The International Energy Agency (IEA, 2013) believes that energy efficiency should be taken as the first fuel rather than a hidden fuel and regards it as “a key tool for boosting economic and social development. From an economic perspective, efficiency is defined as the full and most efficient use of limited and scarce resources to satisfy people’s wants and needs given the technology, that is, produce more with less. If there is no way to make someone better off and nobody worse off, then the situation is Pareto efficient. Extending this concept to production economics, a 100% Pareto–Koopmans efficiency is achieved if and only if no inputs or outputs of any decision-making unit (DMU) can be improved without worsening the other inputs or outputs. However, in most management and social science applications, the theoretically possible Pareto efficiency is unknown. Therefore, it is replaced by relative efficiency, which is fully efficient if and only if other DMUs cannot improve inputs or outputs without worsening some of its other inputs or outputs on the basis of empirically available evidence. In this case, measuring production efficiency is actually evaluating whether there is waste of input by comparing the minimum input with the actual input while the output is unchanged or evaluating whether there is an output shortage by comparing the actual output with the maximum output with the input unchanged.

- total-factor energy efficiency

- total-factor carbon emissions efficiency

- carbon neutral

- sustainable development

- input-output variables

1. Defining Energy Efficiency and Carbon Emissions Efficiency

1.1. The Origin of Energy Efficiency and Carbon Emissions Efficiency

1.2. Single-Factor Indicator of Energy Efficiency and Carbon Emissions Efficiency

1.2.1. Energy Intensity

1.2.2. Carbon Intensity

1.2.3. Inadequacy of Single-Factor Indicator

1.3. Total-Factor Indicator of Energy Efficiency and Carbon Emissions Efficiency

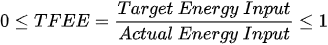

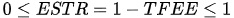

1.3.1. Total-Factor Energy Efficiency

1.3.2. Total-Factor Carbon Emissions Efficiency

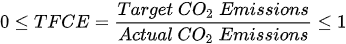

The scientific definition and measurement of total-factor energy efficiency is also applicable to total-factor carbon emissions efficiency. As a byproduct of economic growth generated by energy consumption, CO2 emission is generally incorporated as an undesirable output into the input-output variable [35][36]. With reference to TFEE, TFCE is calculated as follows:

The technical efficiency measured by Charnes, Cooper, and Rhodes (1978) is the minimum efficiency value of each input and output, reflecting the overall performance of each DMU relative to inputs and outputs, so it is usually used to measure environmental or ecological efficiency [37][38]. Compared with overall efficiency, TFEE and TFCE only indicate the performance of energy saving and CO2 emissions, so they are more convincing in the measurement of specific sustainable development goals. In addition, on the basis of TFEE and TFCE, some new indicators for measuring energy consumption and carbon emissions have been developed, such as energy performance index, defined as the ratio of actual energy efficiency to target energy efficiency, and carbon performance index, measured as the ratio of target carbon intensity to actual carbon intensity [30][39].

2. Efficiency Measurement Model Based on DEA

The concept and idea of data envelopment analysis (DEA) was first proposed by Farrell [27] and is a commonly used benchmark tool to measure the production efficiency of decision-making units (DMUs) and to reflect their performance. DEA is a method that is easy to operate. It does not need to make any restrictive assumptions about relevant functions and can deal with multiple input and output variables of different units.

2.1. Radial Model

2.1.1. CCR

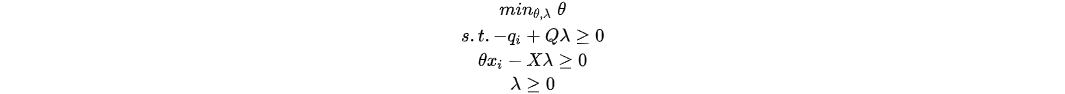

In 1978, Charnes, Cooper, and Rhode [28] first proposed an input-oriented data envelopment analysis, which is based on Constant Return to Scale (CRS) in the intersection of mathematics, operational research, mathematical economics, and management science. Subsequently, this method has attracted widespread attention and application. An input-oriented CRS-DEA model can be expounded as follows:

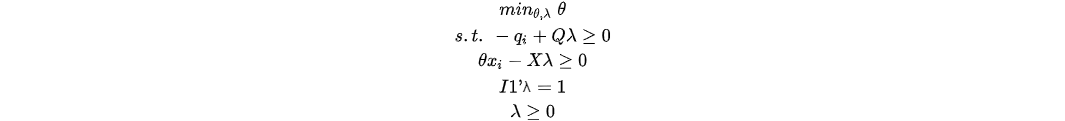

In the case of the production, technology was defined as . Suppose that there are I DMUs, and each DMU has N inputs and M outputs. Measuring the efficiency of the ith DMU is to solve the following mathematical programming problem:

where θ is a scalar, and λ is a I × 1 vector of constants. The column vectors and represent the ith DMU’s input and output, respectively. The N × I input matrix X and the M × I output matrix Q represent the data for all I DMUs. The value of θ is the efficiency score for the ith DMU. The DMU with a score = 1 is the efficient DMU, which means the DMU is on the frontier.

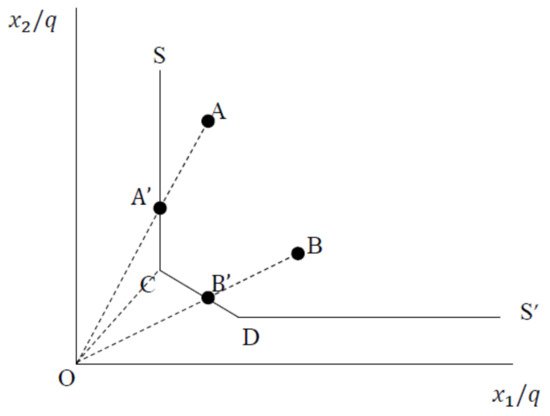

According to Figure 1, SS’ is a piece-wise linear isoquant determined by all the DMUs in the sample, where the radial contraction of the input vector is ( , the radial adjustment is AA’, and the constraints in Equation (1) ensure that the projected point cannot lie outside the feasible set. There are four firms, A, B, C, and D, where firms using input combinations C and D are the two efficient firms that define the frontier, and firms A and B are inefficient firms. Based on the measure of technical efficiency, the efficiency of A and B can be represented as OA′/OA and OB′/OB, respectively. However, it is not certain if A′ is an efficient point because when the use of input is reduced (that is, CA’), it still produces the same output. For firm B, it is effective when B moves to B′, as its input combinations change, i.e., efficiency equals one.

2.1.2. BCC

Considering that in the case of imperfect competition, government regulation, financial constraints, etc., the CRS assumptions will no longer pertain, Banker, Charnes, and Cooper [40] proposed to improve the CRS-DEA method by adding convexity constraint into the CRS-DEA model to explain Variable Return to Scale (VRS).

2.2. Non-Radial Model

2.2.1. Traditional Slacks-Based Measure (SBM) Model

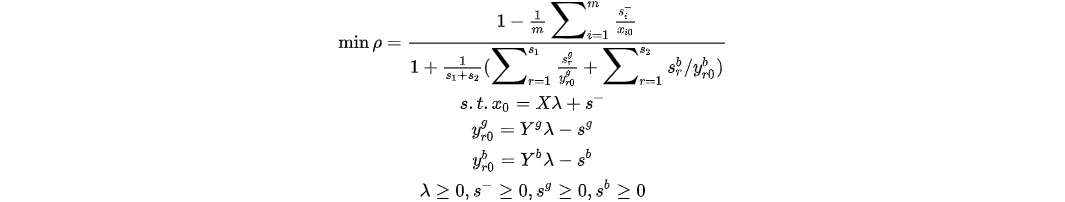

2.2.2. Slacks-Based Measure (SBM) Model with Undesirable Output

where , and are all slacks. , when means the DMU is on the production frontier, which is completely efficient.

3. Input-Output Variables for Efficiency Measurement

3.1. Production Possibility Set

According to production economics [47][48], DMU must ensure the technological feasibility in the production process of transforming inputs into outputs. The state of technology determines and restricts the possibility of inputs to produce outputs. The most general way to express this constraint is to think of the DMU as having a production possibility set, , where each vector is a technologically feasible production plan, observing the convention of if resource j is consumed as input, and if it is produced as an output. In this way, the set Y can fully describe the technological possibilities facing the DMU.

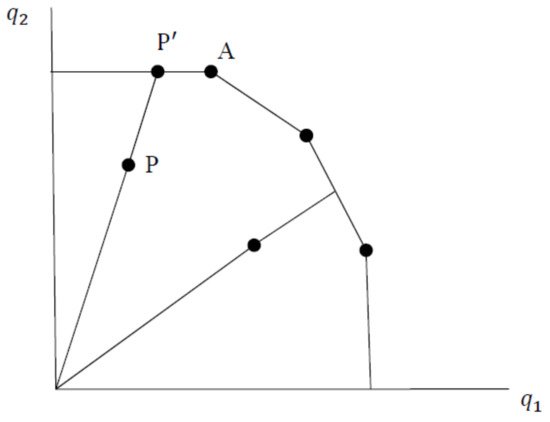

In DEA, production technology set Y is set to describe a multi-input and multi-output production technology [49]. Assuming that x and q denote a non-negative input vector and a non-negative output vector, respectively, the set S is then defined as:

Consisting of all input-output vectors , the set S can be equivalently defined using the output set of all output vectors q that can be produced by the input vector x or the input set of all input vectors x that can produce a given output vector q [50]. In addition, is also the basis for describing the production possibility curve of two-dimensional output vectors and is sometimes referred to as the production possibility set related to various input vectors x.

3.2. Input-Output Variables Selection

This entry is adapted from the peer-reviewed paper 10.3390/en15030962

References

- Samuelson, P.A.; Nordhaus, W.D. Economics, 19th ed.; McGraw-Hill: New York, NY, USA, 2010.

- Jehle, G.A.; Reny, P.J. Advanced Microeconomic Theory, 3rd ed.; Prentice Hall: Harlow, UK, 2011.

- Cooper, W.W.; Seiford, L.M.; Zhu, J. Handbook on Data Envelopment Analysis; Kluwer Academic Publishers: Boston, MA, USA, 2004.

- Dunlop, T. Mind the gap: A social sciences review of energy efficiency. Energy Res. Soc. Sci. 2019, 56, 101216.

- Alexander, J.K. The Mantra of Efficiency: From Waterwheel to Social Control; The Johns Hopkins University Press: Baltimore, MD, USA, 2008.

- Patterson, M.G. What is energy efficiency?: Concepts, indicators and methodological issues. Energy Policy 1996, 24, 377–390.

- Cheng, M.; Yang, S.; Wen, Z. The effect of technological factors on industrial energy intensity in China: New evidence from the technological diversification. Sustain. Prod. Consum. 2021, 28, 775–785.

- IEA. Energy Efficiency. 2020. Available online: https://www.iea.org/reports/energy-efficiency-2020 (accessed on 14 September 2021).

- United Nations (UN). Sustainable Development Goals 7: Affordable and Clean Energy. Available online: https://www.un.org/sustainabledevelopment/energy/ (accessed on 14 September 2021).

- Su, B.; Ang, B.W. Demand contributors and driving factors of Singapore’s aggregate carbon intensities. Energy Policy 2020, 146, 111817.

- He, W.; Zhang, B.; Ding, T. Sources of provincial carbon intensity reduction potential in China: A non-parametric fractional programming approach. Sci. Total Environ. 2020, 730, 139037.

- Goldemberg, J. A note on the energy intensity of developing countries. Energy Policy 1996, 24, 759–761.

- Mielnik, O.; Goldemberg, J. The evolution of the carbonization index in developing countries. Energy Policy 1999, 27, 307–308.

- IEA. Data and Statistics. Available online: https://www.iea.org/data-and-statistics/data-browser/?country=WORLD&fuel=CO2%20emissions&indicator=CO2BySource (accessed on 14 September 2021).

- Borozan, D. Technical and total factor energy efficiency of European regions: A two-stage approach. Energy 2018, 152, 521–532.

- Wu, H.; Hao, Y.; Ren, S. How do environmental regulation and environmental decentralization affect green total factor energy efficiency: Evidence from China. Energy Econ. 2020, 91, 104880.

- Shi, G.-M.; Bi, J.; Wang, J.-N. Chinese regional industrial energy efficiency evaluation based on a DEA model of fixing non-energy inputs. Energy Policy 2010, 38, 6172–6179.

- Cheng, Z.; Li, L.; Liu, J. Industrial structure, technical progress and carbon intensity in China’s provinces. Renew. Sustain. Energy Rev. 2018, 81, 2935–2946.

- Huo, T.; Tang, M.; Cai, W.; Ren, H.; Liu, B.; Hu, X. Provincial total-factor energy efficiency considering floor space under construction: An empirical analysis of China’s construction industry. J. Clean. Prod. 2020, 244, 118749.

- Cheng, Z.; Liu, J.; Li, L.; Gu, X. Research on meta-frontier total-factor energy efficiency and its spatial convergence in Chinese provinces. Energy Econ. 2020, 86, 104702.

- Liu, H.; Zhang, Z.; Zhang, T.; Wang, L. Revisiting China’s provincial energy efficiency and its influencing factors. Energy 2020, 208, 118361.

- Renshaw, E.F. Energy efficiency and the slump in labour productivity in the USA. Energy Econ. 1981, 3, 36–42.

- Proskuryakova, L.; Kovalev, A. Measuring energy efficiency: Is energy intensity a good evidence base? Appl. Energy 2015, 138, 450–459.

- Yao, X.; Guo, C.; Shao, S.; Jiang, Z. Total-factor CO2 emission performance of China’s provincial industrial sector: A meta-frontier non-radial Malmquist index approach. Appl. Energy 2016, 184, 1142–1153.

- Trinks, A.; Mulder, M.; Scholtens, B. An Efficiency Perspective on Carbon Emissions and Financial Performance. Ecol. Econ. 2020, 175, 106632.

- Sun, J.W. The decrease of CO2 emission intensity is decarbonization at national and global levels. Energy Policy 2005, 33, 975–978.

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Soc. Ser. A 1957, 120, 253–290.

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444.

- Wang, Q.; Su, B.; Sun, J.; Zhou, P.; Zhou, D. Measurement and decomposition of energy-saving and emissions reduction performance in Chinese cities. Appl. Energy 2015, 151, 85–92.

- Cheng, Z.; Li, L.; Liu, J.; Zhang, H. Total-factor carbon emission efficiency of China’s provincial industrial sector and its dynamic evolution. Renew. Sustain. Energy Rev. 2018, 94, 330–339.

- Ramanathan, R. Combining indicators of energy consumption and CO2 emissions-a cross-country comparison. Int. J. Glob. Energy Issues 2002, 17, 214–227.

- Hu, J.-L.; Wang, S.-C. Total-factor energy efficiency of regions in China. Energy Policy 2006, 34, 3206–3217.

- Ferrier, G.D.; Lovell, C.K.X. Measuring cost efficiency in banking Econometric and linear programming evidence. J. Econom. 1990, 46, 229–245.

- Honma, S.; Hu, J.-L. Total-factor energy efficiency of regions in Japan. Energy Policy 2008, 36, 821–833.

- Apergis, N.; Aye, G.C.; Barros, C.P.; Gupta, R.; Wanke, P. Energy efficiency of selected OECD countries: A slacks based model with undesirable outputs. Energy Econ. 2015, 51, 45–53.

- Deng, X.; Du, L. Estimating the environmental efficiency, productivity, and shadow price of carbon dioxide emissions for the Belt and Road Initiative countries. J. Clean. Prod. 2020, 277, 123808.

- Zhang, J.; Zeng, W.; Shi, H. Regional environmental efficiency in China: Analysis based on a regional slack-based measure with environmental undesirable outputs. Ecol. Indic. 2016, 71, 218–228.

- Wu, J.; Li, M.; Zhu, Q.; Zhou, Z.; Liang, L. Energy and environmental efficiency measurement of China’s industrial sectors: A DEA model with non-homogeneous inputs and outputs. Energy Econ. 2019, 78, 468–480.

- Zhou, P.; Ang, B.W.; Wang, H. Energy and CO2 emission performance in electricity generation: A non-radial directional distance function approach. Eur. J. Oper. Res. 2012, 221, 625–635.

- Banker, R.D.; Charnes, A.; Cooper, W.W.; Swarts, J.; Thomas, D.A. An introduction to data envelopment analysis with some of its models and their uses. Res. Gov. Nonprofit Account. 1989, 5, 125–165.

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509.

- Tone, K. Dealing with Undesirable Outputs in DEA: A Slacks-based Measure (SBM) Approach Spring 2004 Research Presentation. 2004. Available online: https://www.researchgate.net/publication/284047010 (accessed on 27 September 2021).

- Campbell, N.R. Physics the Elements; Cambridge University Press: London, UK, 2013.

- Lutzenhiser, L. Through the energy efficiency looking glass. Energy Res. Soc. Sci. 2014, 1, 141–151.

- Herring, H. Is energy efficiency good for the environment? Some conflicts and confusions. In The UK Energy Experience: A Model or A Warning? World Scientific Publishing Co. Pte. Ltd.: Singapore, 1996; pp. 327–338.

- Shove, E. What is wrong with energy efficiency? Building Res. Inf. 2017, 46, 779–789.

- Varian, H.R. Microeconomic Analysis, 3rd ed.; W. W. Norton & Company: New York, NY, USA, 1992.

- Mas-Colell, A.; Whinston, M.D.; Green, J.R. Microeconomic Theory; Oxford University Press: New York, NY, USA, 1995.

- Färe, R.; Primont, D. Multi-Output Production and Duality: Theory and Applications; Kluwer Academic Publishers: Boston, MA, USA, 1995.

- Coelli, T.J.; Prasada Rao, D.S.; O’Donnell, C.J.; Battese, G.E. An Introduction to Efficiency and Productivity Analysis, 2nd ed.; Springer Science and Business Media, Inc: New York, NY, USA, 2005.

- Tang, L.; He, G. How to improve total factor energy efficiency? An empirical analysis of the Yangtze River economic belt of China. Energy 2021, 235, 121375.

- Ali, A.; Mohsen, A.; Ghaderi, S.F.; Asadzadeh, S.M. Corrigendum to An integrated DEA PCA numerical taxonomy approach for energy efficiency assessment and consumption optimization in energy intensive manufacturing sectors? Energy Policy 2008, 35, 3792–3806.

- Wang, H.; Wang, M. Effects of technological innovation on energy efficiency in China: Evidence from dynamic panel of 284 cities. Sci. Total Environ. 2020, 709, 136172.

- Honma, S.; Hu, J.-L. Industry-level total-factor energy efficiency in developed countries: A Japan-centered analysis. Appl. Energy 2014, 119, 67–78.