Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Metal additive manufacturing (AM) has been growing remarkably due to the advantages of unmatched flexibility and zero material waste, this clean technology opens the door for new design solutions with greater material efficiency, which are not possible through conventional machining techniques.

- additive manufacturing

- metal AM

- electrical machines

- 3D printed windings

- powder bed fusion

- directed energy deposition

1. Different Technologies of Metal Additive Manufacturing (AM)

The range of metal AM technologies is increasing continuously. To date, 18 different working principles are known for nearly 150 suppliers [11]. The categorization of these techniques is shown in Figure 2a based on feedstock material. Despite the daily improvement of the methodology, the physical concept remains the same, which can be simply described as shown in Figure 2b. Basically, the final metal part is formed by a combination of both raw material and energy, and the simultaneous dynamics of the molten material. However, all these techniques have different levels of maturity as shown in Figure 2c.

Figure 2. Metal Additive Manufacturing technology [11]. (a) Categorization based on the feedstock, (b) Physical concept, (c) AM Maturity Index.

1.1. Powder Bed Fusion (PBF)

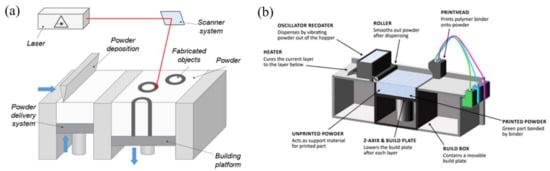

This method is the most widespread technology in the market of metal 3D printing. In this process, the metal powder is placed in the building platform. Then, a laser or an electron beam draws a 2D cross section on the surface of the build area to fuse the material as shown in Figure 3a [15]. Once a single layer is complete, the base plate is lowered just enough to make room for the next layer. More material is raised from cartridge and smoothly swept evenly on the previously finished layer. The 3D printer continues to build layer upon layer, starting from the object bottom upward. Moreover, as the part is being built, support structures are added to give supplemental strength to special overhanging surfaces. Finally, the finished part is farther treated; the surfaces are polished, if necessary, and any support structures are removed.

1.2. Binder Jetting (BJT)

Binder jetting metal AM is inspired by the technology of inkjet printers. In this process, a liquid binder is selectively deposited on the powder bed with a print head. This fast-growing technology can also be used for different applications such as in medical and dental industries. It allows the production of metallic objects but can also be used for ceramic parts as well as sand molds for casting. Similar to the previously described process (PBF), the powder is first placed in the dispenser to ensure a constant supply during printing, and a powder layer of a specific thickness is spread. Thereafter, instead of melting the powder with a laser, the printing head moving on two axes projects the binder where necessary as shown in Figure 3b [16]. Before moving on to the next layer, the solvent contained in the binder is evaporated by an incandescent lamp. The powder bed is then lowered and a fresh layer of build powder is deposited. Therefore, the production takes place in a series of steps that build the part layer by layer. When the cycle is completed, the binder is cured by placing the container in a furnace. The temperature and time depend on the type of binder employed during printing, Finally, unbound particles are removed to reveal the part. After this step, the metal or ceramic parts must undergo sintering heat-infiltration treatment or hot isostatic pressing before used.

1.3. Directed Energy Deposition (DED)

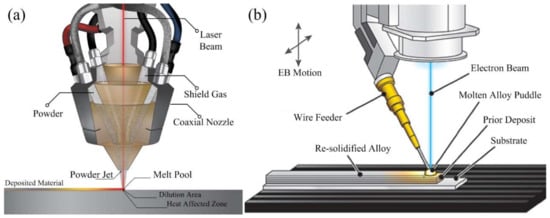

This method is called directed energy deposition because the supply material is directed at the heat source, at the point of deposition. Without the use of hard tooling, this innovative process provides a solution to build complex parts with near net shapes at a much faster rate than the aforementioned processes. The utilized energy source can be laser, electron beam, or arc/plasma as shown in Figure 4 [17,18]. Depending on the type of feedstock, a stream of metal powder is sprayed or a metal wire is pushed into the energy path. Then, the beam fires and creates a melt pool on the surface of the target plate to create the layer. After fusing multiple layers together, a 3D solid metallic build is created. This final printed part goes through a small number of finishing processes such as machining.

One of the most successful applications of DED is repairing metal parts by adding material to damaged components such as turbine blades. Additionally, beyond repair applications, many aerospace and defense applications have already been using this technology. There are many examples, such as titanium fuel tanks in satellites, and structural titanium parts in 787 jet airliners.

Finally, when it comes to manufacturing high-quality, large-volume metal parts, no other metal AM process can be faster or more cost-effective than directed energy deposition, thanks to its high deposition rate.

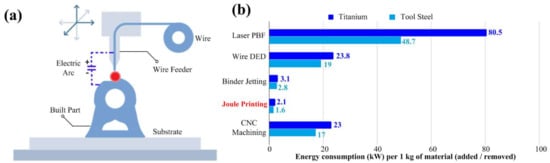

1.4. Joule Printing

In this wire-based method, the concept of resistance heating is applied, as illustrated in Figure 5a, in order to integrate the supply material with heating. Joule Printing can efficiently convert electrical energy into heat precisely at the location where the wire meets the built part without the need for a large liquid melt pool. In other words, Joule Printing adds just enough energy to fully fuse the metal wire to the built part. Thus, this method has the lowest energy consumption among all metal AM processes, as shown in Figure 5b [19].

Figure 5. Joule Printing: (a) The concept; (b) Energy consumption compared to other methods [19].

2. Metal AM for Electrical Machines

2.1. Core

Typically, electrical machines employ soft magnetic materials with high magnetic permeability. The most common magnetic material used for this purpose is stacked laminations of thin sheets (0.1–0.5 mm thick) of ferrosilicon (Fe-Si) alloys, which can provide an effective medium for energy transfer [23,24]. However, in high-power applications, these sheets must provide the same magnetic flux but with less material in the stator and the rotor. Therefore, there is a need to change the method of manufacturing electrical machines, and indeed AM can address some of these needs. Alongside its general advantages, utilizing metal AM has additional benefits in the manufacturing of the core:

-

different materials of metal powder can be easily mixed to control the magnetic properties (high-saturation magnetization, low iron losses, etc.). Examples of such mixtures are cobalt–iron (Co–Fe) or nickel–iron (Ni–Fe) alloys. The magnetic properties of different AM soft magnetic materials are listed in Appendix A Table A1;

-

metal AM allows the construction of a complex flux path, due to the lower constraints on the dimensions compared to conventional stacked silicon steel lamination;

-

integration of the cooling channels with the machine core is much easier [25];

-

metal AM can also tackle the mechanical issues of the machine moving parts by controlling the material microstructure and fillet percentage to control the physical properties (e.g., weight, mechanical strength).

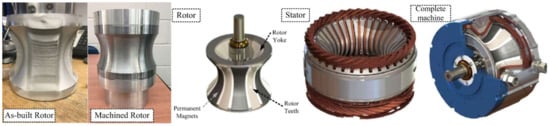

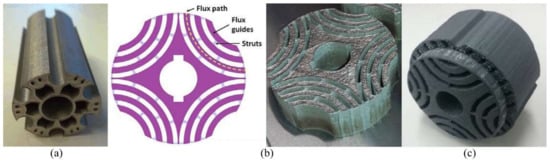

Figure 7a shows a 6-slot rotor for a reluctance machine made from Fe–Co powder (less than 63 um) using PBF AM. The magnetic flux density in this prototype reached a level of 2.3 T [26]. In Figure 7b, a flux barrier motor is designed, addressing both mechanical and electromagnetic performances jointly, and non-magnetic bridges are built simultaneously with the other magnetic parts [27]. Furthermore, in Figure 7c, AM is employed to build both stator and rotor of a line-start synchronous reluctance machine [28].

In [29], a skewed rotor is designed with honeycomb structure as shown in Figure 8, which is difficult to fabricate with conventional methods. Using this rotor, the torque ripple was reduced by nearly 45%.

Figure 8. 3D-printed skewed rotor with honeycomb structure cores for reduced torque ripples [29].

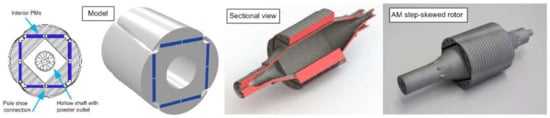

In [30], an AM interior magnet-skewed rotor for PM synchronous machine is prototyped with hollow shaft and lightweight construction as shown in Figure 9. The weight and the inertia of the rotor are also reduced by using a new conical transition region between the active part and the bearings. The rotor weight is reduced by 53%, leading to a roughly 9% faster acceleration from standstill to the nominal speed. The average motor torque is increased by over 5% and the cogging torque is reduced by nearly 90%. The rotor is manufactured from soft-magnetic ferro-silicon alloy using the powder bed-based AM technology of laser beam melting (LBM).

Figure 9. AM interior magnet-skewed rotor for PM synchronous machine with hollow shaft and lightweight construction [30].

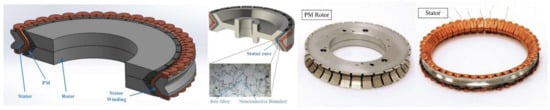

In [31], a new class of electrical machines is presented as shown in Figure 10. Unlike conventional radial-flux or axial-flux approaches, this machine has a unique three-dimensional magnetic flux path. Using additive manufacturing, this machine has been constructed using spray-formed soft magnetic material, enabling smaller, lighter machines with higher power output and better energy efficiency (40% higher power density and 15% lower losses).

Figure 10. Additively manufactured 3D-flux PM brushless machine with spray-formed soft magnetic material core [31].

All the aforementioned cases of utilizing metal AM in building the soft magnetic parts of an electrical machine demonstrate different levels of technological maturity.

2.2. Windings

The implementation of metal AM for the windings of the electrical machines is still in its early stages [32]. However, AM can offer innovative design solutions for coils/windings, which in turn increase its competitiveness with conventional wires. The major contributions of AM in the build of windings include the following:

-

with the high flexibility of AM, the coil cross-section area can be designed with a higher slot fill factor as well as better thermal behavior;

-

the end windings can be customized with up to 50% of its length [33]. That greatly helps in the reduction of machine weight and volume;

-

some techniques allow printing of the winding and insulation at the same time;

-

higher operation temperature can be achieved by using powdered-form temperature-resistant materials such as ceramics, instead of using regular coat (enamel, resin, polymer, etc.). Processing of materials such as ceramics using conventional methods is difficult due to the high melting point;

-

controlling the electric properties of the windings such as conductivity by adapting the material microstructure or by mixing of different materials.

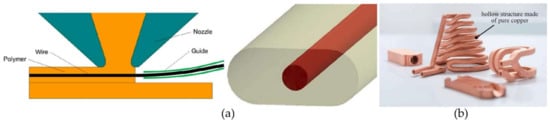

In [34,35], fiber encapsulation AM has been introduced, which can allow a simultaneous fabrication of conductive wires and dielectric material. Figure 11a shows the concept of this technique. As can be seen, this method can uniquely integrate wires not only on the surface but also volumetrically inside the insulation. Figure 11b shows additively manufactured copper hollow conductors [36]. Such integration with the cooling channel can provide an effective solution for the heat dissipation problem in electrical machines with a high power rating. In [37], the thermal performance of the additively manufactured windings have been developed so that they can withstand a current density of 20 A/mm² with liquid cooling.

In [38], AM coils of hollow conductors are proposed for a 250 kW, 5000 r/min high-specific-power P_M machine. The conductors are integrated with cooling channels for direct heat exchange as shown in Figure 12. Two coils are manufactured by direct metal laser sintering (DMLS) using two different materials copper and aluminum alloys. The chemical compositions of the two materials are aluminum–silicon–magnesium (AlSiMg) and copper–chromium–zirconium (CuCrZr), respectively. Compared to AM pure copper or aluminum, these alloys have better mechanical properties, which is promising for aerospace applications since both materials can survive under vibrations. In terms of electromagnetic performance, the aluminum-based design was the best option due to its ability to limit the high-frequency losses at this high-rated speed. A further comparison between the two materials appears in Table 1.

Figure 12. AM coils of hollow conductors integrated with cooling channels for direct heat exchange [38].

In [39,40,41], using direct metal laser sintering (DMLS), shaped profile coils are 3D-printed using different materials as shown in Figure 13. The conductors are shaped to remain parallel to the magnetic flux lines, so that the AC losses can be reduced. First, an example winding is built using AlSiMg alloy at 45° to the build platform to ensure that the structure is self-supporting with minimal size support structure. The build supports are also designed to ensure enough clearance between the turns. Similarly, a CuCrZr alloy coil is manufactured using the same steps. Then, the support structure is mechanically removed by post-manufacture process, before the coil is finally coated with varnish. Such shaped profile windings have the potential for improving efficiency in different applications such as electric vehicle traction, aerospace propulsion fans, and generators.

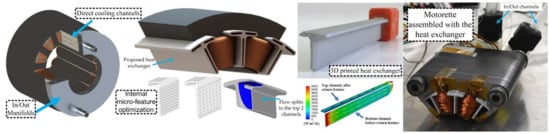

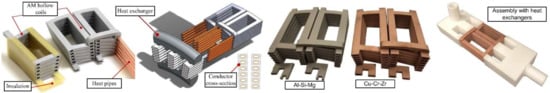

In a further development of the aforementioned shaped profile coils, a unique multi-material coil winding is integrated with heat exchangers as shown in Figure 14 [42]. Using multi-material AM, the incorporated triply periodic minimal surface (TMPS) heat exchanger is printed using pure Cu, pure silver, and copper–silver alloys. One of the challenges of the laser powder bed fusion processing (L-PBF) of pure copper is the reflected infrared lasers, which can reach up to 98% of the laser energy. This issue is overcome by using an M290-400W L-PBF system of high-powered infrared lasers, small spot size lasers, or different wavelength lasers. Apart from the improved thermal performance, the electromagnetic performance of these coils is yet to be evaluated.

Figure 14. Multi-material AM shaped-profile coils with integrated heat exchangers for improved thermal performance [42].

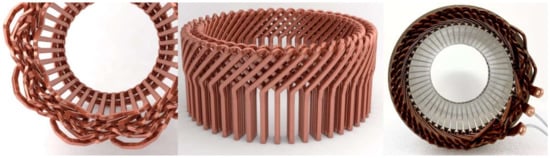

In [43], high-performance 3D-printed single coil winding is developed for a racing engine as shown in Figure 15. With a perfect geometrical fit, the coils have a maximum copper fill factor, and the design enables forced heat transfer from winding to laminated core, preventing hotspot formation. As a result, the power density is increased by more than 45%. The insulation of the turns is made in a separate postprocess. In another approach, in [44], 3D-printed hairpin distributed windings are prototyped for E-traction motors as shown in Figure 16. In this machine, wound copper wires are replaced by rectangular copper rods with only half winding head overhang. In addition, more than 30% torque is obtained for the same slot space.

Figure 15. High-performance 3D-printed single coil winding for racing engine [43].

Figure 16. 3D-printed hairpin distributed windings for E-traction motors [44].

2.3. Complete Machine Parts

With growing technology maturity, AM techniques have proven their potential to manufacture complete machine parts, such as a stator core as well as the winding, or a complete rotor with soft and hard magnetic materials. Examples are explained as follows.

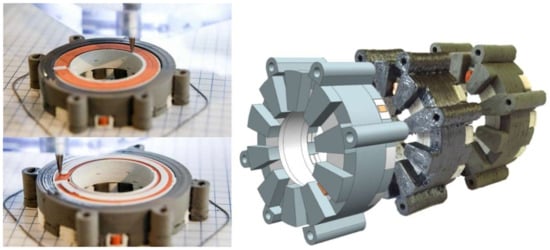

Figure 17 shows a prototype of a fully 3D-printed axial flux machine. The copper windings, insulation, and the core are built simultaneously through fuse filament fabrication with a multiple-nozzle DED technique. With ceramics as insulation material, the coil can withstand a temperature of up to 300 °C [45].

Figure 17. Fully 3D-printed axial flux machine with ceramic insulation [45].

In [46,47,48], a conical air-gap machine is additively manufactured for automotive traction as shown in Figure 18. A complete PM rotor is 3D printed using cold spray technology with NdFeB-Al composite powder. This technology is effective in fabricating motor parts without additional assembly steps. The machine has a promising efficiency with more than 90%. This prototype is undergoing further development so that it can be made commercially available.

2.4. Thermal-Management Parts

The growing adoption of electric vehicles (EV) is spurring the development of more powerful and more highly rated electrical machines. EV manufacturers must surmount the cooling barrier by finding cooling solutions that account for thermal efficiency, temperature uniformity, size, weight, and cost [49]. That is why the design freedom of AM will play an important role in providing an innovative approach to EV cooling challenges, as shown in the following examples.

In [50,51,52], the electrical machine windings are directly cooled using 3D-printed ceramic heat exchangers as shown in Figure 19. By occupying the unused space between double layer concentrated windings, the power density of electrical machines is increased without affecting the electromagnetic design. The microfeatures of inner channels are optimized using different shapes for significantly improved cooling. Ceramics are selected due to their ability to withstand extremely high temperatures. As a result, the winding temperature rise is decreased by 44%. Furthermore, a continuous current density of 35.7 A/mm2 is achieved while keeping the maximum winding temperature below 200 °C.

3. Post-Processing for Metal AM

Post-processes can be divided into three categories, according to the intended effects on the 3D printed part: (1) process-inherent step, (2) material properties, (3) visual appeal step.

-

A process-inherent step is used to free the printed part from the support material and for excess powder removal.

-

Material properties include the improvement of mechanical and electrical properties. For instance, the printed part can go through a controlled heat treatment protocol to relieve residual stress or improve other mechanical properties such as hardness and ductility. This annealing process can also be used for boosting the electrical conductivity.

-

A visual appeal step is the last touch, which includes surface treatment and finishing. In particular, the part is polished and smoothed to decrease roughness. The common surface finishing techniques include CNC machining, blasting, anodizing, and electroplating.

This entry is adapted from the peer-reviewed paper 10.3390/en15031076

This entry is offline, you can click here to edit this entry!