Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Materials Science, Biomaterials

The food packaging sector generates large volumes of plastic waste due to the high demand for packaged products with a short shelf-life. Biopolymers such as starch-based materials are a promising alternative to non-renewable resins, offering a sustainable and environmentally friendly food packaging alternative for single-use products.

- starch-based materials

- processing

- food packaging

1. Advance in Preparation of Functional Starch-Based Food Packaging

Recent advances in the development of starch-based materials for food packaging applications are based on the combination of the emergence of new preparation techniques, equipment and the manipulation of matter at the nanometer scale, which have allowed us to achieve special properties with adequate performance [218,219].

1.1. Incorporating Bioactive

In recent years the incorporation of additives such as antioxidants and antimicrobials in starch-based films plays a key role in improving functional properties. These active packaging films provide a semi-permeable barrier that helps to extend shelf life by reducing the migration of moisture, loss of solutes from fruit respiration and oxidation reaction [218,220]. Essential oils are a clear example of active components in food packaging, their antioxidant and antimicrobial properties have improved the quality and safety of food [221]. Essential oils are natural substances composed of alcohols, phenols, terpenes, esters and among other bioactive agents, whose main function is the release of their active components avoiding microbial and fungal attack and oxidation of food [218]. Oregano oil, thyme [38], cinnamon bark, clove [222], ho wood (Cinnamomum camphora), and cardamom [223] have been evaluated as additives in the control of various pathogens.

Raigong et al. [224] evaluated the addition of clove oil and cinnamon oil in starch films against S. aureus, C jejuni and E. coli, and the results showed the inhibition of the pathogens. Clove oil inhibited between 22–100%, while cinnamon oil was effective against C. jejuni (19–22% inhibition) and E. coli (33–40% inhibition), respectively. Souza et al. [223] evaluated that the addition of Pickering emulsions to essential oils, ho wood (Cinnamomum camphora), cardamom, and cinnamon, showed that the ho wood oil lowered water vapor transmission rate, improving the release of the active compound. Ho wood oil was the most promising with regard to being applied as a biodegradable active packaging. The addition of natural extracts from various sources, such as fruit by-products, has been evaluated in starch-based films. Mango puree and pineapple pomace were incorporated into maize starch-gelatin films, improving the physicochemical properties of the films and increasing the antioxidant activity and antimicrobial activity [218]. Table 6 lists the most recent studies on starch-based bioactive systems prepared by film casting method for food packaging applications.

Table 6. Bioactive system, processing techniques and main results of bioactive starch based materials for food applications.

1.2. Starch Nanostructures (SNEs)

The field of natural biopolymers have shown great potential for important, rapidly growing applications ranging from green electronics, food packaging, dye and heavy metal removal, oil/water separation, therapeutic agent delivery, tissue engineering scaffolds, biological devices, optics, and sensing [238]. However, the application of advanced functional biopolymer materials suffers from their poor processability and weak mechanical properties. Regarding this, there are enormous challenges to break the strong intermolecular interactions (hydrogen bonding) in their native forms, while re-establishing predominant hydrogen bonding in the processed materials in a cost-effective way. The introduction of one or more new functional groups into native polysaccharides alters their physical, chemical and, above all, biological properties. The biological properties of polysaccharide derivatives depend on the molecular weight, the type of modification, the type of native polysaccharide, the conditions of the modification process, the solubility and the conformation of the polysaccharide. The manipulation of matter at the nanometer scale (1 to 100 nm) has recently been studied to create new materials and devices with special properties and adequate performance. The unique properties of nanoparticles depend on the size and shape, charge and surface modification, and hydrophobicity of the starting material [239]. For example, starch nanoparticles prepared by acid hydrolysis from waxy corn and high amylose maize starch exhibit a crystal structure and size of type A-type, B-Type, and 50 nm, 540 nm, respectively, while their morphology was polygonal and smaller starch granules, pores, respectively [240].

In order to alter the crystalline structure of the starch, SNEs are obtained mainly by top-down and bottom-up methods. In the “top-down” method, macroscopic materials are reduced from the microscale to the nanoscale through physicochemical processes such as acid hydrolysis [105,241] due to the sensitivity of the amorphous rings in starch granules to acid treatment, homogenization [69], crushing [242,243], gamma irradiation [244], and ultrasound [245,246]. Acid hydrolysis and ultrasonication methods are particularly effective in breaking up the aggregates of nanoparticles formed through hydrogen bonds, thereby reducing the size and polydispersity of nanoparticles [247].

In the “bottom-up” process, SNEs can be obtained from a buildup of starch molecules in a controlled manner that is regulated by thermodynamic means such as regeneration [248] nanoprecipitation or self-assembly [242]. Micro-nano emulsion and nanoprecipitation are very simple and convenient methods for producing nanoparticles with a desired size [249]. For example, starch granules are dispersed in water or dimethylform sulfoxide, completely gelatinized at 100 °C, and then precipitated by dropwise addition of nonsolvents (such as methanol, ethanol, isopropanol, n-propanol) to obtain SNPs with different sizes [250,251]. In addition, it has been shown that the combination between chemical methods, for example acid hydrolysis, and physical methods such as ultrasonication, generates higher homogeneity and yield in the obtained starch nanostructures [248,252,253].

Among the recently studied starch-based nanostructures are nanoparticles [254,255], nanospheres [18,256], nanocrystals [253,257,258], nanomicelles [259,260], nanogels [261] and nanofibers [262]. Table 7 summarizes the main preparation methods and size of starch nanostructures. Emphasis is placed on their responsiveness, permeability, toxicity, interactions with other components and applications. The aim of producing such nanocrystals or nanoparticles is to use them as fillers in polymeric matrices to improve their mechanical and/or barrier properties. Starch nanoparticles are non-toxic and respond to pH, temperature, light and other stimuli. Starch nanoparticles have a wide range of applications, such as improving the mechanical properties of films and gels, stabilizing emulsions, use as a fluorescent indicator, forming or directing agent in self-assembling structures, scaffolds, and reconstruction of hollow organs.

Table 7. Preparation methods and size of starch nanostructures.

2. Starch Based Materials Application in Food Industry

A fundamental part in the food packaging industry is to innovate, develop new materials with improved properties, reduce food waste, and be economically viable and sustainable, while at the same time complying with the standards of quality, safety and functionality; contain, protect and conserve. Another important issue is that developed materials must facilitate product handling, although they must also preserve nutritional value. Currently, the use of bioplastics has increased significantly, and it is estimated that by 2022 the production of bioplastics will be around 2.44 million tons due to a great demand for biopolymers for various applications and product [5]. This increase in the manufacture of biopolymers as substitutes for conventional packaging is mainly due to the biodegradability, biocompatibility and low cost of these starch base materials [311] as starch by itself or in combination with other biopolymers, have been used in the preservation of fresh products.

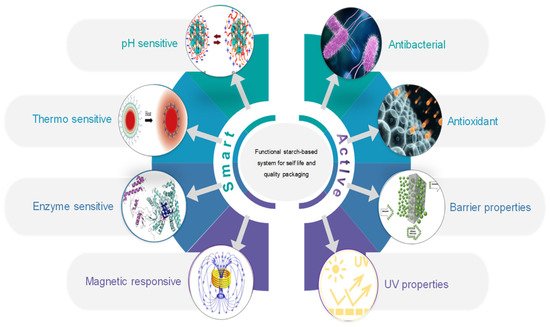

One of the strategies to generate interest among consumers and for the packaging industry to commercialize starch-based materials have been the development of smart and/or functional materials to extend the shelf life of packaged foods (Figure 3). In this context, the main work has focused on: (i) improving the materials so they provide a better barrier to oxygen and water vapor materials by mixing different materials and incorporating micro/nano structures; and (ii) adding bioactive substances such as antioxidant or antibacterial agents by means of micro/nano encapsulation [280].

Figure 3. Active and smart starch-based food packaging to improve shelf life.

Active packaging deliberately modifies the product or environment to improve food safety and quality. Hence, increased attention has been paid to the preparation of bioactive and smart packaging films by active films having antibacterial, antioxidant, and barrier properties [312,313]. Other examples of active packaging include oxygen scavengers to decrease fat oxidation, ethylene scavengers to minimize fruit and vegetable ripening, humidity and odor absorbers [314,315,316,317,318].

Smart packaging informs the consumer about kinetic changes related to the quality of the food or the environment it contains, to minimize losses and ensure food quality. Hence, the temperature can be monitored, providing a thermal history of the foods storage, and informing the most suitable consumption conditions. Some studies have been carried out to produce such materials, and commercial packaging is available in the market. Jederman et al. [319] monitored the temperature curves allowing the evaluation of the cooling efficiency in bananas, the effect of changes in packaging and the respiration heat. Commercial brands are patented by MonitorMark™ and commercialized as a Time–Temperature Indicators (TTI) sensor developed by 3M™ (3M™, Maplewood, MN, USA) and CoolVu indicator developed in Freshpoint-Switzerland.

Fish and meat products are highly susceptible to decomposition by oxidation of fats showing color changes, (e.g., discoloration of pigments such as myoglobin, carotenoids), and off-odors and flavors (e.g., rancidity as a result of lipid oxidation), which leads to nutrient losses (e.g., oxidation of vitamin E, β-carotene, ascorbic acid) and adversely affects the quality [320]. In order to prevent those problems, vacuum packaging has been used as this method does not always remove all oxygen under the packaging. That is why it has been necessary to develop novel packaging materials to prevent oxidation and meat quality loss. In this sense, oxygen scavengers have been supplied in packaging to eliminate the residual oxygen. The oxygen scavengers are incorporated in sachets, films or labels to prevent food products contamination or accidental consumption. Among the substances incorporated are iron powder, ascorbic acid, dyes, enzymes (glucose oxidase and alcohol oxidase), unsaturated fatty acids (oleic or linoleic acids), and immobilized yeast [217]. On the other hand, thermoplastic starch films have also been developed with the purpose of reducing lipid oxidation in foods. Panrong et al. [321] prepared thermoplastic starch films incorporating low-density polyethylene and green tea. They proved that the hydrophobicity of films allows a reduction in the lipid oxidation of packaged soybean oil, which was effectively reduced by up to 38% depending on the TPS ratio used. Similarly, Piñeros-Hernandez et al., [322] prepared edible cassava starch films carrying rosemary antioxidant extracts for use as potential active food packaging. They reported the films enhanced the UV-blocking properties of the films. In this context, several works have been mentioned above in Section 4.1.

Smart packaging films based on a change of color have been developed, and they have pH-sensitive and responsive indicators (e.g., anthocyanins, betacyanins, and curcumin) in a biopolymer-based matrix [312]. These materials are usually synergistically blended with other polymers (PVA, PLA, carrageenan, chitosan), can also respond to magnetic field, or have enzyme-responsive characteristics [313]. Recently, the application of natural pigments and polymer carriers has shown great potential in smart packaging based on pH-responsive indicators [323]. A research work conducted by Silva-Pereira et al. [324] revealed the use of blueberry residues as a potential visual pH indicator in the monitoring of fish spoilage. The indicator carrier matrix was corn starch and chitosan and showed good pH sensitivity and thermal stability. Similarly, films based on cassava starch and anthocyanins showed high pH sensitivity over a wide pH range, which allows monitoring of the quality of various foods [325]. In addition, potato starch-based films with anthocyanins can successfully display the color difference at pH 1–12 and detect the fresh stage (pH = 5.8) and spoiled stage (pH = 8) of pork, demonstrating the potential of potato starch for food product quality detection [326]. Shapi’i et al. [327] evaluated the effect of incorporating chitosan nanoparticles into a starch matrix on the antibacterial properties of the film. The authors found that the starch/chitosan nanoparticle film used to package cherry tomatoes effectively inhibited the growth of microorganisms (7 × 102 CFU/g) compared to pure starch film (2.15 × 103 CFU/g). Another way to inhibit the growth of microorganisms in starch films was reported by Diaz-Galindo et al. [328] by adding a cinnamon oil emulsion to the matrix that reduced the growth rate of Botrytis cinerea by 66%, preventing further contamination of the fruit during storage and transport.

The incorporation of anthocyanin-rich bay laurel berry extracts (BBE) into tapioca starch to develop food packaging films with antioxidant and pH-sensitive properties was studied by Yun et al. [329]. The work demonstrated a significant increase in the DPPH radical scavenging ability of the composite film (24.39–75.01% under 5 mg mL−1) with the incorporation of BBE into the starch matrix. It was observed that when the starch-BBE film was exposed to hydrogen chloride, the color of the film changed from purple to red. The film quickly turned blue and then olive when exposed to ammonia gas. Jayakumar et al. [330] incorporated nutmeg oil, ZnO NP and ham extract into starch/PVA based films. These films showed pH sensitive and antibacterial properties. Under acidic pH, the dark purple extract turned cherry red, while at alkaline pH it changed to brownish yellow to light green at neutral pH. The film mixed with ZnO NP and nutmeg oil inhibited the growth of the foodborne pathogen Salmonella typhimurium. Similarly, the results of Mustafa et al. [331] demonstrated a variation in the coloration of smart and bioactive PVA/starch/propolis/procyanidin rosemary extract films depending on pH; reddish to blue under acidic pH, blue under neutral pH and yellow under alkaline pH. The maximum diameters of the film inhibition zone against E. coli and methicillin-resistant S. aureus were 21 and 15 mm, respectively. Table 8 summarizes some applications in the packaging of various foods, such as fruits and vegetables, bakery goods, meat, and starch-based materials indicating good prospects for commercial utilization.

Table 8. Packaging system, food application and mains results of pre-commercial studies of starch based materials.

Thus, Oliveira et al. [333] evaluated different concentrations of cassava starch in the protection of papaya fruit, reducing the ripening of the fruit and controlling diseases by 100%. Castillo et al. [335] made a Sachet type package of corn starch and chitosan oligomers for perishable foods such as strawberries, ricotta, and flavored breads. Table 9 lists the starch-based products currently available and marketed for food packaging applications where Biotec, Novamont and BioBag Americas are the main manufacturing companies.

Table 9. Commercially available starch-based materials for food packaging applications.

This entry is adapted from the peer-reviewed paper 10.3390/polysaccharides3010007

This entry is offline, you can click here to edit this entry!