3. Fabrication and Structure Design

Fiber- and yarn-based strain sensors are mainly manufactured by spinning and coating. For example, the conductive filler is mixed into the spinning solution to prepare conductive composite fibers. The structure of composite fibers prepared by spinning is round with uniformly distributed conductive materials, or coaxial, porous, hollow, and so on. In terms of coating conductive materials on fibers and yarns, the conductive coating can be designed as a microcrack, fold buckling, multilayer composite structure. Additionally, the geometry of the yarns was designed to control the sensing performance of strain sensors. These preparation strategies and structural design features will be discussed in the following sections. The performances of fiber and yarn strain sensors reported in the literature are summarized in Table 4, Table 5 and Table 6.

3.1. Conductive Composite Fibers

3.1.1. Uniform Mixing of Conductive Materials

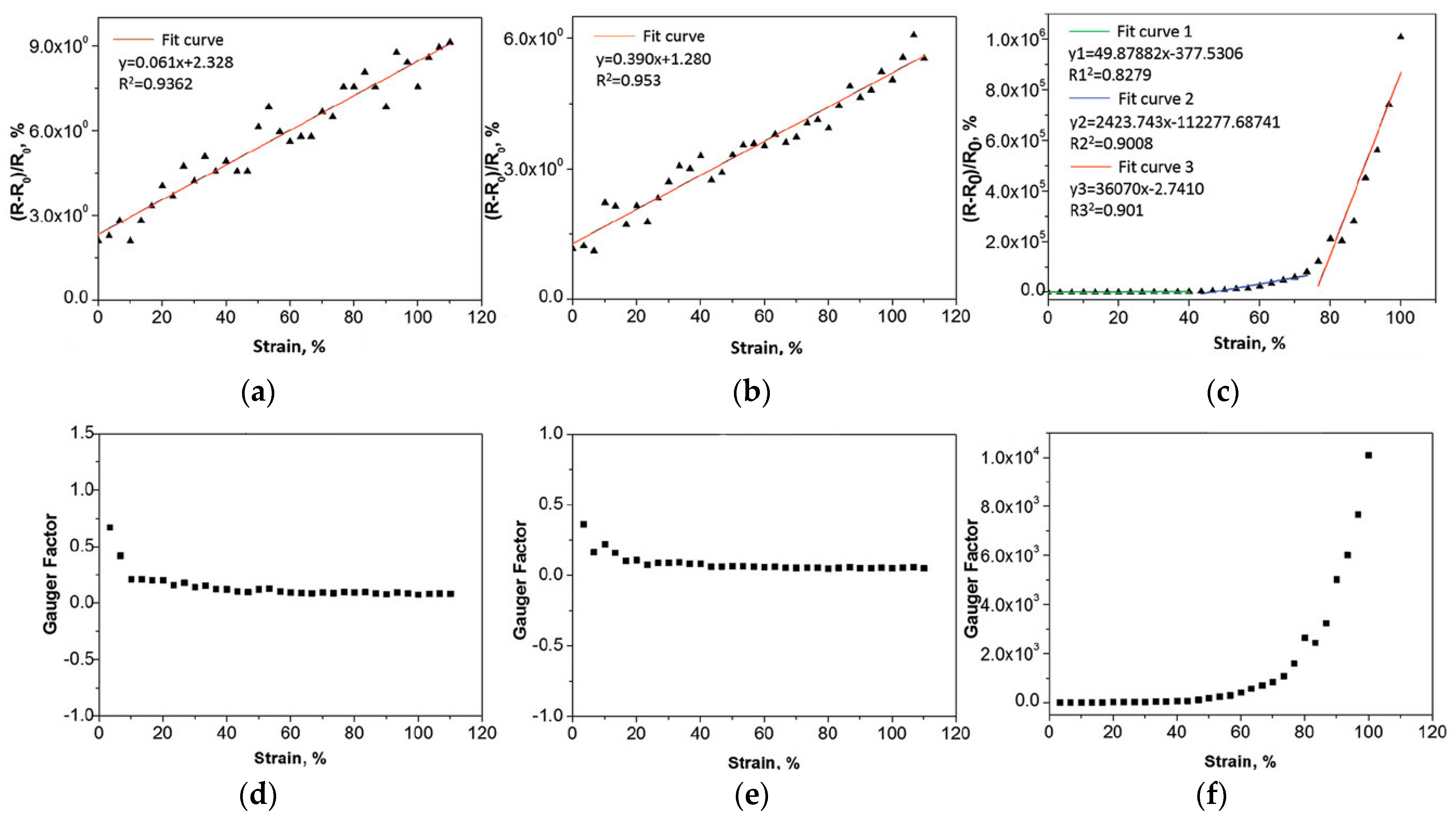

Traditional spinning techniques, such as wet spinning, dry spinning and melt spinning, are the most common methods to prepare a 1D stretchable conductive composite materials; they mix the conductive filler and the elastic matrix directly and uniformly, and then extrude it through the spinneret hole to a coagulating bath to form the composite fiber. Li et al. uniformly mixed Gr into SBS and prepared SBS/Gr composite fiber flexible strain sensors by a simple wet-spinning method, and the Gr content had a significant impact on the morphology, mechanical properties and electromechanical properties of the composite fiber (

Figure 1)

[70]. The fiber with the 5 wt% graphene content has a wide working strain, which reaches 100%. However, its sensitivity increases with the increase in strain, and the sensitivity within 50% strain is changeable at different stretching speeds. He et al. proposed multiwalled carbon nanotube/thermoplastic polyurethane (MWCNT/TPU) fibers by wet spinning

[71]. The gauge factors (GF) of the MWCNT/TPU fiber are about 550 and 2800 in the strain ranges of 1 to 4% and 5 to 100%, respectively. The strain of the MWCNT/TPU fibers decreases significantly under large hysteresis after multiple stretching–releasing cycles, indicating poor sensing repeat stability. At the same time, the influence of different weight ratios of MWCNTs to TPU on the mechanical and electrical properties of composite fibers has been studied. It was found that the concentration and arrangement of MWCNT would change the working strain range and GF of the sensor

[72]. Wang et al. manufactured a fiber strain sensor with a wide response range (320%) and a fast response time (<200 ms) based on MWCNTs and TPU by a simple wet-spinning method

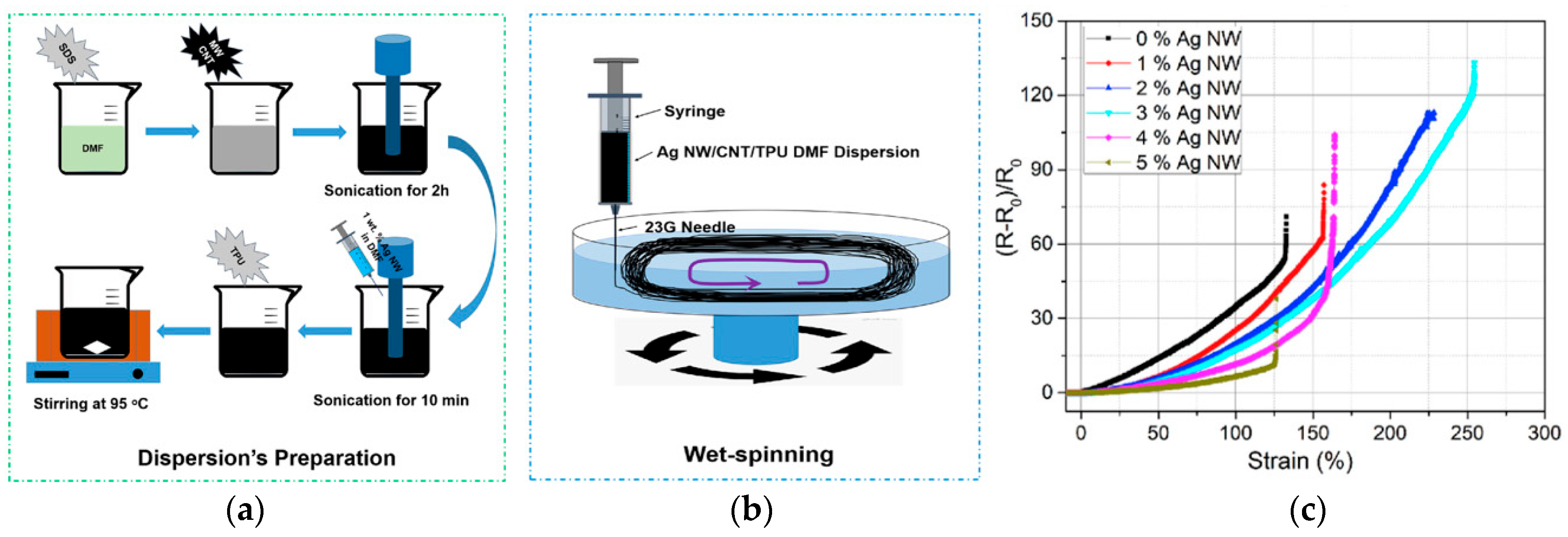

[39]. However, the electrical response of the MWCNT/TPU strain sensor decreased slightly in the initial stage when multiple stretching–releasing cycles were carried out at 100% strain, and it exhibited unstable sensitivity at the same time. To improve the conductivity and the stability of the conductive network, hybrid conductive fillers have been used to achieve a composite synergistic effect to prepare strain-sensing fibers. For instance, Zhang et al. demonstrated a highly conductive AgNW/MWCNT/TPU composite fiber by wet spinning, in which MWCNTs were regarded as the sensitive materials and silver nanowires were used to improve electrical conductivity

[73]. When the contents of AgNWs reached the optimal amount (3%), the working strain range was 254%, and the conductivity was 0.0803 S/cm (

Figure 2). Compared with single-filler composite fibers, the increase in AgNWs improves the conductivity and working strain range of the composite fiber, but its sensitivity decreases. In the case of a strain range of 50–150%, the relative resistance change of the sensor continues to decrease in stretching–releasing tests within 1000 s, showing poor stability.

Figure 1. ΔR/R

0–strain curve and GF–strain curve of SBS-xGr composite fiber with different graphene contents. (

a,

d) SBS-1Gr composite fiber; (

b,

e) SBS-3Gr composite fiber; (

c,

f) SBS-5Gr composite fiber

[70].

Figure 2. (

a) Suspension preparation process; (

b) AgNW/MWCNT/TPU spinning process; (

c) the relative change resistance–strain curve of the fiber strain sensor with different AgNW contents

[73].

3.1.2. Selective Localization of Conductive Materials

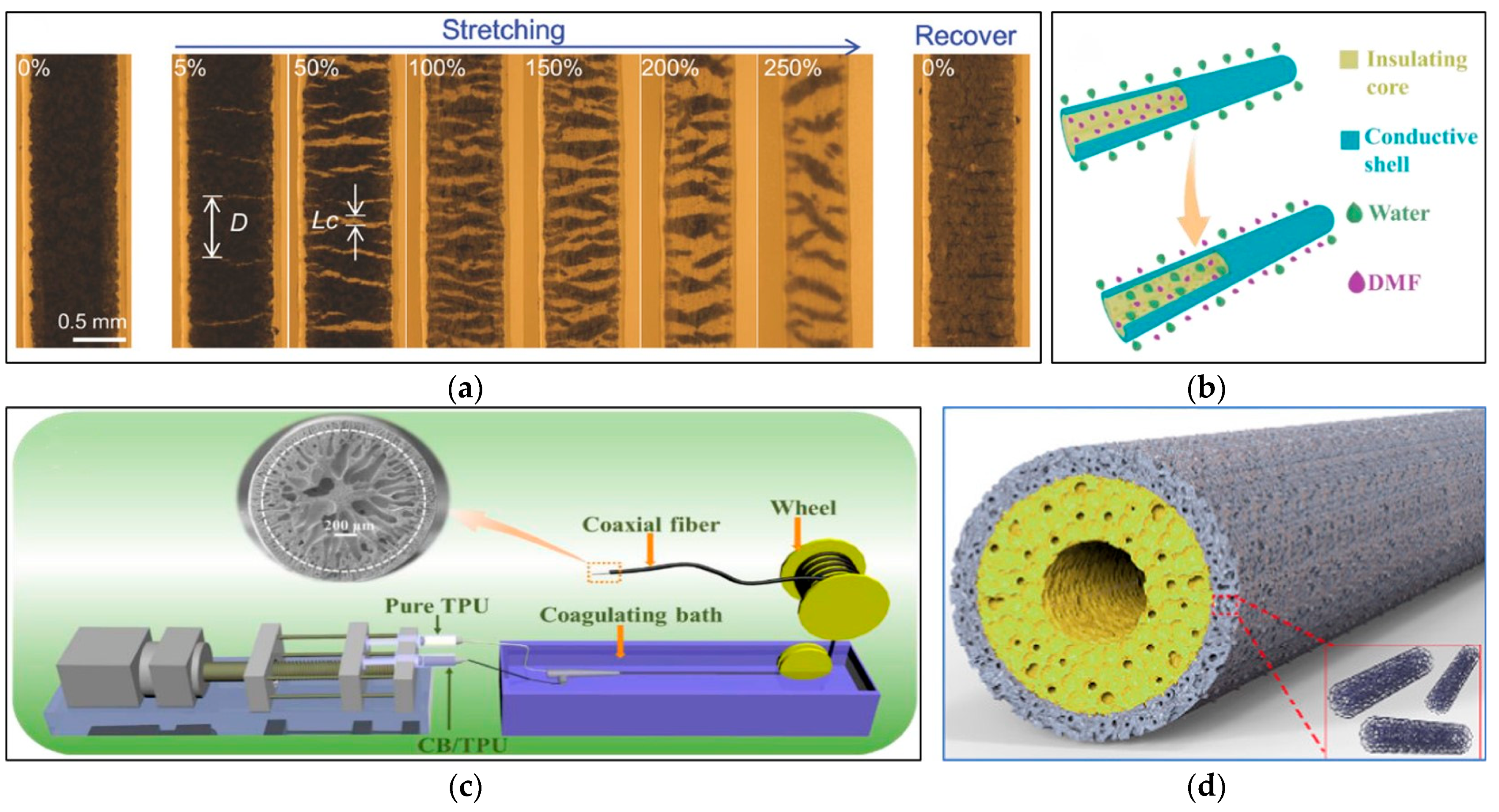

The conductive network was also designed by controlling the distribution of the fillers, such as selective positioning in multiple phases to form a co-continuous structure or a sea-island structure. In this case, the conductivity of the composite is improved by forming a double or triple permeation structure in the polymer matrix. The selective positioning of the fillers at the interface of the co-continuous polymer structure can further reduce the filler content, which is required to form the continuous conductive network. Zhou et al. used the coaxial wet-spinning method and post-treatment process to prepare the thermoplastic elastomer/single-walled carbon nanotube (TPE/SWCNT) ribbon coaxial fiber with good stretchability and high sensitivity (

Figure 3a)

[38]. The strain sensor composed of this fiber has a GF of 48 at 0–5% strain and a GF of 425 at 20–100% strain; a linear change cannot occur in in the full strain range. Tang et al. designed a stretchable core sheath fiber using a one-step coaxial wet-spinning assembly method, in which a high-stretch polymer elastomer Ecoflex wrapped CNT/Ecoflex composite material

[74]. Similar to traditional cables, the outer insulating sheath effectively avoids short circuits and the falling off of conductive fillers. At the same time, it can have good conductivity under a low permeability threshold (0.74 vol%). Strain sensors made of this fiber achieve a high sensitivity of 1378 under 300% strain and show high durability under 100% strain, but they exhibit low sensitivity in a small strain range, non-linear resistance change and obvious overshoot behavior. Yue et al. demonstrated a highly stretchable TPU-CB@TPU fiber strain sensor with a porous core–sheath structure through the coaxial wet-spinning method (

Figure 3b,c)

[37]. Due to the countercurrent diffusion and coagulation of the solvent, this fiber has a porous structure with a wide strain range. The highest GF is 28,084 when the strain is 204%. However, its sensitivity is not large enough in a small strain range, and the resistance change gradually declines over multiple cycles of stretching. A coaxial fiber with an outer layer of MXene/PU composite and an inner layer of PU was prepared by Seyedin et al.

[75]. Compared with the non-coaxial composite fiber, the coaxial fiber shows a larger strain range, a smaller data drift, and an improvement in the cyclic stability of the sensor response. Gao et al. fabricated a coaxial stretchable composite fiber with a double-layer hollow structure (

Figure 3d), in which the conductive outer layer has a CNT/TPU composite as the sensitive area, and the insulating inner layer is made of pure TPU with a hollow core to serve as a flexible support

[76]. The prepared composite fiber (TPU-8CNT@TPU) has an ultralow percolation threshold (0.17 wt%), good durability, and small compression deformation that can be detected. With an increase in the stretching speed, the relative resistance differently changes under the same strain. Additionally, there is an obvious shoulder phenomenon, which may disturb signal identification in an accurate strain monitoring. However, the reason for this shoulder phenomenon is still not clear. The mainstream is attributed to the competition between the destruction and reconstruction of CNT conductive networks in the fiber, which needs further verification.

Figure 3. (

a) The image of a typical coaxial fiber stretched from 0 to 250% strain and relaxed after unloading; D and Lc are the average crack spacing and the average crack opening displacement, respectively

[38]. (

b) Fiber cell structure evolution process (

c) Schematic diagram of the TCTF preparation process

[37]. (

d) Schematic diagram of TPU-8CNT@TPU structure

[76].

The characteristics of various fiber-based strain sensors prepared by spinning technology are summarized in

Table 4. In general, the preparation of stretchable conductive composite fibers as strain sensors by mixing conductive materials and spinning is a process technology that can be produced on a large scale and is widely used in industry. However, the addition of conductive filler will enhance the rigidity of the elastic matrix, and shrink the tensile strain range of the fiber, which leads to the narrow working strain range of the fiber sensor. On the contrary, if the amount of conductive material is too low, the conductivity of the composite fiber will also limit its working strain range. Therefore, there is a paradox between the conductivity and the working strain range of the stretchable conductive fiber, which needs to be balanced. According to the percolation theory

[60][77][78][79][80][81], the content of conductive materials in stretchable conductive composites has a percolation threshold. When the percolation threshold is exceeded, the polymer elastomer changes from an insulator to a conductor, and the conductivity increases with the increase in the content of conductive materials. When the content is near the percolation threshold, the sensitivity of the material is at its greatest

[82]. Therefore, it is still a huge challenge to achieve a high strain range and high sensitivity at the same time for conductive composite fibers. In addition, there is a limit on the production costs of practical commercial applications with the increase in conductive fillers. To reduce the permeation threshold while achieving high conductivity, different strategies have been studied

[50][83][84], such as functionalizing conductive fillers’ surfaces, increasing the aspect ratio of fillers, controlling the arrangement of fillers, and using different mixture of fillers. However, such permeation-based composite strain sensors rarely exhibit good linearity. When the composite fiber is stretched, its resistance is mainly caused by changes in geometry and tunnel theory

[37][39][85]. With an increase in tunneling distance and the destruction of the conductive path, the resistance of composites increases significantly during the tensile process. The maximum GF usually occurs when the conductive material content is close to the permeation threshold. Other shortcomings of strain sensors made of composite fibers include hysteresis, fatigue and so on, which are mostly due to the viscoelasticity and elastic recovery rate of composite fibers.

Table 4. Characteristics of conductive composite fiber-based strain sensors prepared by spinning technology.

| Structure |

Substrate |

Sensitive

Materials |

Breaking Stress and Strain |

Conductivity |

Strain Range |

GF |

Repeatability |

Linearity |

Response Time |

Ref. |

| Monofilament |

SBS |

Gr |

10.16 MPa; 910.83% |

N/A |

100% |

10,083.98 (73–100%) |

2500 (20%) |

N/A |

N/A |

[70] |

| Monofilament |

TPU |

MWCNTs |

28 MPa; 320% |

N/A |

100% |

2800 (5–100%) |

N/A |

N/A |

N/A |

[71] |

| Monofilament |

SIBS |

P3HT |

11.4 MPa; 975% |

0.38 S/cm |

770% |

20 (12.25%) |

N/A |

N/A |

N/A |

[86] |

| Monofilament |

TPU |

MWCNTs/

AgNWs |

32.49 MPa |

0.803 S/cm |

250% |

13 (50–150%) |

N/A |

N/A |

N/A |

[73] |

| Ribbon and coaxial |

TPE |

SWCNTs |

N/A |

N/A |

100% |

425 (100%) |

3250 (20–100%) |

R2 = 0.98 (20–100%) |

N/A |

[38] |

| Core–sheath |

Ecoflex |

CNTs |

N/A |

N/A |

330% |

1378 (330%) |

>10,000 (100%) |

N/A |

>300 ms (100%) |

[74] |

| Porous |

TPU |

CB |

2.15 MPa |

N/A |

380% |

28,084 (204%) |

11,000 (60%) |

N/A |

200 ms |

[87] |

| Coaxial |

PU |

MXene |

20.3 GPa |

N/A |

152% |

238 (50%) |

1000 (50%) |

N/A |

N/A |

[75] |

| Hollow |

TPU |

CNTs |

2.92 MPa; 476% |

N/A |

>350% |

1344.1 (200%) |

10,000 (100%) |

N/A |

167 ms |

[76] |

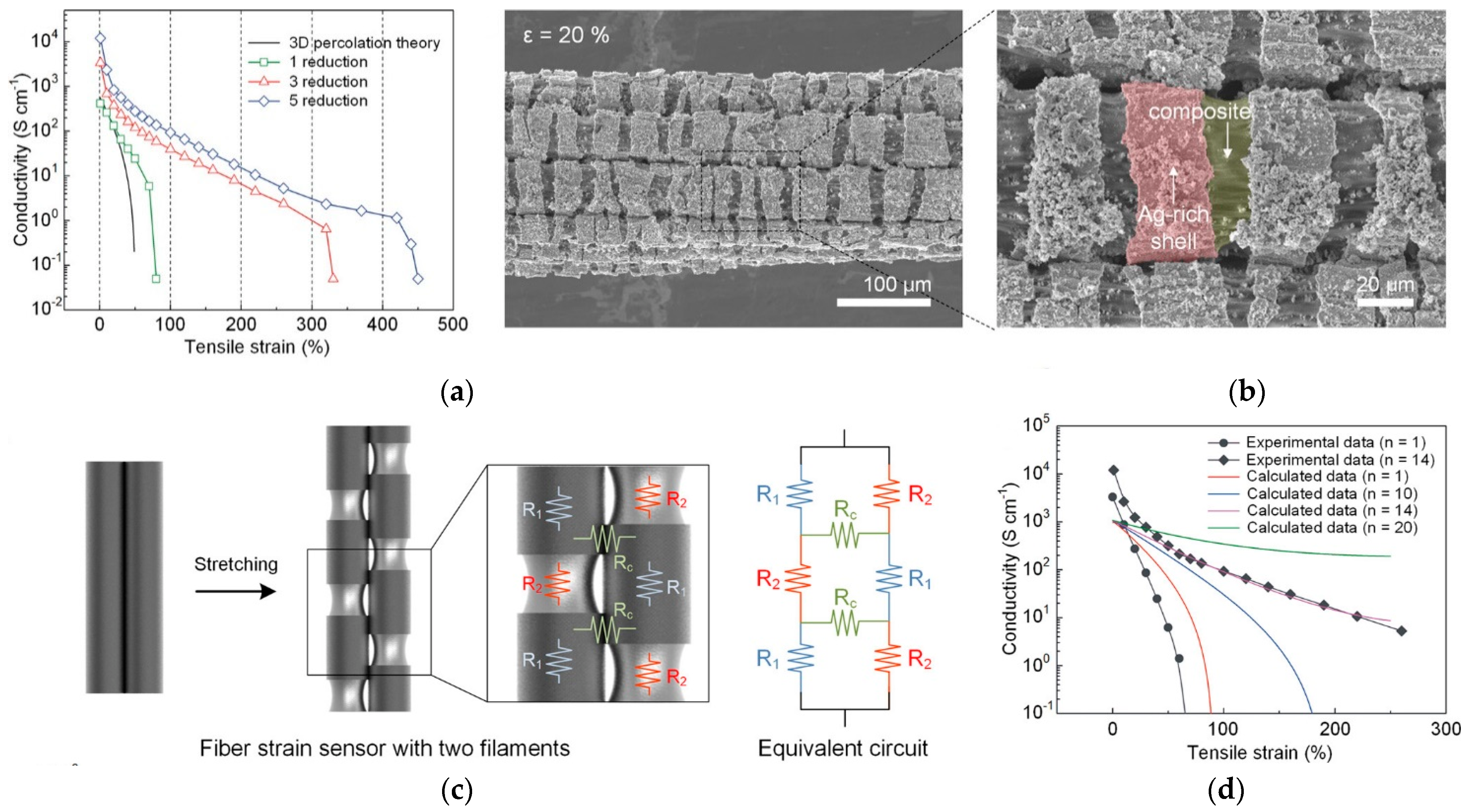

3.2. Conductive Coated Fibers

3.2.1. Microcrack Structure

Coating conductive materials on stretchable fibers or yarns is another way to prepare one-dimensional strain sensors by dipping, spraying, and in situ chemical polymerization, etc. The dip-coating method is one of the easiest and most widely used methods among them, due to its simple, fast and cost-effective characteristics. For example, Lee et al. reported a conductive PU multifilament coated uniformly AgNPs by an in situ reduction method, with low initial resistance (0.16 Ω/cm) (

Figure 4a,b)

[45]. AgNPs are uniformly distributed inside the multifilament and form a dense shell on the outer layer. The GF of the strain sensor reaches about 9.3 × 10

5 (under 450% strain) when the strain sensor is first stretched, while the GF decreases to 659 (under 450% strain) after subsequent stretching. Although the strain sensor has high sensitivity and wide strain range, its sensitivity is unstable and its linearity is poor. Generally speaking, the microcrack structure constructed by the strain sensor in tension is an effective method to achieve a sensing response and high sensitivity of sensors. However, the microcrack structure is usually limited by strain range. Compared with monofilament, the increase in the number of multifilament structures greatly widens its working strain range according to the theory (

Figure 4c,d)

[45]. Eom et al. first polymerized conductive PEDOT on polyester (PS) fibers by in situ polymerization to prepare conductive coated fibers, and then embedded this conductive fiber into fabrics to manufacture textile-based strain/touch/pressure sensors and user interface (UI) equipment

[36]. Due to the multifilament structure of its PEDOT/PS fiber, the resistance of the sensor tends to fall with the increase in strain, which is contrary to the common trend. During stretching, the overall conductivity of the PEDOT/PS multifilament increases, and the PEDOT/PS monofilament exhibits the opposite behavior. Liu et al. designed a monofilament strain sensor with a beaded structure using the Plateau–Rayleigh instability principle. The way to control the strain distribution along the fiber axis is by adjusting the size of the microbeads and the distance between the microbeads (

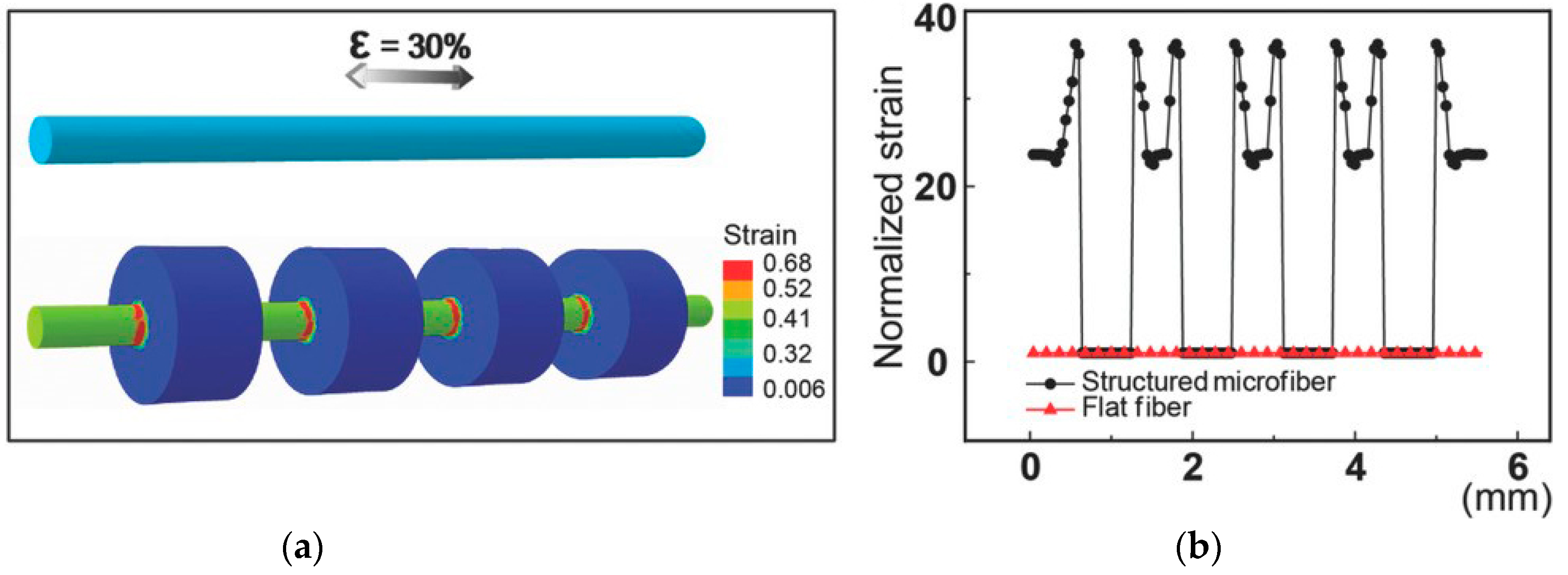

Figure 5)

[88]. This design effectively causes strain concentration and amplifies the local strain. Compared with a single uniform monofilament, the sensitivity of the sensor with a beaded structure is significantly improved. Overall, the sensitivity of the sensor with the crack effect usually increases significantly and then decreases, which is a characteristic of nonlinear sensing

[45]. Due to the destruction and shedding of the conductive layer, the sensor also exhibits a certain amount of hysteresis and poor cycle stability.

Figure 4. (

a) The electrical conductivity of the sensor under different strains; (

b) SEM images of the fiber strain sensor at ε = 20%; (

c) the resistance model of the double-filament strain sensor and the corresponding equivalent circuit; (

d) the relationship between the electrical conductivity of the single-filament/multifilament fiber strain sensor and the tensile strain;

n is the number of multiple filaments in the fiber strain sensor

[45].

Figure 5. (

a) Finite element simulation to study the strain adjustment effect of microstructured fibers compared with flat fibers; (

b) the strain distribution of different structures along the fiber surface

[88].

3.2.2. Wrinkle Structure

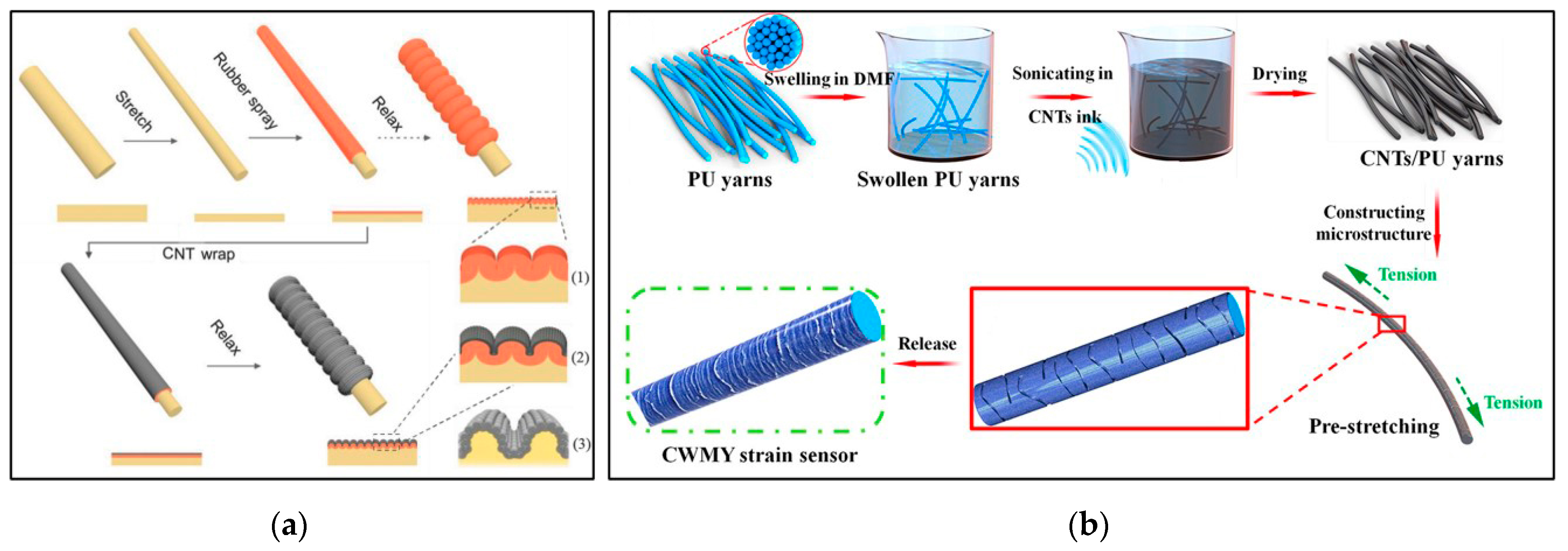

In order to improve the workable strain range, a conductive coating with a wrinkle structure was added to the fiber surface to design a flexible strain sensor. Wang et al. designed a highly stretchable NTSm@rubber@fiber strain sensor with a dual-sheath buckling structure by the pre-stretching method, in which NTS is the carbon nanotube sheets and m represents the number of NTS layers (

Figure 6a)

[89]. The elastic support fiber coaxially coated a curved rubber intermediate layer and a curved NTS conductive layer. At the same time, the GF of the sensor was controlled by changing the manufacturing parameters to adjust the buckling structure, but its overall sensitivity values were very low, only 0.5 (0–200%) and 0.14 (200–600%). The design of a wrinkle structure makes the strain sensor bear high tensile deformation without destroying the conductivity of the material, thereby increasing its sensing range. However, it also causes a small resistance change in the stretched state, showing lower sensitivity. As shown in

Figure 6b, CNT ink/PU yarns with a wrinkle-assisted crack microstructure were created by Sun et al.

[90]. The yarn sensors have an ultralow detection limit and excellent repeat stability. As mentioned above, the complex and multistep manufacturing process poses challenges to realize a large-scale production of strain sensors.

Figure 6. (

a) The manufacturing steps of NTS m @rubber@fiber, the longitudinal cross-sections of the fibers of different manufacturing steps are shown below the rubber fiber. Yellow, red and gray are used for SEBS core, SGE layer and NTS sheath, respectively

[89]. (

b) Schematic diagram of preparation of WCMYSS

[90].

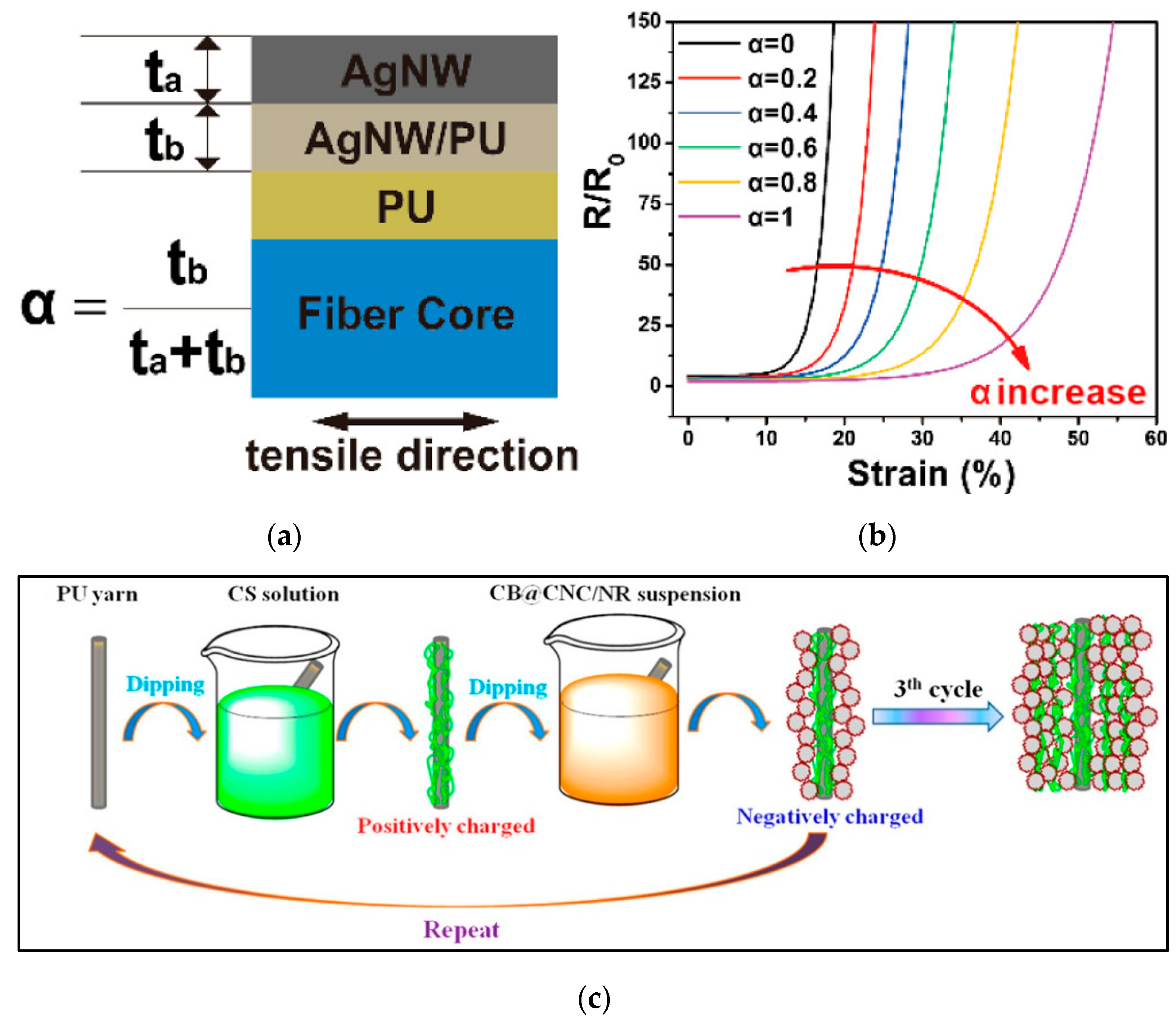

3.2.3. Multilayer Structure

Building a multilayered structure at the fiber scale is another way to design flexible strain sensors. Cao et al. introduced a AgNW/PU fiber with a composite multilayer structure by using an adhesive layer with adjustable adhesion to adjust the interface adhesion and fiber microstructure (

Figure 7a)

[91]. The GF and stretchability of the strain sensor were adjusted by changing the interface layer combination (

Figure 7b). However, its sensitivity was weak and the resistance response was nonlinear. After 100 and 1000 cycles of stretching at 10% strain, the drift rate values of the relative resistance of the sensor were 29.4 and 53.1%, respectively, showing poor repeatability. Liu et al. reported the silver plating polyurethane filaments (SPPF) with good electrical resistivity (4.5 ± 0.1 Ω/cm)

[92]. These AgNPs are bound to the surface of the filament by polydopamine, which remarkably improves the bonding between the conductive material and the fiber interface, but the nonlinear error and hysteresis of the SPPF strain sensor are up to 29.3 and 34.3%, respectively.

Figure 7. (

a) Schematic diagram of the longitudinal section of Ag NW/PU fiber (

b) Modeling of the resistance change and strain of Ag NW/PU fiber with different interface bonding strengths

[91] (

c) Schematic of the preparation of CPC@PU yarn by the LBL assembly process

[34].

The layer-by-layer (LBL) assembly method has been used to develop strain sensors with multilayer structures. The LBL assembly method has been reported as an effective method for manufacturing carbon-based films. Instead of simple deposition, this process includes repeated immersion and evaporation, and various reactions such as electrostatic interactions, hydrogen bonding, or covalent bonding to enhance the adhesion of the interface

[93]. Li et al. prepared a strain sensor using graphene/polyvinyl alcohol (Gr/PVA) composite material as the outer layer conductive sheath and polyurethane as the elastic core fiber

[94]. When the Gr concentration is 1wt% and the number of coatings is nine, the composite coated fiber has the maximum GF (86.9) and a wide strain range (50%) and good linearity (R

2 = 0.97). However, the GF of the strain sensor only reaches more than 40 in the 50% strain extension–release cycles, and the repeatability is 1.81% and the hysteresis error is 9.08% over 100 cycles. A CPC@PU yarn strain sensor was prepared by Wu et al. (

Figure 7c)

[34], in which the ultrathin conductive CPC layer consists of positively charged chitosan (CS) and negatively charged carbon black (CB)/cellulose nanocrystal (CNC)/natural rubber (NR) nanohybrid. Although this fiber sensor based on CPC coating detects strains as low as 0.1% and shows a GF of approximately 38.9 at 1% strain, it is not reliable for detecting strains larger than 5%. Li et al. proposed a core–sheath structure strain sensor, which is composed of PU core yarn, a highly conductive multilayer sheath material, namely graphene nanosheets/thin gold film/graphene nanosheets (GNSs/Au/GNSs), and PDMS coating. This multilayer structure combination can simultaneously achieve high sensitivity, wide strain-sensing range and good waterproof performance. In 10,000 stretch–release cycles at 50% strain, its stability is excellent

[42]. Although the LBL method improves the adhesion of the coating, it takes multiple cycles of treatment to achieve a high conductivity due to the introduction of the insulating polymer.

The characteristics of fiber strain sensors prepared by coating technology are summarized in Table 5. In general, the coating method is easy to implement and the 1D strain sensors produce via this method show good sensing performance. As the mechanical properties of conductive coatings and elastic substrates are inconsistent, conductive coatings propagate small and dense microcracks, which destroys conductive networks and causes the changes of resistance. However, the poor adhesion and the mechanical mismatch between the elastic substrate and the conductive coating often leads to degradation of the sensor response. Therefore, it is still a big challenge to achieve high linearity and cycle stability by a simple coating. Due to the irreversible fracture and shedding of the conductive layer, it is very necessary to explore the stress distribution and interface strength between the conductive coating and the substrate. Although the added adhesive (like the LBL method) has improved adhesion, the fatigue durability of the strain sensor is still a challenge. Additionally, there is a lack of systematic studies on how to control the crack propagation and stability, and on how it affects the sensing performance of strain sensors.

Table 5. Characteristics of fiber strain sensors prepared by coating technology.

| Method |

Structure |

Substrate |

Adhesive |

Sensitive Materials |

Breaking Stress and Strain |

Conductivity |

Strain Range |

GF |

Repeatability |

Linearity |

Response Time |

Ref. |

| In site reduction |

Multifilament |

PU |

N/A |

AgNPs |

N/A |

0.16 Ω/cm |

200% |

659 (150–200%) |

10,000 (10%) |

N/A |

N/A |

[45] |

| In situ polymerization |

Multifilament |

PS |

N/A |

PEDOT |

0.813 ± 0.057 GPa |

600 Ω/cm |

70% |

0.244 (70%) |

1000 (20%) |

N/A |

N/A |

[36] |

| deposition |

Beaded |

PDMS |

N/A |

Au/CNTs |

N/A |

N/A |

125% |

low |

5000 (30%) |

R2 = 0.96 |

N/A |

[88] |

| Spraying |

Double sheath buckle |

SBS |

SGE |

NTS |

N/A |

N/A |

600% |

0.14 (200–600%) |

5000 (100%) |

N/A |

80 ms |

[89] |

| Dip coating |

Wrinkle assisted |

PU |

N/A |

CNTs |

N/A |

N/A |

200% |

1344.1 (200%) |

10,000 (30%) |

R2 = 0.99 (0–50%) |

<88 ms (1%) |

[90] |

| Roller transfer |

Core–sheath |

PU |

PU |

AgNWs |

38.24 MPa; 980% |

240.36 S/cm |

60% |

5~9557 |

10,000 (10%) |

N/A |

120 ms (0.5%) |

[91] |

| In situ polymerization and reduction |

Core–sheath |

PF |

PDA |

AgNPs |

300 cN; 405.9% |

4.5 Ω/cm |

N/A |

N/A |

N/A |

nonlinear error < 29.3% |

N/A |

[92] |

| LBL |

Core–sheath |

PU |

CS |

CB/CNC/NR |

N/A |

4.1 MΩ/cm |

1% |

38.9 (1%) |

10,000 (1%) |

Good linearity |

N/A |

[34] |

| LBL and sputtering |

Core–sheath |

PU |

PVA |

GNSs/Au/GNSs |

N/A |

N/A |

75% |

661.59 (50%) |

10,000 (50%) |

R2 = 0.983 (0–50%) |

N/A |

[42] |

3.3. Conductive Composite Yarns

3.3.1. Wrapped Structure

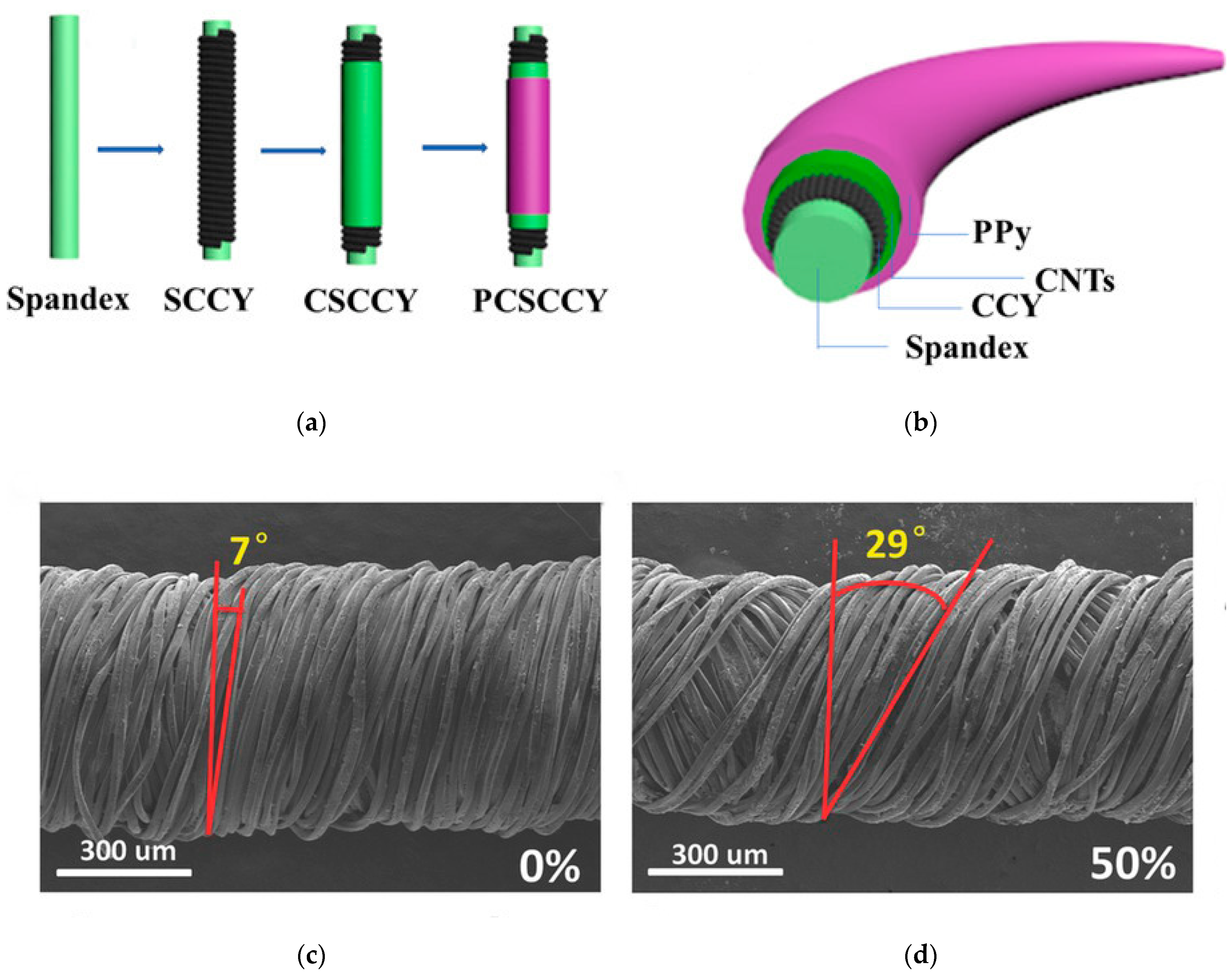

The working strain range of the one-dimensional sensor may be limited if the resistance is changed only by the cracks on the surface of the fiber or yarn. To improve its working strain range and stability, the structural adjustment of the yarns has also been explored. Cai et al. prepared a cotton/CNT core-spun yarn sensor by coating CNTs and depositing PPy on the surface (

Figure 8a,b)

[95]. The yarn has a broad strain range, up to 350%, but its GF is small, only 5.11 and 3.41 at strains of 0–50% and 50–350%, respectively. Cheng et al. developed a simple and mass-produced graphene-based composite yarn with a compression spring structure by plasma treatment and dipping (

Figure 8c,d)

[96]. The minimum and maximum detection limits of this double-wrapped composite yarn are 0.2 and 100% strain, respectively. Additionally, the signal response speed is fast (<100 ms). After several stretching cycles under 30 and 50% strain, the performance is stable, but its sensitivity is very low. Zhu et al. introduced curcumin-assisted chemical deposition (ELD) to prepare a helical yarn with a metal coating, and established a model to analyze its sensing mechanism

[46]. The relative resistance change of the yarn

ΔR¯¯¯ can be expressed as a function related to the tensile strain ε, including θ(ε), g(ε) and

Rdetach(ε) (θ is the winding angle, g is the average gap of the separated winding,

Rdetach is the resistance of an independent winding). As mentioned above, the yarn strain sensors based on geometric change sensing have excellent linearity, low hysteresis, high stability and a large sensing range, but their sensitivity is limited

[15].

Figure 8. (

a) Schematic diagram of rubber thread and different core-spun yarns (

b) Cross-sectional structure of the PCSCCY yarn

[95] (

c) SEM image of PDCY-RGO under 0% strain, 7° (

d) SEM image of PDCY-RGO under 50% strain, with the winding angle marked as 29°

[96].

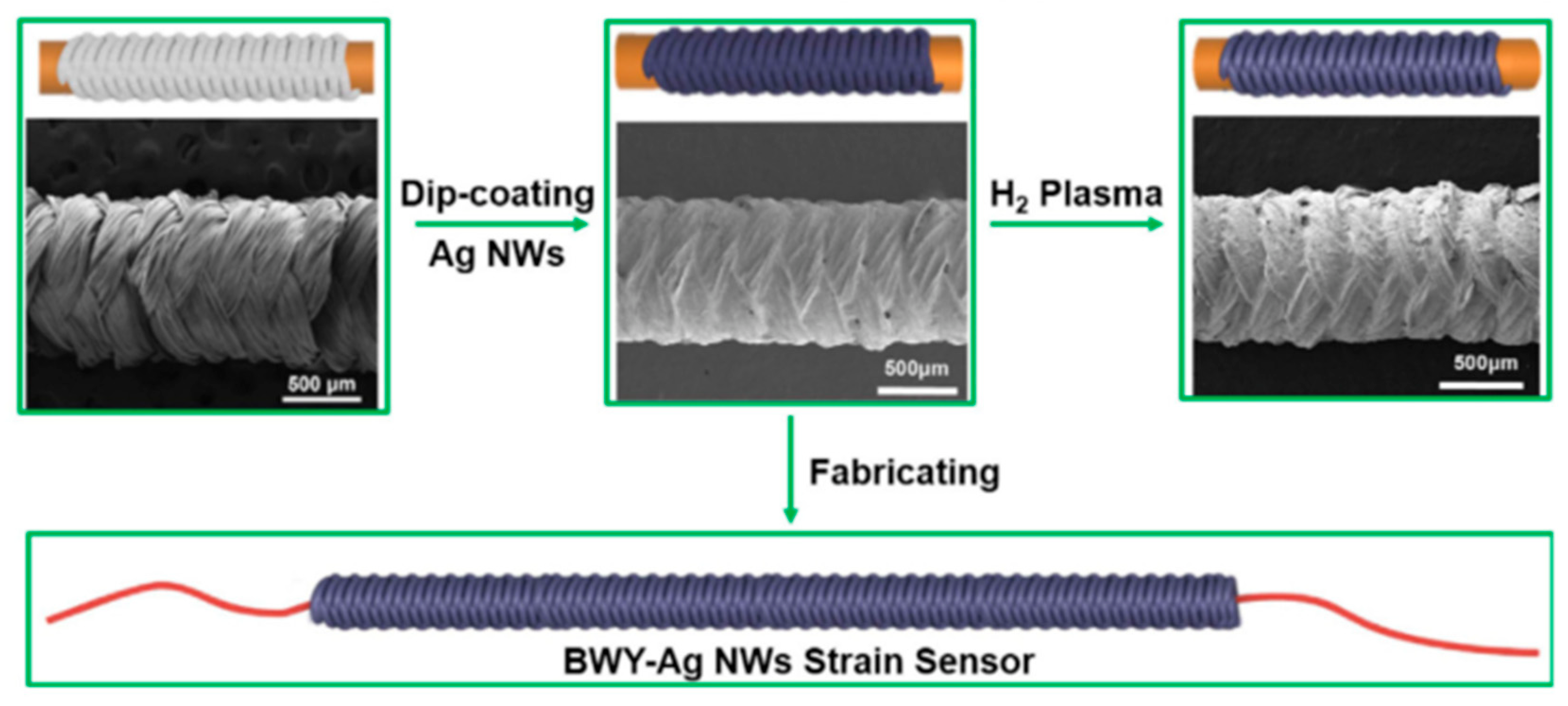

3.3.2. Braided Structure

Another design is to use braided yarns to fabricate yarn-based strain sensors. Shi et al. reported a sensor (BWY-AgNWs) composed of stretchable yarns with a braided structure and silver nanowires by dip coating (

Figure 9)

[97]. The fiber sensor can not only detect various deformations such as stretching, torsion, and bending, but also has a high stable sensitivity (GF = 65) in a larger sensing range (strain can reach 100%). However, due to the insufficient recovery of the microstructure and the brittleness of the AgNWs film, the microcracks cannot be completely merged after release, resulting in the poor repeatability of the strain sensor during multiple cycles of stretching. Furthermore, the high hysteresis of the strain sensor makes its strain response slow, which limits its wearable application. Yang et al. proposed a PET/AgNW/PDMS yarn sensor with braid yarns as the substrate, AgNW as the active material and PDMS as the protective layer by dip coating

[98]. The yarn sensor has high conductivity and a wide range of stretchable strain. However, the resistance change does not increase monotonously with the increase in strain, instead of a downward trend after 40% strain. In addition, the relative resistance changes in PET/AgNW/PDMS yarns with an upward trend show relatively instability during multiple stretching and bending cycles. Pan et al. designed a yarn sensor with a core–sheath yarn structure, in which a braided composite yarn coated with CNTs is used as the core (BYs-CNT) and electrospun polyurethane nanofibers are used as the sheath

[35]. This kind of combination of the yarn has extremely high sensing sensitivity (maximum GF up to 980) and long-term stability, but poor linearity. Additionally, the yarn preparation process is complicated and cannot be easily produced en masse. Similarly, the relative resistance change shows a downward trend after the strain exceeds 40%, due to the changes in the braid angle and contact area of braided yarns PET during the stretching process.

Figure 9. Schematic diagram of the manufacturing process of the BWY-Ag NW strain sensor

[97].

3.3.3. Helical and Winding Structure

In addition to fancy yarn, unconventional yarn sensors have been formed by twisting and winding conductive coated films, which remarkedly enhance the tensile strain range of one-dimensional sensors. Compared with the conventional planar wave structure, the coil structure has greater stretchability because the local stress is suppressed during the stretching process and the local maximum strain is reduced due to the non-planar motion of the coil

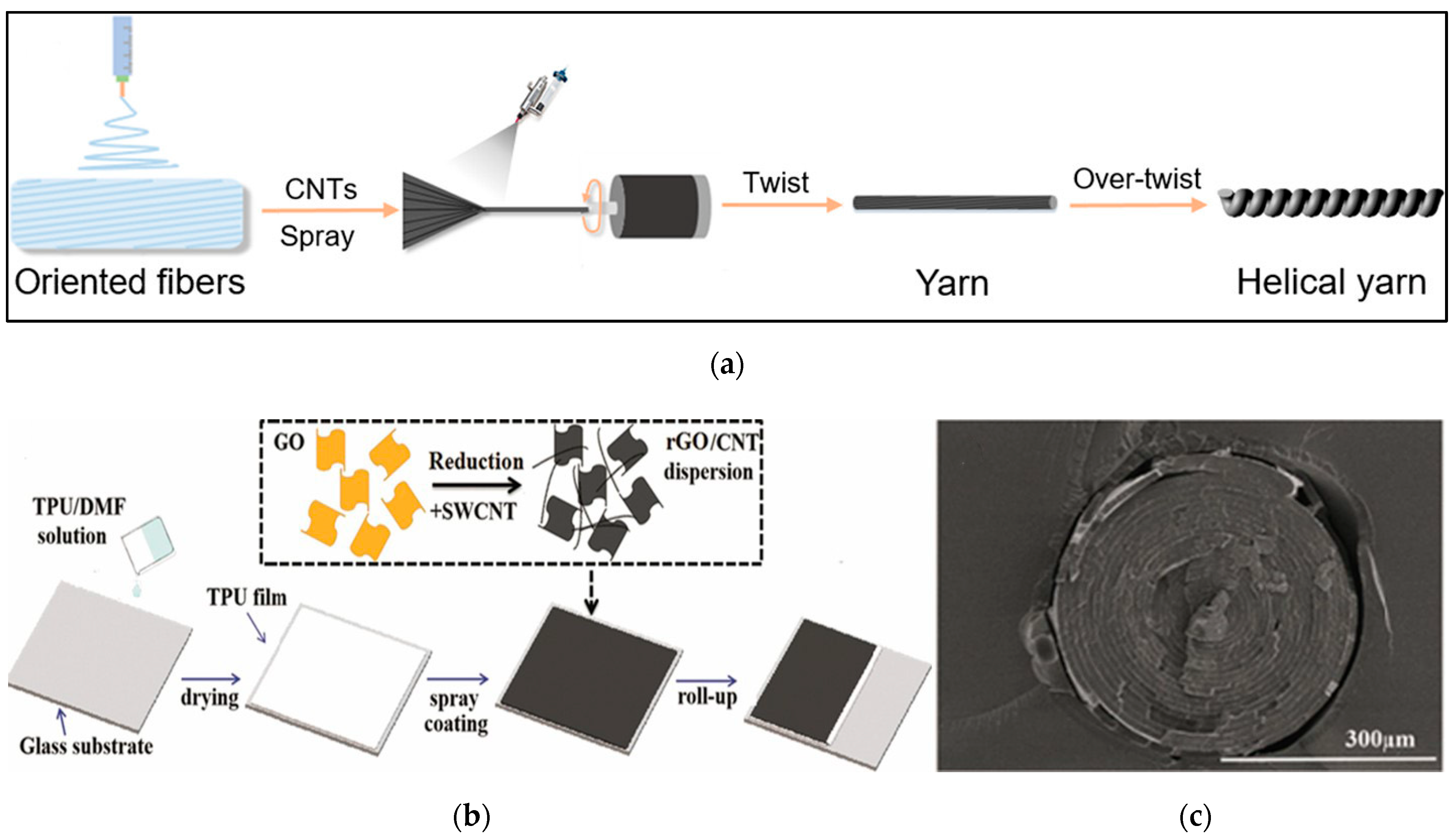

[99]. Ultrahigh stretchable conductive helical yarn with CNT/PU nanocomposite fiber helical yarn was prepared by simple electrospinning, spraying and twisting processes (

Figure 10a)

[99]. With the help of the synergistic effect of the flexible polymer chain and the nanofiber spiral coil structure, the CNT/PU helical yarn will break the limitation of material stretchability due to its rigidity and excellent stretchability. Its recovery is within 900% strain, and the maximum of tensile elongation can reach 1700%, while its sensitivity is very low. Xie et al. designed a SWCNT-RGO/TPU spiral layered composite yarn by spraying and winding technology (

Figure 10b,c)

[100]. Due to the special spiral layered structure of the composite yarn, the conductive layer is wrapped and protected by the elastic polymer layer, and there is no obvious interruption or crack on the surface of the yarn. Compared with the SWCNT-RGO/TPU thin-film sensor, the yarn sensor has a wider working strain range and has five linear regions. In the 50% tensile strain cycles, the relative resistance of the sensor continued to increase during the initial 100 cycles and then began to stabilize.

Figure 10. (

a) Schematic diagram of the preparation of helical CNT/PU yarn

[99] (

b) Schematic diagram of the preparation of SWCNT-RGO/TPU strain sensor (

c) SEM image of spiral layered SWCNT-RGO/TPU yarn

[100].

The performance of yarn-based strain sensors with different structures are summarized in Table 6. On the basis of the coating, improving the linearity and stability of the strain sensor by changing the yarn structure is an excellent method because the resistance change mainly depends on the structure of the composite yarn. For example, in terms of wrapped yarn-based sensors, the decrease in the contact of the spiral winding leads to an increase in resistance, but this also reduces the sensitivity and working strain range to a certain extent. Therefore, it is necessary to discuss the influence of structural changes on the sensing performance so that the yarn strain sensor has balanced performance indicators.

Table 6. Characteristics of various yarn-based strain sensors.

| Method |

Structure |

Substrate |

Sensitive Materials |

Breaking Stress and Strain |

Conductivity |

Strain Range |

GF |

Repeatability |

Linearity |

Response Time |

Ref. |

| Dip coating and in situ polymerization |

Core-spun yarn |

PU/cotton |

CNT/PPy |

>7 N; >300% |

310 Ω/cm |

350 |

5.11 (0–50%); 3.41 (50–100%) |

N/A |

Linearity at 0–50% and 50–350% strain, respectively |

N/A |

[95] |

| Dip coating |

Wrapped yarn |

PU/PE |

Gr |

29.14 MPa; 676% |

0.012 S/m |

0.2–100% |

3.7 (50%) |

10,000 (30% and 50%) |

N/A |

<100 ms |

[96] |

| ELD |

Wrapped yarn |

PU |

Cu |

N/A |

0.2 Ω/cm |

50% |

N/A |

5000 (50%) |

Good linearity |

N/A |

[46] |

| Dip coating |

Braided yarn |

PU/PET |

AgNWs |

N/A |

0.5 Ω/cm |

108.92% |

767.50 (97.28–108.92%) |

4000 (30%) |

R2 = 0.975 (97.28–108.92%) |

<100 ms (0.5%) |

[97] |

| Coating |

Braided yarn |

Rubber/PET |

AgNWs |

N/A |

3 Ω/cm |

100% |

11.4 (100%) |

1700 (30%) |

N/A |

N/A |

[98] |

| Dip coating |

Braided yarn |

Rubber/PET |

CNT |

44N; 350% |

0.12 kΩ/cm |

44% |

980 (29–44%) |

1000 (20%) |

N/A |

200 ms |

[35] |

| Spraying |

Helical coil |

PU |

CNT |

50.2 MPa; 1700% |

N/A |

900% |

N/A |

100 (200%) |

N/A |

N/A |

[99] |

| Spraying |

Helical layer |

TPU |

SWCNT/RGO |

40.0 MPa; 1237% |

821.8 S/m |

620% |

2160.4 (550–620%) |

1000 (50%) |

N/A |

N/A |

[100] |

4. Interconnection and Packaging

For wearable electronic applications, strain-sensing fibers or yarns need to be interconnected with other structural circuit elements or data acquisition circuits to fully integrate electronic devices. In wearable electronic devices, it is required that the sensing element must be firmly, elastically and electrically connected to the conductive wire or the data connector, and the interconnection point can still maintain high conductivity under considerable mechanical stress. In addition, the interconnection needs to robustly transmit the signal to the transmission board or processing electronics with minimal loss. At present, the common bonding methods in interconnection are mechanical bonding, physical bonding and chemical bonding

[101][102]. However, the chemical bonding is not suitable for the interconnection of heterogeneous devices. Mechanical bonding refers to the use of friction to clamp or connect electronic components to wires, which is suitable for electronic connections of various conductive textiles. For fiber or yarn strain sensors, the mechanical bonding can be thread-to-thread knotting, or embroidery

[103][104], stitching

[72], or interlacing. Physical bonding includes soldering

[105], adhesive bonding

[96] and so on. The advantages and disadvantages of different interconnection methods are summarized in

Table 7. Soldering is a process that the metal is melted with the high temperature to tightly coat and wrap electronic components to form a connection. However, few common fibers and yarns with conductive materials can withstand high temperature welding, and the narrow interface between the components is too small and difficult to handle. It is a method widely used in laboratories to connect strain-sensing yarns and functional components with conductive adhesives such as conductive glue and copper tape. For example, He et al. stitched MWCNT/TPU fibers onto an elastic bandage with cotton yarns to detect the wrist bending (

Figure 11a)

[72]. Both ends of the fibers were connected with conductive wires using silver paste and fixed by conductive tapes and medical tapes. Cheng et al. used conductive copper tape and silver paste to interconnect the two ends of graphene-based fibers as external electrodes with copper wires (diameter: 2 μm) (

Figure 11b)

[96]. Although this method is simple to operate, the electrical connection quality of the conductive adhesive is affected by humidity and temperature, and the copper tape is easily oxidized and has poor mechanical fatigue resistance, which may cause safety problems. Therefore, this type of interconnection often requires further suitable packaging protection.

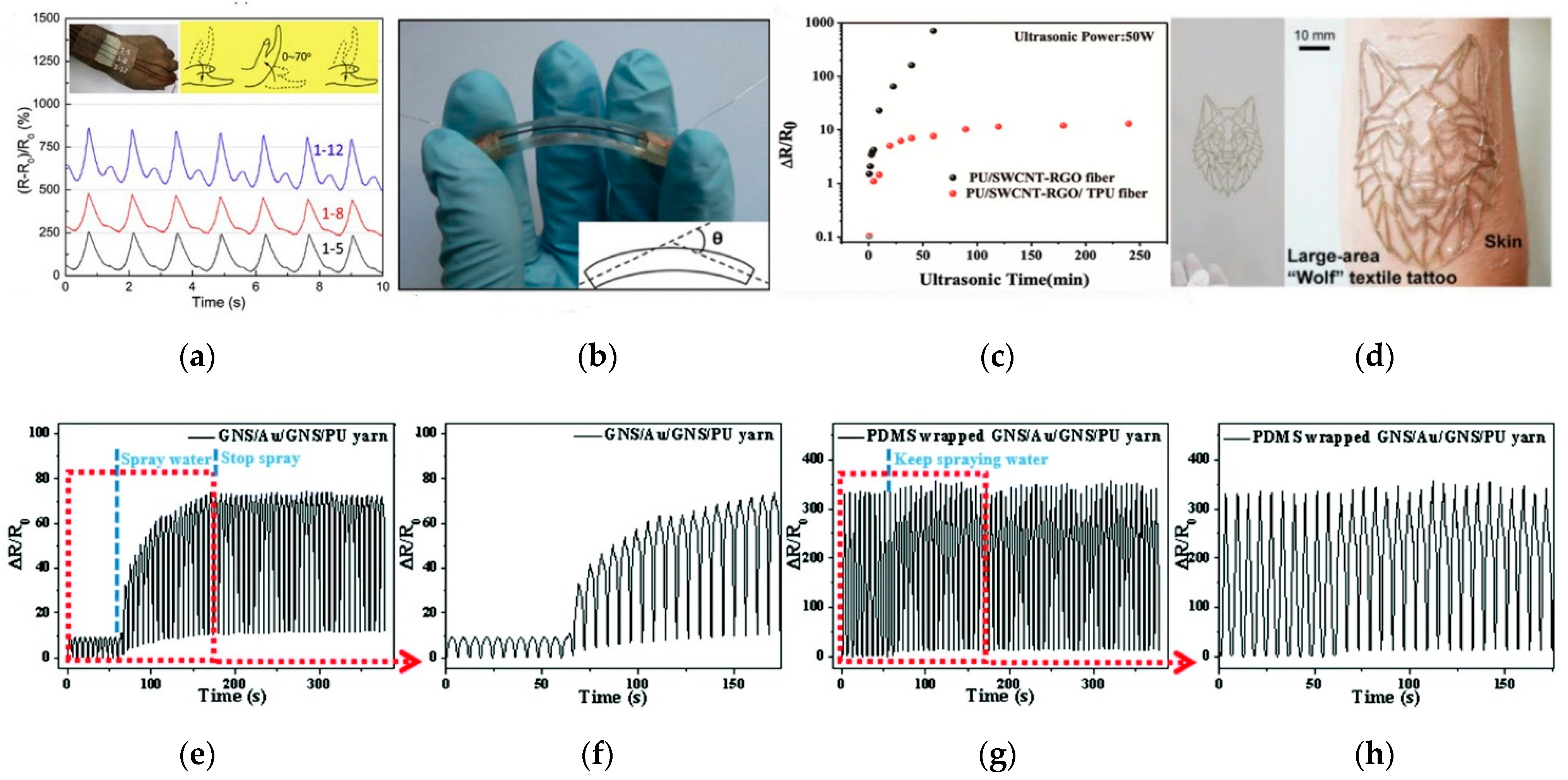

Figure 11. (

a) MWCNT/TPU fiber sensors on an elastic bandage

[72]. (

b) The use of copper tape and silver paste to form the interconnections

[96]. (

c) ΔR/R

0 of the sensor with 50 wt% RGO as a function of ultrasonic time

[106]. (

d) Photograph showing a large textile tattoo of a wolf on skin

[107]. (

e,

f) Resistance–time relationships of the GNS/Au/GNS/PU yarn strain sensor (

g,

h) Resistance–time relationships of the PDMS-wrapped GNS/Au/GNS/PU yarn strain sensor with an applied strain of 50% under water spray

[42].

Table 7. Features of various interconnection methods.

| Method |

Merits |

Demerits |

| Soldering |

Tight connection and high conductivity. |

Brittle fracture, high welding temperature and limited welding interface. |

| Mechanical clamping |

Flexible connection and wide range of application. |

Easy to break under large deformation. |

| Conductive adhesive |

Simple operation and less limitation to materials. |

Easily affected by temperature and humidity. |

Considering the stability and reliability of electrical interconnection and the durability of the strain sensor, the strain sensor is packaged for use. If strain sensors are integrated into clothing by textile technology, insulating coatings are considered to protect the sensors. For example, Li et al. used hydrophobic PDMS to pack the yarn-based strain sensor to achieve a good waterproof performance

[42]. The relative resistance change values of the sensor without the hydrophobic packing increased significantly when the sensor was sprayed with water during the tensile cycle test (

Figure 11e,f). On the contrary, the relative resistance change values changed slightly before and after water (

Figure 11g,h). Xu et al. reported the encapsulated TPU/SWCNT-RGO/PU core–sheath fiber

[106]. The ΔR/R0 of the encapsulated composite fiber firstly increased by 10 and then remained stable, showing great washability compared with the SWCNT-RGO/PU sensor (

Figure 11c). Kwon et al. used self-healing polymers (T-SHPs) as self-adhesive and durable interconnection materials to encapsulate conductive sensing fibers. This method easily achieved the patterned design (

Figure 11d), but also effectively improved the conductivity of the sensing fiber over the 1000 stretch cycles

[107]. Additionally, it is easy and convenient to fabricate, but not safe and reliable, only being suitable for laboratory tests. In addition, the strain sensor can be directly integrated into fabrics by the hot-melting process. The hot-melting package is made of elastic thermoplastic materials, such as TPU hot-melting adhesives. The materials are heated to the melting temperature and cooled after molding. For instance, Bahadir et al. reported a waterproof textile transmission line with GoreTex

® waterproof welding tape by hot air sealing

[108]. From the perspective of structural mechanics, electronic packaging can be seen as a composite structure made of different materials (substrate-conductive coating-encapsulation layer), and the physical parameters between the layers will affect the average strain transfer rate and sensing performance. In addition, when the device is subjected to thermo-mechanical loads, the interface between these materials is the most prone to failure. This is due to the inherent stress concentration generated by the interface bonds between different materials and the free surface of the two materials. Under repeated external mechanical action, cracks are not limited to the interface, but also propagate and expand parallelly to the interface

[109]. Therefore, the system integration of interconnected wires and strain sensors under high-level strain loads is still a huge challenge. Poor interfaces will not only cause serious errors, but also lead to low reliability of the entire sensor system. The mechanical and sensing properties of conductive yarns before and after encapsulation will change to a certain degree. However, there is currently a lack of comprehensive research on the effect of packaging process on the sensing performance of stretchable conductive fibers or yarns.