Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Civil

|

Engineering, Environmental

The use of waste products in the production of asphalt binders and asphalt mixtures has become widespread due to economic and environmental benefits. In particular, the use of recycled waste plastic in asphalt binders and mixtures is gaining more attention. Overall, the incorporation of plastic waste into asphalt mixtures can significantly improve high-temperature performance and has potential economic and environmental benefits.

- recycled waste plastic

- asphalt binder and mixture

- composite modification

- performance

1. The Use of Waste Plastics in Asphalt

1.1. Forms of Waste Plastics Used in Asphalt

Waste plastics can be used as asphalt modifiers in a variety of forms through further processes. In the early days, waste plastics were processed into pellet form (Figure 1a) and were intended to be incorporated directly into the asphalt production plant [29,53]. These pellets were produced from 100% waste plastics, with sizes measuring between 0.3 mm and 0.5 mm [9]. In recent years, waste plastics have begun to be processed into shredding form, as shown in Figure 1b. However, the waste plastics in both pellet and shredding forms can only be processed through the complicated industrial system. Researchers have recently produced waste plastics as a modifier in more accepted forms by using common methods such as scissors and crushers in the lab. For example, Modarres and Hamedi [54] cut waste PET bottles and cans into small pieces (larger than shredding) and crushed them into flake form using a special crusher, as shown in Figure 1c. Kumar and Garg [55] and Lin et al. [56] made modified asphalt with waste plastics in thin strip form (20 × 3 mm2) and fiber form (less than 2 mm). Furthermore, waste HDPE powder and electronic-plastic (e-waste) powder (as shown in Figure 1d) have been used as asphalt modifiers [32,40].

1.2. Approaches to Incorporating Waste Plastics into Asphalt

There are two main approaches used to incorporate waste plastics into the asphalt: the wet process and the dry process [9]. In the wet process, waste plastics are added directly into the asphalt binder at high temperatures, where mechanical mixing is required to achieve a homogeneous plastic-modified binder blend. The mixing temperature and mixing time depend on the nature of the waste plastic source and asphalt binder. In the dry process, waste plastics are added directly to the asphalt mixture, either as a partial aggregate replacement or a mixture modifier [59]. When the addition of waste plastic is carried out by a wet process, the waste plastics are added to the asphalt binder to modify their properties before coming into contact with the aggregates [60]. When the plastics are added using a dry process, the waste plastics are mixed with aggregates so that they actually act as reinforcement materials [9].

Both the wet and dry methods have advantages as well as drawbacks, as shown in Table 1. The wet process is a conventional way of adding waste plastics, whereby they are mixed with the asphalt in a high-shear mill. Thus, the wet process requires specialized mixing and storage facilities [61], and it is better for controlling the properties of the modified asphalt binder [62]. This is likely the reason why the wet method is currently the most widely used in asphalt modification. By contrast, the dry process does not require professional equipment. It can be applied in any asphalt plant without major modifications [9]. The results from previous research have shown that the modified asphalt binder produced by the wet process has a higher viscosity, which allows a better coating of the aggregate particles, without exudation or drainage problems [63]. The modified asphalt mixture produced by the dry method has relatively poor water stability [62]. In terms of cost, the AC-16 mixture production materials using the dry method costs around CNY 290,000 per kilometer, which is lower than the wet method [64].

Table 1. The advantages and drawbacks of different processes.

| Method | Production Cost | Technological Problem | Performance of Mixture | ||

|---|---|---|---|---|---|

| Advantage | Drawback | Advantage | Drawback | ||

| Wet process |

Expensive (AC-16) |

Normative guidance and engineering experience | Complex production process (specialized mixing and storage facilities) | Higher viscosity |

Poor storage stability |

| Dry process |

Cheap (AC-16) |

Lack of normative guidance | Simple production process (no need of professional facility) | - | Poor water stability |

The performances of asphalt mixtures containing different waste plastics are significantly different because of the wet or dry process. Overall, the asphalt mixtures containing waste HDPE and EVA show similar properties for both the wet and dry processes. However, the waste HDPE mixture produced using the dry process exhibits poor water sensitivity [62].

Most previous studies focused on the wet process. The wet process is currently the most widely used for polymer asphalt modification because of its enhanced thermal behavior. However, the dry process is more cost-effective and has a simpler production process, meaning it is more convenient for waste plastic-modified asphalt production. Thus, further research is needed due to the lack of normative guidance and engineering experience for the dry process.

1.3. Single and Composite Modification

1.3.1. Single Modification

Each type of waste plastic has its own chemical composition, unique structure, molecular weight, etc., all of which affect the performance of modified asphalt [26] when such plastics are used as a modifier independently in asphalt production.

- (1)

-

Waste LDPE

LDPE has a lower specific gravity, strength, and temperature resistance than HDPE because of its long, flexible, and linear polyethylene chain [65]. Due to the irregular structure of the multimolecular chain arrangement of LDPE, the branched chains in asphalt combine with each other to form reticular three-dimensional structures, which can better improve the properties of modified asphalt. Thus, LDPE is widely used as a modified material for asphalt. Since the 1990s, several studies in China, Europe, the US, and the UK have reported the use of modifiers made by recycled LDPE independently [66,67]. Khan et al. [68] studied waste LDPE, HDPE, and crumb rubber (CR) as an addition to base bitumen, and showed that modified asphalt binder with 10% LDPE offers the best resistance against rutting compared to HDPE and CR. Ho et al. [69] investigated combinations of three types of recycled LDPE as asphalt modifiers. The results have shown that the molecular weight and molecular weight distribution of waste LDPE have significant effects on the asphalt’s low-temperature performance, thermal storage stability, and polymer phase distribution. The recycled LDPE with lower molecular weight and wider molecular weight distribution is more suitable for asphalt modification, compared with high molecular weight LDPE with very narrow molecular weight distribution.

- (2)

-

Waste HDPE

如上所述,HDPE的高结晶度使其难以浸入沥青中,这也影响了改性沥青的相容性。人们一致认为,废HDPE改性沥青具有更高的刚度和粘度,以及更好的防潮性[70]。Costa等人[37]表明,与SBS改性沥青相比,废弃HDPE改性沥青具有更高的刚度和更低的穿透力,但更差的回弹性和蠕变回收率。

- (3)

-

废旧聚丙烯

再生PP改性沥青具有热塑性聚酯改性沥青的共同特点,特别是高温性能的优越性。然而,废PP的添加降低了改性沥青的延展性,降低了疲劳开裂性能[71]。具体而言,当5%的废PP被添加到沥青中时,延展性的降低约为20%[71,72]。因此,建议废PP改性沥青适用于高温高湿地区,但粘度需要提高[45]。

- (4)

-

废聚氯乙烯

最近的研究表明,添加废PVC会增加基础沥青的粘度和刚度,使改性沥青具有更好的抗车辙性。一个可能的原因是PVC中的氯化物和碳键偶极子提供了更大的刚度[73]。Ziari [74]的一项研究表明,废聚氯乙烯提高了抗疲劳性,但抗热开裂性较差。值得注意的是,当PVC加热到高温时,氯化氢(HCL)可以形成并排放到大气中[26]。因此,应采取措施避免空气污染。

- (5)

-

废旧聚酯

根据健康恢复行动计划(WRAP),PET是回收率最高的塑料废物之一[47]。由于熔点高,大多数研究人员倾向于使用废PET进行干改性[75]。结果表明,当PET的用量分别为30%和50%时,使用干法开发的废PET改性混合物具有改进的高温性能和降低的抗断裂性[76]。

- (6)

-

废物 PS

使用干法开发的废PS改性沥青混合物被发现具有更高的刚性,但就抗开裂性而言,这可能是较冷地区的一个问题[33]。具体而言,与使用干法的废PE,PP和橡胶沥青混合物相比,废PS在改性沥青混合物中表现出最低的弹性行为[42]。Fang等人[77]成功地利用了极低密度的PS废料来扩大沥青的刚度并提高其抗车辙性。Hasan等人[71]表明,在沥青中添加废物高冲击PS(HIPS)可以提高沥青的刚度,但会降低低温性能。此外,应该更加注意当PS加热到70°C以上时会释放有害物质的事实。

- (7)

-

废旧伊娃

废旧EVA与沥青具有良好的相容性,因此已被广泛研究和应用。结果表明,当EVA与沥青混合时,大体积的醋酸乙烯酯基团成为非结晶区域或无定形区域,其起着类似于橡胶的作用。EVA的结晶区具有较高的刚度,起到增强棒的作用,大大提高了改性沥青[78]的高温稳定性、耐低温开裂性和粘度。当添加少量废物EVA(2-4%)时,它在低温性能方面也表现出一定的改善[79]。

- (8)

-

废旧 ABS

来自最近研究的证据表明,使用电子塑料粉末进行沥青改性有助于提高沥青的粘度以及混合和混合温度,同时与原始沥青相比降低了车辙敏感性[80]。ABS改性沥青的低温性能相当于原始沥青粘结剂[81]。与废旧EVA和PE改性沥青相比,废ABS作为沥青改性剂的性能较差,但似乎具有更好的储存稳定性[26]。而且,废ABS改性沥青的路面性能优于未改性沥青[82]。根据机械经验路面设计指南(M-E PDG)[83],使用干法使用电子废物作为沥青混合物的改性剂将减少沥青层的设计厚度[84]。

- (9)

-

废聚氨酯

Bazmara et al. [85] used thermoplastic PU and synthetic PU as modifier additives in asphalt production. The results showed that the addition of synthetic PU increased the asphalt’s viscosity and stiffness. Both types of PU improved the performance of base asphalt at high temperatures, including high rutting resistance and performance grade; however, they had no notable effects on asphalt performance at low temperatures. A similar result was reported by Cong [86], who noted that waste PU-modified asphalt had good deformation resistance, aging resistance, fatigue resistance, and high-temperature storage performance. Waste PU-modified asphalt mixture developed using the wet method also had excellent water stability and deformation resistance [87]. Hot-mix asphalts with PU-modified bitumen yielded improvements in stability and lower deformation [88]. With regard to the PU-modified mixture, Salas et al. showed that, compared with the virgin sample, the PU-modified MA from the wet method exhibited lower indentation, and thus the modified mastic asphalts (MA) can be used for heavy-traffic roads [89].

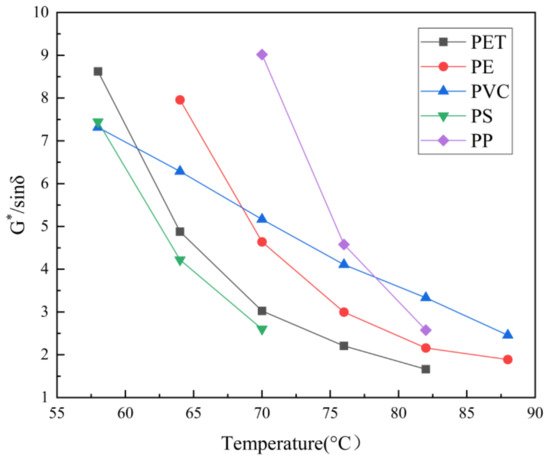

Table 2 presents a summary of the effects of waste plastics on asphalt performance with respect to compatibility, high- and low-temperature performance, and viscosity, based on the most recent literature reviewed in this paper. It is evident that the addition of waste plastics can most likely increase the high-temperature stability and viscosity as well as decrease the low-temperature flexibility. Waste LDPE, PP, EVA, ABS, and PU have good compatibility with asphalt compared with other types of waste plastics, which can be seen from the summary of the rheological results of various waste plastic-modified asphalt in Figure 2. The high-temperature rheological property of PP-modified asphalt was the best, followed by PE- and PVC-modified asphalt, and PS-modified asphalt was the least effective. However, further research is needed due to the difference in dosage and asphalt.

Table 2. Characteristics of common waste plastics.

1.3.2. Composite Modification

The application of waste plastic as an independent modifier in asphalt is rare in current studies and engineering practices. This is because the key properties of asphalt cannot be improved by using only one type of waste plastic. In order to enhance and optimize the properties of waste plastic-modified asphalt binder to meet the needs of increased traffic demands, there has been growing interest in composite modification. Recently, more and more studies have investigated the properties of modified asphalt binders containing waste plastic and various materials [95]. This interesting trend means that the application of waste plastic as an asphalt modifier has been accepted by researchers and engineering practice. Some researchers investigated modified blends containing two or more types of waste plastic. For instance, Brovelli et al. [96] and García-Morales et al. [97] assessed the high-temperature stability of base asphalt modified by combining LDPE and EVA. Lai et al. [98] studied the compatibility and performance of waste HDPE/LDPE/PP-modified asphalt. Other researchers focused on the application of various modified blends of waste plastics and common polymers. Nasr and Pakshir [99] tested three melt-compounding combinations of waste PET and crumb rubber to improve the rutting and fatigue damage resistance of two base asphalt binders. A study reported by Al-Abdul Wahhab et al. [44] suggested that waste LDPE/HDPE-modified asphalt, in combination with an elastomeric SBS, can obtain higher recovery and strain resistance, which are better than using the same amount of SBS alone. Additionally, Krzysztof et al. [100] improved the conventional and thermal properties of asphalt by blending waste LDPE, ground tire rubber (GTR), and elastomer. Other studies have reported that waste plastics can be mixed with some common materials such as sulfur [101,102], carbon black [103], and polyphosphoric acid [104,105] as asphalt modifiers.

2. Factors Affecting Properties of Waste Plastic-Modified Asphalt

2.1. Waste Plastic Properties

The characteristics of waste plastics, such as type, chemical composition and structure, and molecular weight, affect the time required for blending, as plastics with higher molecular weight require more time to blend homogeneously with the asphalt binder. Additionally, waste plastics are produced in smaller sizes to help disperse and dissolve into the asphalt binder [94].

PE is one of the most popular thermos-plastics, and it is one of the earliest waste plastics to be used as an asphalt modifier in the world. PE has the simplest polymer structure, with each carbon atom connected to two hydrogen atoms. PE is categorized based on density into HDPE, LDPE, and Linear LDPE (LLDPE) [106]. Evidence from the literature shows that, compared with HDPE, the intermolecular force in LDPE is weaker, which is beneficial to the compatibility between asphalt and LDPE [31,32,50]. It is consequently suggested that both HDPE and LDPE are appropriate for asphalt modification, but LDPE is better.

In recent years, various types of waste plastics have been used as an asphalt modifier. Hu et al. [92] reported that the rheological properties of asphalt binder are enhanced when using waste packaging tape PP as the modifier. Gürü et al. [107] confirmed that thin liquid polyol PET (TLPP) and viscous polyol PET (VPP) made from waste PET bottles can improve the low-temperature performance and fatigue resistance of the modified asphalt. Furthermore, Köfteci et al. [108] found a significant difference in the performances of asphalt binders modified by different waste PVC sources (window, blinds, and cable wastes).

2.2. Asphalt Binder Properties

Asphalts are composed of two main phases: (1) an oily phase consisting of saturated hydrocarbons, aromatic cyclic products, and resins, and (2) a non-oily phase formed by asphaltenes and carbenes; however, the chemical composition and structure are different [109]. Elemental analyses indicate that most asphalts contain 79–88 weight percent (wt%) carbon, 7–13 wt% hydrogen, 2–8 wt% oxygen, traces to 8 wt% sulfur, and traces to 3 wt% nitrogen. Asphaltene contents provide a basis for the classification of asphalts into sol- or gel-types. In general, an asphalt low in asphaltene content (5–10 wt%) has properties characteristic of sol-type asphalt, and has high-temperature susceptibility, high ductility, and a low oxidative hardening rate. In contrast, asphalt with high asphaltene content (20–30 wt%) is gel-type, and has low-temperature susceptibility, low ductility, and a susceptibility to oxidative age hardening. Certainly, asphalt with intermediate asphaltene contents has properties intermediate between the sol- and gel-type behavior [110,111,112]. A study reported by Lesueur [113] shows that high asphaltene content decreases the compatibility between polymer and asphalt. Furthermore, Giavarini et al. [114] found that modified asphalt’s properties depend not only on the difference in density and viscosity between asphalt and polymer, but also on asphalt structure.

2.3. Waste Plastic Dosage

The utilization of suitable waste plastics in asphalt modification shows an improvement in asphalt properties; however, there is an optimum point between the waste dosage and asphalt properties. Many studies available investigated the effects of modified asphalt containing waste plastics at various dosages on its properties and pavement performance. The dosage range of common polymer-modified asphalt is between 2.5 wt% and 3.5 wt%, with a higher dose range greater than 7 wt% being referred to as highly modified asphalt [115]. Mashaan et al. [28] reported that the ideal content of waste plastic is 6–8 wt% to improve the rutting and aging resistances of modified asphalt. Naskar et al. [90] found that modified asphalt with 5 wt% waste plastic has the highest thermal stability compared to the other binders investigated. However, the penetration, softening point, and elasticity of the binder are negatively affected when the waste plastic content is up to 7 wt%. Fuentes-Audén et al. [116] also concluded that only low waste plastic concentrations (0–5 wt%) can be used for road paving whereas high waste plastic concentrations (10–15 wt%) are suitable for roofing. A similar study by Fernandes et al. [117] reported that increasing the waste plastic content in base asphalt improves the softening point temperature, resilience, and viscosity. Moreover, Karmakar and Roy [118] and Ameri et al. [79] indicated that an increased modifier content negatively affects the compatibility between modifier and asphalt, and low-temperature performance. Therefore, the authors recommended that a waste plastic concentration of approximately 5 wt% is better for asphalt properties [21]. Specifically, the optimal percentages of waste PET, PVC, and PP are 3.47 wt%, 6.25 wt%, and 4.64 wt%, respectively [95]. Briefly, the optimal dosage of waste plastics in modified asphalt is not only highly dependent on the properties of the waste plastic and base binder, but also the specific requirements of the asphalt binder.

2.4. Blending Conditions

The results from recent studies indicated that the blending conditions (blending temperature, blending time, and blending speed) used for asphalt modification strongly affect the asphalt properties [78,112,119]. Many studies have been conducted to find the optimum blending conditions for various waste plastic-modified asphalt production. García et al. [120] found that the stirring speed for asphalt preparation determines the size of the polymer particles and thus the rheological properties of modified asphalt. Babalghaith et al. [121] suggested that the optimal blending time for common modified asphalt to achieve the best rheological properties is about 30 min. Fang et al. [57] reported that the optimum parameters for waste PE-modified asphalt preparation were a shear rate of 3750 revolutions per minute (rpm), a temperature of 150 °C, and a shear time of 1.5 h. Another study found a longer blending time of 6 h [97].

The optimum blending conditions used for various types of waste plastic-modified asphalt are summarized in Table 3. The selection of mixing methods mostly depends on the specific type of waste plastic and its content use—the optimum content is about 3–6 wt%. For these seven types of waste plastics, the blending temperature is about 150 to 180 °C, blending time is between 1 and 3 h, and blending speed is from 1200 to 5000 rpm.

Table 3. Blending conditions commonly used for waste plastic-modified asphalt.

| Waste Plastic | Optimum Content (wt.%) | Blending Temperature (°C) | Blending Time (min) | Blending Speed (rpm) | Reference |

|---|---|---|---|---|---|

| PE | 3–6 | 145–190 | 60–150 | 1750–4000 | [31,32,106,122] |

| PP | 3–6 | 160–180 | 45–90 | 1800–4000 | [45,72,90,123] |

| PVC | 4–8 | 160–180 | 60–180 | 1300–2000 | [36,108] |

| PET | 2–8 | 180 | 60 | 13,000 | [37,38,56,78] |

| EVA | 3–5 | 140–180 | 80–120 | 1800–3000 | [37,38,78] |

| PS | 4–6 | 150–190 | 90–120 | 3000 | [33,77] |

2.5. Pretreatment Methods for Waste Plastic

It is necessary to carefully consider the appropriate pretreatment method for waste plastic before it is added into the asphalt, as it affects the compatibility between the asphalt and modifier. Generally, pretreatment methods can be divided into two main methods: the physical method and the chemical method. It seems that most researchers (approximately 85%) prefer using the physical method to pretreat waste plastics, according to all of the related research papers referenced in this review.

2.5.1. Physical Method

Waste plastics can be processed into smaller particles through physical methods such as grinding, shredding, pulverization, and extrusion.

Table 4 shows a comparison of the common physical methods used for pretreating waste plastics. Waste plastics can be pretreated using a suitable physical method into various forms of smaller size, based on their sources and purpose of use. For example, waste PET bottles can be processed into particles of larger or smaller sizes by crushing or grinding.

Table 4. Comparison of physical methods for pretreating waste plastics.

| Type | Source | Physical Method | Form | Size | Reference |

|---|---|---|---|---|---|

| Waste plastic bag waste plastic pipe | - | Shredding | Strip Fiber |

1–2 cm 20 × 3 mm2 |

[35,55,90] |

| Waste plastic bottle | PET | Cutting and crushing | Particle | 0.45–1.18 mm | [54] |

| Waste milk bag | - | Extruding | Pellet | - | [57] |

| Waste plastic bottle waste express bag |

PET | Grinding | Particle Piece |

0.45–0.5 mm 2–5 mm |

[56,124] |

| Waste window blind and cable |

PVC | Pulverization | Powder | - | [108] |

2.5.2. Chemical Method

The use of the chemical method for the preparation of waste plastic is commonly carried out through grafting or irradiation to provide better compatibility and properties with the modifier, so that the performance of modified asphalt is improved. Li et al. [125] successfully increased the reaction of LDPE and asphalt through grafting LDPE with glycidyl methacrylate (GMA) containing carbon double bonds, epoxy groups, and epoxy functional groups, resulting in improved performance of the modified asphalt. Vargas et al. [43] improved the asphalt performance at a higher temperature using a similar method of grafting HDPE with glycidyl methacrylate. Yeh et al. [126] reported a similar result by grafting maleated PP.

In recent studies, a novel method named irradiation was used for pretreating waste plastic. Ahmedzade et al. [127] found that the chemical interaction between the waste HDPE and asphalt could be caused by irradiated waste HDPE, consequently enhancing the physical properties of the asphalt. Thus, the irradiated HDPE used as a modifier is recommended. A similar result was achieved by replacing electron beams with gamma rays [128].

This entry is adapted from the peer-reviewed paper 10.3390/ma15010110

This entry is offline, you can click here to edit this entry!