The use of waste products in the production of asphalt binders and asphalt mixtures has become widespread due to economic and environmental benefits. In particular, the use of recycled waste plastic in asphalt binders and mixtures is gaining more attention. Overall, the incorporation of plastic waste into asphalt mixtures can significantly improve high-temperature performance and has potential economic and environmental benefits. The performance of modified asphalt is highly dependent on multiple factors, such as waste sources, waste plastic dosages, blending conditions, and the pretreatment methods for waste plastic.

- recycled waste plastic

- asphalt binder and mixture

- composite modification

- performance

1. The Use of Waste Plastics in Asphalt

1.1. Forms of Waste Plastics Used in Asphalt

1.2. Approaches to Incorporating Waste Plastics into Asphalt

| Method | Production Cost | Technological Problem | Performance of Mixture | ||

|---|---|---|---|---|---|

| Advantage | Drawback | Advantage | Drawback | ||

| Wet process |

Expensive (AC-16) |

Normative guidance and engineering experience | Complex production process (specialized mixing and storage facilities) | Higher viscosity |

Poor storage stability |

| Dry process |

Cheap (AC-16) |

Lack of normative guidance | Simple production process (no need of professional facility) | - | Poor water stability |

1.3. Single and Composite Modification

1.3.1. Single Modification

(1) Waste LDPE

(2) Waste HDPE

(3) Waste PP

(4) Waste PVC

(5) Waste PET

According to the Wellness Recovery Action Program (WRAP), PET is one of the most recycled plastic wastes [30]. Because of the high melting point, most researchers tend to use waste PET for dry modification [31]. Results have shown that waste PET-modified mixtures developed using the dry method have an improved high-temperature performance and reduced fracture resistance when the dosage of PET is 30% and 50% [32].

(6) Waste PS

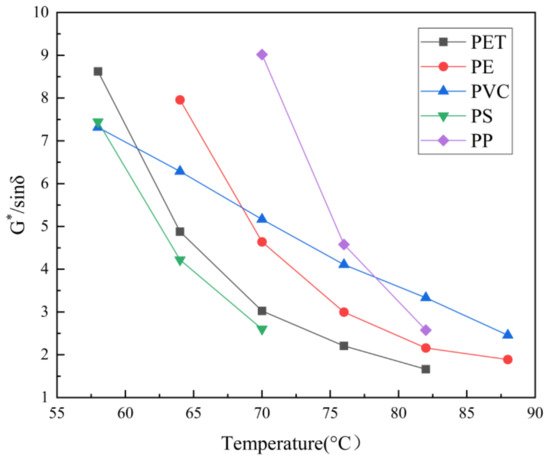

Waste PS-modified asphalt mixtures developed using the dry process are found to have higher rigidity, but this could be a problem in colder areas in terms of cracking resistance [33]. Specifically, waste PS exhibits the lowest elastic behavior in the modified asphalt mixture compared with waste PE, PP, and rubber asphalt mixture using the dry process [34]. Fang et al. [35] successfully used a very low-density PS waste to expand the stiffness of asphalt and improve its rutting resistance. Hasan et al. [24] indicated that the addition of waste high impact PS (HIPS) in asphalt improves the asphalt’s stiffness, but decreases the low-temperature properties. Furthermore, much more attention should be paid to the fact that harmful substances are released when PS is heated above 70 °C.

(7) Waste EVA

(8) Waste ABS

(9) Waste PU

| Type | Characteristics of Waste Plastic | Reference | |||

|---|---|---|---|---|---|

| Compatibility | High-Temperature Stability | Low-Temperature Flexibility | Viscosity | ||

| LDPE | √ | √ | - | √ | [53] |

| HDPE | √ | - | [54][7] | ||

| PP | √ | √ | - | √ | [55][26][56] |

| PVC | - | √ | - | √ | [57][48] |

| PET | - | √ | - | √ | [58] |

| PS | - | √ | - | √ | [33] |

| EVA | √ | √ | √ | √ | [7][23][59][36] |

| ABS | √ | √ | - | - | [29] |

| PU | √ | - | - | √ | [43][45] |

1.3.2. Composite Modification

2. Factors Affecting Properties of Waste Plastic-Modified Asphalt

2.1. Waste Plastic Properties

2.2. Asphalt Binder Properties

2.3. Waste Plastic Dosage

2.4. Blending Conditions

| Waste Plastic | Optimum Content (wt.%) | Blending Temperature (°C) | Blending Time (min) | Blending Speed (rpm) | Reference |

|---|---|---|---|---|---|

| PE | 3–6 | 145–190 | 60–150 | 1750–4000 | [54][7][72][90] |

| PP | 3–6 | 160–180 | 45–90 | 1800–4000 | [26][25][56][91] |

| PVC | 4–8 | 160–180 | 60–180 | 1300–2000 | [48][75] |

| PET | 2–8 | 180 | 60 | 13,000 | [23][59][6][36] |

| EVA | 3–5 | 140–180 | 80–120 | 1800–3000 | [23][59][36] |

| PS | 4–6 | 150–190 | 90–120 | 3000 | [33][35] |

2.5. Pretreatment Methods for Waste Plastic

2.5.1. Physical Method

| Type | Source | Physical Method | Form | Size | Reference |

|---|---|---|---|---|---|

| Waste plastic bag waste plastic pipe | - | Shredding | Strip Fiber |

1–2 cm 20 × 3 mm2 |

[57][5][56] |

| Waste plastic bottle | PET | Cutting and crushing | Particle | 0.45–1.18 mm | [4] |

| Waste milk bag | - | Extruding | Pellet | - | [9] |

| Waste plastic bottle waste express bag |

PET | Grinding | Particle Piece |

0.45–0.5 mm 2–5 mm |

[6][92] |

| Waste window blind and cable |

PVC | Pulverization | Powder | - | [75] |

2.5.2. Chemical Method

This entry is adapted from the peer-reviewed paper 10.3390/ma15010110

References

- Nikolaides, A.F.; Manthos, E. Bituminous Mixtures and Pavements VII, 1st ed.; CRC Press: Thessaloniki, Greece, 2019.

- White, G.; Reid, G. Recycled Waste Plastic for Extending and Modifing Asphalt Binders, Proceedings of the 8th Symposium on Pavement Surface Characteristics: SURF 2018, Brisbane, Australia, 2–4 May 2018; Australian Road Research Board: Brisbane, Australia, 2018.

- Li, M.; Zhang, M.; Rong, H.; Zhang, X.; He, L.; Han, P.; Tong, M. Transport and deposition of plastic particles in porous media during seawater intrusion and groundwater-seawater displacement processes. Sci. Total Environ. 2021, 781, 146752.

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffness and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15.

- Kumar, P.; Garg, R. Rheology of waste plastic fibre-modified bitumen. Int. J. Pavement Eng. 2011, 12, 449–459.

- Lin, Y.; Hu, C.; Adhikari, S.; Wu, C.; Yu, M. Evaluation of Waste Express Bag as a Novel Bitumen Modifier. Appl. Sci. 2019, 9, 1242.

- Hinislioglu, S.; Agar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271.

- Shahane, H.A.; Bhosale, S.S. E-Waste plastic powder modified bitumen: Rheological properties and performance study of bituminous concrete. Road Mater. Pavement Des. 2019, 22, 682–702.

- Fang, C.; Liu, P.; Yu, R.; Liu, X. Preparation process to affect stability in waste polyethylene-modified bitumen. Constr. Build. Mater. 2014, 54, 320–325.

- Balasubramanian, B.; Gopala Krishna, G.V.T.; Saraswathy, V.; Srinivasan, K. Experimental investigation on concrete partially replaced with waste glass powder and waste E-plastic. Constr. Build. Mater. 2021, 278, 122400.

- Yue, H.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2008, 52, 58–73.

- Movilla-Quesada, D.; Raposeiras, A.C.; Silva-Klein, L.T.; Lastra-González, P.; Castro-Fresno, D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760.

- White, G.; Magee, C. Laboratory Evaluation of Asphalt Containing Recycled Plastic as a Bitumen Extender and Modifier. J. Traffic Transp. Eng. 2019, 7, 218–235.

- Ranieri, M.; Costa, L.; Oliveira, J.R.M.; Silva, H.M.R.D.; Celauro, C. Asphalt Surface Mixtures with Improved Performance Using Waste Polymers via Dry and Wet Processes. J. Mater. Civ. Eng. 2017, 29, 04017169.

- Chavez, F.; Marcobal, J.; Gallego, J. Laboratory evaluation of the mechanical properties of asphalt mixtures with rubber incorporated by the wet, dry, and semi-wet process. Constr. Build. Mater. 2019, 205, 164–174.

- Wang, J. Application of Direct Investment SBS Modification Technology in Solid Engineering. J. China Foreign Highw. 2017, 37, 253–256. (In Chinese)

- Fang, C.; Wu, C.; Hu, J.; Yu, R.; Zhang, Z.; Nie, L.; Zhou, S.; Mi, X. Pavement Properties of Asphalt Modified with Packaging-Waste Polyethylene. J. Vinyl Addit. Technol. 2014, 20, 31–35.

- Lu, J.; Zhang, Z. Study and Practice on Road Performance of Waste Polyethylene Plastic Modified Asphalt. Highw. Eng. 1996, 76, 62–64. (In Chinese)

- Dalhat, M.A.; Al-Abdul Wahhab, H.I.; Al-Adham, K. Recycled Plastic Waste Asphalt Concrete via Mineral Aggregate Substitution and Binder Modification. J. Mater. Civ. Eng. 2019, 31, 04019134.

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F.F. Asphalt Design Using Recycled Plastic and Crumb-rubber Waste for Sustainable Pavement Construction. Procedia Eng. 2016, 145, 1557–1564.

- Ho, S.; Church, R.; Klassen, K.; Law, B.; MacLeod, D.; Zanzotto, L. Study of recycled polyethylene materials as asphalt modifiers. Can. J. Civ. Eng. 2006, 33, 968–981.

- Punith, V.S.; Veeraragavan, A.; Amirkhanian, S.N. Evaluation of Reclaimed Polyethylene Modified Asphalt Concrete Mixtures. Int. J. Pavement Res. 2011, 4, 1–10.

- Costa, L.M.B.; Silva, H.M.R.D.; Peralta, J.; Oliveira, J.R.M. Using waste polymers as a reliable alternative for asphalt binder modification—Performance and morphological assessment. Constr. Build. Mater. 2019, 198, 237–244.

- Otuoze, H.S.; Ejeh, S.P.; Amartey, Y.D.; Joel, M. Rheology and Simple Performance Test (SPT) Evaluation of High-Density Polypropylene (HDPP) Waste-Modified Bituminous Mix. Jordan J. Civ. Eng. 2018, 12, 35–44.

- Al-Hadidy, A.I.; Tan, Y. Mechanistic approach for polypropylene-modified flexible pavements. Mater. Des. 2009, 30, 1133–1140.

- Ahmedzade, P.; Demirelli, K.; Günay, T.; Biryan, F.; Alqudah, O. Effects of Waste Polypropylene Additive on the Properties of Bituminous Binder. Procedia Manuf. 2015, 2, 165–170.

- Cheng, Y.; Fu, Q.; Fang, C.; Zhang, Q.; Lu, C. Preparation, Structure, and Properties of Modified Asphalt with Waste Packaging Polypropylene and Organic Rectorite. Adv. Mater. Sci. Eng. 2019, 2019, 5362795.

- Ziari, H.; Nasiri, E.; Amini, A.; Ferdosian, O. The effect of EAF dust and waste PVC on moisture sensitivity, rutting resistance, and fatigue performance of asphalt binders and mixtures. Constr. Build. Mater. 2019, 203, 188–200.

- Costa, L.M.B.; Silva, H.M.R.D.; Oliveira, J.R.M.; Fernandes, S.R.M. Incorporation of Waste Plastic in Asphalt Binders to Improve their Performance in the Pavement. Int. J. Pavement Res. Technol. 2013, 6, 457–464.

- Cuadri, A.A.; Partal, P.; Ahmad, N.; Grenfell, J.; Airey, G. Chemically modified bitumens with enhanced rheology and adhesion properties to siliceous aggregates. Constr. Build. Mater. 2015, 93, 766–774.

- Ghabchi, R.; Dharmarathna, C.P.; Mihandoust, M. Feasibility of using micronized recycled Polyethylene Terephthalate (PET) as an asphalt binder additive: A laboratory study. Constr. Build. Mater. 2021, 292, 123377.

- Esfandabad, A.S.; Motevalizadeh, S.M.; Sedghi, R.; Ayar, P.; Asgharzadeh, S.M. Fracture and mechanical properties of asphalt mixtures containing granular polyethylene terephthalate (PET). Constr. Build. Mater. 2020, 259, 120410.

- Vila-Cortavitarte, M.; Lastra-González, P.; Calzada-Pérez, M.Á.; Indacoechea-Vega, I. Analysis of the influence of using recycled polystyrene as a substitute for bitumen in the behaviour of asphalt concrete mixtures. J. Clean. Prod. 2018, 170, 1279–1287.

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2021, 280, 124355.

- Fang, C.; Jiao, L.; Hu, J.; Yu, Q.; Guo, D.; Zhou, X.; Yu, R. Viscoelasticity of Asphalt Modified With Packaging Waste Expended Polystyrene. J. Mater. Sci. Technol. 2014, 30, 939–943.

- González, O.; Muñoz, M.E.; Santamaría, A.; García-Morales, M.; Navarro, F.J.; Partal, P. Rheology and stability of bitumen/EVA blends. Eur. Polym. J. 2004, 40, 2365–2372.

- Ameri, M.; Mansourian, A.; Sheikhmotevali, A.H. Investigating effects of ethylene vinyl acetate and gilsonite modifiers upon performance of base bitumen using Superpave tests methodology. Constr. Build. Mater. 2012, 36, 1001–1007.

- De la Colina Martínez, A.L.; Martínez Barrera, G.; Barrera Díaz, C.E.; Ávila Córdoba, L.I.; Ureña Núñez, F.; Delgado Hernández, D.J. Recycled polycarbonate from electronic waste and its use in concrete: Effect of irradiation. Constr. Build. Mater. 2019, 201, 778–785.

- Colbert, B.W.; You, Z. Properties of Modified Asphalt Binders Blended with Electronic Waste Powders. J. Mater. Civ. Eng. 2012, 24, 1261–1267.

- Ameri, M.; Yeganeh, S.; Erfani Valipour, P. Experimental evaluation of fatigue resistance of asphalt mixtures containing waste elastomeric polymers. Constr. Build. Mater. 2019, 198, 638–649.

- AASHTO. Mechanistic-Empirical Pavement Design Guide; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2008.

- Colbert, B.W.; Diab, A.; You, Z. Using M-E PDG to study the effectiveness of electronic waste materials modifications on asphalt pavements design thickness. Int. J. Pavement Res. Technol. 2013, 6, 319–326.

- Bazmara, B.; Tahersima, M.; Behravan, A. Influence of thermoplastic polyurethane and synthesized polyurethane additive in performance of asphalt pavements. Constr. Build. Mater. 2018, 166, 1–11.

- Cong, L.; Yang, F.; Guo, G.; Ren, M.; Shi, J.; Tan, L. The use of polyurethane for asphalt pavement engineering applications: A state-of-the-art review. Constr. Build. Mater. 2019, 225, 1012–1025.

- Sun, M.; Zheng, M.; Qu, G.; Yuan, K.; Bi, Y.; Wang, J. Performance of polyurethane modified asphalt and its mixtures. Constr. Build. Mater. 2018, 191, 386–397.

- Salas, M.Á.; Pérez-Acebo, H.; Calderón, V.; Gonzalo-Orden, H. Bitumen modified with recycled polyurethane foam for employment in hot mix asphalt. Ing. Investig. 2018, 38, 60–66.

- Salas, M.Á.; Pérez-Acebo, H. Introduction of recycled polyurethane foam in mastic asphalt. Gradevinar 2018, 70, 403–412.

- Behl, A.; Sharma, G.; Kumar, G. A sustainable approach: Utilization of waste PVC in asphalting of roads. Constr. Build. Mater. 2014, 54, 113–117.

- Ameri, M.; Nasr, D. Properties of asphalt modified with devulcanized polyethylene terephthalate. Pet. Sci. Technol. 2016, 34, 1424–1430.

- Hu, C.; Lin, W.; Partl, M.; Wang, D.; Yu, H.; Zhang, Z. Waste packaging tape as a novel bitumen modifier for hot-mix asphalt. Constr. Build. Mater. 2018, 193, 23–31.

- Padhan, R.K.; Sreeram, A.; Gupta, A. Evaluation of trans-polyoctenamer and cross-linking agents on the performance of waste polystyrene modified asphalt. Road Mater. Pavement Des. 2018, 21, 1170–1182.

- Dalhat, M.A.; Al-Abdul Wahhab, H.I. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2017, 18, 349–357.

- Hariadi, D.; Saleh, S.M.; Anwar Yamin, R.; Aprilia, S. Utilization of LDPE plastic waste on the quality of pyrolysis oil as an asphalt solvent alternative. Therm. Sci. Eng. Prog. 2021, 23, 100872.

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7.

- Razali, M.N.; Aziz, M.A.A.; Jamin, N.F.M.; Salehan, N.A.M. Modification of bitumen using polyacrylic wig waste. AIP Conf. Proc. 2018, 1930, 020051.

- Naskar, M.; Chaki, T.K.; Reddy, K.S. Effect of waste plastic as modifier on thermal stability and degradation kinetics of bitumen/waste plastics blend. Thermochim. Acta 2010, 509, 128–134.

- Abdel-Goad, M.A.H. Waste polyvinyl chloride-modified bitumen. J. Appl. Polym. Sci. 2006, 101, 1501–1505.

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Eng. J. 2021, 12, 1569–1574.

- Fang, C.; Zhou, S.; Zhang, M.; Zhao, S.; Wang, X.; Zheng, C. Optimization of the modification technologies of asphalt by using waste EVA from packaging. J. Vinyl Addit. Technol. 2009, 15, 199–203.

- Vargas, C.; El Hanandeh, A. Systematic literature review, meta-analysis and artificial neural network modelling of plastic waste addition to bitumen. J. Clean. Prod. 2021, 280, 124369.

- Brovelli, C.; Crispino, M.; Pais, J.; Pereira, P. Using polymers to improve the rutting resistance of asphalt concrete. Constr. Build. Mater. 2015, 77, 117–123.

- García-Morales, M.; Partal, P.; Navarro, F.J.; Gallegos, C. Effect of waste polymer addition on the rheology of modified bitumen. Fuel 2006, 85, 936–943.

- Lai, Z.; Liu, K.; Yang, X.; Yang, D. Research on Performance of Asphalt Modified with Waste Plastics. J. Shandong Univ. Sci. Technol. 2010, 29, 73–77. (In Chinese)

- Nasr, D.; Pakshir, A.H. Rheology and storage stability of modified binders with waste polymers composites. Road Mater. Pavement Des. 2017, 20, 773–792.

- Al-Abdul Wahhab, H.I.; Dalhat, M.A.; Habib, M.A. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2016, 18, 1117–1134.

- Formela, K.; Sulkowski, M.; Saeb, M.R.; Colom, X.; Haponiuk, J.T. Assessment of microstructure, physical and thermal properties of bitumen modified with LDPE/GTR/elastomer ternary blends. Constr. Build. Mater. 2016, 106, 160–167.

- Yi, X.; Wu, G.; Lu, F.; Tang, A. Hydrolysis of aromatic heterocyclic polymers in high temperature water. J. Appl. Polym. Sci. 2001, 82, 907–915.

- Wen, G.; Zhang, Y.; Zhang, Y. Improved Properties of SBS-Modified Asphalt with Dynamic VuIcanization. Polym. Eng. Sci. 2002, 42, 1070–1081.

- Wang, S.; Ma, P.; Ouyang, C.; Zhang, Y. Study on stabilization of polyethylene/carbon black modified asphalt. Pet. Asph. 2006, 20, 22–26. (In Chinese)

- Nuñez, J.Y.M.; Domingos, M.D.I.; Faxina, A.L. Susceptibility of low-density polyethylene and polyphosphoric acid-modified asphalt binders to rutting and fatigue cracking. Constr. Build. Mater. 2014, 73, 509–514.

- Yadollahi, G.; Sabbagh Mollahosseini, H. Improving the performance of Crumb Rubber bitumen by means of Poly Phosphoric Acid (PPA) and Vestenamer additives. Constr. Build. Mater. 2011, 25, 3108–3116.

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844.

- Yang, X.; Liu, K.; Yang, D. Some Problems of PE Modified Asphalt. J. China Foreign Highw. 2008, 28, 203–207. (In Chinese)

- Guru, M.; Cubuk, M.K.; Arslan, D.; Farzanian, S.A.; Bilici, I. An approach to the usage of polyethylene terephthalate (PET) waste as roadway pavement material. J. Hazard Mater. 2014, 279, 30210.

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build. Mater. 2014, 73, 592–602.

- Roja, K.L.; Masad, E. Influence of Chemical Constituents of Asphalt Binders on Their Rheological Properties. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 458–466.

- Huang, S.C.; Benedetto, H.D. Advances in Asphalt Materials, 1st ed.; Woodhead Publishing: Abington, UK, 2015; pp. 31–57.

- Behnood, A.; Modiri Gharehveran, M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791.

- Masad, E.; Roja, K.L.; Rehman, A.; Abdala, A.A. A Review of Asphalt Modification Using Plastics: A Focus on Polyethylene. Available online: https://www.researchgate.net/publication/341152175_A_Review_of_Asphalt_Modification_Using_Plastics_A_Focus_on_Polyethylene (accessed on 30 August 2021).

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82.

- Giavarini, C.; Filippis, P.D.; Santarelli, M.L.; Scarsella, M. Production of stable polypropylene-modified bitumens. Fuel 1996, 75, 681–686.

- Rivera, C.; Caro, S.; Arámbula-Mercado, E.; Sánchez, D.B.; Karki, P. Comparative evaluation of ageing effects on the properties of regular and highly polymer modified asphalt binders. Constr. Build. Mater. 2021, 302, 124163.

- Fuentes-Audén, C.; Sandoval, J.A.; Jerez, A.; Navarro, F.J.; Martínez-Boza, F.J.; Partal, P.; Gallegos, C. Evaluation of thermal and mechanical properties of recycled polyethylene modified bitumen. Polym. Test. 2008, 27, 1005–1012.

- Fernandes, S.; Costa, L.; Silva, H.; Oliveira, J. Effect of incorporating different waste materials in bitumen. Ciência Tecnol. Mater. 2017, 29, e204–e209.

- Karmakar, S.; Roy, T.K. Effect of Waste Plastic and Waste Tires Ash on Mechanical Behavior of Bitumen. J. Mater. Civ. Eng. 2016, 28, 04016006.

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62.

- Lu, X.; Lsacsson, U. Modification of road bitumens with thermoplastic polymers. Polym. Test. 2000, 20, 77–86.

- Alberto, G.G.E.; Rafael, H.N. Effect of Stirring Speed in Hot Mixing Process of Modified Asphalt with SBS Copolymer on Polymeric Distribution and its Rheological Properties. In Proceedings of the MRS Materials Research Society, Florence, Italy, 28 March–1 April 2016; 1813.

- Babalghaith, A.M.; Koting, S.; Ramli Sulong, N.H.; Karim, M.R. Optimization of mixing time for polymer modified asphalt. IOP Conf. Ser. Mater. Sci. Eng. 2019, 512, 012030.

- Liang, M.; Xin, X.; Fan, W.; Wang, H.; Jiang, H.; Zhang, J.; Yao, Z. Phase behavior and hot storage characteristics of asphalt modified with various polyethylene: Experimental and numerical characterizations. Constr. Build. Mater. 2019, 203, 608–620.

- Rojo, E.; Fernández, M.; Peña, J.J.; Peña, B.; Muñoz, M.E.; Santamaría, A. Rheological aspects of blends of metallocene-catalyzed atactic polypropylenes with bitumen. Polym. Eng. Sci. 2004, 44, 1792–1799.

- Padhan, R.K.; Mohanta, C.; Sreeram, A.; Gupta, A. Rheological evaluation of bitumen modified using antistripping additives synthesised from waste polyethylene terephthalate (PET). Int. J. Pavement Eng. 2018, 21, 1083–1091.

- Li, J.; Zhang, Y.; Zhang, Y. The research of GMA-g-LDPE modified Qinhuangdao bitumen. Constr. Build. Mater. 2008, 22, 1067–1073.

- Vargas, M.A.; Vargas, M.A.; Sánchez-Sólis, A.; Manero, O. Asphalt/polyethylene blends: Rheological properties, microstructure and viscosity modeling. Constr. Build. Mater. 2013, 45, 243–250.

- Yeh, P.-H.; Nien, Y.-H.; Chen, J.-H.; Chen, W.-C.; Chen, J.-S. Thermal and rheological properties of maleated polypropylene modified asphalt. Polym. Eng. Sci. 2005, 45, 1152–1158.

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Grygoryeva, O. Modification of bitumen by electron beam irradiated recycled low density polyethylene. Constr. Build. Mater. 2014, 69, 1–9.

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Starostenko, O.; Kovalinska, T. Effect of Gamma-Irradiated Recycled Low-Density Polyethylene on the High- and Low-Temperature Properties of Bitumen. Int. J. Polym. Sci. 2013, 2013, 8062–8070.