Combustion of fuels in internal combustion engines is based on the use of one type of fuel which is ignited either by forced spark ignition (SI) or by compression ignition (CI). The highest efficiency is currently achievable thanks to the ignition of a homogeneous air–fuel mixture in homogeneous charge compression ignition (HCCI) engines, where the ignition of all the fuel in the combustion chamber occurs simultaneously. This combustion takes place at a lower temperature than in a classic diesel engine, which leads to lower heat losses and the formation of less NOX, which translates into higher thermal efficiency for engines with this type of ignition.

- alternative fuels for IC engines

- combustion control

- emission characteristics

- biofuels blending

- hydrogen enriched fuels

- RCCI engine

- HVO fuel

- HCNG fuel

- dual-fuel engine

1. Introduction

High carbon dioxide emissions can be reduced by increasing the efficiency of the internal combustion engine or reducing the carbon content of the fuel burned. Reasonable use of alternative fuels will allow one to reduce these emissions through the use of both of these factors. Effective reduction of GHG by reducing the number of carbon atoms in the fuel and improving the efficiency of the engine can be achieved thanks to the fuels presented in this study.

The use of alternative fuels in SI engines that are adapted to burn conventional hydrocarbon fuels such as gasoline shows no measurable increase in overall engine efficiency. The biggest impact that the use of an alternative fuel has on the overall efficiency of the engine is a change to its thermal efficiency. Homogeneous and low-temperature methods of combustion of the fuel–air mixture are the most effective methods to achieve high thermal efficiency of the engine. This translates directly into the overall efficiency of the engine and lowering of carbon dioxide emissions [1].

In the case of gaseous fuels, their combustion in diesel engines is difficult due to the specificity of the construction and operation of such an engine. Direct gas injection into the engine TDC is not yet a proven solution that allows for independent operation of a diesel engine using gas fuel [2].

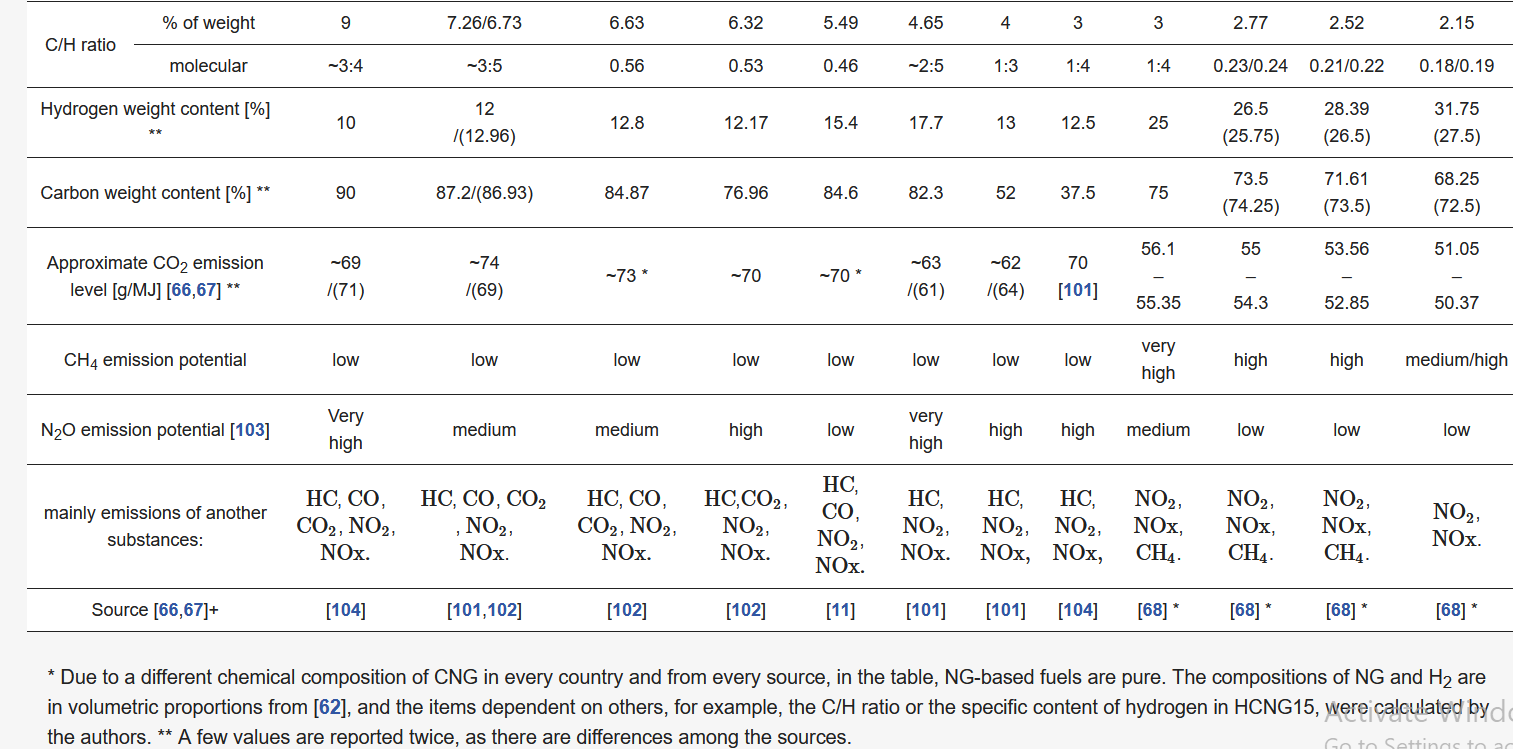

A diesel engine can operate effectively using two fuels at the same time. The gaseous fuel burned in this type of engine is ignited by a small dose of diesel fuel (pilot dose), or another liquid fuel that replaces diesel and has similar properties to regular diesel. The current aims when developing alternative engine fuels are continuously increasing engine efficiency and reducing GHG emissions [3]. The most important greenhouse engine combustion gases are colored yellow in all Table 1 .

| Name | Formula | CO2-Equivalent |

|---|---|---|

| Carbone dioxide | CO2 | 1 |

| Methane | CH4 | 25 |

| Nitrous oxide | N2O | 310 |

| Water vapor | H2O | Situation dependent |

| CFC-11, CFC-12 (chlorofluorocarbons) | CX, FY, ClZ | 5700–11,900 |

| Sulphur hexafluoride | SF6 | 22,200 |

2. Low-CO2 Emission Fuels for a Dual-Fuel RCCI Engine

3. Conclusions

This entry is adapted from the peer-reviewed paper 10.3390/en14165067

References

- Djermouni, M.; Ouadha, A. Thermodynamic analysis of an HCCI engine based system running on natural gas. Energy Convers. Manag. 2014, 88, 723–730.

- Eldin, A.H.; Medhat Elkelawy, M.; Zhang, Y.-S. HCCI Engines Combustion of CNG Fuel with DME and H2 Additives; SAE International: Warrendale, PE, USA, 2010.

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71.

- Kuiken, K. Gas- and Dual-Fuel Engines for Ship Propulsion, Power Plants and Cogeneration. In Book I: Principies; Target Global Energy Training: Onnen, The Netherlands, 2016; pp. 1–488.

- Mariani, A. Hydrogen—Natural Gas (HCNG) Mixtures as Fuels in Internal Combustion Engines; International Workshop of Hydrogen and Fuel Cells: Orlean, France, 2012.

- Kalsi, S.S.; Subramanian, K.A. Experimental investigations of effects of hydrogen blended CNG on performance, combustion and emissions characteristics of a biodiesel fueled reactivity-controlled compression ignition engine (RCCI). Int. J. Hydrogen Energy 2017, 42, 4548–4560.

- Kokjohn, S.L.; Hanson, R.M.; Splitter, D.A.; Reitz, R.D. Fuel reactivity-controlled compression ignition (RCCI): A pathway to controlled high-efficiency clean combustion. Int. J. Engine Res. 2011, 12, 209–226.

- Del Vescovo, D.A.; Daniel, A. The Effects of Fuel Stratification and Heat Release Rate Shaping in Reactivity Controlled Compression Ignition (RCCI) Combustion. Ph.D. Thesis, The University of Wisconsin, Madison, WI, USA, 2016.

- Preliminary Findings on Possible Euro 7 Emission Limits for LD and HD Vehicles. Available online: https://circabc.europa.eu/sd/a/fdd70a2d-b50a-4d0b-a92a-e64d41d0e947/CLOVE%20test%20limits%20AGVES%202020-10-27%20final%20vs2.pdf (accessed on 30 April 2021).

- Tsujimura, T.; Suzuki, Y. The utilization of hydrogen in hydrogen/diesel dual fuel engine. Int. J. Hydrogen Energy 2017, 42, 14019–14029.

- Lubowicz, J. Impact of Bio-Component Obtained by the “Co-Processing” on Properties of Diesel Fuel; Oil and gas Institute National Research Institute: Kraków, Poland, 2016; p. 208.

- Wartości Opałowe (WO) i Wskaźniki Emisji CO2(WE) w Roku 2017do Raportowania w Ramach Systemu Handlu Uprawnieniami do Emisji Za Rok 2020; The National Centre for Emissions Management: Warsaw, Poland, 2019.

- Wartości Opałowe (WO) i Wskaźniki Emisji CO2(WE) w Roku 2018 do Raportowania w Ramach Systemu Handlu Uprawnieniami do Emisji Za Rok 2021; The National Centre for Emissions Management: Warsaw, Poland, 2020.

- Zareei, J.; Rohani, A. Optimization and study of performance parameters in an engine fueled with hydrogen. Int. J. Hydrogen Energy 2020, 45, 322–336.

- The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/co2-emission-fuels-d_1085.html (accessed on 29 April 2021).

- Nguyen, V.H.; Duong, M.Q.; Nguyen, K.T.; Pham, T.V.; Pham, P.X. An Extensive Analysis of Biodiesel Blend CombustionCharacteristics under a Wide-Range of ThermalConditions of a Cooperative Fuel Research Engine. Sustainability 2020, 12, 7666.

- Lipman, T.; Delucchi, M.A. Emissions of Nitrous Oxide and Methane from Conventional and Alternative Fuel Motor Vehicles. Clim. Chang. 2002, 53, 477–516.

- Dahodwala, M.; Joshi, S.; Koehler, E.; Franke, M.; Tomazic, D.; Naber, J. Investigation of Diesel-CNG RCCI Combustion at Multiple Engine Operating Conditions; SAE International: Warrendale, PE, USA, 2020.