In this encyclopedia entry, we are introducing a new deposit technique called glancing angle deposition (GLAD). We found that this technique is very competitive and proficient method to fabricating a nanostructured surface that enhanced the sensitivity of Surface Plasmon Resonance (SPR) sensors. We fabricated the SPR sensor with hybrid GLAD nanostructures of 30 nm height and with inter-structural gap size of around 12 nm. Theoretical and experimental analyses published in our recent article showed 4 times higher sensitivity compared to that of a conventional SPR sensor.

- Glancing Angle Deposition

- Surface Plasmon Resonance

- Localized Surface Plasmon Resonance

- Refractive Index

- Nanostructures

Surface Plasmon Resonance (SPR) is currently considered a highly sensitive sensing technique for optical sensors that enables real-time, fast, and very accurate detection[1]. The most known and effective architecture configuration (Kretschmann Reather) of SPR sensor is the arrangement of a metallic thin film deposited onto a glass substrate and attaching this substrate onto the base of a right-angled glass prism. This configuration allows for the interrogation of several properties of light including wavelength, incidence angle, or optical power. To generate SPR on the metallic thin-film surface, a p-polarized and collimated light beam is directed toward one of the sides of a glass prism[2]. The SPR sensors count the small changes in the refractive index (RI) of a sensing medium above a thin-film metallic layer of gold or silver[3][4]. The details of literature about the background and on-going improvement of SPR sensor structures have been reported in Ref[1].

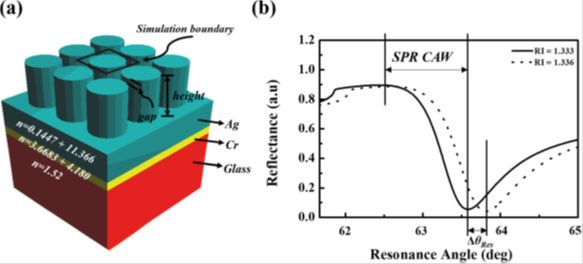

A number of hybrid structures containing SPR thin films covered with metallic nanostructures with different shapes, including periodic T-shape rods[5],gratings[6][7], nano spots[8], and nanowires[9][10], have been reported to enhance the SPR sensitivity using Kretschmann Reather configuration but none of them is easy and cost-effective. However, the glancing angle deposition technique (GLAD) is a versatile single step, cost-effective, and time efficient method to fabricate nanostructures that can enhance the sensitivity of conventional SPR sensors. In literature it was found about the effectiveness of GLAD nanostructures that improve the sensitivity of surface-enhanced Raman scattering (SERS) and metal-enhanced fluorescence (MEF) substrates[11][12]. The SPR sensor performance including the configuration of the hybrid nanostructures, were investigated using the rigorous coupled wavelength analysis (RCWA) method built into the commercially available Diffract Mod software package (R Soft Design Synopsys. Inc., Mountain View, CA, USA). Figure 1 which is imported from the Ref[1], shows the schematic illustrations of the configuration of the hybrid nanostructures and optimized performance in terms of SPR CAW (angular difference between the maximum and minimum reflectance).

Fig. 1 Schematic diagram of the simulated model (a), and response curves of the conventional SPR sensor (b)[1].

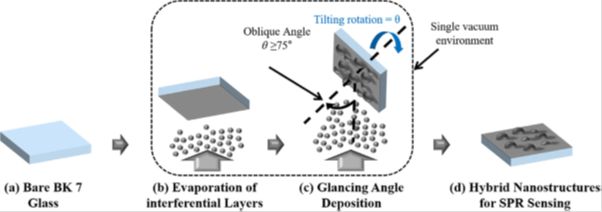

The GLAD process to fabricate the silver (Ag) nanostructures on top of the metallic thin layers already deposited onto a glass substrate were practically performed at Department of Mechanical Engineering, Chung-Ang University, South Korea, and Electron Science Research Institute (ESRI), Edith Cowan University, Australia.

Fig. 2 Schematic illustration of the fabricated hybrid nanostructures using the GLAD process[1].

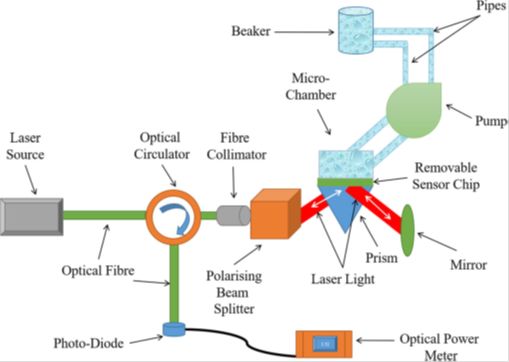

The developed sensor configuration enables the measurement of the effective RI changes due to changing the concentration of compounds in a solution of water. The effect of Ag nanostructures geometry on SPR sensor sensitivity was deeply investigated in this study. The viability and sensitivity of the hybrid nanostructured SPR configuration for detecting changes in RI of water was experimental performed. Fig. 3 shows the experimental set up to examine the variations in the reflected intensity of a broadband light source.

Fig. 3 Schematic diagram of the experimental setup used to measure the sensitivity of different types of SPR sensor chips [1].

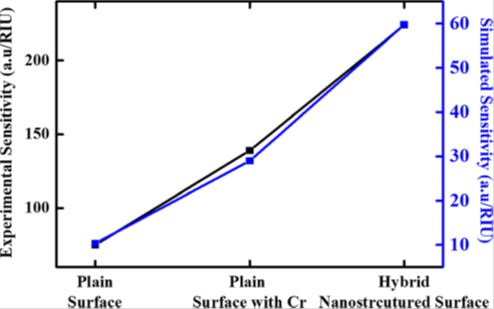

The hybrid GLAD nanostructured SPR surface was found to be more sensitive to the variations of the solution RI. The experimental results plotted against the simulated results (Fig. 4) confirmed that the hybrid GLAD nanostructured sensor enhances the sensitivity of the SPR sensor.

Fig. 4 Measured and simulated sensitivity of fabricated surface for measuring the RI variations[1].

We have successfully demonstrated a hybrid nanostructured SPR sensor fabricated a single and simple area GLAD process, which displayed enhanced sensitivity to changes in the RI of solutions. The cost-effective GLAD hybrid nanostructured SPR sensor displayed a measured detection resolution of 3.81× 10−6 RIU and a measured sensitivity of 230 a.u/RIU, which were in good agreement with the simulated results. Since GLAD is a simple and efficient fabrication process and does not require time-consuming fabrication steps, such as lithography, the GLAD process will make easy to construct high-sensitivity SPR sensors for future applications in various industries and research fields.

References

- Mohsin Ali Badshah, et. al, Enhancing the Sensitivity of a Surface Plasmon Resonance Sensor with Glancing Angle Deposited Nanostructures, Plasmonics, https://doi.org/10.1007/s11468-020-01245-0.

- Roh S, Chung T, Lee B (2011) Overview of the characteristics of micro- and nano-structured surface plasmon resonance sensors. Sensors 11:1565–1588.

- Homola J, Yee SS, Gauglitz G (1999) Surface plasmon resonance sensors: review. Sensors Actuators B Chem 54:3–15.

- Michel D, Xiao F, Alameh K (2017) A compact, flexible fibreoptics surface plasmon resonance sensor with changeable sensor chips. Sensors Actuators B Chem 246:33.

- Byun KM, Kim D, Kim SJ (2006) Sensors actuators. B Chem 117: 401.

- Alleyne CJ,KirkAG,McPhedran RC, Nicorovici N-AP,Maystre D (2007) Enhanced SPR sensitivity using periodic metallic structures. Opt Express 15:8163–8169.

- El-Gohary SH, EomS, Lee SY, ByunKM(2016) Dispersion curvebased sensitivity engineering for enhanced surface plasmon resonance detection. Opt Commun 370:299–305.

- Malic L, Cui B, Veres T, Tabrizian M (2007) Enhanced surface plasmon resonance imaging detection of DNA hybridization on periodic gold nanoposts. Opt Lett 32:3092–3094.

- Kim D (2006) Effect of resonant localized plasmon coupling on the sensitivity enhancement of nanowire-based surface plasmon resonance biosensors. J Opt Soc Am A 23:2307.

- Byun KM, Yoon SJ, Kim D, Kim SJ (2007) Experimental study of sensitivity enhancement in surface plasmon resonance biosensors by use of periodic metallic nanowires. Opt Lett 32:1902–1904.

- Badshah, M. A., Ju, J., Lu, X., Abbas, N., Kim, S., M. (2018) Enhancingthe sensitivity of DNA microarrays by metal-enhanced fluorescence using vertical nanorod structures. Sensors Actuators B Chem 274: 451.

- Shanmukh S, Jones L, Driskell J, Zhao Y, Dluhy R, Tripp RA (2006) Rapid and sensitive detection of respiratory virus molecular signatures using a silver nanorod array SERS substrate. Nano Lett 6:2630–2636.