Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Agriculture, Dairy & Animal Science

Soil is a compound mixture and a non-renewable natural resource, as it can only be restored on a geological timescale. It can be easily defined as the loose inorganic or organic matter of the surface that assists as a natural habitat for terrestrial plants. Heavy metals are very hazardous to the environment and living things.

- heavy metal

- remediation

- environmental

- phytoremediation

- nanotechnology

1. Heavy Metals Contamination and Toxicity in Soil Ecosystem

Heavy metal accumulation in the soil is hazardous to the environment and human health, and well-known harmful contaminants have devastating effects on the biological circulation of terrestrial species with variations in the structural composition of nucleic acids, proteins and osmotic balance [32]. Although several remediation techniques such as hardening/stabilization (S/S), soil leaching, electrokinetic remediation, and chemical oxidation/reduction are used to fix, remove, or detoxify HMs in the soil, these traditional approaches do not result in overall sustainability [33].

Metal toxicity not only affects aquatic organisms, but also harmful to soil flora, plants, animals, and humans as well. Oxidative stress results in damage to cell morphology and inhibits cytoplasmic enzymes [34]. Usually, these metals exist in nature individually or in grouping with other elements, but anthropogenic activity increases their concentrations in the environment [35]. Since HMs are water-soluble, they are mainly soluble in solutions. This makes it difficult to remove by physical and chemical separation processes in the soil [36]. Solubility of HMs is determined by their chemical morphology in the environment. So, for improving the remediation efficiency of microbial fuel cell (MFC), appropriate methods for converting HMs into easy-to-move forms (such as acid-soluble fractions) are needed. Some research has used auxiliary reagents like small-molecule organic acids (citric acid, CA; and acetic acid, HAc), inorganic acids (HCl, HNO3), and synthetic chelating agents (ethylenediaminetetraacetic acid, EDTA) [37,38].

These chemicals help in desorbing and dissolving HMs in the soil, allowing them to move around more freely. Synthetic chelating chemicals pose a risk since polymer chelates migrate slowly in electric fields and secondary ecological settings [39]. This study used two small-molecule organic acids (CA, HAc) that are commonly available, reasonably inexpensive, and ecologically benign, as well as a mineral acid (HCl) [39]. The rate of faster improvement of the industrial sector has raised the HM contamination problem, like a hike in manufacturing purposes for other metals. Heavy metals like Cd, Pb, As, Cr, Cu, and Zn are mainly used in industry and agriculture. Small amounts of these metals are lethal.

Although these metals are present naturally in the environment, tampering occurs when there are large amounts of these metals on land due to continuous mining as well as smelting [7,40]. As industrialization progresses and the natural biogeochemical cycle are disrupted, the issue of HM contamination becomes more and more serious. Heavy metals, unlike biological compounds, seldom biodegrade and hence gather in the environment. Accumulation of HMs takes place in the tissues of an organism (bioaccumulation), and their concentrations increase as they transition from low to high trophic levels (biomagnification). Heavy metals in the soil have toxicological consequences on soil microorganisms, which leads to reduced numbers and activity [1].

2. Sustainable Remediation Strategies

2.1. Nano-Bio Remediation of Heavy Metals: Application and Implications

In the modern era, the usage of nanoparticles (NPs) in industry, medicine, agriculture and cosmetics has increased significantly [67,68,69,70,71,72,73,74,75,76,77,78,79,80]. Materials with at least one dimension smaller than 100 nm are commonly referred to as NP. NPs with various particle sizes, shapes, as well as functions are produced as per requirement [81]. Compared to conventional materials, NPs possess a lot of advantages, including increased surface activity, extra reactive sites on the surface, increased catalytic efficiency, and special optical as well as magnetic properties [82,83,84]. The environmental impact of NPs is discussed in previous research: Hao et al. showed that even at 10 mg L−1, rice contained endophytic fungi sensitive to carbon-based NPs [85]. It is reported that exposure to Ag NPs at a dose of 50 mg kg−1 adversely affects the biomass and quality of peanuts [86]. In addition, low dosages (5 and 50 mg kg−1) of NiO had no effect on the survival, reproduction as well as rate of growth of adult earthworms, whereas high dosages (200 and 500 mg/kg) expressly affects physiological and biochemical effects and turned out to be the endpoint [80]. As many field studies (pilot and life-size) and laboratory studies show, the use of nanotechnology for water remediation, used for drinking purification and pollution control, is very favorable.

There are many reviews of applications based on nanotechnology. However, in order to further elucidate its significance as well as guide development, it is necessary to directly compare existing therapeutic methods with new approaches using nanotechnology. In this review, the effectiveness of nanotechnology and old technologies for water purification as well as environmental improvement to provide industries, researchers, and policy makers with insight into the status of water purification methods, are compared. Contaminants were classified into a wide range of classes and the most gainful methods were compared in each class described in the literature. A case study is also presented that directly compared conventional techniques to nanotechnology-based techniques for similar contaminants. Nanotechnology-based methods are generally considered costly, but many of these offer inexpensive and more operative options to traditional technologies. Additionally, nano-based technologies can be critical to complying with progressively stringent water quality standards, especially to remove new and low-concentration pollutants [87].

All latest techniques as well as industries in pharmaceutical departments are interfaced by nanotechnology [88,89], textile industry [90], electrical industry [91,92], mechanical technology, and environment-related industries. Nanotechnology is considered as the synthesis and processing of nanoscale materials [93]. Their small size is the only cause that increases the cost of these materials [94]. Due to their small size, the surface area to volume ratio is significantly improved and the bandgap is clean and wide. As a result, their optical, physical, and electrical properties differ significantly from large volumes of material. Nanomaterials can be metal, semiconductors, or organic [95]. The generation of artificial NPs is attracting attention as an effective recovery method. In addition to other environmental uses, NPs can be inserted underground in the form of sediment to offer conditions for chemical recovery of pollutant columns and for use as adsorbents and catalysts in wastewater treatment processes. Its efficiency is based on its chemical composition, well-defined shape and high specific surface area. Today, many NP products are formulated to effectively remove contaminants. However, there is rising concern about the probable impacts in the secondary life cycle linked with production [96,97].

Biosynthetic NPs help green remediation in a variety of methods. Iron-based NPs should be used directly as a fixative. For example, nano zero ferrous iron (nZVI) by waste tea can be used to reduce Cr (VI) in soil. Iron oxide NPs made from leaf extract can steady Cd and As in soil by coprecipitation [98,99]. For additional data on the use of nZVI NPs as well as iron oxide, refer to the reader [100]. Green NPs indirectly aid in soil regeneration. Ag NPs mediated by plant extracts can promote plant growth by increasing soil pH value, nutrient bioavailability and water retention capacity [65,68,101]. Naturally benign nano-sized mineral built soil conditioners can be organized with feldspar and lime consuming a mild hydrothermal method [102]. Their use in NPs synthesis is attracting more and more attention. Summarizing the current report on the synthesis of NPs for environmental restoration with the help of plant extracts (bud system). NP recovery in vivo is attained through the occurrence of biomolecules contained in plant extracts.

2.2. Biochar Based Sustainable Amelioration of Soil

In recent times, biochar has gained increasing courtesy as an environmentally friendly tactic, especially as a weather protection strategy [106] (Figure 1). Biochar is considered as a carbon-rich, fine-grained, porous material formed by the thermal decay of biomass at relatively low temperatures under oxygen-restricted conditions (<700 C) [76,79,107]. It is also considered as a predominantly stable and stubborn organic carbon (C) compound formed when biomass (raw material) has a temperature typically between 300 °C and 100 °C at low oxygen levels.

Biochar is rich in carbon, porous, and has a large exact surface area, and this exact structure has been shown to be capable of enhancing soil moisture and nutrient retention [108]. Biochars range from crop residues (corn stalks, rice straw, rice husks, rapeseed stalks, etc.), grass, wood, sewage sludge, anaerobic digests, and animal excrement (poultry litter, pig manure, etc.). It can be produced by heat treatment of biological waste, and chicken manure) [109,110,111]. Biochar interacts with HMs in many ways. Complex formation of the outer sphere, complex of the inner sphere, electrostatic interactions, surficial precipitation, and exchange of ion are potential mechanisms of metal fixation [20,112]. A new trend has appeared in biochar pyrolysis as well as post-pyrolysis transformation plans to increase the metal binding capacity of biochar adsorbents (Table 1) [113].

2.3. Fly Ash- Industrial-Based Materials for Sustainable Remediation

Since they are mass-produced every year, industrial by-products are attracting attention. Reuse as a soil conditioner is a viable method to the sustainable use of these minimum value by-products. Fly ash from coal combustion is a distinctive byproduct of the coal industry. About 780 million tons are made yearly. The chemical composition of fly ash differs due to its dissimilar source and composition of burned coal, but all types include significant amounts of SiO2, Al2O3, Fe2O3, and CaO [73,116,117]. It has a similar mechanism of metal immobilization by oxides (i.e., lime and precipitation, surface complexion). The Bayer process in the alumina industry gives red mud as a by-product [118].

However, industrial waste can contain large amounts of poisonous metals as well as organic pollutants. When applied to the soil, these pollutants are out and can move over the long term, posing a danger to the environment [119]. Agriculture, livestock as well as food industries in particular are the major producers of organic waste. Sludge from the sugar industry alone accounts for 30 million tons worldwide [120]. In India alone, the paper industry, which uses large amounts of water and plant cellulose materials, produces 3.033 tons of bio-waste by-products annually from paper mills [121]. In fact, Asian countries have deprived reprocessing systems and faced more ecological problems. Industrial waste is composed of various harmful substances, especially HMs as well as other organic pollutants that affect the quality of the soil. Currently, more than 40% of bio-waste is landfilled, producing both carbon dioxide and methane [122]. Unlimited greenhouse gas creation from bio-waste landfills that endanger the environment and environmental issues require scientific intervention. As shown, the origin as well as industrial biowaste production can be manageable in a variety of ways, ultimately leading to agriculture. The wastes which are polluted dispose in open places that risk to the environment. Generally, pollutants can be separated into two subgroups: (i) organic and (ii) inorganic [66,123,124]. Currently, contaminated bio-waste is disposed of in vacancies, which are a major cause of environmental pollution, especially water and soil pollution. Therefore, restoration techniques are needed to manage some bio-waste [125] (Figure 2).

2.4. Employing Bioremediation for Remediation of Contaminated Soil

Biotechnology which utilizes plants’ potential to improve the health of the environment is called phytoremediation. Applied research shows that plants have the capability to eliminate and degrade a range of HM toxicants. Due to being cost effective, simple, sustainable, and being compatible with the environment it is considered as more aesthetic than traditional technologies. Remediation of large amounts of toxic groundwater and treatment of large volumes of diluted wastewater can be implemented in situ. Plants respond differently to metal adulteration in soil and should be divided into different groups depending on their response to metal adulteration in the rooting medium. Plants should be divided as accumulators, indicators, or excluders, dependent on the uptake and movement of metal into the ground by the plant [20]. The phytoremediation technique is simple, inexpensive, sustainable, companionable, environment friendly as well as one of the key contents of green technology.

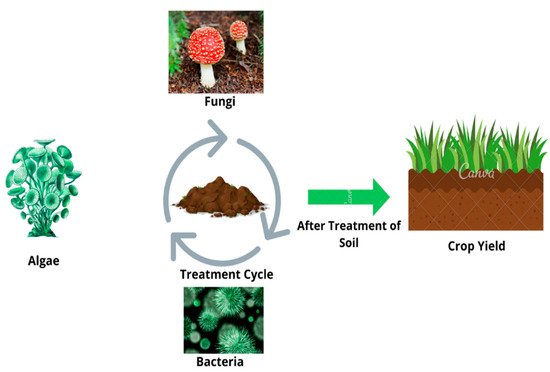

Plants have the natural capability to break down the HMs through a variety of procedures such as bioaccumulation, translocation, and storage/decomposition of pollutants. Phytoremediation is 10 times more inexpensive than traditional technical approaches because it is field-based, photovoltaic, and can function with minimal post-installation maintenance [75,77,128]. Plants have been reported to be highly resistant to HM pollution without causing serious harm; these properties of plants suggest that they could be used to detoxify pollutants through novel approaches to agriculture and genetic engineering. Some of the plants have the natural capability to break down many awkward xenobiotic substances and are therefore considered “green livers” that serve as an essential source of absorption of environmentally harmful chemicals. Nature gives plants the excellent ability to defuse these poisonous elements in the growing matrix, whether in soil or water (Figure 3) [129].

Figure 3. Bioremediation process showing the role of algae, fungi, and bacteria for the enhancement of soil health.

This entry is adapted from the peer-reviewed paper 10.3390/min12010085

This entry is offline, you can click here to edit this entry!