Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Task-offloading approaches can be efficiently combined with energy harvesting to address the issue of insufficient battery capacity and limited computation resources in IoMT devices and consequently increase the operating time of wearable devices.

- Energy

- IoMT

- Power Supply

- Wearables

1. Thermoelectric Generators

Energy can be derived from heat using thermoelectric generators (TEGs) based on the thermoelectric effect. It is also known as the Seebeck effect, according to which electricity is generated by the temperature gradient between two conductors. A TEG can be attached to the body to convert the temperature difference between a body skin and the surrounding environment into voltage. This concept was launched in 1999, where the first wristwatch supplied by body heat was invented [92]. TEGs can be used as an efficient power supply for wearable devices when the human body and the surrounding environment have a temperature difference of 5 to 10 degrees.

The electric potential of a TEG is expressed by Equation: where S is the Seebeck coefficient of the material used and T is the temperature difference across the TEG.

where S is the Seebeck coefficient of the material used and T is the temperature difference across the TEG.

where S is the Seebeck coefficient of the material used and T is the temperature difference across the TEG.

where S is the Seebeck coefficient of the material used and T is the temperature difference across the TEG.

A thermally powered wearable device that incorporates an accelerometer to sense falls was developed in [93]. In this application, the device generated 520 W of output power at 15 C, which charged a capacitor and a power management unit, included to link the thermal source and a sensor node.

An in-depth analysis of thermoelectric generation technology was recently presented in [94], illustrating the working principles of TEGs and their applications. Nevertheless, the development of thermoelectric materials with acceptable power factors remains a major challenge, for which various techniques have been investigated to achieve better efficiencies.

2. Kinetic Energy Harveters

In contrast to solar or thermal energy, a kinetic energy source is not dependent on location or time. Kinetic harvesters are based on the extraction of vibration or motion and the conversion of the mechanical energy into electrical power through one or a combination of different transduction mechanisms. The most common ones are piezoelectric, electromagnetic, electrostatic, and triboelectric. These harvesters are classified related to their transduction mechanisms. Unlike other means of transduction, piezoelectric harvesters directly convert human motion changes into electrical signals without any requirements for further external input. Piezoelectric (PE) harvesters operate through the piezoelectric effect. When a force is applied to a PE element, a mechanical strain is developed, causing the material to exhibit changes in its polarization, causing the accumulation of electrical charges across the piezoelectric material. The changes in charge distribution produce an electric field depending on the applied force, frequency of oscillation, and geometry of the harvester.

Electromagnetic kinetic energy harvesters operate based on Faraday’s law induction which states that once a conductor moves through an electric field, a current is induced. A system of springs, magnets and coils are used in electromagnet energy-harvesting systems. Coil number and magnetic mass are the main determinants of the output power of these energy harvesters. Therefore, reducing their size, weight and complexity is challenging. As example, the authors of [95] demonstrated the effectiveness of a frequency-converted electromagnetic harvester which extracts energy mainly from human limb motion. A power density of 0.33 mW/cm3

was achieved in this work using low-frequency human vibration to power wearable devices at extremely low frequencies.

3. Flexible Piezoelectric Generators

The body is an excellent source of significant amounts of mechanical energy which can be produced from several biological processes, including walking, heartbeat, breathing and muscle movements. Thanks to their high flexibility, piezoelectric nanogenerators (PENGs) can convert this mechanical stress into electrical charges through nanostructured piezoelectric materials when stretched, pressed or flexed. In addition, this technology can potentially be integrated with other energy-harvesting mechanisms, resulting in hybrid energy-harvesting solutions. The simple architecture of PENGs makes them attractive and considered to be the most promising energy harvesters for wearable devices and microsystems. The materials used in piezoelectricity are diverse, including crystals, ceramics, and polymers. The converter needs to be attached to a part of the body subjected to strong compressive stress to maximize the piezoelectric effect. PENGs can provide enough power to supply devices with power consumption ranging from microwatts to milliwatts, which best fits the wearable sensor range as seen in Table 1 where the energy consumption of typical wearable sensors is presented.

Table 1. Energy consumption of typical medical sensors.

| Wearable Sensors | Voltage Range |

Power Consumption |

Description |

|---|---|---|---|

| Optical heart rate sensors - BH1790GLC optical heart rate sensor [96] |

1.7–3.6 V | 720 µW | Measures the pulse waves that occur when the heart pumps blood. |

| Blood pressure sensors - Capacitive tactile sensor [97] |

1.8–3.3 V | 1.2–4.6 mW | Measures the pressure exerted by the circulating blood on the walls of blood vessels. |

| Glucometers - Implantable RFID glucose monitoring sensor [98] |

1.0 V–1.2 V | 50 µW | Measures the average blood glucose concentration. |

| Pulse oximeter sensors -MAX30102 pulse oximetry [99] |

1.8 V–3.3 V | <1 mW | It attaches to a body part, most commonly to a finger to measure the oxygen saturation level of the circulating arterial blood. |

Flexible Piezoelectric generators can be modeled as sinusoidal current sources Ip in parallel with parasitic capacitances Cp and Rp internal resistances when excited by sinusoidal vibrations at their resonant frequencies. Since the piezoelectric transducer can deliver an alternating irregular AC current rather than direct current (DC), an electronic interface is essential to enable voltage compatibility between the piezoelectric element and the load. The electronic interface greatly influences the energy-harvesting effectiveness [100], which has driven a variety of research efforts to develop PENG-compatible energy management interfaces [101]. Implementing these circuits is mostly intended to allow the user to use irregular AC power harnessed by piezoelectric transducers (PTs) to supply loads such as wearable sensors. The rectification stage of PEH systems is usually coupled with a DC-DC converter [100] to scale the rectified voltage to match the application’s requirements.

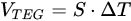

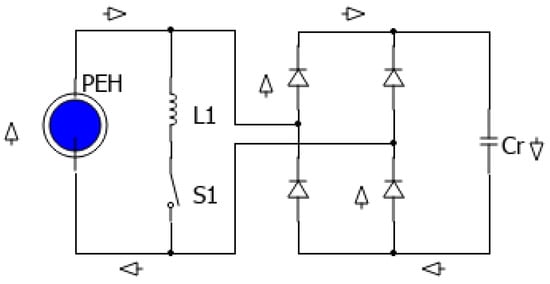

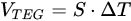

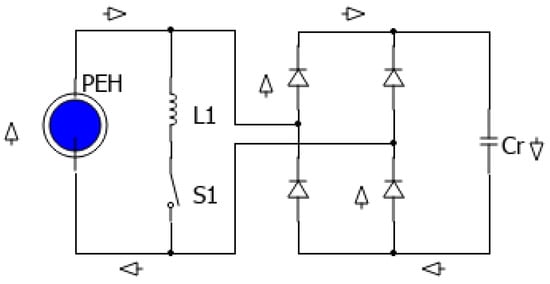

One limitation of the classic AC-DC energy-harvesting circuits when implemented with PEts is that negative output power is produced because the output current and voltage could not keep the same phase, leading to a loss of an amount of the harvested energy. P-SSHI and S-SSHI have been proposed to overcome this limitation. The main difference between the circuits is how Researcher connect the switch S and the inductor L, either in series, so researchers are talking about SSHI or in parallel to deal with P-SSHI. When the vibration occurs, the switch S remains open, allowing the current to flow through the circuit to the storage element Cr. If the piezoelectric element’s voltage drops below a certain threshold, the switch S will automatically close, inverting the voltage across the PE element and therefore stopping current flow. This means that the switch is kept closed until a full inversion of the PEt’s voltage has been achieved. Nevertheless, this voltage inversion causes an electrical damping that opposes the mechanical vibrations on the piezoelectric material. This effect is known as Synchronized Switch Damping (SSD). It can significantly affect the overall conversion efficiency, and it is consequently the main limitation of both P-SSHI and S-SSHI circuits. Figure 1 and Figure 2 display the P-SSHI and S-SSHI energy-harvesting interfaces, respectively.

Figure 1. Schematic of P-SSHI energy extraction interface.

Figure 2. Schematic of S-SSHI energy extraction interface.

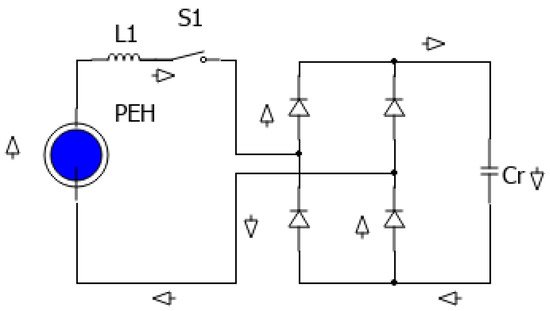

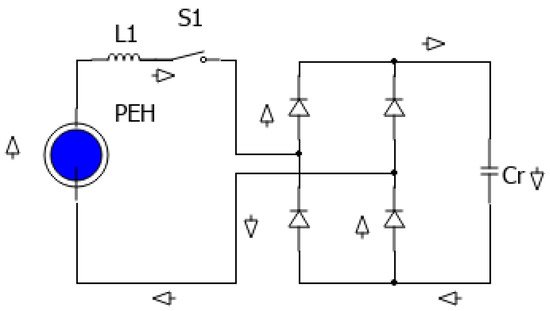

SECE circuit, displayed in Figure 3, mainly prevents the SSD effect, which is the main limitation of P-SSHI and S-SSHI circuits. This effect is caused by the direct connection between the output load and the piezoelectric transducer during the hole vibration phase. When the PEH generates the voltage, the switch S will be closed, and the energy will be stored in the inductor L as seen in the figure.

Figure 3. Schematic of SECE energy extraction interface when the switch S is closed.

When the vibration stops, the voltage across the piezoelectric element falls to zero, and the switch S will open immediately. Consequently, the energy accumulated in the inductor will be directly transferred to the storage capacitor and the load. One limitation for this interface is the complexity when compared to the simple architecture and switching strategy that characterize SSHI circuits.

The control of the integrated switches was a common limitation for the reviewed interfaces, so several researchers were focusing on developing self-powered resonant energy-harvesting circuits. In [102], authors demonstrated an optimized self-powered P-SSHI circuit that can automatically switch once the voltage exceeds its maximum threshold. In addition, this technology can potentially be integrated with other energy-harvesting mechanisms, resulting in hybrid harvesting solutions [103].

4. Energy-Storage Techniques

Using energy harvesting to achieve battery-free operation has gained high interest. However, any interruption in the energy-harvesting source will affect the wearable device’s operation. Therefore, an energy-storage mechanism is still required to maintain a smooth power supply for charge loads and serve as a backup whenever the energy source is unavailable.

The harnessed energy can be stored before being supplied to the MCU, or the power can be delivered directly. The decision of whether implementing a storage element in a wearable device considers different factors:

-

Placement of the device: implant or outside.

-

Energy source: type

-

Requirements of the application: either it needs a sustainable supply for the wearable device or a non-critical usage.

Batteries and super capacitors are the two main solutions for energy storage. Energy storage for wearable devices must comply with several requirements. First, the storage element needs to be rechargeable to avoid frequent battery replacements, which can be inconvenient in several cases. In pacemakers, as an example, surgery needs to be performed every eight years to replace their lithium batteries [104]. As a second requirement, the storage device needs to be capable of supporting long-term application with minimal impact on battery parameters.

The following Table 2 compares two storage mechanisms, batteries and capacitors.

Table 2. Comparison between different storage techniques for energy harvesters in IoMT devices.

| Comparison | Conventional Batteries | Supercapacitors |

|---|---|---|

| Storage mechanism | Chemical | Physical |

| Energy storage | High | Limited |

| Recharging cycles | 100 s | Millions |

| Charging time | Hours | Sec-minutes |

| Impedance | Low-high | Low |

| Physical size | Large | Medium |

| Capacity | 0.3–2500 mAH | 10–100 µAH |

They differ mostly in the number of charging cycles since capacitors can reach millions of cycles. In addition, capacitors require only a few seconds for charging, so the charging time is very fast compared to batteries. In contrast, supercapacitors cannot be used in AC and high frequency circuits and have lower capacity than batteries, but this can satisfy the requirements of some low-power applications. One more limitation for using batteries as a storage element is that the battery is susceptible to leakage, leading to chemical poisoning, especially when used in implants. Batteries can leak chemicals when overcharged or heated (above 60 ∘

C). This can lead to chemical burns risking human beings. Due to their advantages over batteries, super capacitors are a promising alternative to store energy. In a super capacitor, thin dielectric layers and electrodes hold power at the electrode–electrolyte interface to be accessed when needed. Thanks to their high pulse power capacity, they can also handle small power surges. Super capacitors’ excellent cycle lifetime also makes them ideally suited to act as energy-storage components in energy-harvesting-based sustainable power systems.

6. Recent Energy-Harvesting Solutions for Wearables

The human body can be a versatile source of energy harvesting [105,106]. Energy can be harvested from everyday activities, such as breathing, arm motion, walking, running, or pedaling, without performing a specific workout. The body can produce mechanical energy through various body zones movements, such as the elbow, the knee, the ankle or the heels. The performance of three vibrating generators was studied in [107] at nine different body locations for a person walking on a treadmill. The results indicate that the energy generated at lower-body locations (hip, knee, and ankle) is four times greater than the energy generated at upper-body locations. Additionally, body heat offers promising possibilities for supplying wearable systems. Based on the Seeback effect, a flexible TEG generated 4.95 mW of body heat and was used for a wearable multi-sensing bracelet [108]. A energy-autonomous, multi-sensing bracelet can operate under varying conditions, including human motion. The amount of energy in such systems is highly dependent on the temperature difference between the human body and the ambient environment [109]. Several studies have shown that physiological activities, such as blood pressure, heart motion and breathing, can regularly provide wearable devices with energy supply. In [110], cardiac contractions are used to supply low-powered pacemakers. When powered by a constant heartbeat of 90 bpm, the harvester can deliver 11.1 j of electrical energy. Because of the small size and weight requirement, energy extraction from the human body is much more complicated than energy harvesting from machines [111]. The available power is often weak and difficult to use, such as human kinetic energy, which typically has a low frequency and a low amplitude.

Recently, thermoelectric nanogenerators (TENGs) were demonstrated as a conventional technique for rehabilitation in [112]. As an exercise gaming device, a wearable TENG-based rehabilitation device (Rehab-TENG) was developed. The device was used to control a game on a laptop by flexing and extending the arm. It is an effective way of testing the motor function of an impaired arm. Rehab-TENG is also used as an energy harvester in an exercise system where the patient moves an impaired arm to store energy in a capacitor. It is possible to assess the level of deficiency by measuring the charging rate of the storage element, which consequently enhances patients’ motivation for exercising more repetitive movements of the impaired body zone. This, in turn, speeds up recovery. Furthermore, the authors suggested using the Rehab-TENG device as an autonomous home exercise and monitoring system, which is particularly relevant during pandemics, therefore reducing the necessity for hospital visits for rehabilitation.

An emerging trend in energy-harvesting technologies for IoMT is developing bio-compatible wearable harvesters, such as textiles, footwear, or watches, which are energy-autonomous, lightweight, flexible, and have more computational resources for better performance. Consequently, various energy-saving approaches were proposed to mitigate the problem of excessive energy demands during the operation of devices. Task offloading is a promising and effective technique that extends the operating time of wearables by migrating the energy intensive task to edge device. Task-offloading algorithms attempts to solve an optimization problem by looking for a suitable remote processor to perform the offloading, taking into consideration the overheads caused by the communication link (energy and latency). Real-time implementation of task offloading for wearables is still in its infancy.

This entry is adapted from the peer-reviewed paper 10.3390/electronics11030383

This entry is offline, you can click here to edit this entry!