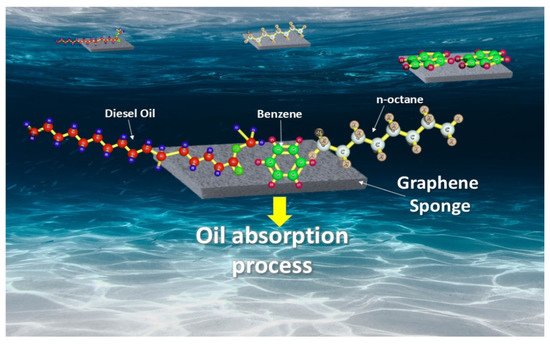

Oily wastewaters, oil spills from the petroleum industry, and oil-shipping accidents have caused detrimental effects on aquatic ecosystems. Several methods were proposed by various number of studies to tackle oil spillage cleanups; these methods include absorption, dispersants, solidifiers, and controlled burning. Absorption is one of the most commonly used methods in the separation and recovery of spilled oil from water thanks to its good efficiency, simple operation, and flexibility to combine with other methods. Graphene has a large surface area, with a high chemical and thermal stability. It is an excellent adsorption material and has several applications in the field of oil spill cleanup and water purification processes.

- nanomaterials

- graphene

- water–oil separation

- graphene oxide

- reduced graphene oxide

- foams

- sponges

- metal meshes

1. Graphene-Based Sponges for Oil/Water Separation

| Sorbent Material | Type of Oil | Sorption Capacity (g/g) | Reference |

|---|---|---|---|

| rGO@MF modified sponge | Crude oil-in-water | 2.1–5.6 | [7] |

| Graphene-based sponge | Oil and organic solvents | 50–165 | [8] |

| SiO2/GO-PU sponge | Oil and organic solvents | 80.0–180.0 | [9] |

| Graphene-coated PU sponge | lubricate oil | 31.0 | [10] |

| NMP/graphene PU sponge | Oil and organic solvents | 40.0–80.0 | [11] |

| GO/PU sponge | Oil and organic solvents | 30.0–55.0 | [12] |

| Thiolated graphene/PU sponge | crude oil | 29.5–90.0 | [13] |

| RGO/PU sponge | Oil and organic solvents | 24.2–37.6 | [14] |

| RGO/OAP/PU sponge | Oil and organic solvents | 24.7–80.3 | [15] |

| G sponge | Machine oil | 35.5 | [16] |

| Polyethylenimine/RGO decorated PU sponge |

Bicycle chain oil | 8.8 | [1] |

| RGO and octadecylamine decorated PU sponge |

Silicon oil | 29.7 | [17] |

3. Graphene-Based Aerogels for Oil/Water Separation

This entry is adapted from the peer-reviewed paper 10.3390/nano12010087

References

- Periasamy, A.P.; Wu, W.-P.; Ravindranath, R.; Roy, P.; Lin, G.-L.; Chang, H.-T. Polymer/reduced graphene oxide functionalized sponges as superabsorbents for oil removal and recovery. Mar. Pollut. Bull. 2017, 114, 888–895.

- Liu, C.; Yang, J.; Tang, Y.; Yin, L.; Tang, H.; Li, C. Versatile fabrication of the magnetic polymer-based graphene foam and applications for oil–water separation. Colloids Surf. A Physicochem. Eng. Asp. 2015, 468, 10–16.

- Shiu, R.-F.; Lee, C.-L.; Hsieh, P.-Y.; Chen, C.-S.; Kang, Y.-Y.; Chin, W.-C.; Tai, N.-H. Superhydrophobic graphene-based sponge as a novel sorbent for crude oil removal under various environmental conditions. Chemosphere 2018, 207, 110–117.

- Pethsangave, D.A.; Wadekar, P.H.; Khose, R.V.; Some, S. Super-hydrophobic carrageenan cross-linked graphene sponge for recovery of oil and organic solvent from their water mixtures. Polym. Test. 2020, 90, 106743.

- Petridis, L.V.; Kokkinos, N.C.; Mitropoulos, A.C.; Kyzas, G.Z. Chapter 8—Graphene aerogels for oil absorption. In Interface Science and Technology; Kyzas, G.Z., Mitropoulos, A.C., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 30, pp. 173–197.

- Yuan, J.; Zhang, M.; Xia, M.; Cao, W.; Du, M.; Dou, J.; Zhao, D. Novel high-capacity and reusable carbonaceous sponges for efficient absorption and recovery of oil from water. Appl. Surf. Sci. 2019, 487, 398–408.

- Ahmed, R.M.G.; Anis, B.; Khalil, A.S.G. Facile surface treatment and decoration of graphene-based 3D polymeric sponges for high performance separation of heavy oil-in-water emulsions. J. Environ. Chem. Eng. 2021, 9, 105087.

- Nguyen, D.D.; Tai, N.-H.; Lee, S.-B.; Kuo, W.-S. Superhydrophobic and superoleophilic properties of graphene-based sponges fabricated using a facile dip coating method. Energy Environ. Sci. 2012, 5, 7908–7912.

- Lü, X.; Cui, Z.; Wei, W.; Xie, J.; Jiang, L.; Huang, J.; Liu, J. Constructing polyurethane sponge modified with silica/graphene oxide nanohybrids as a ternary sorbent. Chem. Eng. J. 2016, 284, 478–486.

- Zhang, X.; Wang, Y. How to reduce household carbon emissions: A review of experience and policy design considerations. Energy Policy 2017, 102, 116–124.

- Kong, Z.; Wang, J.; Lu, X.; Zhu, Y.; Jiang, L. In situ fastening graphene sheets into a polyurethane sponge for the highly efficient continuous cleanup of oil spills. Nano Res. 2017, 10, 1756–1766.

- Luo, Y.; Jiang, S.; Xiao, Q.; Chen, C.; Li, B. Highly reusable and superhydrophobic spongy graphene aerogels for efficient oil/water separation. Sci. Rep. 2017, 7, 7162.

- Zhang, L.; Li, H.; Lai, X.; Su, X.; Liang, T.; Zeng, X. Thiolated graphene-based superhydrophobic sponges for oil-water separation. Chem. Eng. J. 2017, 316, 736–743.

- Xia, C.; Li, Y.; Fei, T.; Gong, W. Facile one-pot synthesis of superhydrophobic reduced graphene oxide-coated polyurethane sponge at the presence of ethanol for oil-water separation. Chem. Eng. J. 2018, 345, 648–658.

- Jamsaz, A.; Goharshadi, E.K. Flame retardant, superhydrophobic, and superoleophilic reduced graphene oxide/orthoaminophenol polyurethane sponge for efficient oil/water separation. J. Mol. Liq. 2020, 307, 112979.

- Wu, R.; Yu, B.; Liu, X.; Li, H.; Wang, W.; Chen, L.; Bai, Y.; Ming, Z.; Yang, S.-T. One-pot hydrothermal preparation of graphene sponge for the removal of oils and organic solvents. Appl. Surf. Sci. 2016, 362, 56–62.

- Oribayo, O.; Feng, X.; Rempel, G.L.; Pan, Q. Synthesis of lignin-based polyurethane/graphene oxide foam and its application as an absorbent for oil spill clean-ups and recovery. Chem. Eng. J. 2017, 323, 191–202.

- Rahmani, Z.; Samadi, M.T.; Kazemi, A.; Rashidi, A.M.; Rahmani, A.R. Nanoporous graphene and graphene oxide-coated polyurethane sponge as a highly efficient, superhydrophobic, and reusable oil spill absorbent. J. Environ. Chem. Eng. 2017, 5, 5025–5032.

- Qiang, F.; Hu, L.-L.; Gong, L.-X.; Zhao, L.; Li, S.-N.; Tang, L.-C. Facile synthesis of super-hydrophobic, electrically conductive and mechanically flexible functionalized graphene nanoribbon/polyurethane sponge for efficient oil/water separation at static and dynamic states. Chem. Eng. J. 2018, 334, 2154–2166.

- Khalilifard, M.; Javadian, S. Magnetic superhydrophobic polyurethane sponge loaded with Fe3O4@oleic oxide as high performance adsorbent oil from water. Chem. Eng. J. 2020, 408, 127369.

- Qin, Y.; Li, S.; Li, Y.; Pan, F.; Han, L.; Chen, Z.; Yin, X.; Wang, L.; Wang, H. Mechanically robust polybenzoxazine/reduced graphene oxide wrapped-cellulose sponge towards highly efficient oil/water separation, and solar-driven for cleaning up crude oil. Compos. Sci. Technol. 2020, 197, 108254.

- Mao, M.; Xu, H.; Guo, K.-Y.; Zhang, J.-W.; Xia, Q.-Q.; Zhang, G.-D.; Zhao, L.; Gao, J.-F.; Tang, L.-C. Mechanically flexible, super-hydrophobic and flame-retardant hybrid nano-silica/graphene oxide wide ribbon decorated sponges for efficient oil/water separation and fire warning response. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106191.

- Zhang, Z.; Liu, H.; Qiao, W. Reduced graphene-based superhydrophobic sponges modified by hexadecyltrimethoxysilane for oil adsorption. Colloids Surf. A Physicochem. Eng. Asp. 2020, 589, 124433.

- Zhou, J.; Zhang, Y.; Yang, Y.; Chen, Z.; Jia, G.; Zhang, L. Silk fibroin-graphene oxide functionalized melamine sponge for efficient oil absorption and oil/water separation. Appl. Surf. Sci. 2019, 497, 143762.

- Wang, Y.; Zhou, L.; Luo, X.; Zhang, Y.; Sun, J.; Ning, X.; Yuan, Y. Solar-heated graphene sponge for high-efficiency clean-up of viscous crude oil spill. J. Clean. Prod. 2019, 230, 995–1002.

- Yang, S.; Ji, Y.; Wu, Y.; Ma, J.; Zou, Z.; Lu, H. Air-dried graphene-based sponge for Water/oil separation and strain sensing. Colloids Surf. A Physicochem. Eng. Asp. 2018, 555, 358–364.

- Peng, M.; Chen, G.; Zeng, G.; Chen, A.; He, K.; Huang, Z.; Hu, L.; Shi, J.; Li, H.; Yuan, L.; et al. Superhydrophobic kaolinite modified graphene oxide-melamine sponge with excellent properties for oil-water separation. Appl. Clay Sci. 2018, 163, 63–71.

- Meng, H.; Yan, T.; Yu, J.; Jiao, F. Super-hydrophobic and super-lipophilic functionalized graphene oxide/polyurethane sponge applied for oil/water separation. Chin. J. Chem. Eng. 2018, 26, 957–963.

- Sun, S.; Tang, S.; Chang, X.; Wang, N.; Wang, D.; Liu, T.; Lei, Y.; Zhu, Y. A bifunctional melamine sponge decorated with silver-reduced graphene oxide nanocomposite for oil-water separation and antibacterial applications. Appl. Surf. Sci. 2019, 473, 1049–1061.

- Zhou, S.; Hao, G.; Zhou, X.; Jiang, W.; Wang, T.; Zhang, N.; Yu, L. One-pot synthesis of robust superhydrophobic, functionalized graphene/polyurethane sponge for effective continuous oil–water separation. Chem. Eng. J. 2016, 302, 155–162.

- Zhao, J.; Guo, Q.; Wang, X.; Xie, H.; Chen, Y. Recycle and reusable melamine sponge coated by graphene for highly efficient oil-absorption. Colloids Surf. A Physicochem. Eng. Asp. 2016, 488, 93–99.

- Yang, W.; Gao, H.; Zhao, Y.; Bi, K.; Li, X. Facile preparation of nitrogen-doped graphene sponge as a highly efficient oil absorption material. Mater. Lett. 2016, 178, 95–99.

- Huang, J.; Liu, H.; Chen, S.; Ding, C. Graphene aerogel prepared through double hydrothermal reduction as high-performance oil adsorbent. Mater. Sci. Eng. B 2017, 226, 141–150.

- Ji, K.; Gao, Y.; Zhang, L.; Wang, S.; Yue, Q.; Xu, X.; Kong, W.; Gao, B.; Cai, Z.; Chen, Y. A tunable amphiphilic Enteromorpha-modified graphene aerogel for oil/water separation. Sci. Total Environ. 2020, 763, 142958.

- Chatterjee, S.; Ke, W.-T.; Liao, Y.-C. Elastic nanocellulose/graphene aerogel with excellent shape retention and oil absorption selectivity. J. Taiwan Inst. Chem. Eng. 2020, 111, 261–269.

- Zhan, C.; Jana, S.C. Shrinkage reduced polyimide-graphene oxide composite aerogel for oil absorption. Microporous Mesoporous Mater. 2020, 307, 110501.

- Meng, Y.; Liu, T.; Yu, S.; Cheng, Y.; Lu, J.; Wang, H. A lignin-based carbon aerogel enhanced by graphene oxide and application in oil/water separation. Fuel 2020, 278, 118376.

- Kang, W.; Cui, Y.; Qin, L.; Yang, Y.; Zhao, Z.; Wang, X.; Liu, X. A novel robust adsorbent for efficient oil/water separation: Magnetic carbon nanospheres/graphene composite aerogel. J. Hazard. Mater. 2020, 392, 122499.

- Thakkar, S.V.; Pinna, A.; Carbonaro, C.M.; Malfatti, L.; Guardia, P.; Cabot, A.; Casula, M.F. Performance of oil sorbents based on reduced graphene oxide–silica composite aerogels. J. Environ. Chem. Eng. 2020, 8, 103632.

- Luo, Z.; Wang, X.; Yang, D.; Zhang, S.; Zhao, T.; Qin, L.; Yu, Z.-Z. Photothermal hierarchical carbon nanotube/reduced graphene oxide microspherical aerogels with radially orientated microchannels for efficient cleanup of crude oil spills. J. Colloid Interface Sci. 2020, 570, 61–71.

- Hu, J.; Zhu, J.; Ge, S.; Jiang, C.; Guo, T.; Peng, T.; Huang, T.; Xie, L. Biocompatible, hydrophobic and resilience graphene/chitosan composite aerogel for efficient oil−water separation. Surf. Coat. Technol. 2020, 385, 125361.

- Sun, A.; Hou, X.; Hu, X. Super-performance photothermal conversion of 3D macrostructure graphene-CuFeSe2 aerogel contributes to durable and fast clean-up of highly viscous crude oil in seawater. Nano Energy 2020, 70, 104511.

- Zhang, S.; Liu, G.; Gao, Y.; Yue, Q.; Gao, B.; Xu, X.; Kong, W.; Li, N.; Jiang, W. A facile approach to ultralight and recyclable 3D self-assembled copolymer/graphene aerogels for efficient oil/water separation. Sci. Total Environ. 2019, 694, 133671.

- Zhou, L.; Xu, Z. Ultralight, highly compressible, hydrophobic and anisotropic lamellar carbon aerogels from graphene/polyvinyl alcohol/cellulose nanofiber aerogel as oil removing absorbents. J. Hazard. Mater. 2020, 388, 121804.

- Song, Y.; Li, H.; Gao, Y.; Yue, Q.; Gao, B.; Kong, W.; Zang, Y.; Jiang, W. Grass-modified graphene aerogel for effective oil-water separation. Process Saf. Environ. Prot. 2019, 129, 119–129.

- Chen, C.; Li, F.; Zhang, Y.; Wang, B.; Fan, Y.; Wang, X.; Sun, R. Compressive, ultralight and fire-resistant lignin-modified graphene aerogels as recyclable absorbents for oil and organic solvents. Chem. Eng. J. 2018, 350, 173–180.

- Mi, H.-Y.; Jing, X.; Politowicz, A.L.; Chen, E.; Huang, H.-X.; Turng, L.-S. Highly compressible ultra-light anisotropic cellulose/graphene aerogel fabricated by bidirectional freeze drying for selective oil absorption. Carbon 2018, 132, 199–209.

- Cao, N.; Lyu, Q.; Li, J.; Wang, Y.; Yang, B.; Szunerits, S.; Boukherroub, R. Facile synthesis of fluorinated polydopamine/chitosan/reduced graphene oxide composite aerogel for efficient oil/water separation. Chem. Eng. J. 2017, 326, 17–28.

- Yu, X.; Wu, P.-w.; Liu, Y.-c.; Wang, L.; Feng, L.-j.; Li, C.-h. Dopamine and L-arginine tailored fabrication of ultralight nitrogen-doped graphene aerogels for oil spill treatment. J. Fuel Chem. Technol. 2017, 45, 1230–1235.

- Cheng, Y.; Xu, P.; Zeng, W.; Ling, C.; Zhao, S.; Liao, K.; Sun, Y.; Zhou, A. Highly hydrophobic and ultralight graphene aerogel as high efficiency oil absorbent material. J. Environ. Chem. Eng. 2017, 5, 1957–1963.