-

- (1)

-

Waste LDPE

LDPE has a lower specific gravity, strength, and temperature resistance than HDPE because of its long, flexible, and linear polyethylene chain [

65]. Due to the irregular structure of the multimolecular chain arrangement of LDPE, the branched chains in asphalt combine with each other to form reticular three-dimensional structures, which can better improve the properties of modified asphalt. Thus, LDPE is widely used as a modified material for asphalt. Since the 1990s, several studies in China, Europe, the US, and the UK have reported the use of modifiers made by recycled LDPE independently [

66,

67]. Khan et al. [

68] studied waste LDPE, HDPE, and crumb rubber (CR) as an addition to base bitumen, and showed that modified asphalt binder with 10% LDPE offers the best resistance against rutting compared to HDPE and CR. Ho et al. [

69] investigated combinations of three types of recycled LDPE as asphalt modifiers. The results have shown that the molecular weight and molecular weight distribution of waste LDPE have significant effects on the asphalt’s low-temperature performance, thermal storage stability, and polymer phase distribution. The recycled LDPE with lower molecular weight and wider molecular weight distribution is more suitable for asphalt modification, compared with high molecular weight LDPE with very narrow molecular weight distribution.

- (2)

-

Waste HDPE

As discussed above, the high crystallinity of HDPE makes it difficult to immerse in asphalt, which also affects the compatibility of modified asphalt. It is agreed that the waste HDPE-modified asphalt has higher stiffness and viscosity, and better moisture resistance [

70]. Costa et al. [

37] indicated that waste HDPE-modified asphalt has higher stiffness and lower penetration, but worse resilience and creep recovery, compared with SBS-modified asphalt.

- (3)

-

Waste PP

Recycled PP-modified asphalt has the common characteristics of thermoplastic polyester modified asphalt, especially the superiority of high-temperature performance. However, the addition of waste PP reduces the ductility of modified asphalt and decreases the fatigue cracking performance [

71]. Specifically, the reduction of the ductility is around 20% when 5% of waste PP is added to the asphalt [

71,

72]. Thus, it is recommended that waste PP-modified asphalt is suitable for high-temperature and high-humidity areas, but the viscosity needs to be improved [

45].

- (4)

-

Waste PVC

Recent studies have shown that the addition of waste PVC increases the viscosity and stiffness of base asphalt so that the modified asphalt has better rutting resistance. One possible reason is that the chloride and carbon bond dipole in PVC provides a greater stiffness [

73]. A study by Ziari [

74] indicated that waste PVC improves the fatigue resistance, but the thermal cracking resistance is poor. It is noteworthy that hydrogen chloride (HCL) can be formed and discharged into the atmosphere when PVC is heated to a high temperature [

26]. Thus, measures should be taken to avoid air pollution.

- (5)

-

Waste PET

According to the Wellness Recovery Action Program (WRAP), PET is one of the most recycled plastic wastes [

47]. Because of the high melting point, most researchers tend to use waste PET for dry modification [

75]. Results have shown that waste PET-modified mixtures developed using the dry method have an improved high-temperature performance and reduced fracture resistance when the dosage of PET is 30% and 50% [

76].

- (6)

-

Waste PS

Waste PS-modified asphalt mixtures developed using the dry process are found to have higher rigidity, but this could be a problem in colder areas in terms of cracking resistance [

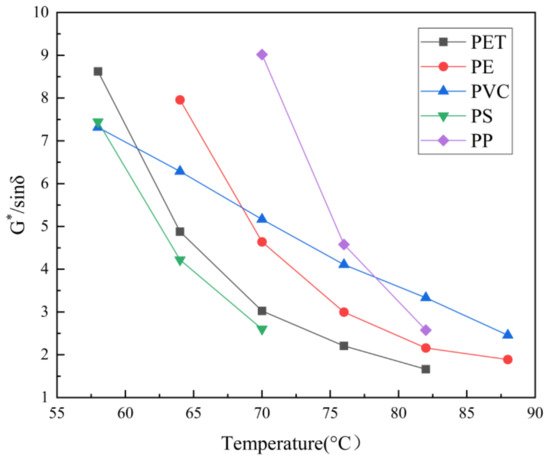

33]. Specifically, waste PS exhibits the lowest elastic behavior in the modified asphalt mixture compared with waste PE, PP, and rubber asphalt mixture using the dry process [

42]. Fang et al. [

77] successfully used a very low-density PS waste to expand the stiffness of asphalt and improve its rutting resistance. Hasan et al. [

71] indicated that the addition of waste high impact PS (HIPS) in asphalt improves the asphalt’s stiffness, but decreases the low-temperature properties. Furthermore, much more attention should be paid to the fact that harmful substances are released when PS is heated above 70 °C.

- (7)

-

Waste EVA

Waste EVA has good compatibility with asphalt, so it has been widely studied and applied. The results have shown that the large volume of the vinyl acetate group becomes a non-crystalline area or amorphous area, which plays a role similar to rubber when EVA is mixed with asphalt. The crystalline area of EVA has high stiffness, which acts as a reinforcing bar, and greatly improves the high-temperature stability, low-temperature cracking resistance, and viscosity of modified asphalt [

78]. It also exhibits certain improvements in low-temperature performance when small amounts of waste EVA are added (2–4%) [

79].

- (8)

-

Waste ABS

The most common e-plastics used in the manufacture of electronic devices are ABS. Evidence from recent studies indicated that the use of e-plastic powders for asphalt modification helped improve the asphalt’s viscosity and blending and mixing temperatures, meanwhile decreasing rutting susceptibility compared to virgin asphalt [

80]. The low-temperature performance of ABS-modified asphalt is equivalent to that of virgin asphalt binders [

81]. Compared with waste EVA- and PE-modified asphalt, waste ABS has poor performance as an asphalt modifier, but it seems to have better storage stability [

26]. Moreover, the pavement performance of waste ABS-modified asphalt is better than unmodified asphalt [

82]. According to the Mechanistic-Empirical Pavement Design Guide (M-E PDG) [

83], using e-waste materials as modifiers for asphalt mixtures using the dry method would decrease the design thickness of the asphalt layers [

84].

- (9)

-

Waste PU

Bazmara et al. [

85] used thermoplastic PU and synthetic PU as modifier additives in asphalt production. The results showed that the addition of synthetic PU increased the asphalt’s viscosity and stiffness. Both types of PU improved the performance of base asphalt at high temperatures, including high rutting resistance and performance grade; however, they had no notable effects on asphalt performance at low temperatures. A similar result was reported by Cong [

86], who noted that waste PU-modified asphalt had good deformation resistance, aging resistance, fatigue resistance, and high-temperature storage performance. Waste PU-modified asphalt mixture developed using the wet method also had excellent water stability and deformation resistance [

87]. Hot-mix asphalts with PU-modified bitumen yielded improvements in stability and lower deformation [

88]. With regard to the PU-modified mixture, Salas et al. showed that, compared with the virgin sample, the PU-modified MA from the wet method exhibited lower indentation, and thus the modified mastic asphalts (MA) can be used for heavy-traffic roads [

89].