aviation industry value chain, smart contracts can enable an efficient flow of transactions between these different entities. Proof-of-work (PoW) is used to verify the legitimacy of data; this system can be implemented to provide a consensus within the network.

Trust is one of the essential elements in Blockchain. Blockchain technology is open-ended; it operates on a decentralized basis, allowing data to be stored and exchanged on a peer-to-peer (P2P) basis. P2P will enable individuals who do not know or have a relationship with others to form a trustworthy ledger where information is stored. This information can consist of contract outlines, payment history and data and is tamperproof, making Blockchain transparent. Allowing direct access to several information systems instead of one system generates higher efficiency and faster execution. P2P systems have been researched and identified as a system that can be used in several areas concerning exchanging and storing data [18][19].

Blockchain data can be shared and secured due to consensus-based algorithms. The consensus mechanism is a program where nodes agree on a result; each participant’s system validates the information and distributes it to the other participants. When each participant has received this information, each computer system runs the same algorithms to achieve the correct result [20].

In conclusion, Blockchains’ main characteristics are (a) efficient transaction settlement, (b) transparency and auditability and (c) reliability. Nevertheless, Blockchain technology implementation requires a significant financial investment, which is a challenge for many organizations [21]. Barriers can be grouped to intra-organizational, inter-organizational, system-related and external barriers. The barriers relevant to MROs are a hesitation to share information, limited use cases in MRO and technical challenges. According to Gartner’s Blockchain spectrum model, Blockchain technology is growing, and Blockchain-inspired solutions will dominate enterprise implementation in the early 2020s. In 2023, enterprise-ready complete solutions will emerge, and in 2025 Blockchain will incorporate complementary technologies (e.g., Internet of Things and artificial intelligence).

3. Maintenance Repair and Overhaul: The Industry Needs

MROs are described as when “all actions that have the objective of retaining and restoring an item in or to a state in which it can perform its required function. The actions include a combination of all technical and corresponding administrative, managerial and supervision actions” [6]. Aircraft maintenance is essential to guarantee the safety and security of the aircraft in commercial airlines. An aircraft fleet is one of the airlines most valuable assets [22] [23]. Maintaining the fleet plays a crucial role in ensuring the reliability and safety of these fleets in the commercial and private sectors [24]. MRO is seen as a significant percentage of airline operating costs; it represents approximately 12–15% of airline costs annually. There are over 480,000 people directly employed in MRO worldwide, and annual expenditures on MRO were estimated to be approximately $50 billion in 2013 and over $80 billion in 2019.

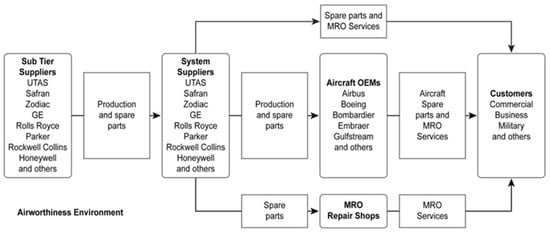

Aircraft maintenance can be categorized into scheduled and unscheduled maintenance. Scheduled maintenance ensures that products function correctly at pre-set times; these are routine inspections, with ‘A’, ‘B’, ‘C’ and ‘D’ checks broken down into line maintenance (the aircraft remains under the control of Operations) and base maintenance (the aircraft is removed from service and usually-placed in a hangar for a few days, at least) categories. They are preventative actions. Unscheduled maintenance is not pre-planned. The maintenance of each part of an aircraft must be continuously tracked throughout its lifecycle, with the maintenance of documentation and originality/quality being an essential task for MROs. For example, a Boeing 737 has 367,000 parts, and keeping accurate aircraft maintenance records of these parts is critical in proving an aircraft’s airworthiness. The supply chain in the aviation industry is highly complex (as seen in Figure 1). Once an aircraft begins operations, its parts become part of a global supply chain involving several parties, such as Original Equipment Manufacturers (OEMs), lessors, airlines, MROs, regulators and parts manufacturers. Each party has its system for storing data and information about parts and aircraft in its possession.

Figure 1. Simplified parts and MRO services flow in the aeronautical industry (Source: Vieira and Loures, 2016).

When an aircraft or a part of an aircraft is transferred, there is complex paperwork to ensure authenticity. The paperwork includes physical paper tags and an extensive history about the part or aircraft, with a record of all repairs and modifications that have taken place. The part leaves the Enterprise Resource Planning (ERP) of the MRO and is transferred to the ERP of the airline. Then, the cycle repeats itself, this time possibly with a different MRO. If the part is crossing international borders, the customs office becomes involved. Reports must also be carried out to ensure airworthiness and commercial traceability. Each year, millions of parts are moved worldwide; this can lead to a high level of inefficiency and lack of transparency, leading to added costs. The decentralized identifier (DID), a unique, verifiable, decentralized digital identity, can be the mechanism to trace the full records of a part.

At present, aircraft maintenance logbooks are stored in a physical ledger, typically in the aircraft and/or in the aircraft’s owner’s possession. Several risks are associated with maintaining a physical logbook; for example, it is susceptible to being damaged and lost or stolen, rendering the aircraft not airworthy. If the aircraft logbook is mislaid, the records must be reconstructed, leading to delays and increased costs. In addition to this, the reconstruction of maintenance logs can be a long and tedious task. As each aircraft ages, the maintenance facility that carried out work may no longer be in business, and therefore they may not hold the records for this aircraft. If this is the case, the aircraft owner must make a notarized statement explaining the loss of records and estimate the time the aircraft was in use according to the Federal Aviation Administration. Finally, it is possible to falsify records through the forgery of signatures with physical logbooks.

Paper records account for nearly 90% of all commercial aircraft maintenance records worldwide. An aircraft will typically be owned by five or six owners between delivery and retirement. Maintaining documentation is a challenge due to the high volume of movement and activity throughout the aircraft’s lifespan. Maintenance records for legacy aircraft are vulnerable to damage, missing documents and even misinterpreted handwritten text. Considering the number of documents, it is probable that the history of the maintenance of an aircraft will not be complete.

Digitally transferring data can create problems: the buyer and seller may be using different systems that are not compatible, and therefore there is a risk of data being lost. Thus, the interoperability of Air Transport Association (ATA) standards and the security of transferring data become paramount when electronic data transfers occur.

The second most important problem for MROs is the use of spare parts. Individual aircraft parts and airframes are imported, the inventory is maintained and the aircraft is assembled. The aircraft supply chain is well regulated and monitored at individual levels. There is the risk that replacement parts may be unapproved or of substandard quality replication or products sold on the black market. Counterfeiting strategies are evolving and becoming more sophisticated and are increasingly affecting the legitimacy of the supply chain; this applies to things such as stolen or parts recovered after they have been permanently removed from service. Parts are manufactured illegally by sub-contractors and then sold as legitimate parts [45].

The aviation industry’s number one priority is safety, and it is deeply concerned with detecting counterfeit products within the aircraft parts supply chain. A small number of aircraft parts may be counterfeit or missing records, which can have a detrimental result if they are not manufactured to the standards set by regulators. In 2016, the FAA stated that 273 counterfeit parts from China were installed in some Boeing 777 wing spoilers—these caused the aircraft to slow down during landing. If Blockchain technology was implemented in MRO, a common ledger would be used by all relevant parties for entering, storing and retrieving information regarding the aircraft and its parts.

This entry is adapted from the peer-reviewed paper 10.3390/su14052643

References

- Darli Rodrigues; Paula Lavorato; Maintenance, Repair and Overhaul (MRO) Fundamentals and Strategies: An Aeronautical Industry Overview. International Journal of Computer Applications 2016, 135, 21-29, 10.5120/ijca2016908563.

- Karel Joris Bert Lootens; Marina Efthymiou; The Adoption of Network-Centric Data Sharing in Air Traffic Management. Information Resources Management Journal 2019, 32, 48-69, 10.4018/irmj.2019070103.

- Karel Joris Bert Lootens; Marina Efthymiou; The Adoption of Network-Centric Data Sharing in Air Traffic Management. Research Anthology on Reliability and Safety in Aviation Systems, Spacecraft, and Air Transport 2021, 1, 127-151, 10.4018/978-1-7998-5357-2.ch006.

- Amulya Gurtu; Jestin Johny; Potential of blockchain technology in supply chain management: a literature review. International Journal of Physical Distribution & Logistics Management 2019, 49, 881-900, 10.1108/ijpdlm-11-2018-0371.

- Hokey Min; Blockchain technology for enhancing supply chain resilience. Business Horizons 2018, 62, 35-45, 10.1016/j.bushor.2018.08.012.

- Marina Efthymiou; Katie McCarthy; Chris Markou; John F. O’connell; An Exploratory Research on Blockchain in Aviation: The Case of Maintenance, Repair and Overhaul (MRO) Organizations. Sustainability 2022, 14, 2643, 10.3390/su14052643.

- Laurie Hughes; Yogesh K. Dwivedi; Santosh K. Misra; Nripendra P. Rana; Vishnupriya Raghavan; Viswanadh Akella; Blockchain research, practice and policy: Applications, benefits, limitations, emerging research themes and research agenda. International Journal of Information Management 2019, 49, 114-129, 10.1016/j.ijinfomgt.2019.02.005.

- Tsung-Ting Kuo; Hyeoneui Kim; Lucila Ohno-Machado; Blockchain distributed ledger technologies for biomedical and health care applications. Journal of the American Medical Informatics Association 2017, 24, 1211-1220, 10.1093/jamia/ocx068.

- Samuel Fosso Wamba; Maciel M. Queiroz; Blockchain in the operations and supply chain management: Benefits, challenges and future research opportunities. International Journal of Information Management 2020, 52, 102064, 10.1016/j.ijinfomgt.2019.102064.

- Chung-Shan Yang; Maritime shipping digitalization: Blockchain-based technology applications, future improvements, and intention to use. Transportation Research Part E: Logistics and Transportation Review 2019, 131, 108-117, 10.1016/j.tre.2019.09.020.

- Marina Dehez Clementi; Nicolas Larrieu; Emmanuel Lochin; Mohamed Ali Kaafar; Hassan Asghar; When Air Traffic Management Meets Blockchain Technology: a Blockchain-based concept for securing the sharing of Flight Data. 2019 IEEE/AIAA 38th Digital Avionics Systems Conference (DASC) 2019, 1, 1-10, 10.1109/dasc43569.2019.9081622.

- Yusuf Zakir; Khondker S. Hasan; Naomi S. Wiggins; Amlan Chatterjee; Improving Data Security in Message Communication between ACT and Aircraft using Private Blockchain. 2019 Sixth International Conference on Internet of Things: Systems, Management and Security (IOTSMS) 2019, 1, 506-513, 10.1109/iotsms48152.2019.8939209.

- Yingli Wang; Meita Singgih; Jingyao Wang; Mihaela Rit; Making sense of blockchain technology: How will it transform supply chains?. International Journal of Production Economics 2019, 211, 221-236, 10.1016/j.ijpe.2019.02.002.

- Rebecca Yang; Ron Wakefield; Sainan Lyu; Sajani Jayasuriya; Fengling Han; Xun Yi; Xuechao Yang; Gayashan Amarasinghe; Shiping Chen; Public and private blockchain in construction business process and information integration. Automation in Construction 2020, 118, 103276, 10.1016/j.autcon.2020.103276.

- Zibin Zheng; Shaoan Xie; Hongning Dai; Xiangping Chen; Huaimin Wang; An Overview of Blockchain Technology: Architecture, Consensus, and Future Trends. 2017 IEEE International Congress on Big Data (BigData Congress) 2017, 1, 557-564, 10.1109/bigdatacongress.2017.85.

- Quinn Dupont; Blockchain Identities: Notational Technologies for Control and Management of Abstracted Entities. Metaphilosophy 2017, 48, 634-653, 10.1111/meta.12267.

- Lin William Cong; Zhiguo He; Blockchain Disruption and Smart Contracts. The Review of Financial Studies 2019, 32, 1754-1797, 10.1093/rfs/hhz007.

- Yong Yuan; Fei-Yue Wang; Towards blockchain-based intelligent transportation systems. 2016 IEEE 19th International Conference on Intelligent Transportation Systems (ITSC) 2016, 1, 2663-2668, 10.1109/itsc.2016.7795984.

- Jiaxing Li; Jigang Wu; Long Chen; Block-secure: Blockchain based scheme for secure P2P cloud storage. Information Sciences 2018, 465, 219-231, 10.1016/j.ins.2018.06.071.

- Bin Liu; Xiao Liang Yu; Shiping Chen; Xiwei Xu; Liming Zhu; Blockchain Based Data Integrity Service Framework for IoT Data. 2017 IEEE International Conference on Web Services (ICWS) 2017, 1, 468-475, 10.1109/icws.2017.54.

- Rami Alkhudary; Xavier Brusset; Pierre Fenies; Blockchain in general management and economics: a systematic literature review. European Business Review 2020, 32, 765-783, 10.1108/ebr-11-2019-0297.

- John F. O'Connell; Raquel Martinez Avellana; David Warnock-Smith; Marina Efthymiou; Evaluating drivers of profitability for airlines in Latin America: A case study of Copa Airlines. Journal of Air Transport Management 2020, 84, 101727, 10.1016/j.jairtraman.2019.101727.

- Marina Efthymiou; David Usher; John F. O'Connell; David Warnock-Smith; Gerry Conyngham; The factors influencing entry level airline pilot retention: An empirical study of Ryanair. Journal of Air Transport Management 2020, 91, 101997, 10.1016/j.jairtraman.2020.101997.

- Mahmood Shafiee; Stefanka Chukova; Maintenance models in warranty: A literature review. European Journal of Operational Research 2013, 229, 561-572, 10.1016/j.ejor.2013.01.017.

- Mahmood Shafiee; Stefanka Chukova; Maintenance models in warranty: A literature review. European Journal of Operational Research 2013, 229, 561-572, 10.1016/j.ejor.2013.01.017.

- Marina Efthymiou; David Usher; John F. O'Connell; David Warnock-Smith; Gerry Conyngham; The factors influencing entry level airline pilot retention: An empirical study of Ryanair. Journal of Air Transport Management 2020, 91, 101997, 10.1016/j.jairtraman.2020.101997.

This entry is offline, you can click here to edit this entry!